Computer controlled cutting

Assignment Overview

Group Assignment

- Do your lab's safety training

- Characterize our lasercutter's

Individual Assignment

- Cut something on the vinyl cutter

- Design, lasercut, and document a parametric construction kit:

- Accounting for the lasercutter kerf

- Which can be assembled in multiple ways

- For extra credit, include elements that aren't flat

Group Assignment

1. Safety Rules for Laser and Vinyl Cutters

FabLab Indoamérica

General Safety Guidelines

- Only trained and authorized personnel may operate the machines.

- Personal protective equipment (PPE) must be worn when necessary (e.g., safety glasses for the laser cutter).

- Machines should never be operated without supervision.

- Keep the workspace clean and free of flammable objects.

- Ensure ventilation and smoke extraction systems are active before operating the laser cutter.

Laser Cutter (Epilog FusionMaker) Safety Rules

Before Operation

- Ensure the material is laser-compatible and does not release toxic fumes.

- Check that the laser optics (mirrors and lenses) are clean.

- Set power, speed, and frequency according to the material specifications.

- Close the machine’s lid properly before starting the cut.

During Operation

- Never leave the machine unattended while running.

- Watch the process through the safety window without opening the lid.

- In case of fire, stop the machine immediately and use the lab fire extinguisher.

After Operation

- Wait for the cut pieces to cool before handling.

- Clean any debris from the cutting area.

- Turn off the machine and disconnect it if not in use for an extended period.

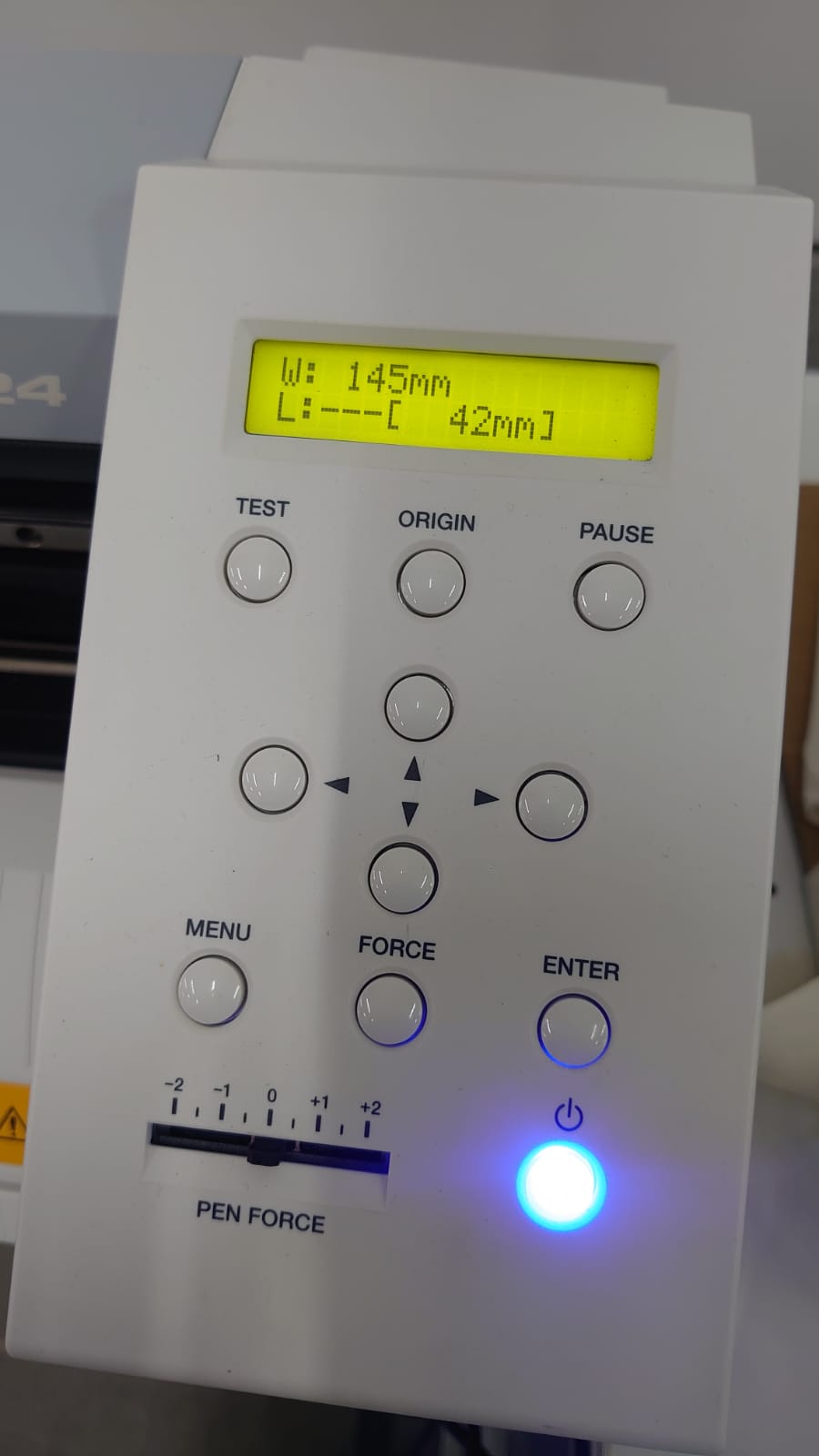

Vinyl Cutter (Roland) Safety Rules

Before Operation

- Ensure the blade is properly adjusted and in good condition.

- Set the correct pressure and speed based on the material.

- Align and secure the vinyl properly in the machine.

During Operation

- Keep hands away from the cutting head while the machine is running.

- Supervise the process to prevent material misalignment or blade damage.

- Stop the machine immediately if an issue occurs.

After Operation

- Carefully remove the cut material and clean the workspace.

- Turn off the machine when not in use.

- Store blades and tools properly after use.

Emergency Procedures

- In case of fire, use the CO₂ extinguisher available in the FabLab.

- Report any incidents or machine malfunctions to the FabLab supervisor.

- Follow first aid protocols and contact lab personnel if an injury occurs.

2. Characterization of the Epilog FusionMaker Laser Cutter

FabLab Indoamérica

General Information

- Brand & Model: Epilog FusionMaker

- Type: CO₂ Laser Cutter

- Functionality: Precision cutting and engraving

- Common Uses: Prototyping, fabrication, artistic engraving, industrial applications

Technical Specifications

- Laser Type: CO₂ laser

- Power: 30W, 40W, or 50W options

- Work Area: Approx. 24” x 12” (609 mm x 305 mm)

- Resolution: Up to 1200 DPI

- Speed & Power Control: Adjustable settings

Supported Materials

Cutting Capabilities

- Wood (MDF, plywood, etc.)

- Acrylic

- Leather

- Cardboard

- Fabric

- Some plastics (Non-PVC)

Engraving Capabilities

- Glass

- Ceramic

- Coated metals

Prohibited Materials: PVC, polycarbonate, and materials that release toxic fumes.

Key Features

- Enclosure: Fully enclosed system with a transparent lid

- Ventilation System: Integrated air exhaust

- Control Panel: Digital interface

- Air Assist: Reduces flaming and improves precision

- Red Dot Pointer: Previews the cutting area

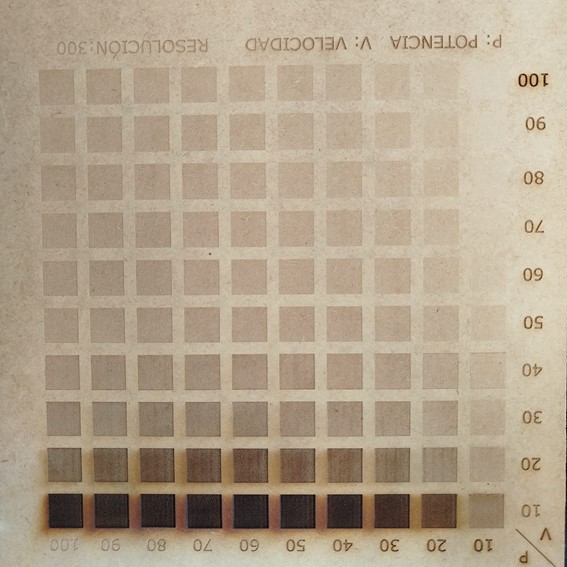

Laser Calibration Grid

Displayed in the first image, the power vs. speed test grid is used to determine optimal settings for different materials.

- Power settings range from 10% to 100%

- Speed settings range from 10% to 100%

- The darker the engraving, the more material was removed

Safety Considerations

- Protective Gear: Safety glasses for reflective materials

- Machine Supervision: Never leave unattended

- Fire Prevention:

- Keep a CO₂ fire extinguisher nearby

- Avoid highly flammable materials

- Ensure proper ventilation

- Cleanliness: Regular maintenance to prevent overheating

Laser Cutter Tolerance Test

FabLab Indoamérica

Objective

This experiment aims to determine the optimal fit for interlocking laser-cut pieces by testing different slot widths and evaluating tolerances.

Methodology

- Material: Medium-density fiberboard (MDF) or plywood.

- Laser Cutter Used: Epilog FusionMaker.

- Slot Widths Tested: Ranging from 2.9 cm to 3.6 cm in 0.1 cm increments.

- Kerf Consideration: Adjustments were made to account for material removal by the laser.

- Laser Settings: Power, speed, and frequency optimized for minimal burning and clean cuts.

Observations

- Tighter Fits: Slots between 2.9 cm - 3.2 cm required force for assembly.

- Looser Fits: Slots between 3.4 cm - 3.6 cm allowed for easy but potentially unstable connections.

- Optimal Fit: Likely within the 3.2 cm - 3.3 cm range.

- Burn Marks: Indicating laser power may be slightly high or multiple passes were used.

Adjustments for Future Tests

- Refining kerf compensation based on precise measurements.

- Optimizing laser power and speed to reduce burns.

- Testing different materials like acrylic and plywood for comparison.

- Evaluating mechanical strength of each fit under load conditions.

Conclusion

This test is essential for achieving precise fits in interlocking structures such as furniture, enclosures, and mechanical joints. Adjusting design files based on these results ensures accurate assembly and functional strength.

Individual Assignment

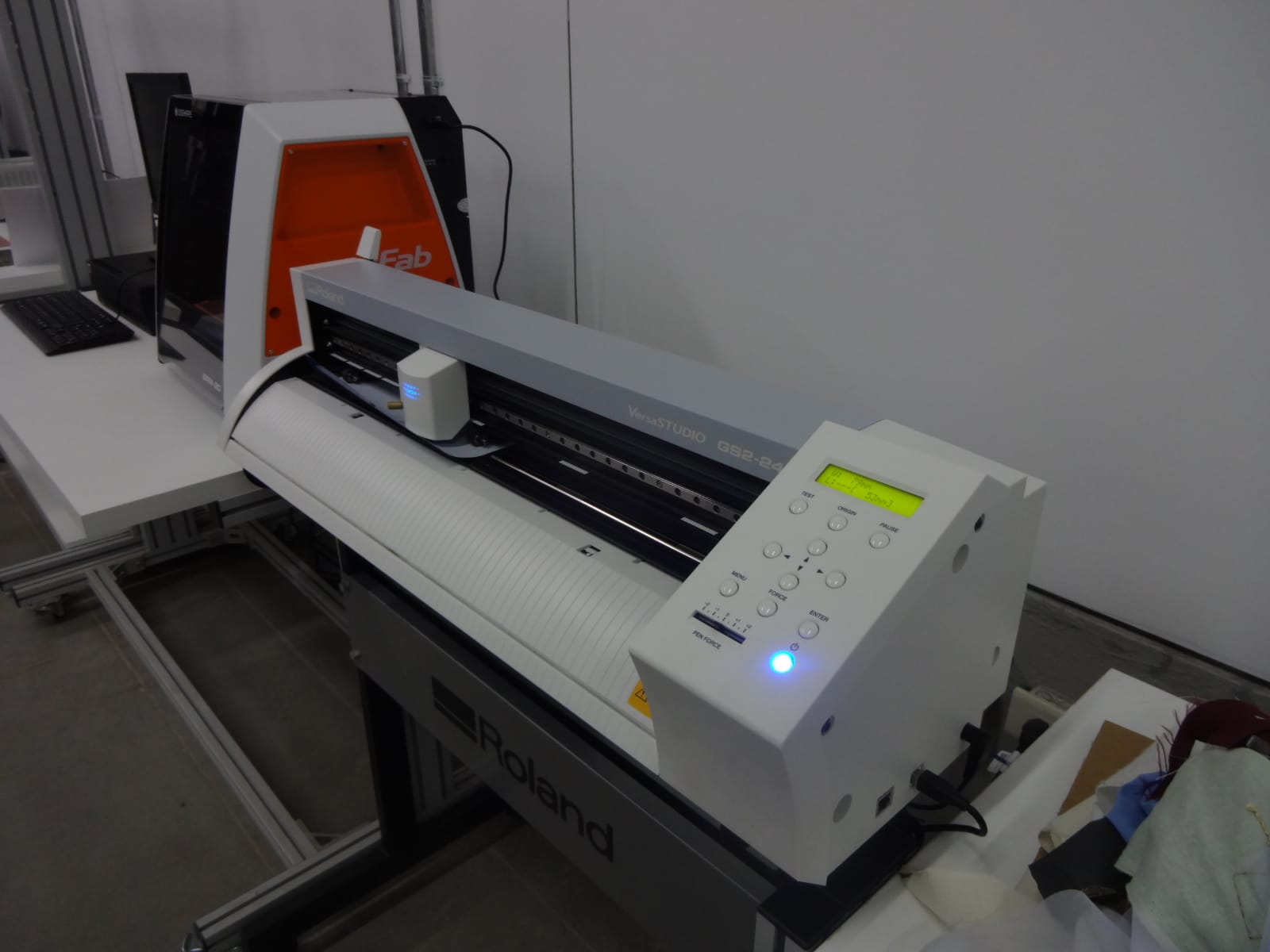

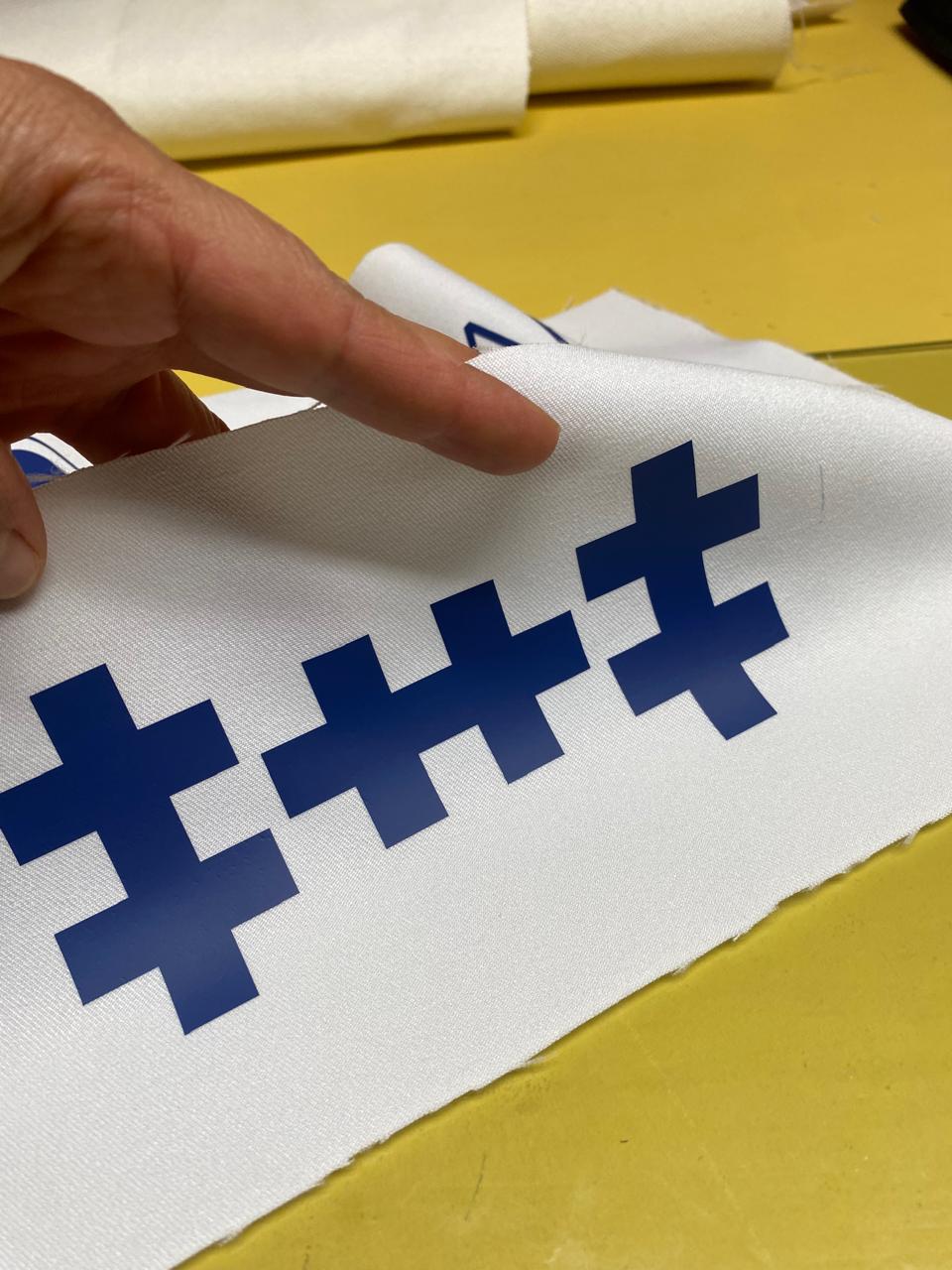

3. Vinyl Cutting Process

This is the step-by-step procedure to efficiently perform vinyl cutting.

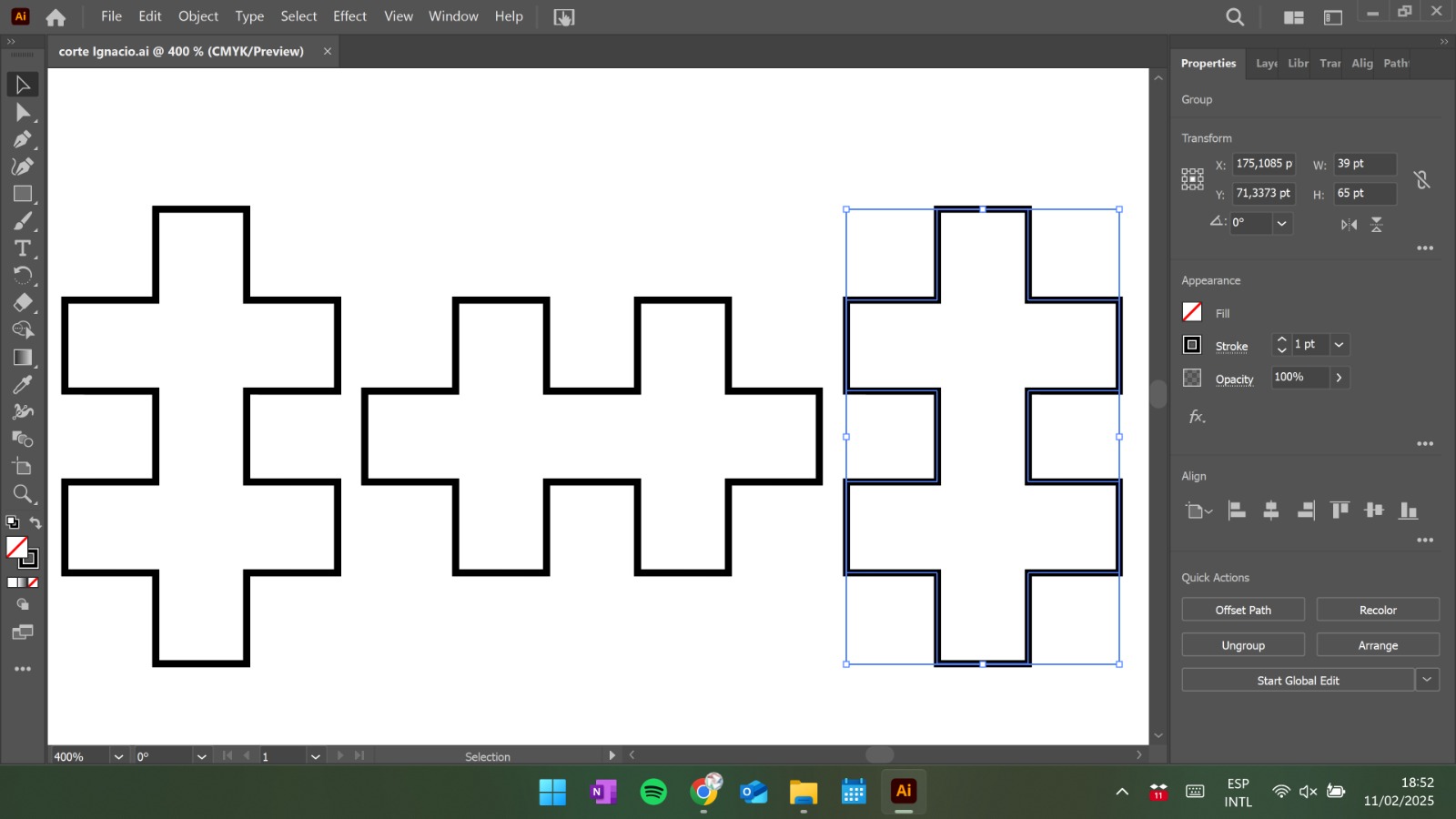

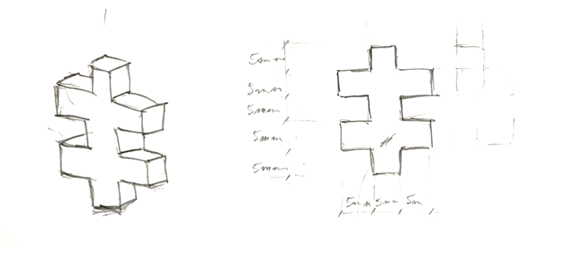

3.1. Modeling in Illustrator

- Use the square tool to create the base shape.

- Join pieces using the union tool to form a single piece.

- Use copy and symmetry to create the final composition.

3.2. File Export

- Save in JAPAN ILLUSTRATOR 3 format, compatible with the cutter.

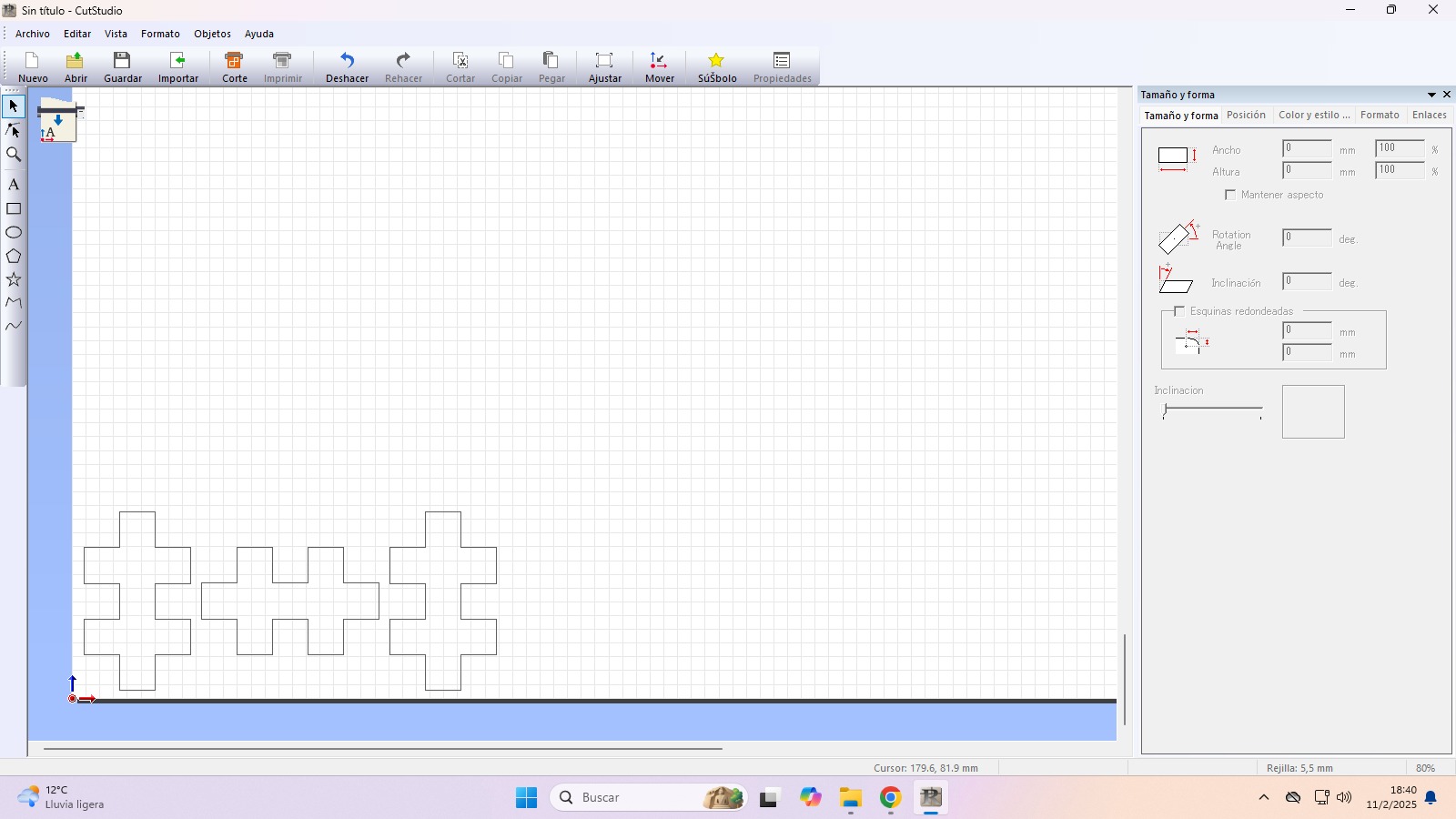

3.3. File Import

- Open the vinyl cutter software.

- Import the file generated in Illustrator.

3.4. Machine Configuration

- Adjust parameters such as pressure, speed, and blade type.

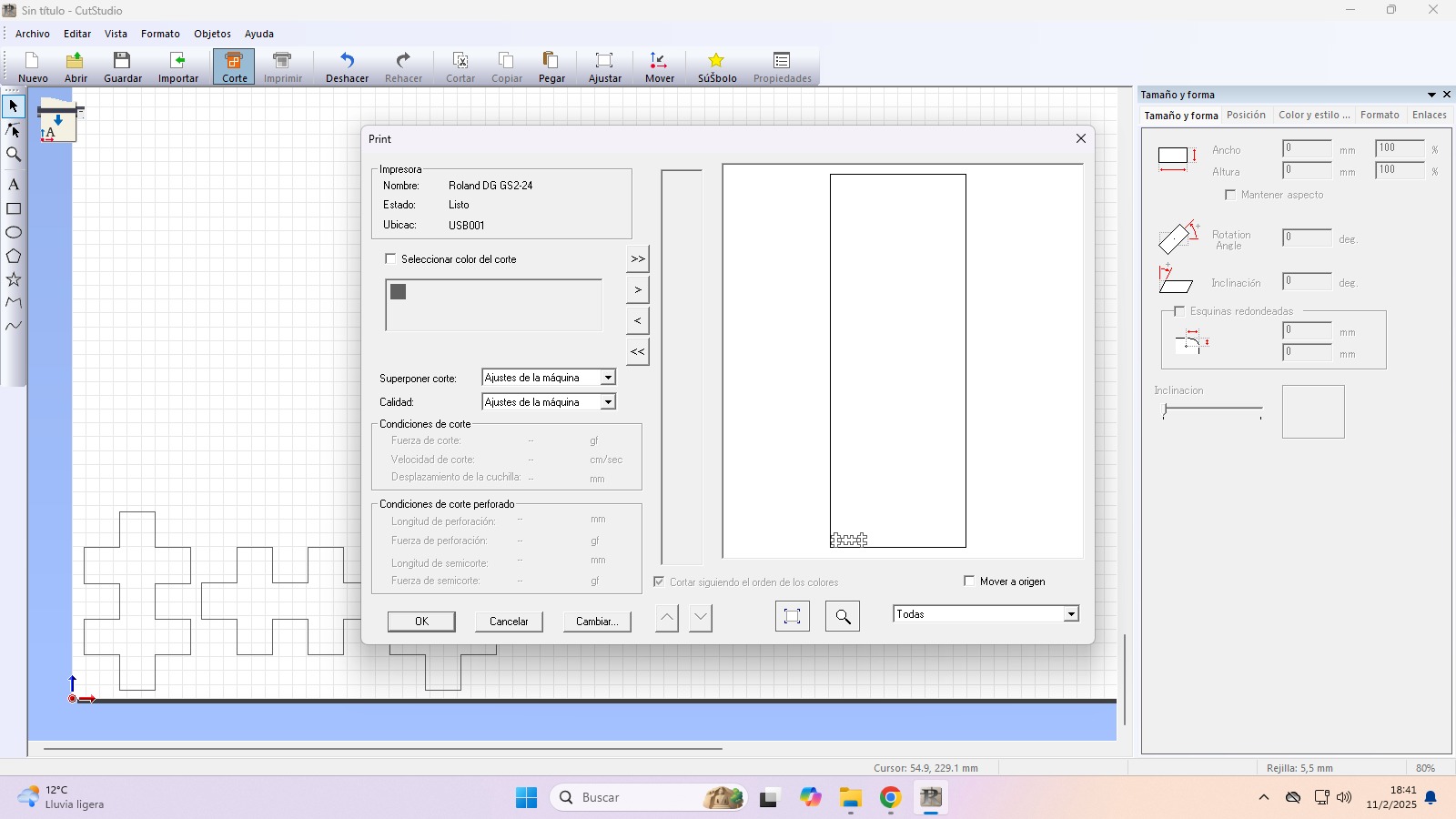

3.5. Sending and Cutting

- Send the design to the machine and ensure the vinyl is correctly placed.

- Supervise the process for precise cuts.

3.6. Removal and Application

- Carefully remove the cut vinyl.

- Apply the vinyl as needed (using transfer if complex).

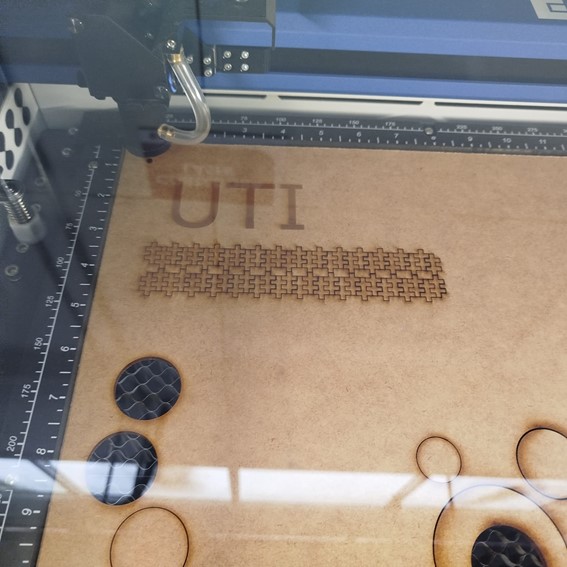

4. kit Standard Modular Pieces for Configurable Structures

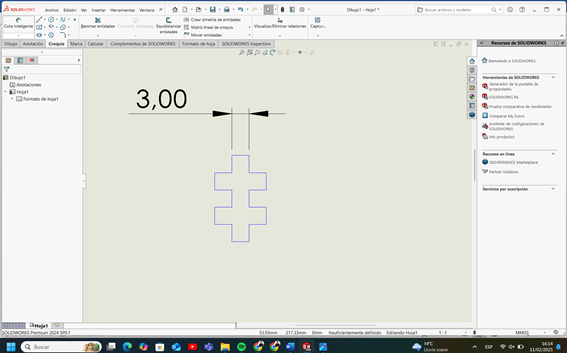

The image shows a set of laser-cut interlocking wooden pieces designed in a standardized modular format. These pieces can be assembled in various ways to create different 3D structures.

4.1. Modular Design Concept

- The pieces follow a uniform interlocking system, meaning each component has standardized slot widths and depths.

- They resemble cross-shaped connectors, allowing them to fit together in multiple orientations.

- The uniformity in dimensions enables scalability and expansion without the need for additional connectors.

4.2. Features of the Pieces

- Laser-Cut Precision: Ensures tight-fitting joints by compensating for kerf width.

- Symmetry: Allows multiple assembly possibilities without predefined constraints.

- Material: Likely MDF or plywood, chosen for its strength and ease of laser cutting.

- Edge Burn Marks: Indicate controlled cutting power for maintaining structural integrity.

4.3. Configurability and Possible Forms

These pieces can be used to construct:

- Geometric Shapes: Cubes, spheres, or irregular polyhedrons.

- Mechanical Structures: Frames for lightweight mechanical systems.

- Architectural Prototypes: Scaled-down modular buildings or conceptual frameworks.

- Artistic & Educational Models: Useful for hands-on learning and creative design exercises.

4.4. Advantages of This System

- Reusability – Components can be disassembled and reassembled into new configurations.

- Expandability – The modular nature allows for additional pieces to be integrated easily.

- Parametric Design – This system can be adapted for larger-scale projects by adjusting the slot dimensions.

- Efficient Manufacturing – Minimal material waste and easy mass production using a laser cutter.

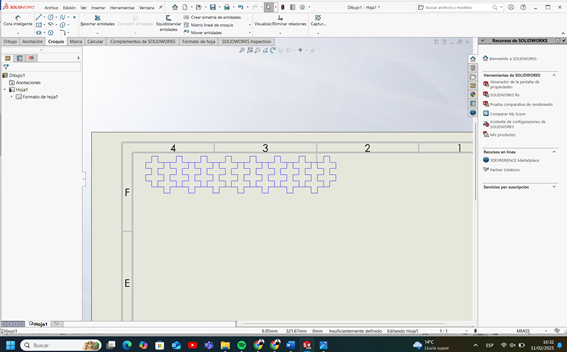

4.5 Design and Laser Cutting Process

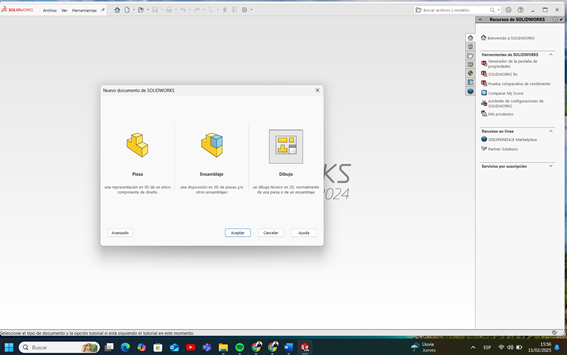

- Open SolidWorks: Select "File" → "New Part" → "2D Drawing".

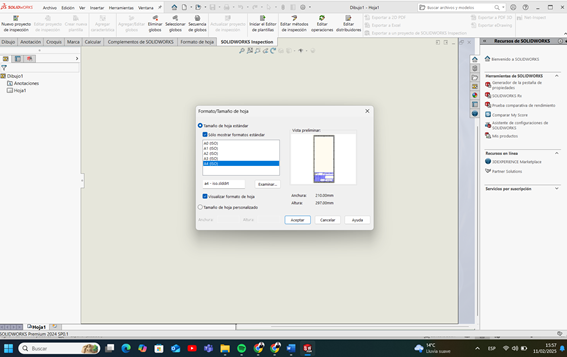

- Select Size: Configure the appropriate drawing size.

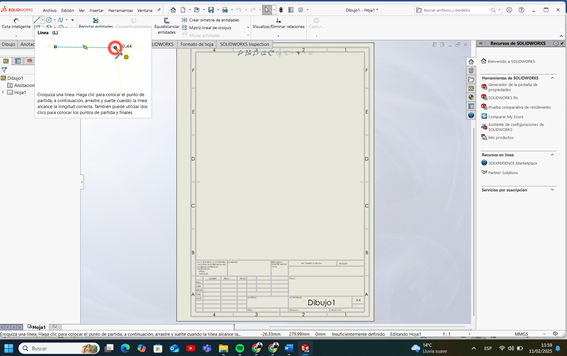

- Create Sketch: Select the "Line" tool to start the sketch.

- Draw the Piece: Create the 2D design with precise measurements.

- Create Cutting Mesh: Prepare the design for the laser cutting process.

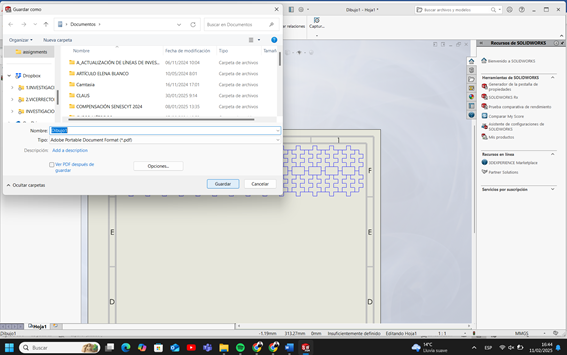

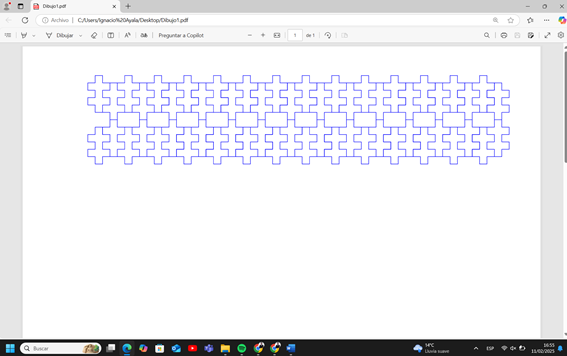

- Export to PDF: Generate a PDF file of the final design.

- Send to Machine Software: Upload the PDF file to the cutting machine software.

- Execute the Cut: Start the laser cutting process on the chosen material.

- Kit: Assembled parts kit.

4.6. Potential Improvements

- Adjustments for Tolerances: Fine-tuning the slot width to account for kerf variations in different materials.

- Different Thicknesses: Testing with acrylic or thicker wood for added durability.

- Integration with Other Materials: Combining with 3D-printed or metal parts for hybrid structures.

Conclusion

This modular system of standardized laser-cut parts is an excellent tool for rapid prototyping, educational purposes, and scalable design. It demonstrates how simple geometric components can be configured to create complex and functional structures.