Assignment Overview

Group assignment:

-Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

compare mold making processes

Group-Molding and casting

Group-Molding and casting

Individual assignment:

-Design a mold around the process you'll be using,

-produce it with a smooth surface finish that does not show the production process toolpath,

and use it to cast parts

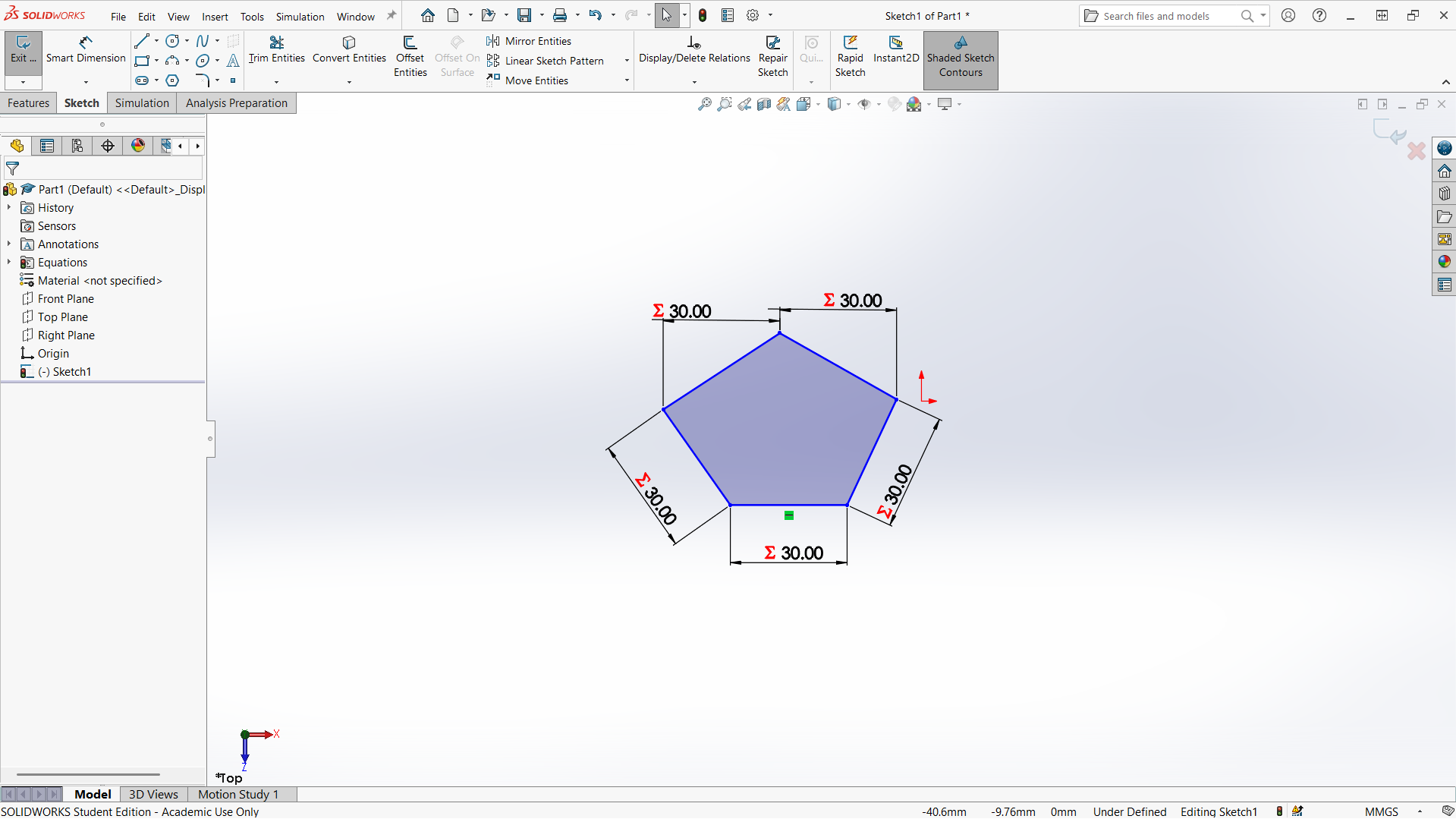

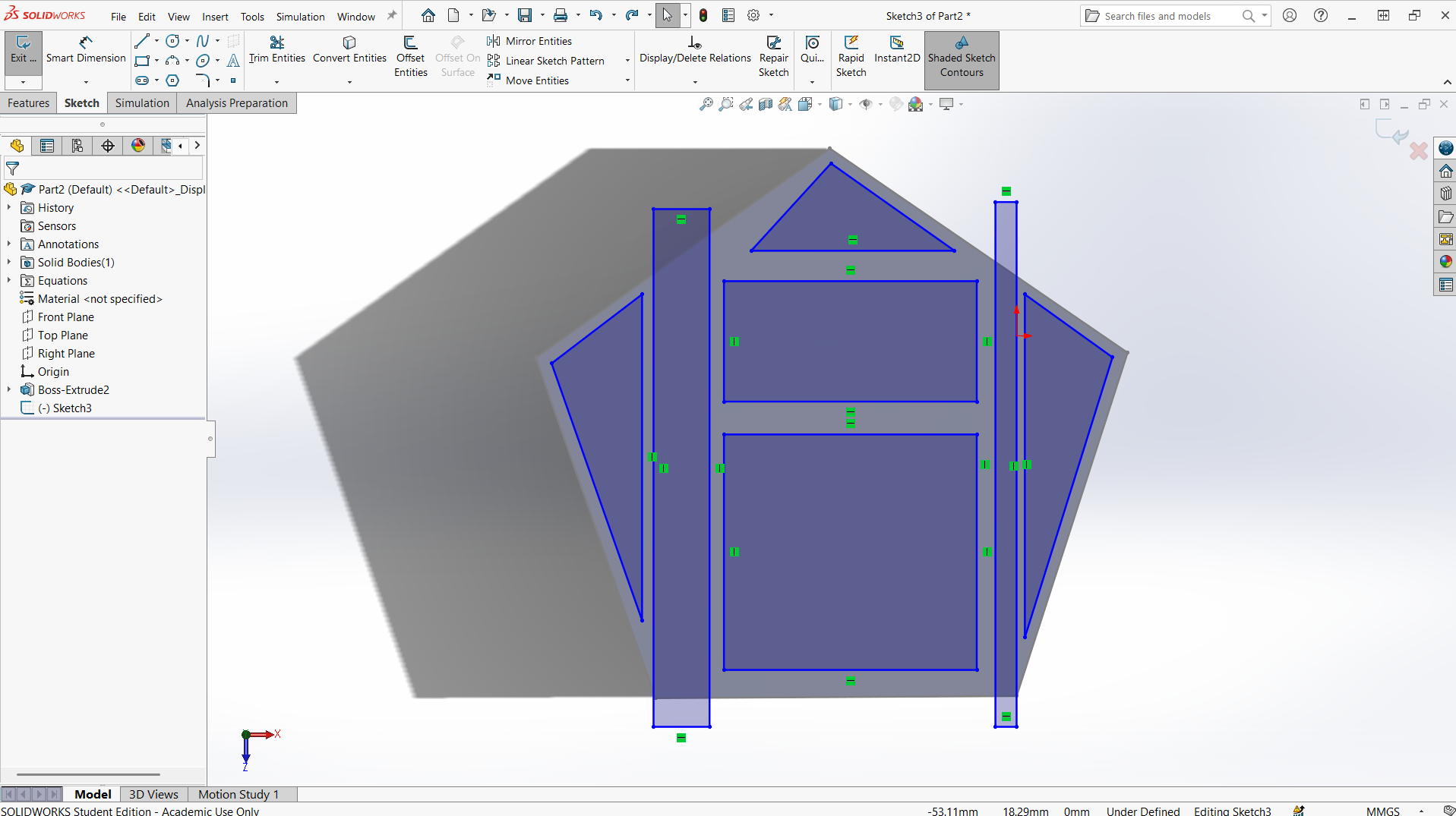

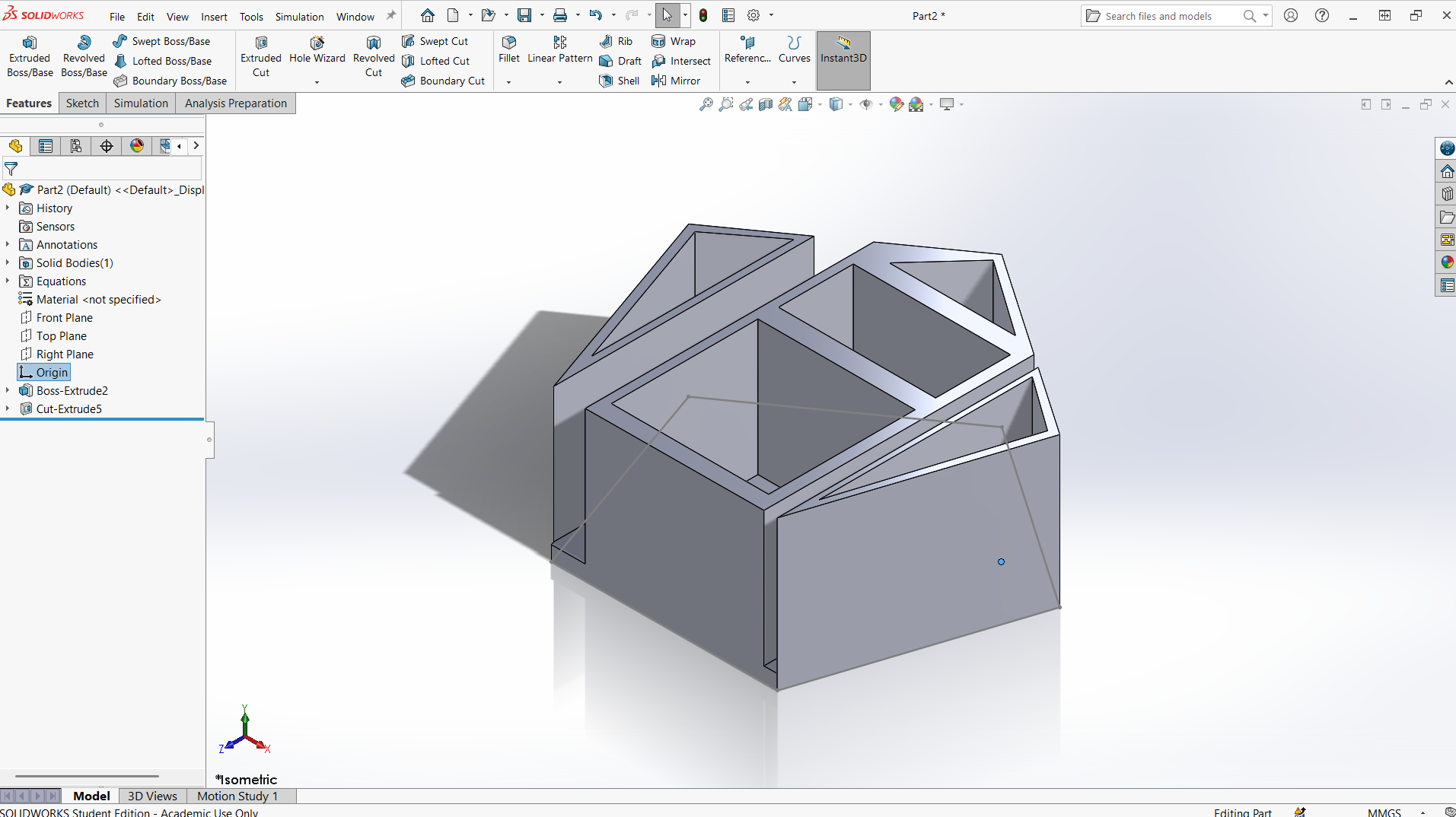

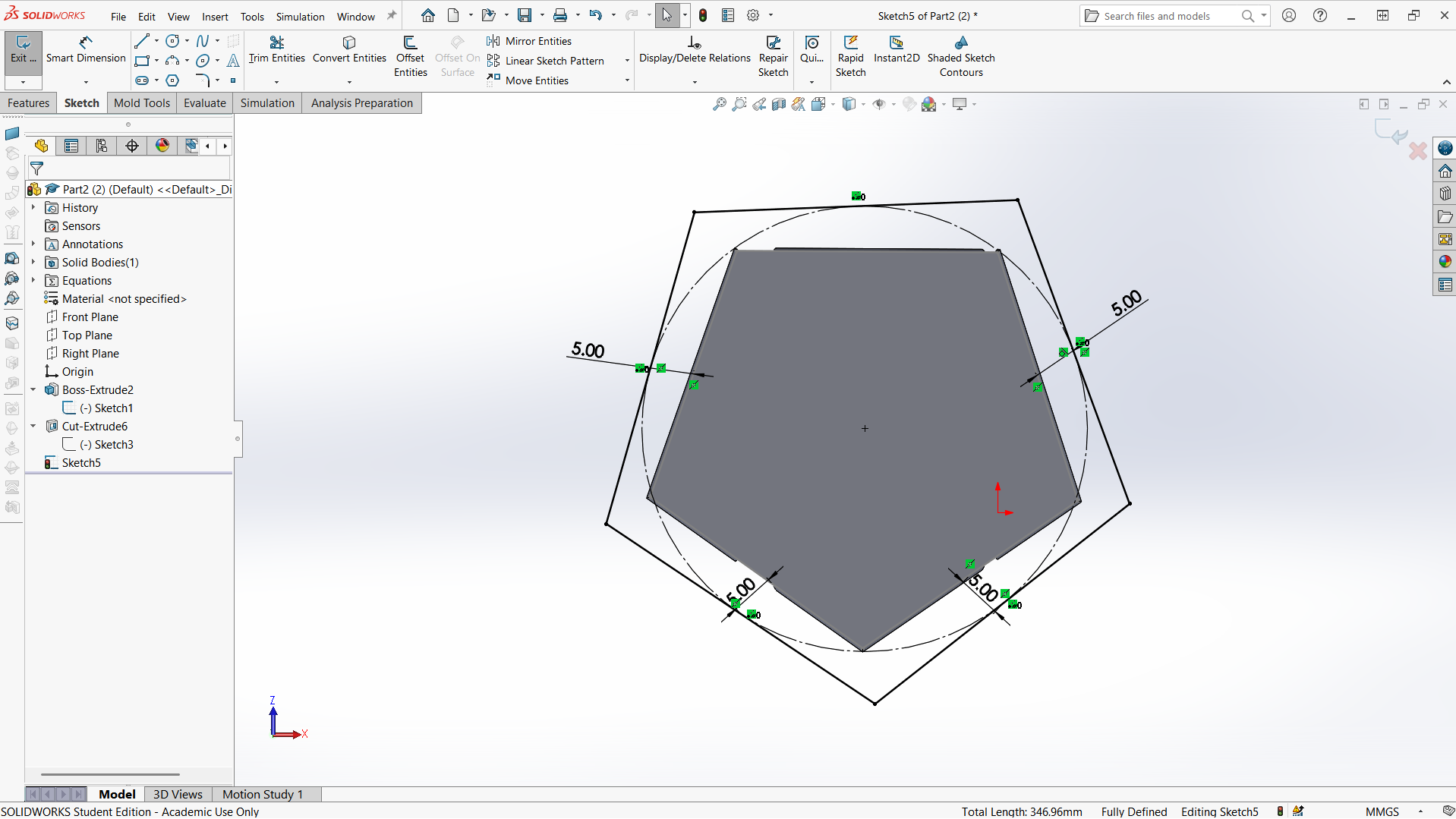

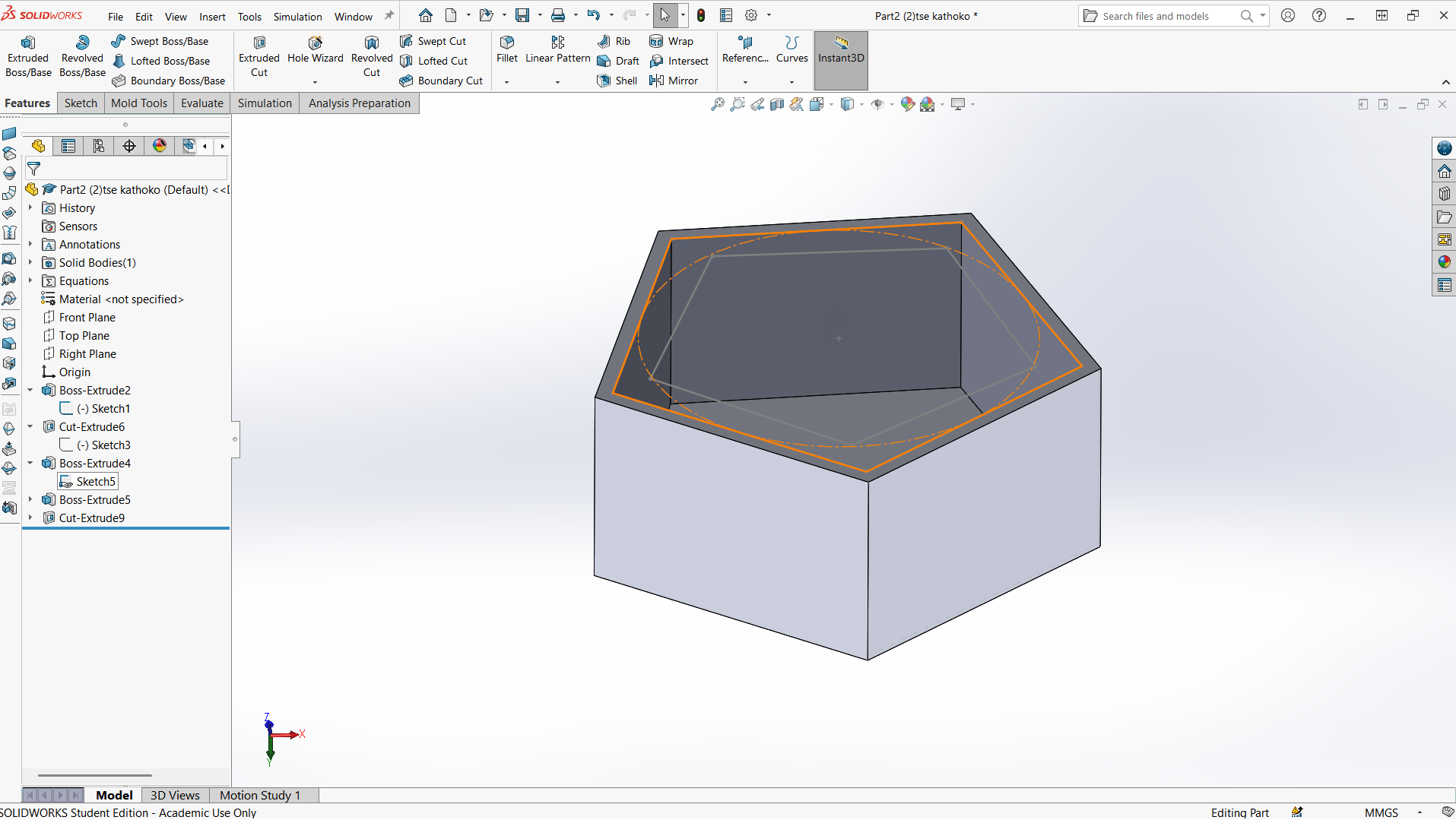

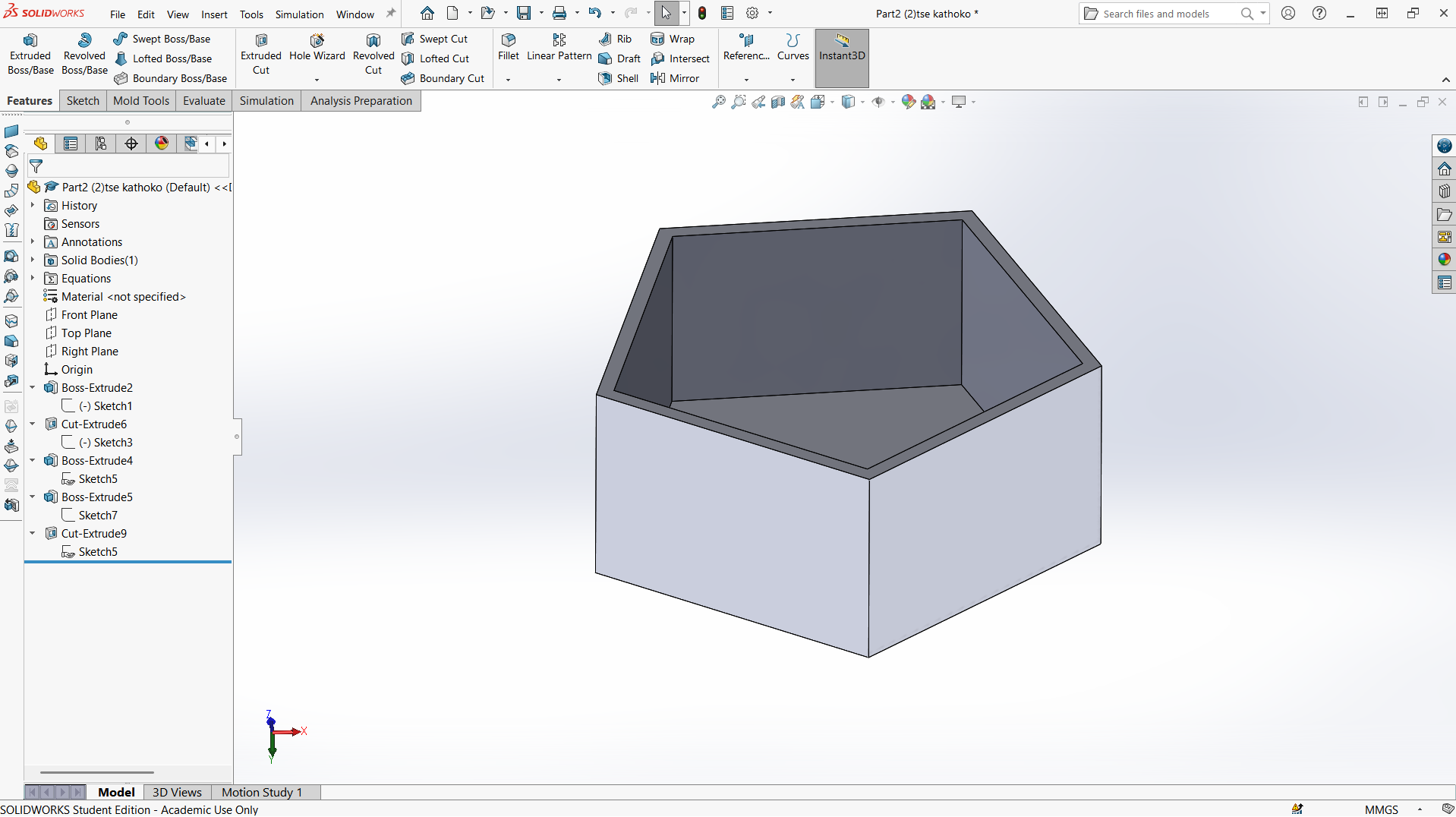

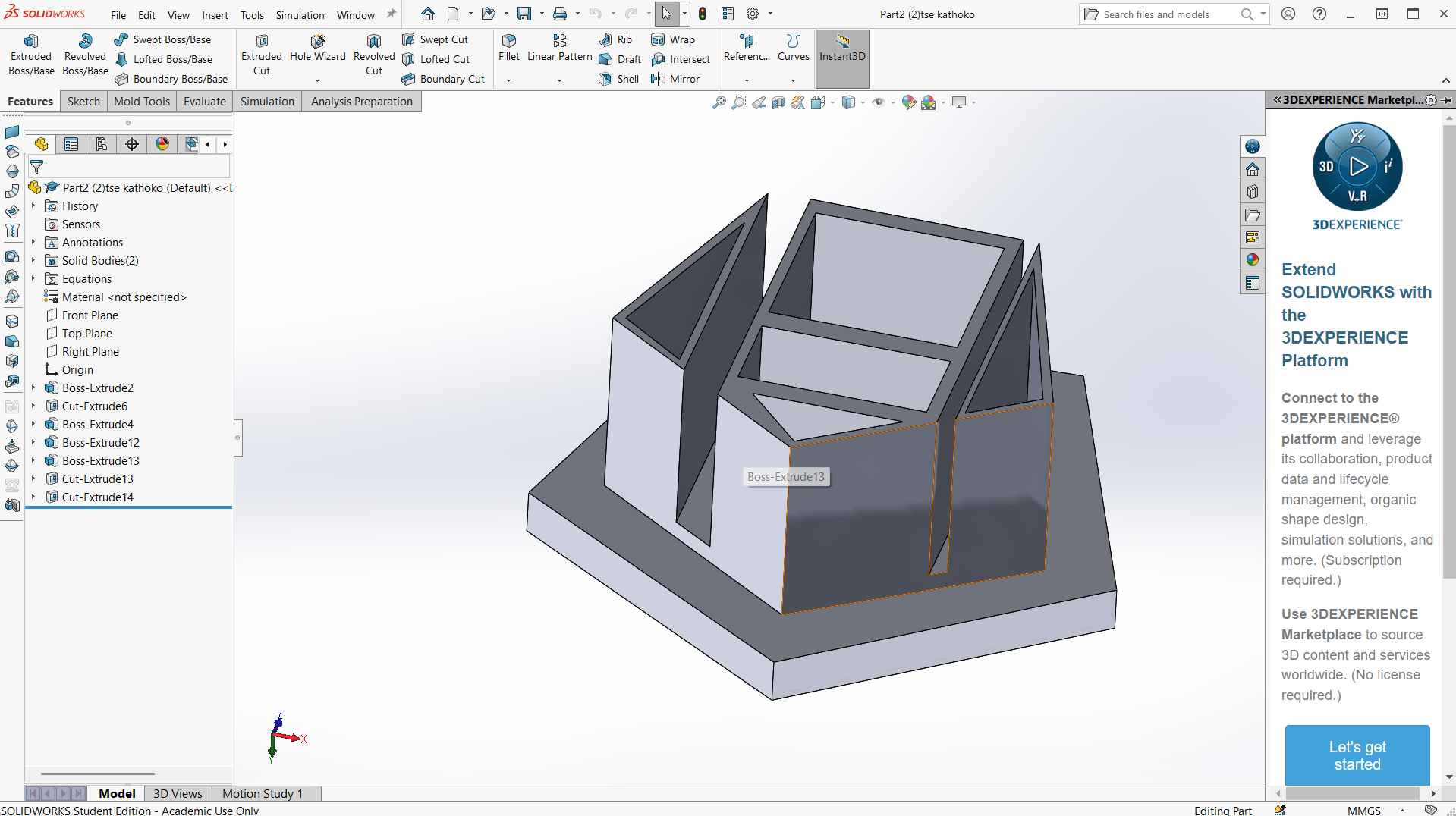

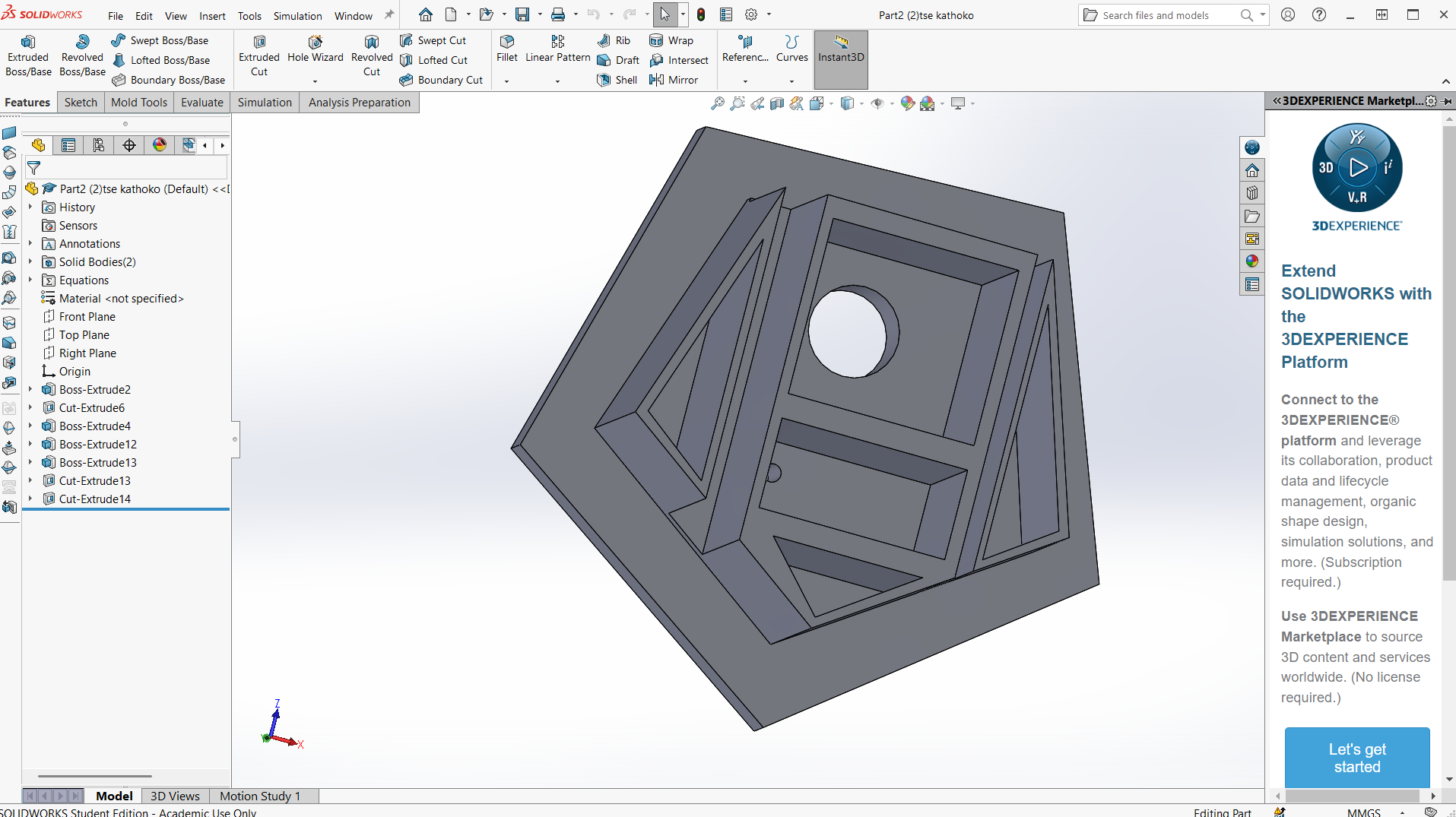

3D mold design

Steps to make a mold

1. Designed the Master Model

- Design an object to mold and 3D printed it

- Ensure surface is clean and smooth

2.Prepare the Master and Mold Box

- Printed the mold box to be used

- Clean the object and apply silicone mold

- Put it on the flat surface to avoid imbalance

- My mold is 3D printed, and below are the post processing done.

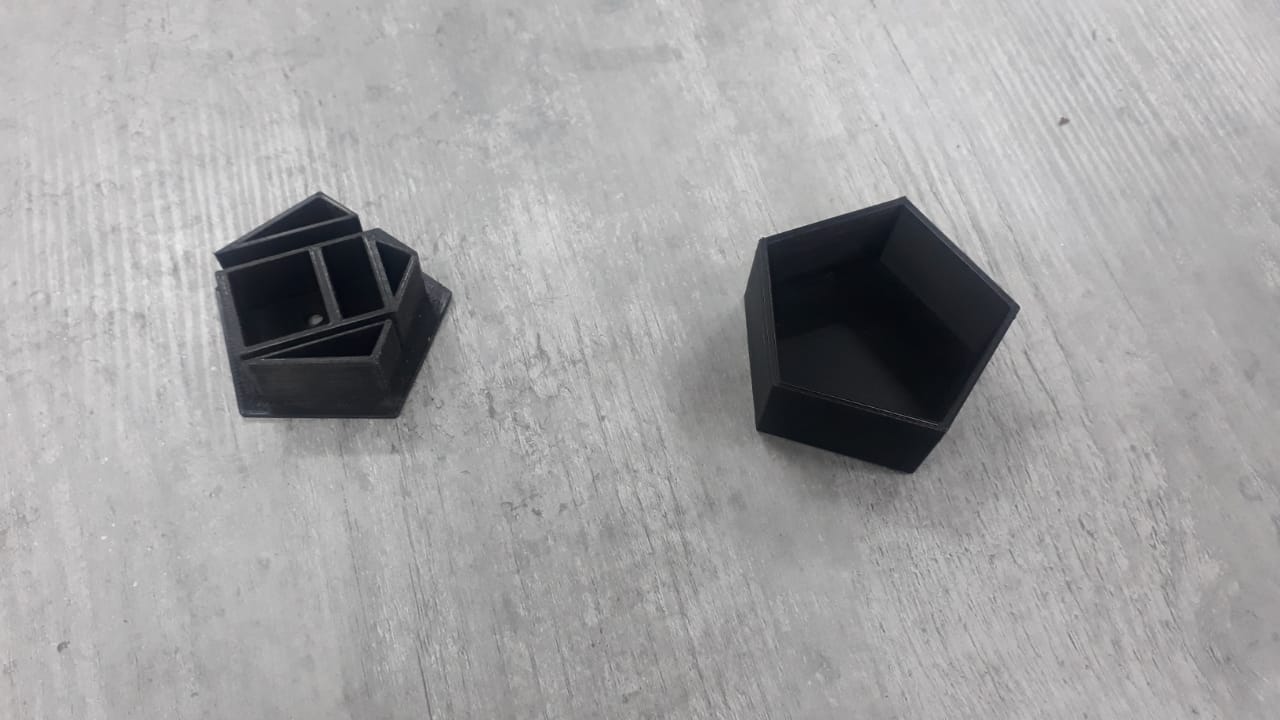

- The mold pieces to post process

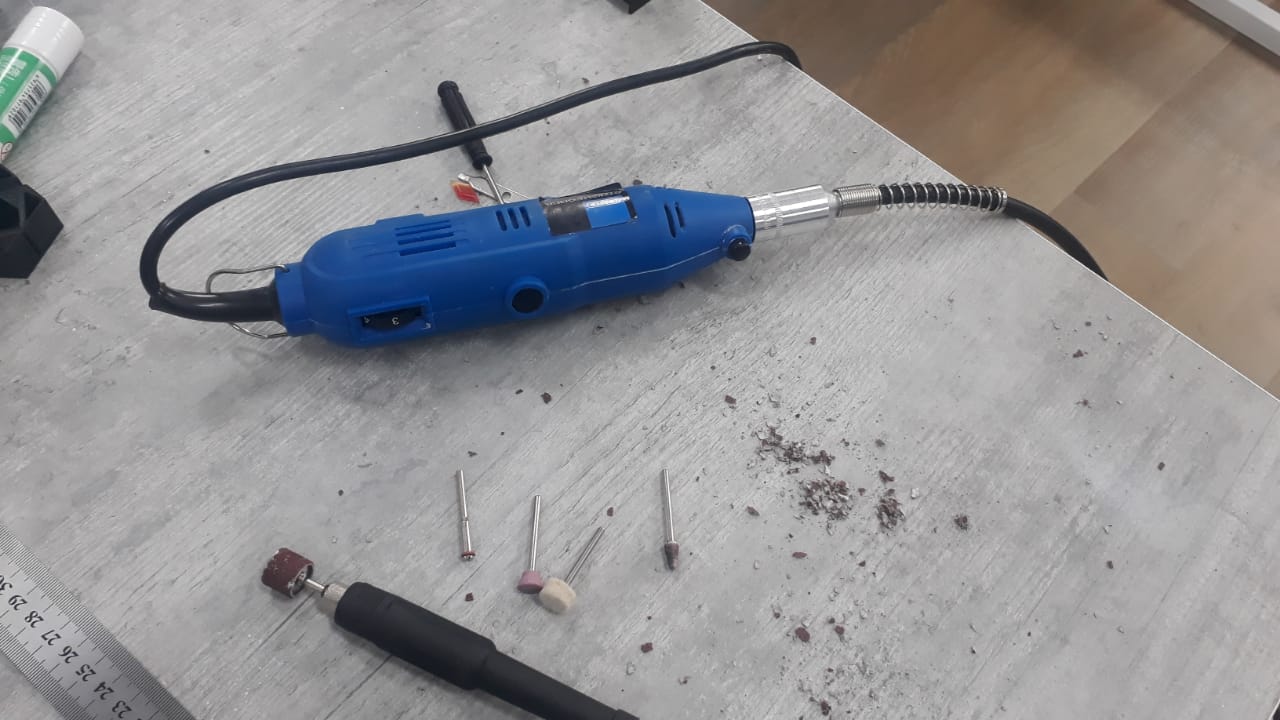

- Tools used to smoothen the mold pieces

- The video demostrates how the smoothening of the mold is done.

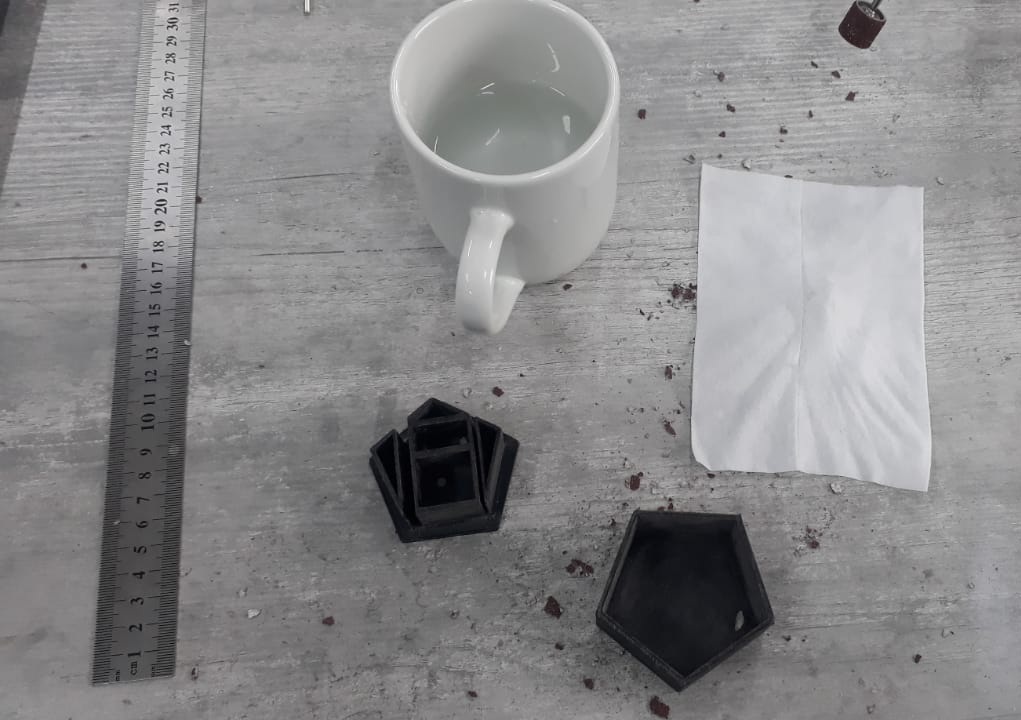

- Before cleaning

- After cleaning with water

I used Rotary tool IDE grinder and sand paper to smoothen the mold

3.Measure and Mix Silicone Rubber

- Use a 2-part silicone rubber kit

- Mix Parts A and B thoroughly with the ratio: 1:1

- Stir slowly to avoid air bubbles

- Use a vacuum chamber for 2 minutes

- Let bubbles rise and collapse before pouring

- Pour slowly from the opening stream

- Let silicone flow around the object naturally

- Tap or shake mold box gently to release bubbles

- Let the silicone cure undisturbed for 4–24 hours

- Time depends on product and room temperature

- Remove mold box

- Carefully extract the master

- Trim excess material or flash

Molding post processes

-

Post-Processing on Silicone Molds

- Peel off any flash around seams.

- Wash with warm soapy water.

- Use isopropyl alcohol for stubborn residue.

- Use sharp blades to clean edges.

- Trim pour spouts and air vents cleanly.

- Apply mold release spray before casting.

- Check for air bubbles or tears.

- Ensure mold alignment and tight seams.

- Use a quick material like hot glue or clay.

- Evaluate detail capture and demolding.

- Store flat and away from UV light.

- Avoid contact with sulfur-based materials.

- Apply mold release before each casting

- Pour resin, wax, soap, or other materials, here I used epoxy in a ratio of 100:45g

- Allow curing before de-molding the final part

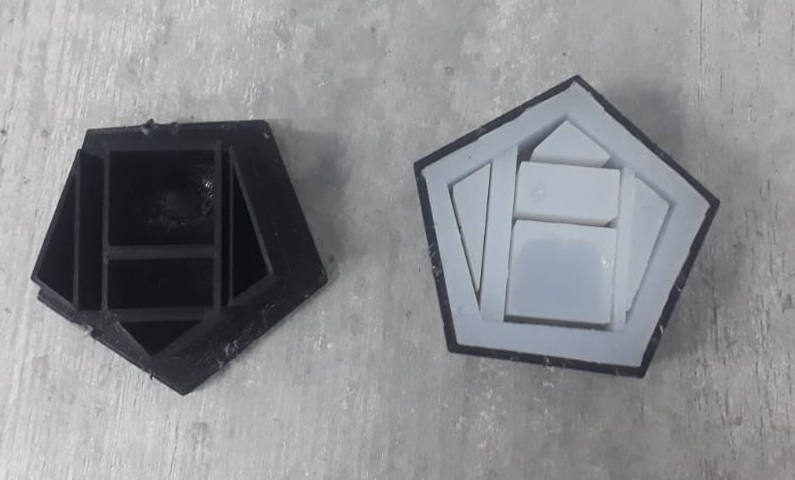

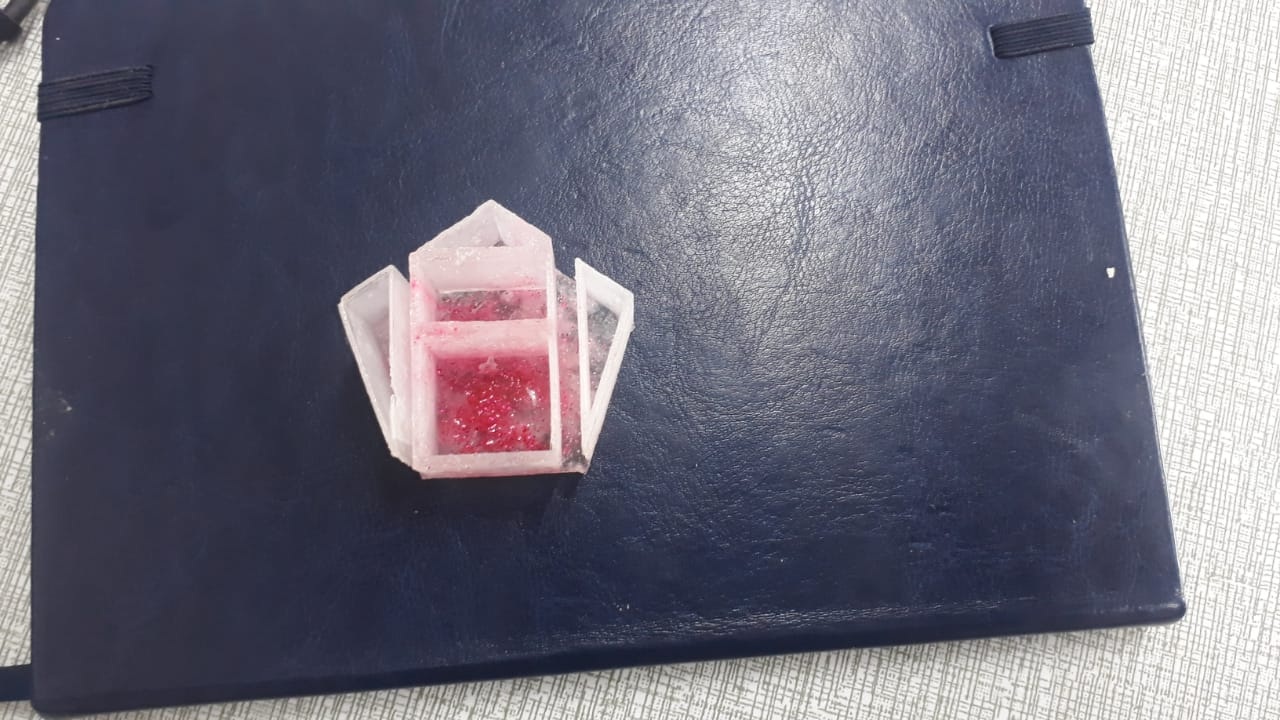

- The master piece and the Copy

1. Cleaning & Flash Removal

Here I used cooking oil to apply on the mold

Mold Ready for Casting