Sponge Puppet with Mechanism for Storytelling

1. Introduction

Storytelling is a powerful tool for stimulating children's imagination, improving language comprehension, and strengthening the bond between the narrator and the listener. This project aims to design and build a sponge puppet with an internal mechanism that synchronizes facial movements with narration.

2. General Objective

Design and construct an interactive sponge puppet with a movement mechanism synchronized with the voice, making storytelling more engaging for children.

3. Specific Objectives

- Design an internal structure that enables mouth movement and basic facial expressions.

- Use accessible materials and digital fabrication techniques to build the puppet.

- Implement an activation mechanism based on servo motors controlled by an electronic board.

- Develop an automatic synchronization system between narration and mouth movement.

4. Justification

Puppets have been used for centuries as educational and entertainment tools. However, most require manual manipulation, limiting immersion in the story. This project seeks to create an interactive puppet that enhances the storytelling experience, offering a more dynamic and immersive way to tell stories.

5. Methodology

5.1 Product Specifications

Product Objective: Develop an interactive sponge puppet that synchronizes facial movements with storytelling narration, enhancing children's storytelling experiences.

Functional Requirements

- Mouth and facial expressions synchronized with the narrator’s voice.

- Real-time response to audio signals.

- Simple user interface for control and configuration.

Non-Functional Requirements

- Use of safe and durable materials suitable for children.

- Minimum autonomy of 2 hours of continuous use.

- Ergonomic and visually appealing design for children.

Constraints

- Maximum budget of $200.

- Compliance with toy safety regulations.

- Size and weight limitations for easy handling.

Specification Table

Category Specification Details Product Name Sponge Puppet with Mechanism for Storytelling Interactive storytelling puppet Objective Develop an interactive puppet with synchronized facial movements Enhancing storytelling experience for children Target Audience Children (4-10 years old) and educators Suitable for schools and home storytelling Functional Features Mouth and facial expressions synchronized with voice Real-time response to narration Control System Microcontroller (Arduino or similar) Processes audio signals for movement control Actuators Servo motors (low-power) Enables smooth mouth and facial movements Sensors Microphone / Voice recognition sensor Detects narration to trigger movements Power Source Rechargeable battery or USB power supply Minimum 2-hour autonomy Materials Flexible sponge, internal support, 3D-printed components Lightweight and child-safe materials Manufacturing Method Digital fabrication (3D printing, laser cutting, hand assembly) Ensures precise and efficient production Software Custom synchronization software Aligns movements with narration User Interface Simple buttons or mobile app Easy-to-use control for customization Ergonomics Lightweight and easy to handle Suitable for children and adult storytellers Safety Compliance Must meet toy safety regulations Non-toxic materials, no small detachable parts Size & Weight Compact and lightweight Approx. 30 cm height, <500g weight Budget Maximum $200 Cost-effective production 5.2 Conceptual Design

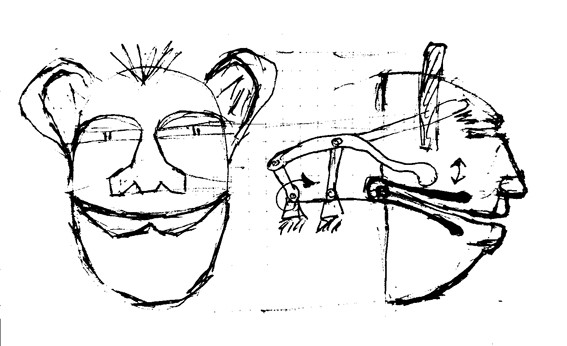

Based on the specifications, multiple concepts are generated to meet the established requirements. Each concept is evaluated considering factors such as technical feasibility, cost, ease of manufacturing, and user experience. Tools such as function diagrams, sketches, and preliminary models are used to visualize and communicate ideas.

Optimal Concept Selection

A decision matrix is used to compare the different concepts developed in the previous phase. Criteria considered include:

- Compliance with functional and non-functional requirements.

- Estimated production cost.

- Ease of assembly and maintenance.

- Potential user acceptance.

The concept with the highest score will be selected for detailed development.

5.3 Materialization Design.

Mechanical Design

- 3D modeling of the puppet's internal and external structure.

- Specification of materials and mechanical components, including servo motors and transmission mechanisms.

- Tolerance and adjustment analysis to ensure optimal functionality.

Electronic Design

- Circuit schematics and selection of electronic components, including microcontrollers, audio sensors, and communication modules.

- Printed Circuit Board (PCB) design and component layout.

- Firmware development for motion control and audio signal processing.

Aesthetic and Ergonomic Design

- Selection of colors, textures, and shapes to make the puppet attractive to children.

- User interface design, ensuring an intuitive and user-friendly interaction.

- Ergonomic considerations for easy manipulation of the puppet by storytellers.

5.4 Detail Design.

The Detail Design is the final phase in the development process of a product, system, or engineering project. In this stage, all the necessary elements for the manufacturing, assembly, implementation, or construction of the final product are precisely defined.

This methodology, inspired by Concurrent Engineering and Integrated Product Development approaches, ensures that all disciplines work in a coordinated manner from the initial stages of the project, minimizing rework and optimizing the development process of the "Sponge Puppet with Mechanism for Storytelling".

6. Expected Impact

- Improvement in storytelling experiences.

- Increased attention and interaction from children.

- Use of accessible technologies for education and entertainment.

Project Schedule

| Phase | Description | Duration | Key Activities | Milestone |

|---|---|---|---|---|

| Definition & Specifications | Gathering requirements and validating needs. | 2-3 weeks |

|

Requirements and specifications validated. |

| Conceptual Design | Creation and evaluation of initial concepts. | 3-4 weeks |

|

Final concept approved. |

| Materialization Design | Development of detailed models and technical validation. | 4-6 weeks |

|

Design ready for detailing. |

| Detail Design | Preparation of final documentation for manufacturing. | 4-5 weeks |

|

Final design ready for production. |

References

Carles Riba Romeva, "Diseño Concurrente," UPC Publications. Available at: UPC Repository