Week 17 - Applications and Implications, Project Development

Assignment:

Applications and Implications:

Propose a final project masterpiece that integrates the range of units covered.

Your project should incorporate:

• 2D and 3D design

• Additive and subtractive fabrication processes

• Electronics design and production

• Embedded microcontroller interfacing and programming

• System integration and packaging.

Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

See Final Project Requirements for a complete list of requirements you must fulfil. The answers to the questions in the checklist will allow you to create your BOM (Bill Of Materials).

Project Development

• Complete your final project tracking your progress.

Overview

For this week’s assignment, I answer the following questions about my Final Project:

What will it do?

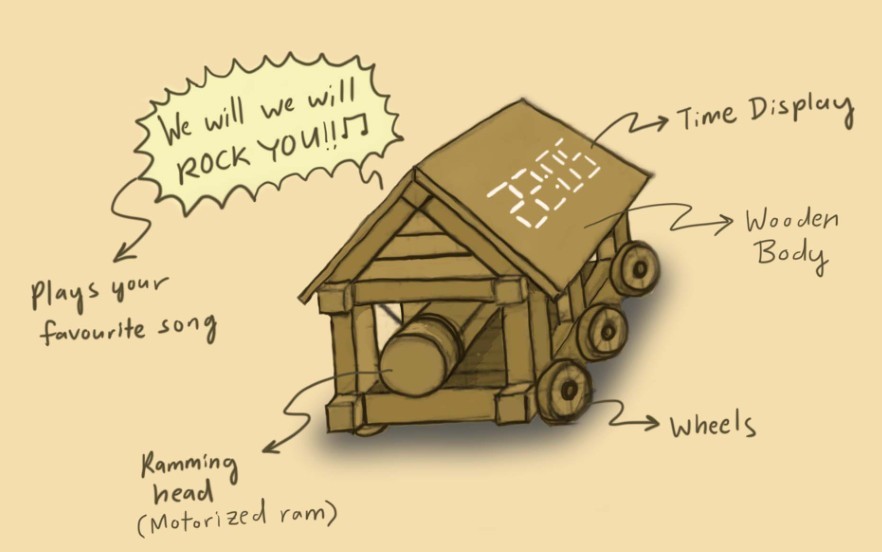

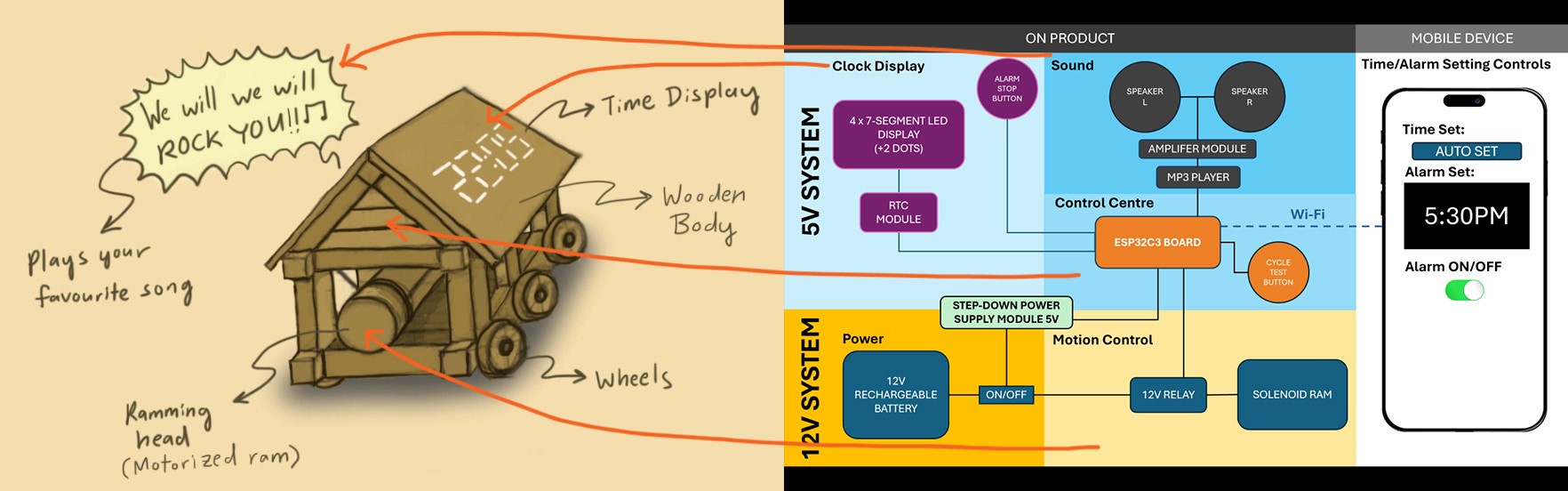

As I head towards the final stretch of my Fab Academy journey, I look back at my Week 01 sketch and find that I still want to make the same Battering Ram Alarm Clock.

It is an alarm clock with a 7-segment LED clock display. When the alarm is triggered, it makes sounds/plays music and produces a ramming action to alert the user.

Who has done what beforehand?

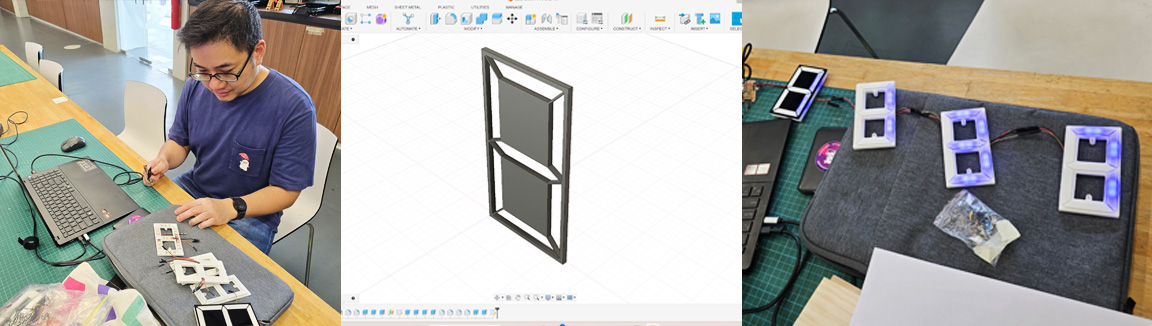

There have been plenty of examples of LED clock projects such as the ones shown below. Some are commercial products while others are DIY projects from makers. The maker pictured below on the right is Ivan Miranda. I draw a lot of inspiration from his LED clock. You can watch his YouTube here.

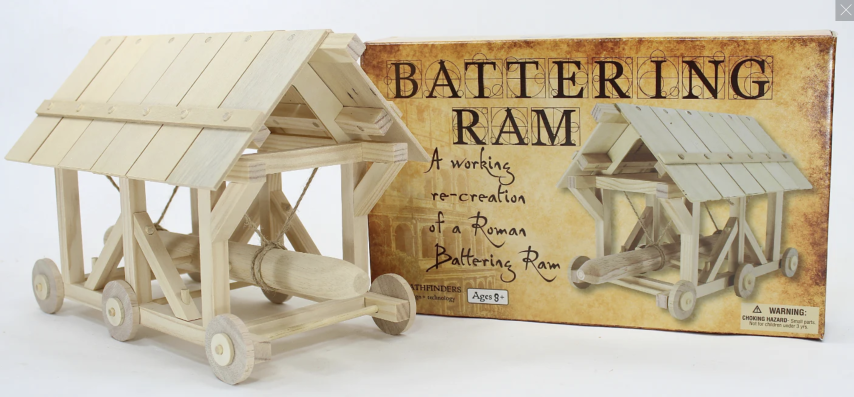

There are also toy battering rams such as the one shown below.

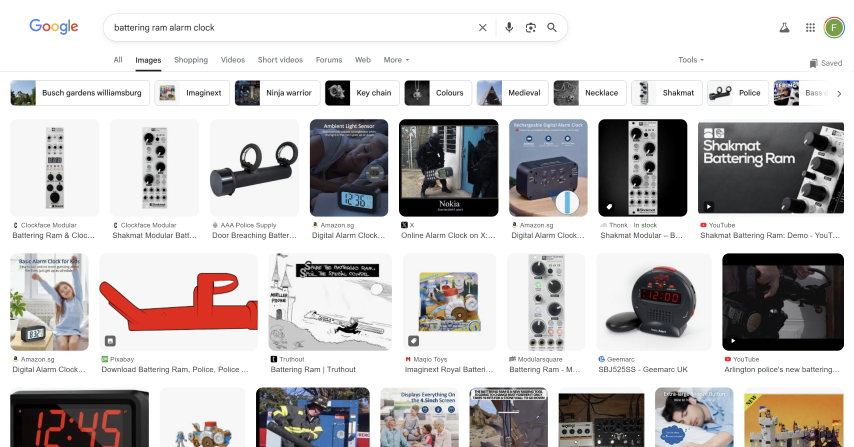

Yet to the best of my knowledge, no one has actually put a battering ram and an alarm clock together in one product. A quick google search of the keywords battering ram alarm clock does not bring up anything that looks like my final project.

What will you design?

I will design the battering ram alarm clock based on the systems diagram shown below.

Each system can be mapped to a particular part of the product (e.g. the clock display system will be housed in the clock display panel, the sound system in the sound panel, the control centre in the prism core, and the power and motion systems in the lower base).

As such, I will design each system (starting with the clock display system) and document it under my Week 15 Systems Integration Assignment.

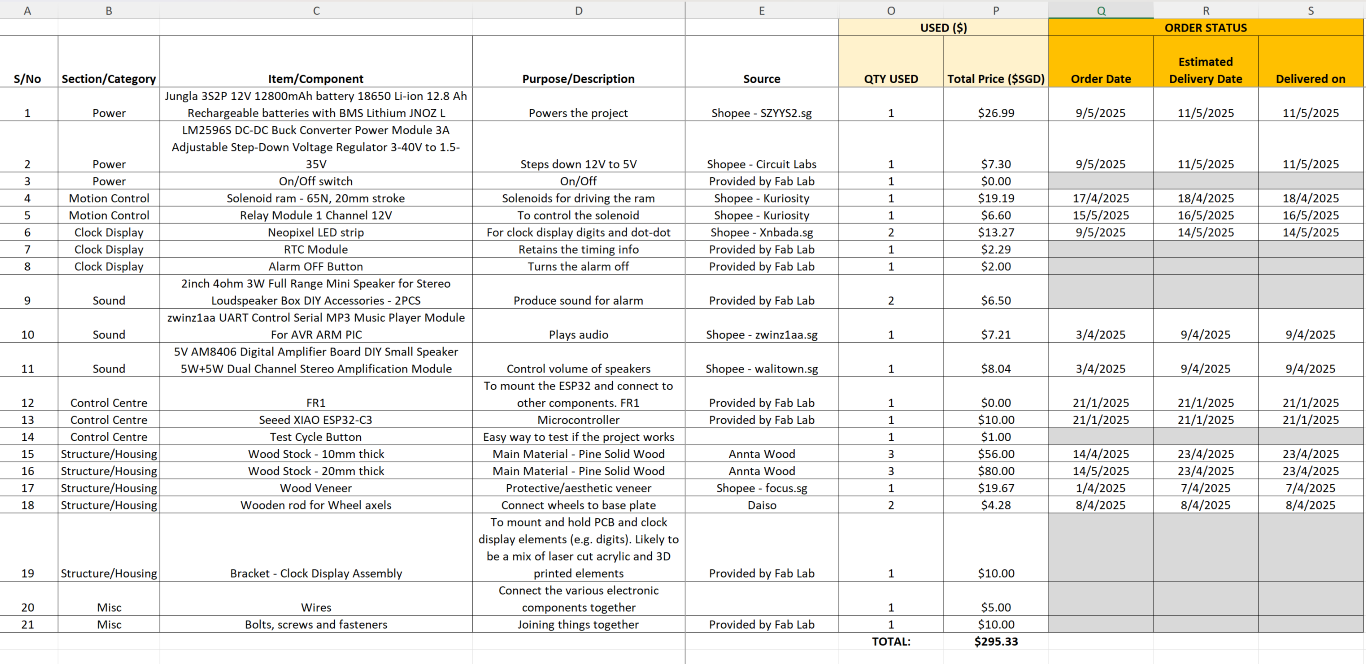

What materials and components will be used? Where will they come from? How much will they cost?

Please refer to the BOM here.

The materials/components have mainly come from 2 main sources:

1. Online shopping platform (Shopee)

2. Provided by Fab Lab Please refer to the BOM image from the previous section for the sources of other materials.

The project will cost around $300 Singapore dollars (approx. $233 USD), with the main cost coming from the furniture grade pine wood.

What parts and systems will be made?

Please refer to my Week 15 Systems Integration Assignment for details and ongoing documentation.

What processes will be used?

I am intending to use:

• 3D Printing – For general parts and concept prototyping and testing

• Laser Cutting – For flat panels

• CNC Milling – For milling the PCB and also the wooden parts

• Programming – Arduino IDE

How will it be evaluated?

Here is how I think the project should be evaluated:

30% - The clock display tells the time accurately.

20% - The alarm can be set to trigger sounds and actions.

10% - Ease of use. Users do not find it annoying to use.

10% - Build quality. It is put together and finished well.

10% - Aesthetic quality. It looks appealing.

20% - I am proud of making this and want to keep it with me for a long time.

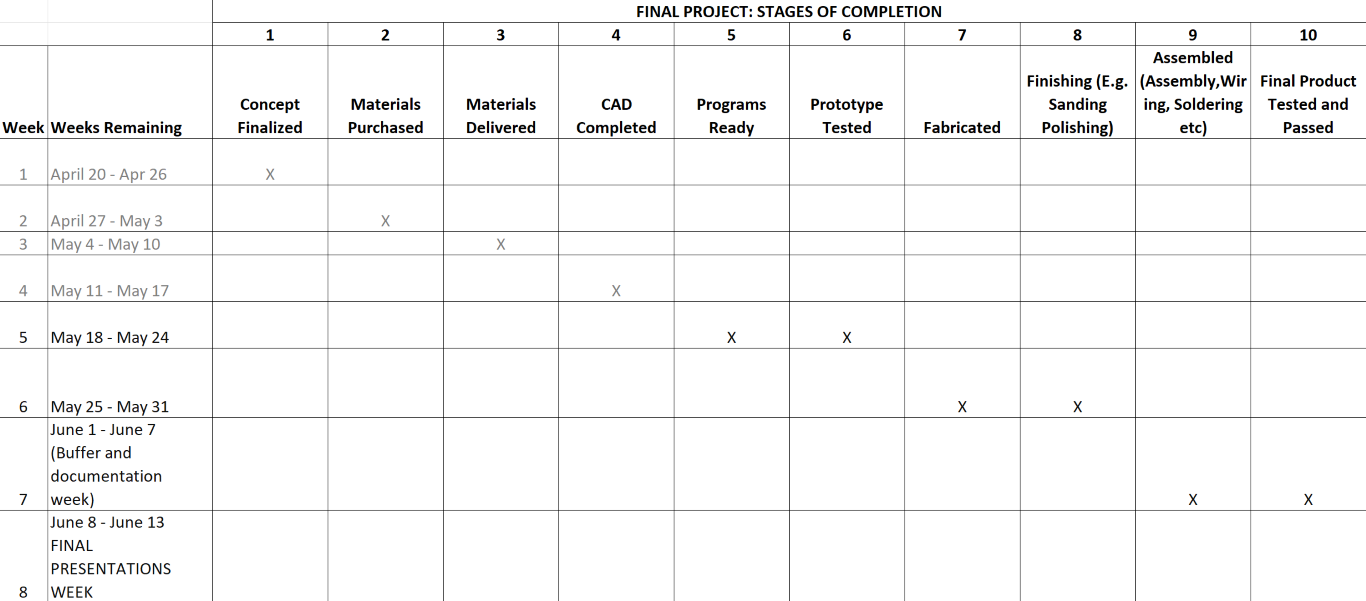

What tasks have been completed? What tasks remain?

I have made progress on the clock display panel and this is about 20% of the work. However, there is still a lot left to be done. Ideally, I want to have the housing/structure 3D printed and tested before I mill the wood.

Let's break it down by system.

Clock display

Left to do:

The dot-dot

Alarm off button

Laser cut black frame

3D printed test panel

Test clock code

Assembly and connection to other systems.

How to do:

Get the clock display panel (skeleton) done by this week (no later than 1st June 2025) to have a good chance of completing the project on time.

Control Center

Left to do:

Confirm connection schematic

Designing and milling the board

Assembly and connection to other systems.

How to do:

Get help to confirm the schematic and board requirements by this week (no later than 1st June 2025). Leave one day for designing the board, one day for milling and soldering the board.

Structure/Housing

Left to do:

Figure out how to connect the panels to the triangular frame

CAD for Clock display panel

CAD for Sound display panel

CAD for prism's triangular frame

CAD for car base

3D Print test

Wood milling

How to do:

Create the clock display panel skeleton and figure out how to attach it to the triangular frame. Also get the schematic done so that you know where the wiring holes go.

Sound

Left to do:

Get a memory card for the mp3

Solder and connect the components together

Test the sound system.

Assembly and connection to control center

How to do:

Work out the final size of the sound system panel. Wire the components together. Do a joint test with my Fab Academy Haw Ren. Share the codes and the testing effort.

Power

Left to do:

Understand how the power is connected to work the 5V and 12V systems. Connect them up (relay, ON/OFF switch)

How to do:

Connect the power to the various systems and test them.

Motion

Left to do:

Get the solenoid ram moving.

CAD/model some ram end cap (OPTIONAL)

How to do:

Connect the power to the motion system and test them.

WiFi Control

Left to do:

Get the code working with the test connection

How to do:

Test the WiFi control after the test connection has been completed.

What questions need to be resolved? What questions need to be answered?

Seems like there are still a whole lot of questions to answer but the questions that will help the most to progress the projects are:

• How can the clock display panel be finalized?

• How does the clock panel connect to the triangular frame?

• How does each component connect together in the schematic?

• How should the board be designed?

• How will the wooden parts be milled?

• How will the components be tested?

What has worked? What hasn't?

I have been documenting my work and progress under the following pages:

• Final Project page – For a general account of how the project is moving along.

• Systems Integration page – For more detailed information about the project, including what has worked and what has not.

What will happen when?

What have you learned?

Here are some things I have learned so far:

• Dealing with Task Saturation – This is something that happens quite often during Fab Academy. Watch this YouTube video about managing tasks. It talks about asking this question whenever task saturation happens (when you have too many tasks to do in a given time).

"What is the next task that I can carry out in the shortest amount of time?"

As each task completes, I gain momentum to clear the other tasks.

• Seek Progress not Perfection – As makers, some days don’t go as well as intended and it can be incredibly frustrating to fail at a task that you have spent an entire day working on. I have learnt that this is okay. This is progress and learning how NOT to do something is also learning. I will just pick myself up and keep trying.

• You Never Walk Alone – I am by no means a hardcore Liverpool fan but throughout my Fab Academy journey, I have learnt that I am never alone in my journey (although it sometimes feels that way). There are always friends, colleagues, instructors and the wider Fab Academy community willing to help out. I have learned so many things beyond technical skills, and I could not have made it so far without all their help.

This concludes this week’s assignment.