3D Scanning and Printing

Group Assignment

- Test the design rules for your 3D printer(s).

Individual Assignment

- Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively.

- 3D scan an object (and optionally print it).

This week was pretty fun. I tried 3D print some piece I designed and 3D scanned!

Introduction

In this week’s assignment, I explored 3D printing and scanning processes to

print a custom-designed lamp inspired by a

Pinterest

Model.

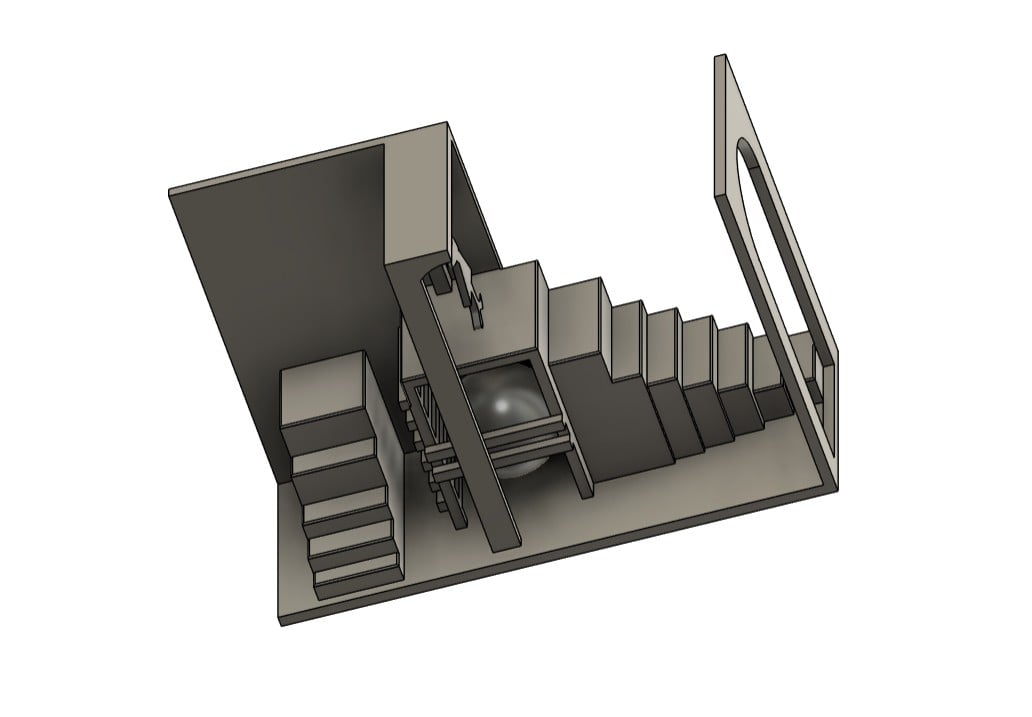

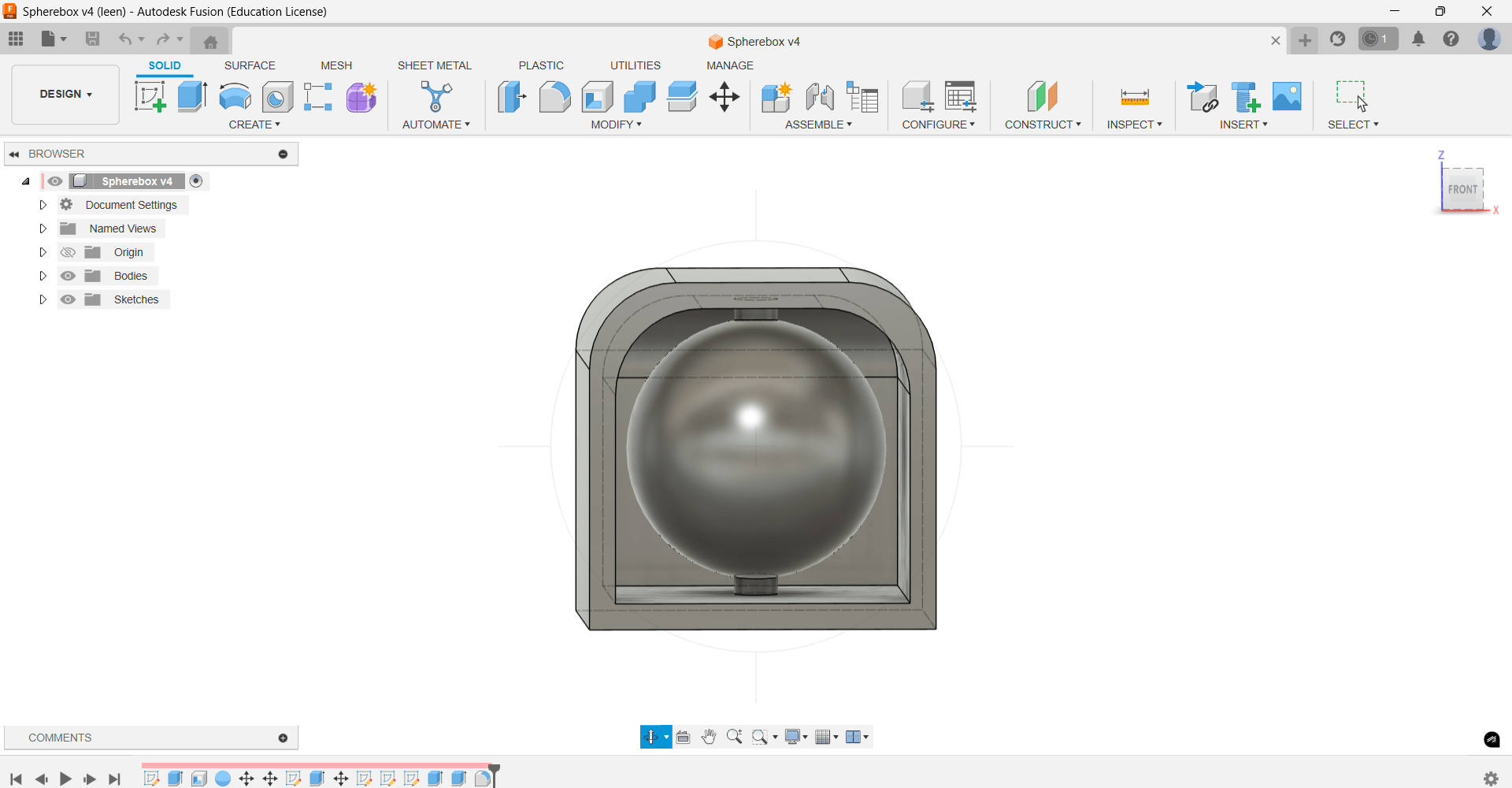

In order to make sure that my design can't be manufactured subtractively, I decided to add

underneath the figurine a cavity, where I inserted a sphere and enclosed it from the sides to

add complexity to the design.

In my opinion, it gives the illusion that this figurine is standing on a spherical pedestal that

is surrounded by prison-like grid, improving the visual appearance of the lamp and it is up to

the viewer whether to interpret it as empowering and freeing or restricting and limiting!

3D Designing My Lamp

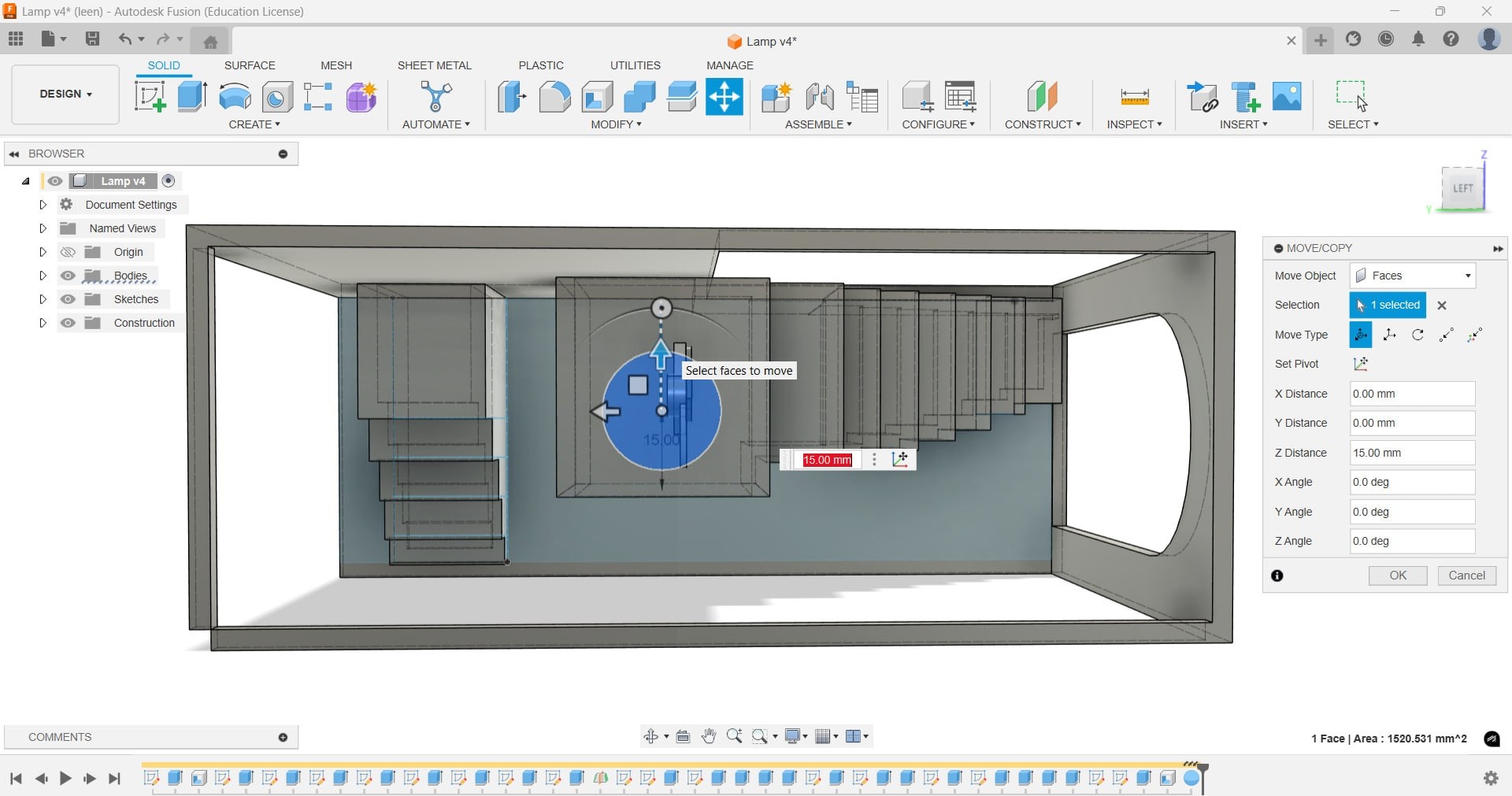

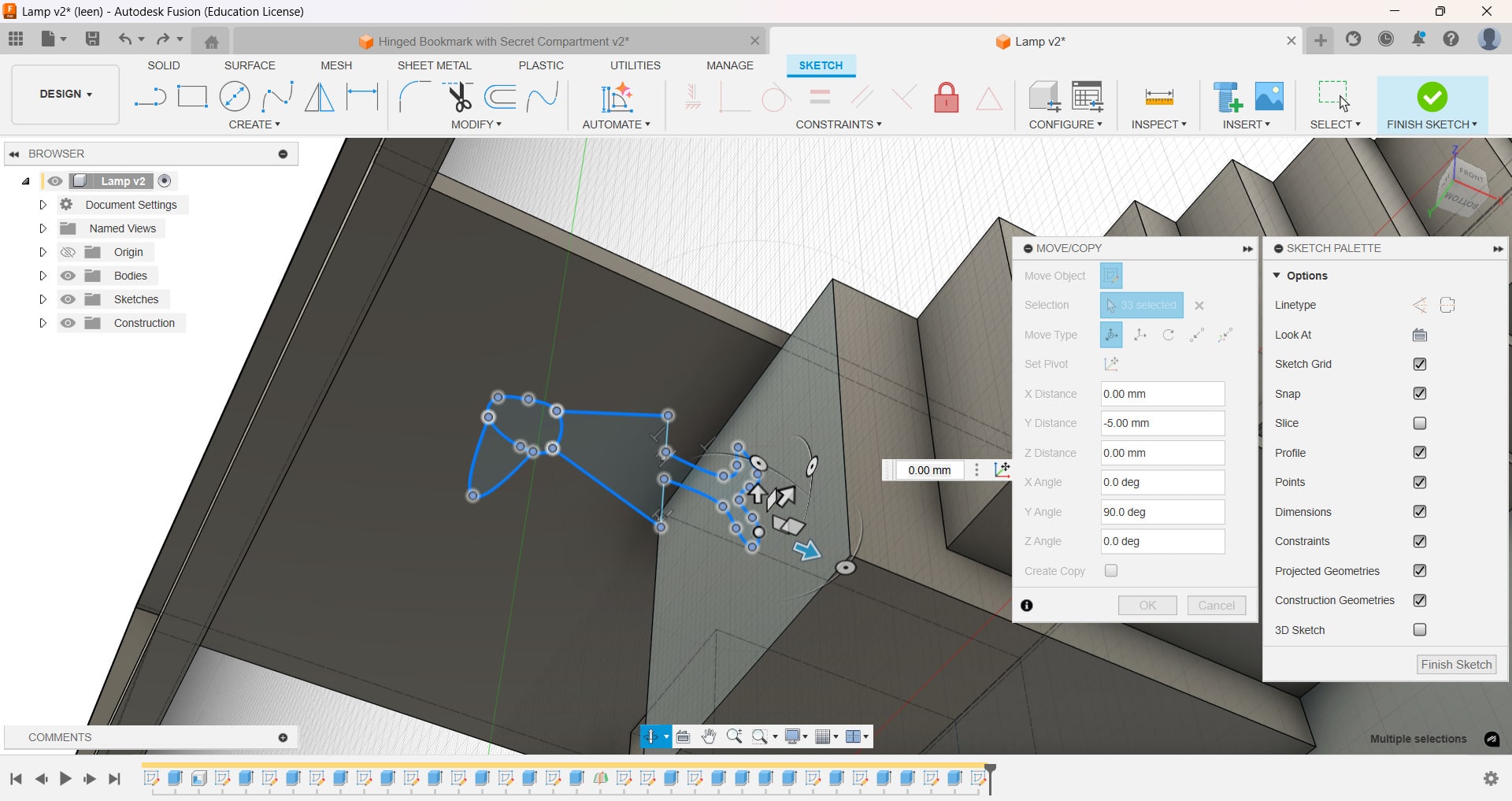

I learned new skills like adding Sphere, manipulating using the

move and rotate

functions to make sure it is inside the box.

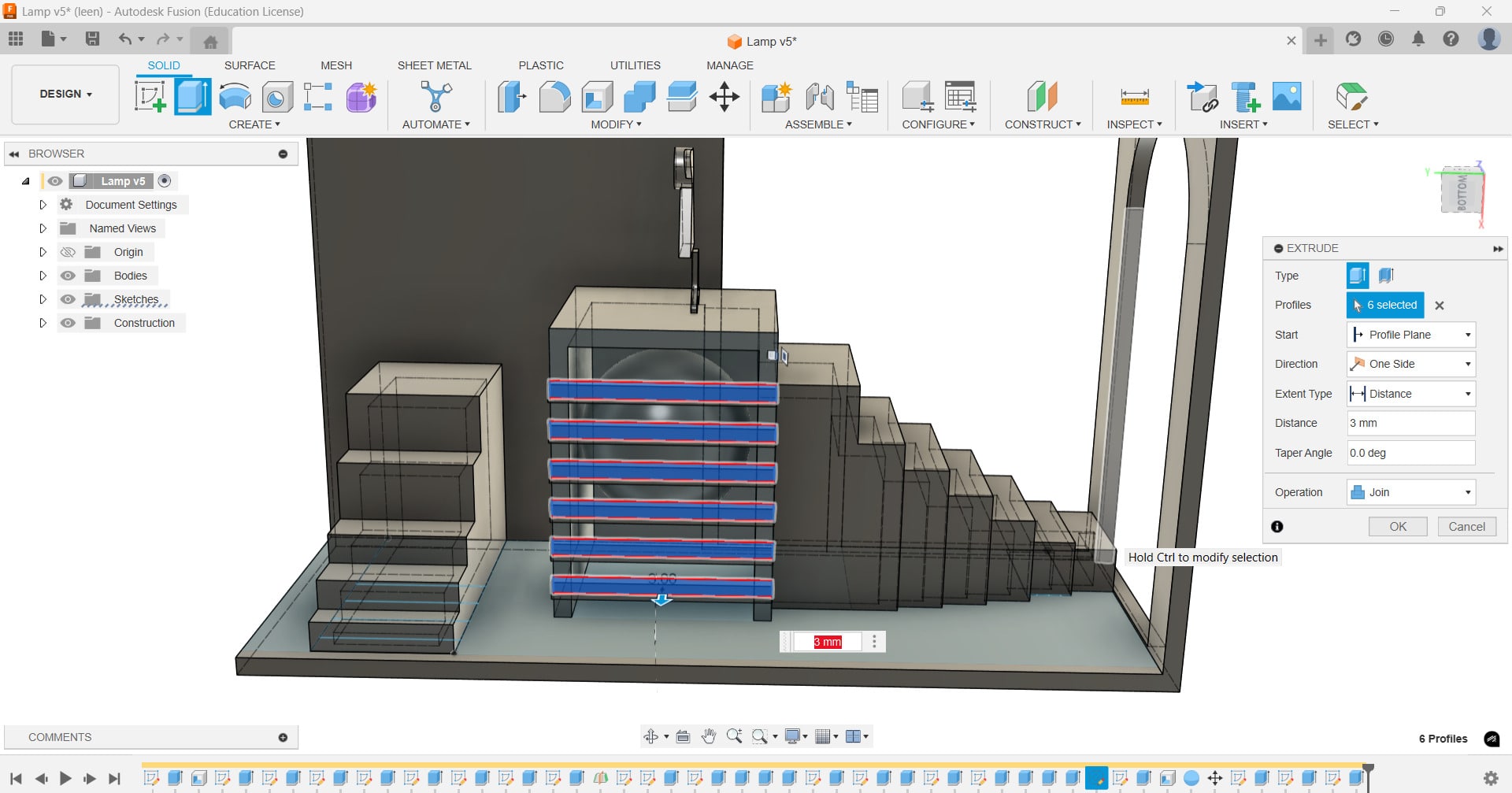

To make the design a little bit more complicated, I decided to add grid-like structure that

encloses

the sphere box, with leaving some gaps in between for visibility. This enables me to put the

claimed

advantages of 3D printing into test, namely making more complicated shapes and cavities in the

design.

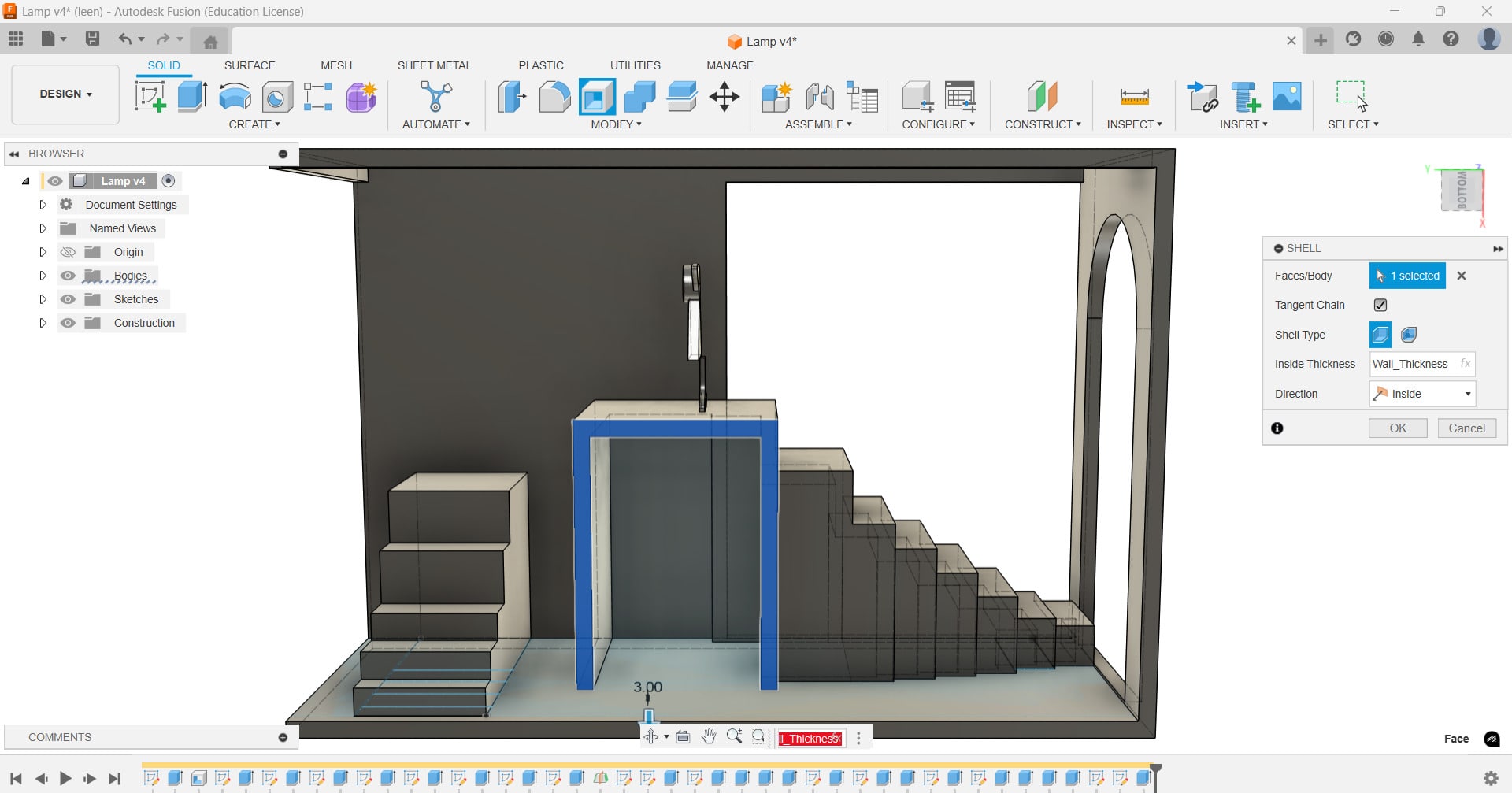

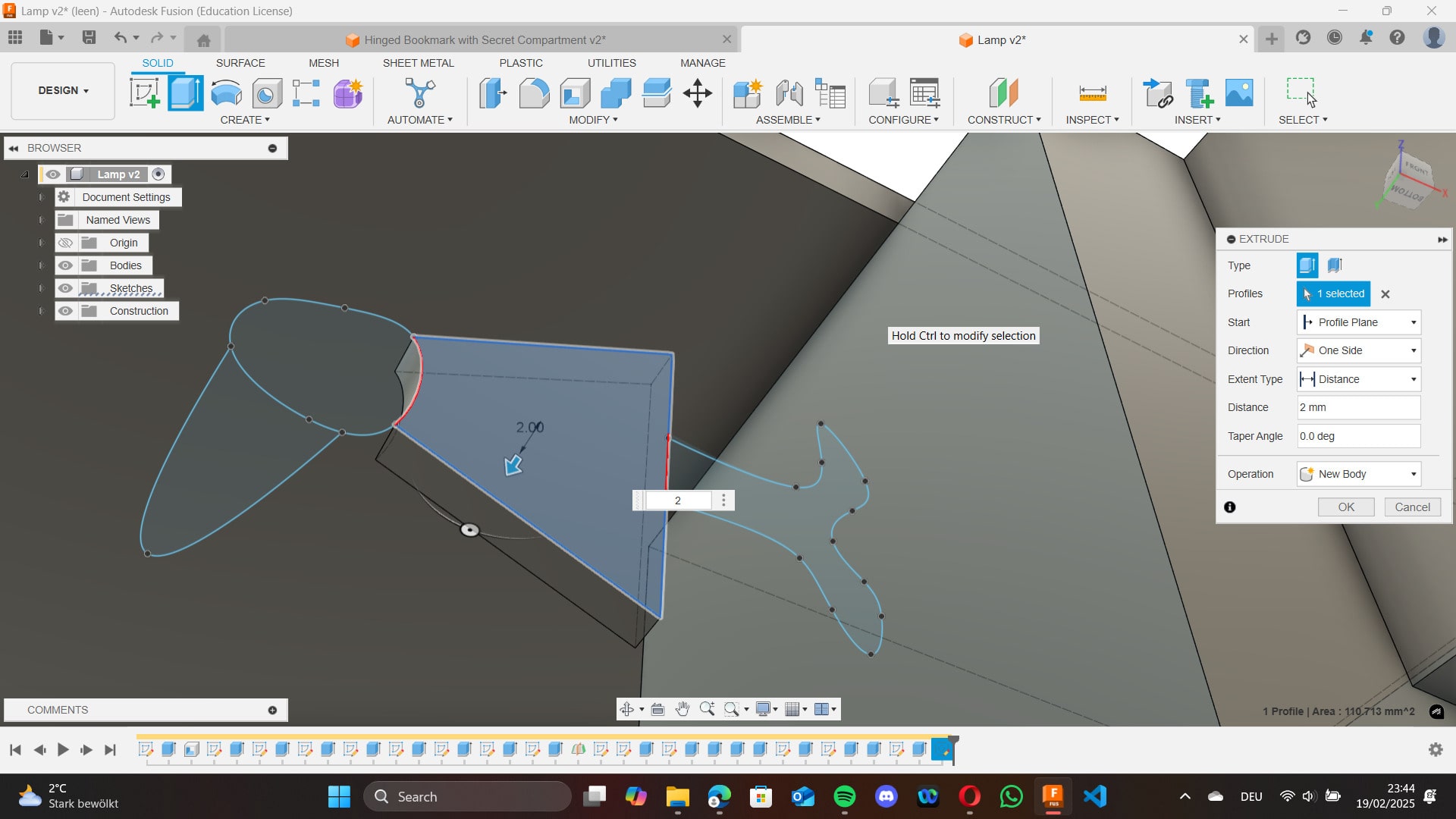

Other functions I already used like extrude for cutting and joining walls and

stairs

together, also adding arcs into my designing by extruding half squares together with rectangles

on

each side to form this Arch door entrance. It was quite fun.

I also added a little figurine by using the spline tool and drew it on the

plane,

then rotated it 90° to appear like it is standing on the platform.

To form the arch ceiling, behind it, I added an Offset Plane right behind the

figurine

to sketch another arch on it and created the 3D illusion.

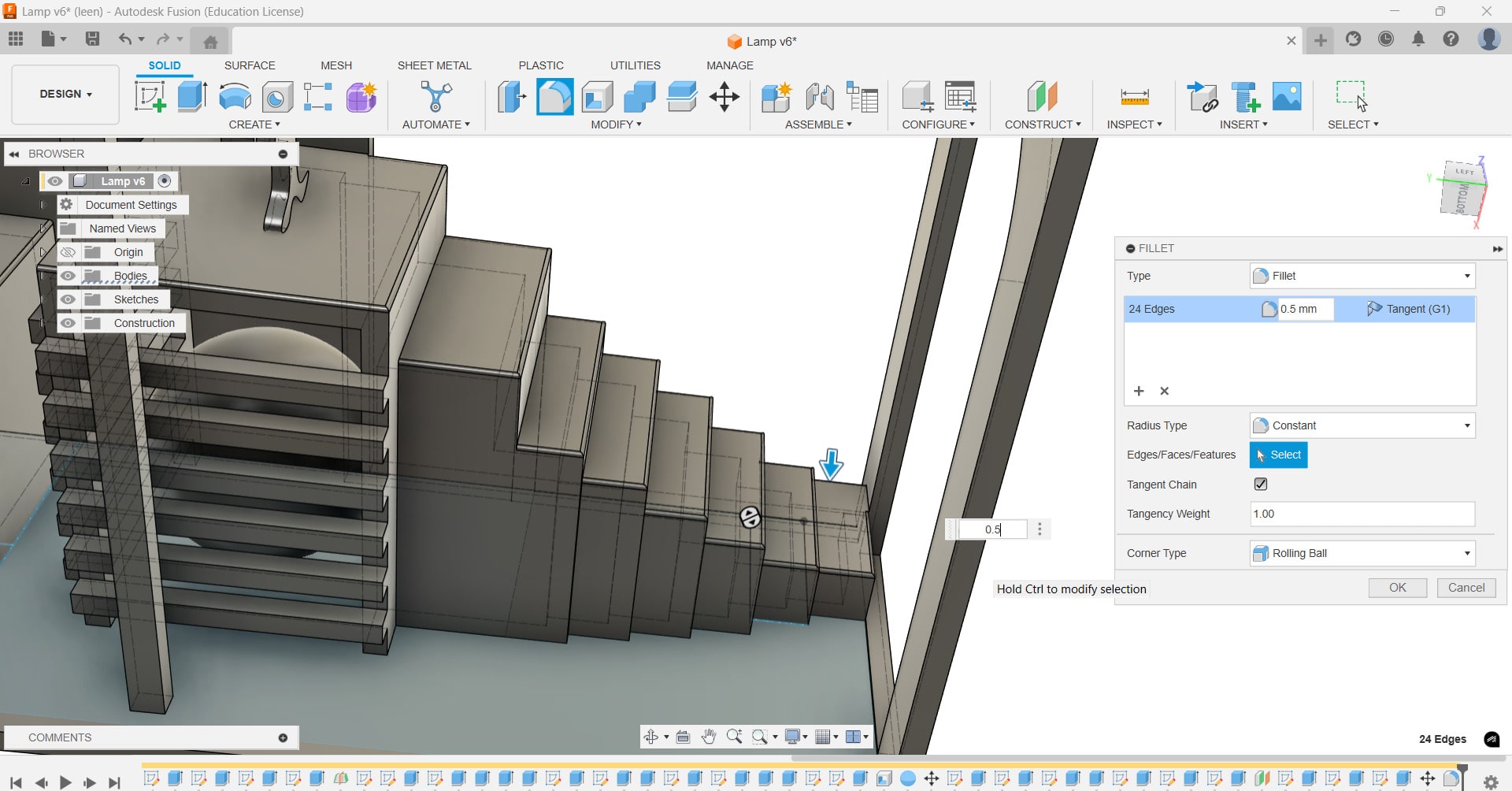

For visual effects, I added Fillet to the arch and Chamfer

onto the

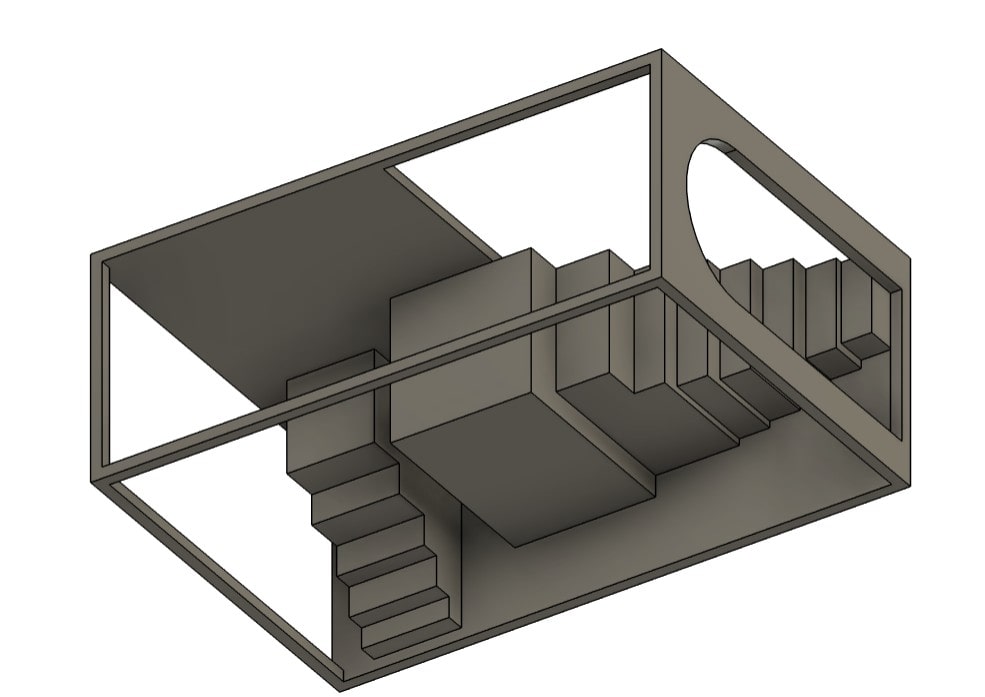

stairs to smoothen them out. The overall piece was 150 mm long, 100 mm wide, and 60 mm high.

Final Lamp Design

Note: For basic functions I attempted, you can check

Week 2 - Computer-Aided Design.

3D printing my Lamp

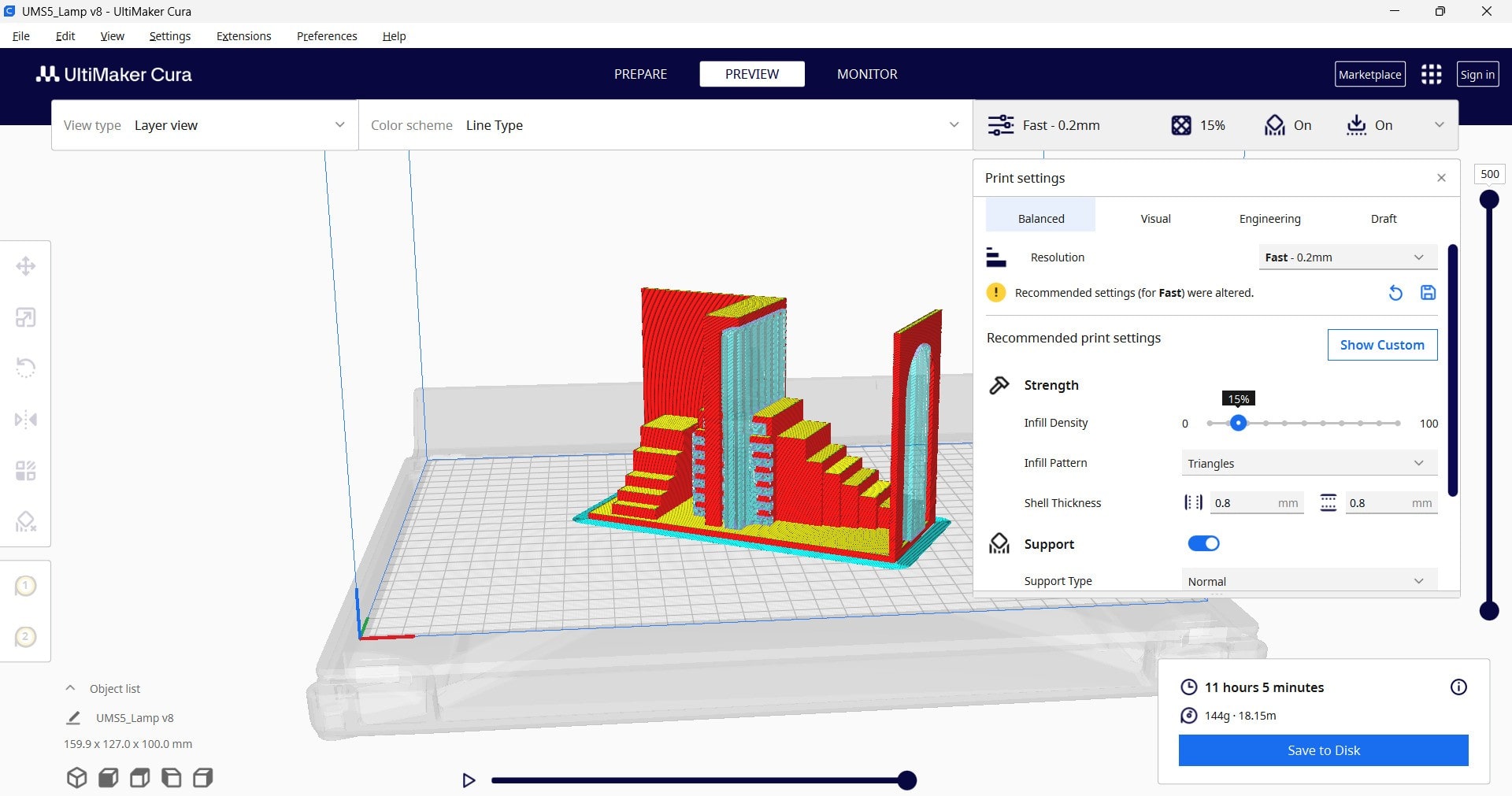

After exporting my design as .STL file, I installed

Ultimaker Cura

5.8.1

and I opened my saved file.

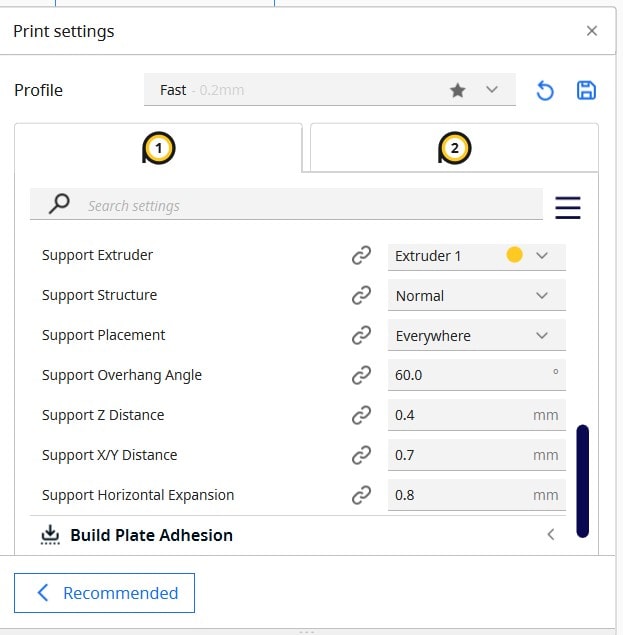

To set the setting, I selected material to Generic PLA 0.4 AA, the infill density to 15%. and

infill type

to triangle. In order to make sure my object does not have any overhang or sagging, I ticked the

option

for "support". For the support structure, I selected Normal and the placement

to

everywhere and the support z distance to 0.4mm.

These settings were expected to require a lot of post processing, but I did not want to change

my

design so I had to take responsibility for my decision.

After slicing, it stated that the print will need 11 h 5 min.

Then I fed the file into the printer, specifically Ultimaker S5. I just had to start it by pressing "start print".

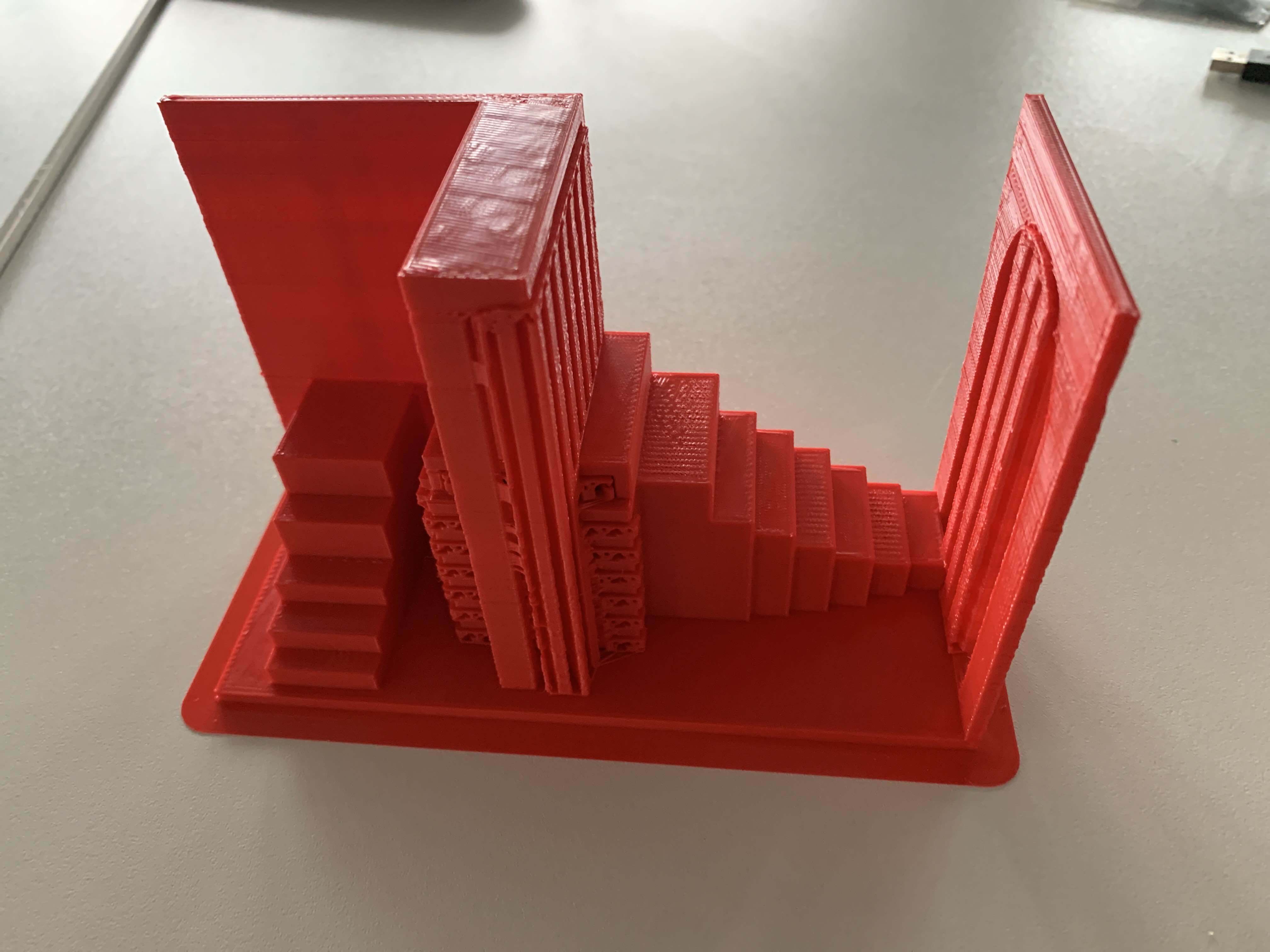

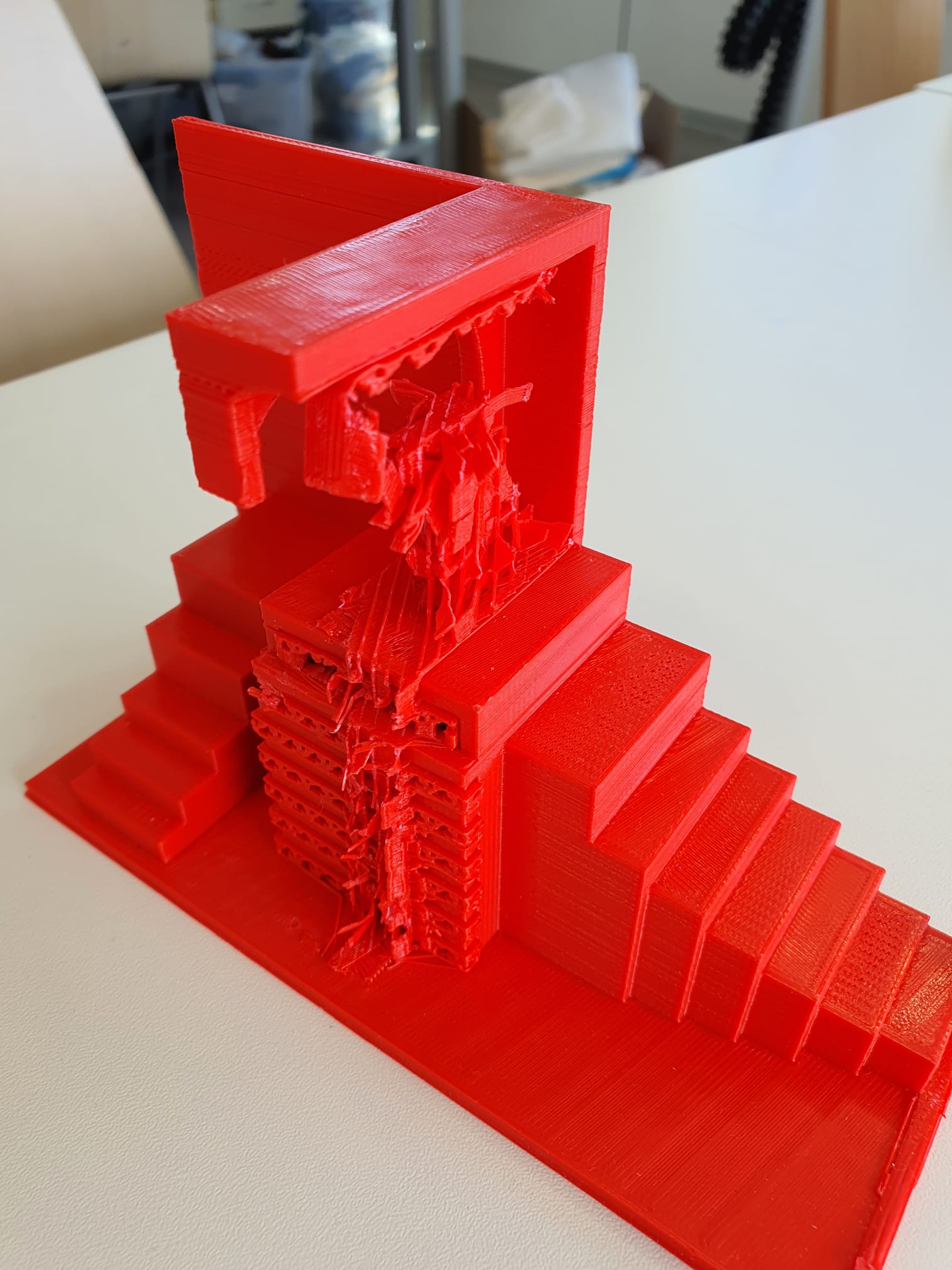

Print before removing Support Material

Reflection: Removing Support Material Failure

With the normal type support, the material could not be removed at all without breaking pieces

apart. Due to the print settings, namely the support gap (distance between the object and the

support material)

and the density of the support material added, it was almost impossible to remove the support

material without

damaging the object itself.

Since it was my first complicated design experience, I wanted to test printing with support

material with the

ultimaker. Although my local instructor Ahmed mentioned to me that with the ultimaker, removing

the normal

support material is very tricky and difficult, I wanted to test it myself and learn from my own

mistakes.

Moreover, due to the lengthy print time of the full sized design with the support material, I

had to deal with

the time pressure and improvise a simple alternative to fulfill the requirements of my

assignment.

Therefore, I decided to scale down my design and try with a different 3D printer and a different

support

type.

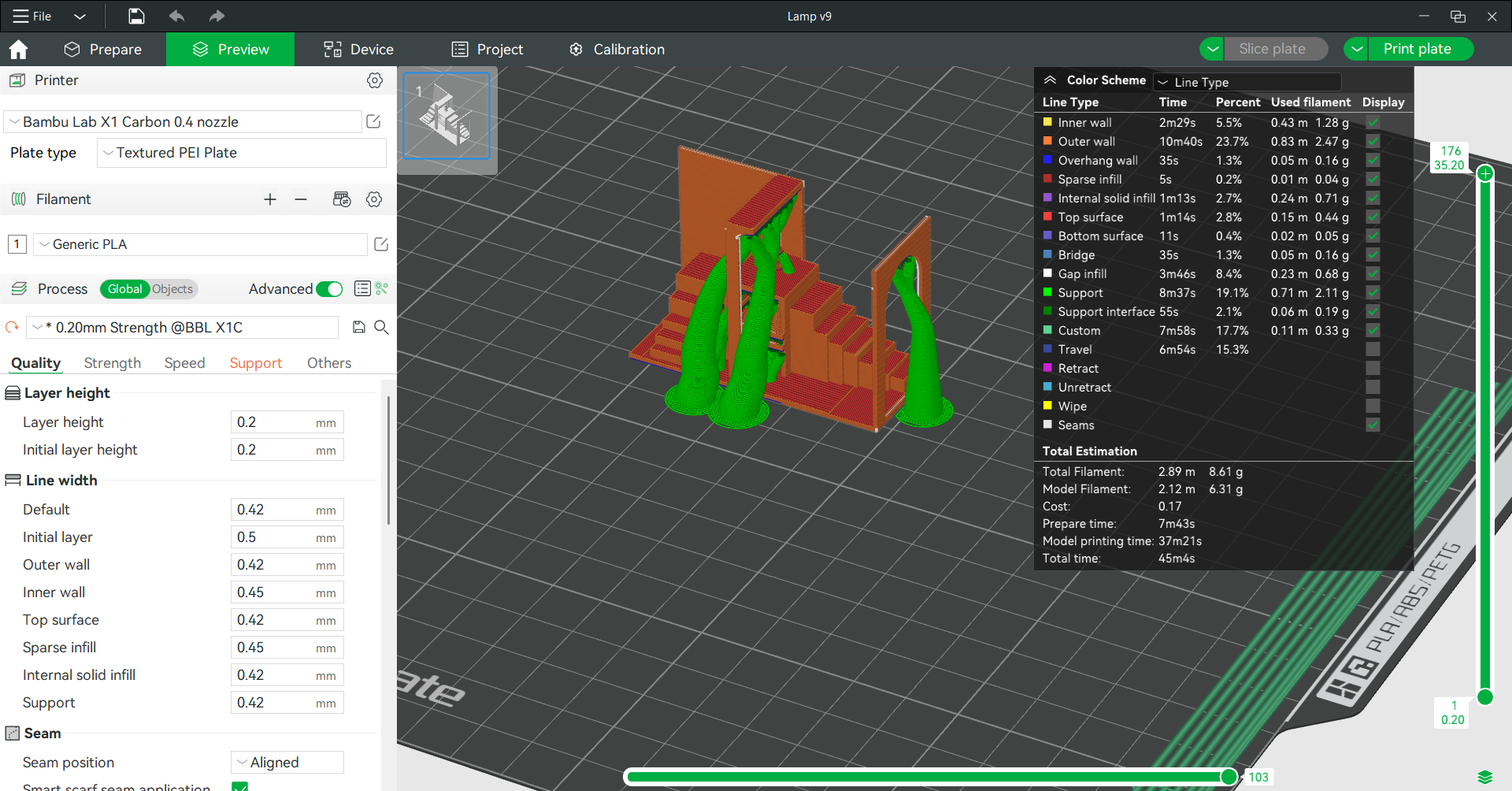

Second Lamp Print Attempt Process

I decided to give it a shot with the organic support type

using the Bambulab that

Lysander characterized.

Furthermore, I reduced the scale down to 35%, so it is

significantly less time and material costly.

After slicing, it took roughly 45 min to print!

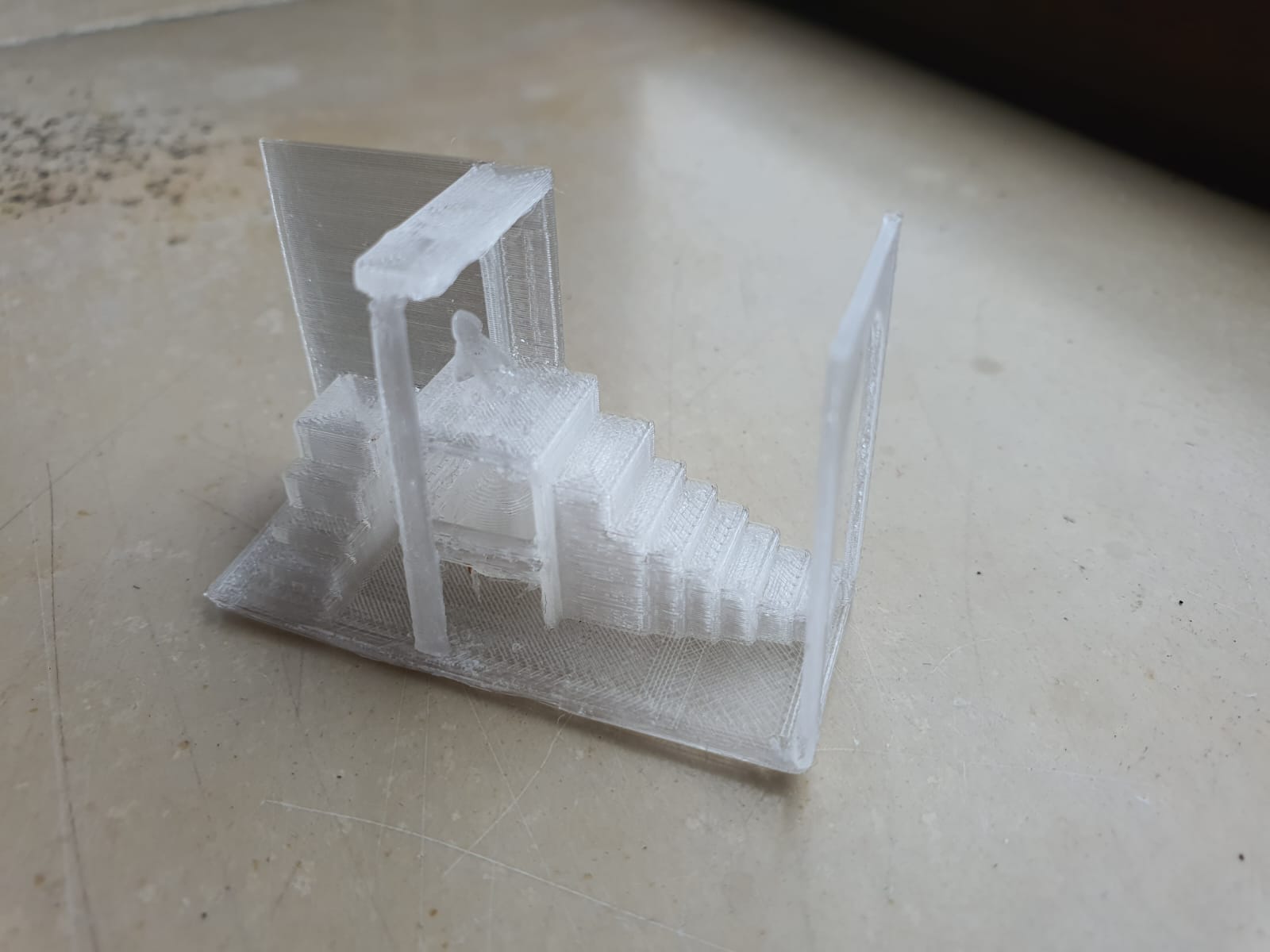

Second Lamp Print Attempt Result

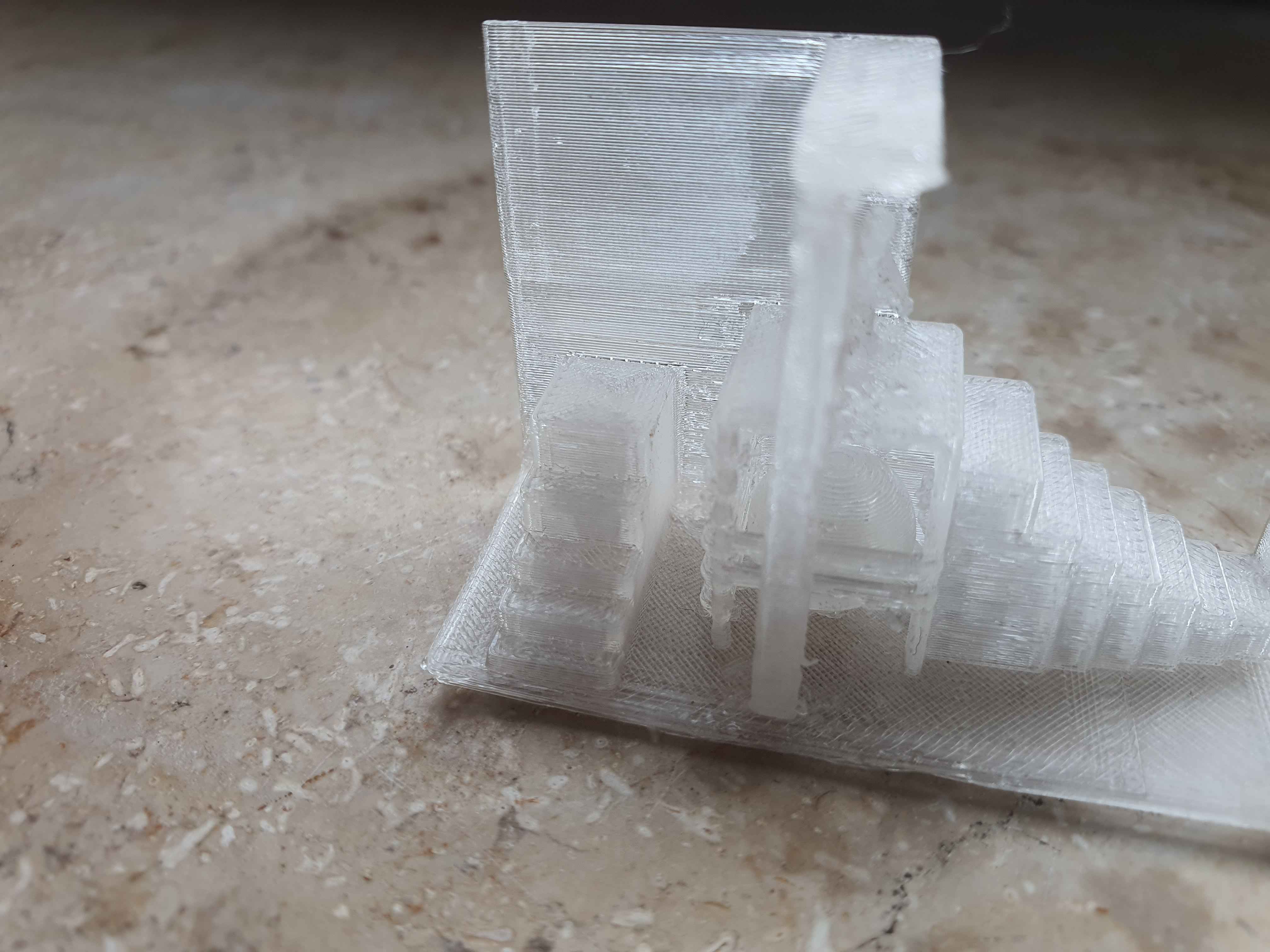

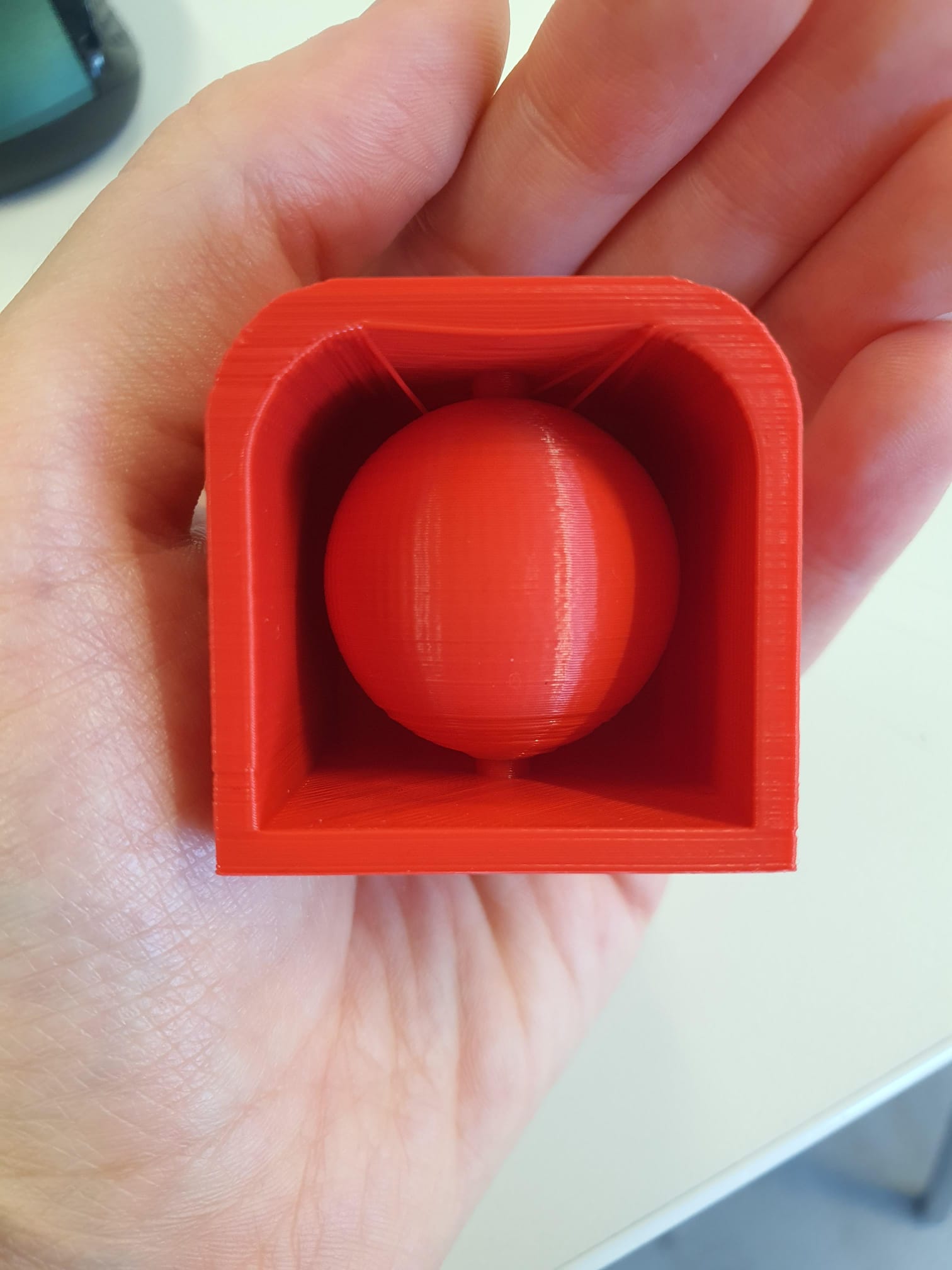

Third Experiment: 3D printing the Lamp's Inner Box with the Sphere

Since printing my lamp was not a very successful practice using the ultimaker normal support

setting, I designed the box with the sphere inside and I added a pipe going

through the center of the sphere by sketching a circle at the bottom surface of the cube and

extruding it from top to bottom of the cube, and set the operation to join, so

the support is technically not needed.

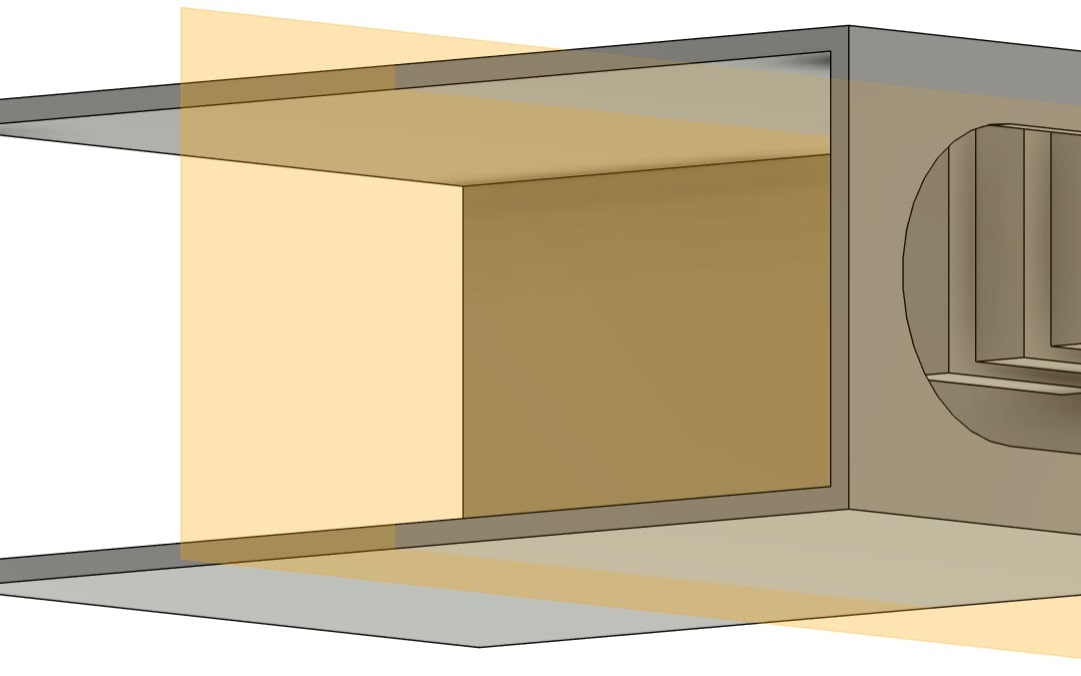

Why Subtractive Manufacturing Won't Work?

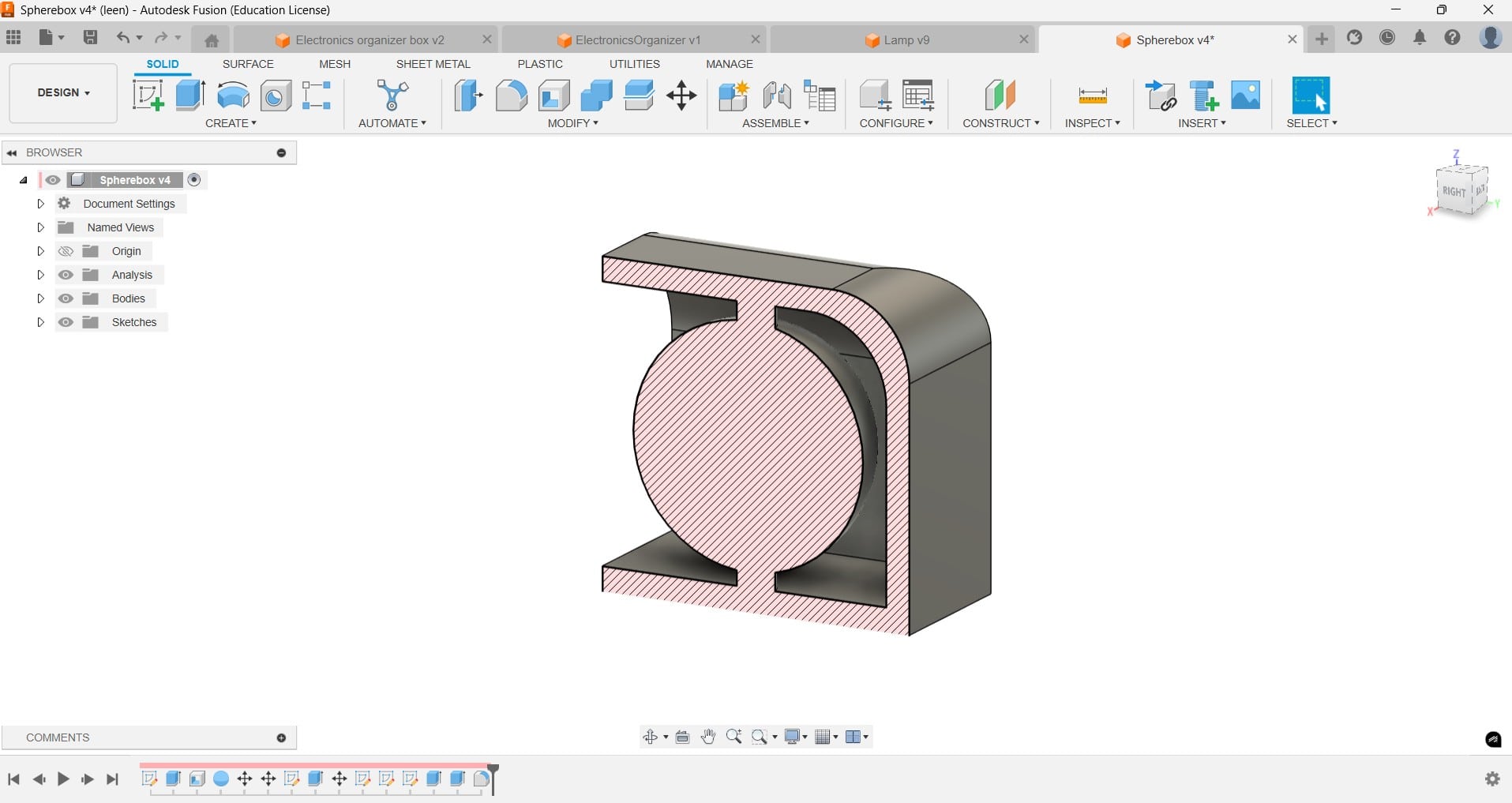

Looking at the cross-section analysis, the geometry of the sphere inside the housing makes it

hard for any CNC machine that is not multi-axis to manufacture!

The machine needs to access the area inside the housing and remove the extra material between

the ball and the inner wall of the curve. Unlike additive manufacturing, which allows forming

cavities or partially enclosed geometries without complicated toolpaths.

See Week 7 - Computer-controlled Machining

(Subtractive Manufacturing) for further input on CNC Machining.

Why Support Material was not Needed?

The print turned out very well! You can see because of the borderline bridging with the pipe

going through the ball and the short distance (~2.7 mm) between the ball and the inner roof of

the cube, no support material was needed!

Moreover, the overhang of the ball (angle <= 30°) relative to the horizontal line helped prevent

a spaghetti-like structure from hanging underneath.

Reflection

Subtractive manufacturing principle is based on removing material from a solid block,

which limits it to objects that the cutting tools can easily reach.

In my lamp design, there are many intricate details—like the curved arches, and internal

cavity with the sphere inside—which makes it challenging for CNC machine to make it

accurately.

In the case of 3D printing (additive manufacturing), the piece is built layer by layer,

which allows creating delicate figures, without the constraints of tool access or the

large amounts of material waste like in subtractive methods.

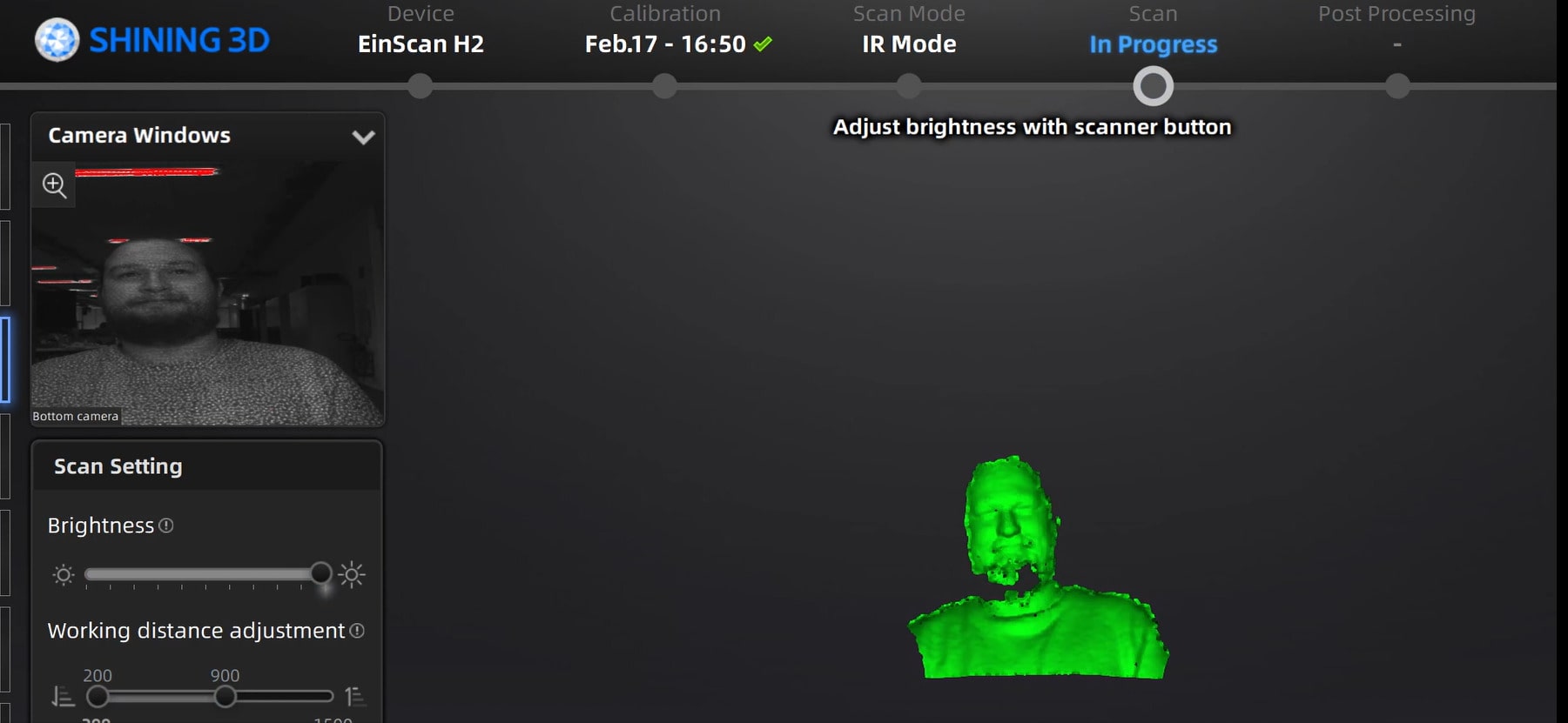

3D Scanning

For this task, I decided to 3D scan my teammate

Mika's Week 5 and vice versa, so we helped each other!

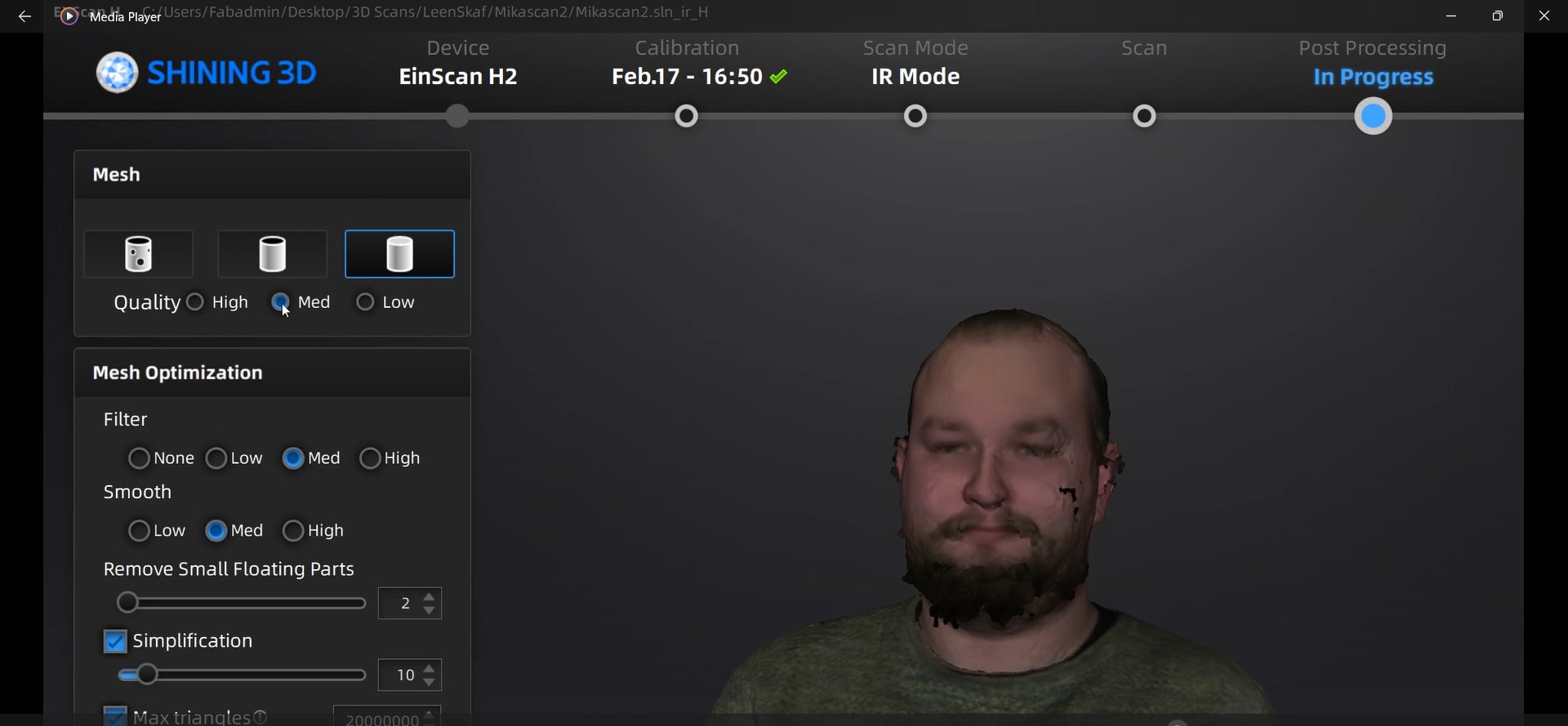

For calibrating and setting scanning parameters, I used

Shining 3D.

After we calibrated

EinScan H2, which is a scanner primarily used to scan human

bodies,

I started setting the parameters for the scanning progress.

I selected the scan mode to be "IR Mode". Then, I created a new project folder and named

it

"MikaScan". Scan Target was set to "Portrait", the alignment to be "hybrid", resolution

to be

"medium".

Afterwards, I started slowly with the machine scanning all angles

trying to get as clean of a scan as possible. Finally, I pressed done and manipulated

the scan in the software. I removed random points. After being satisfied with the

result, I carried on with "optimizing and generating point clouds". This is done by

the software to try and patch missing points from the scan.

Then, for meshing I set the mesh quality, filter, and smooth to "medium".

Lastly, I saved the files in all types (.stl, .obj, .ply, .mdf), and

I scaled down the size to 30%. These files could be used for further processing

in case Mika wants to 3D print a miniature version of himself :D.

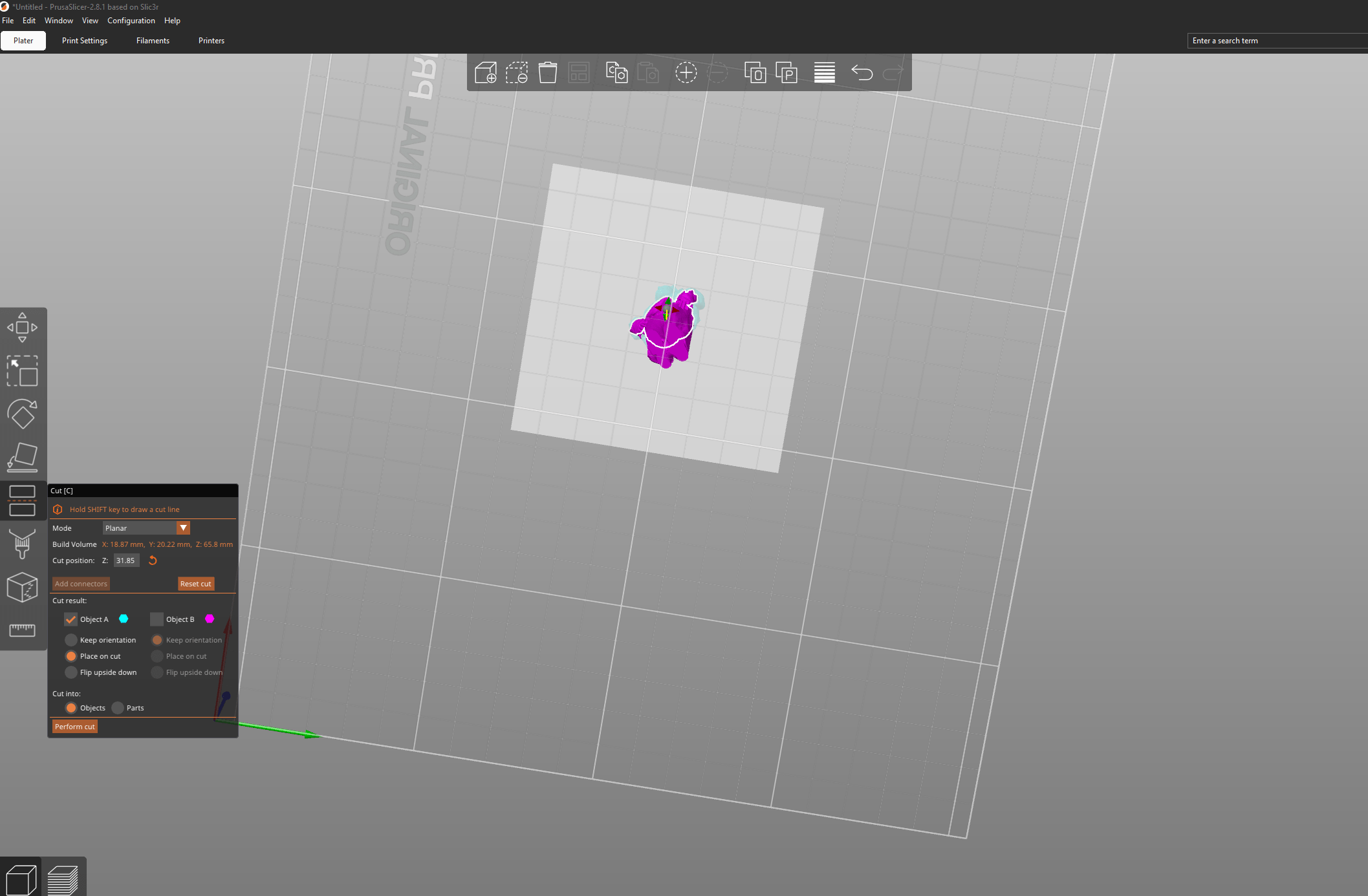

3D printing my Miniature Scan

After Mika scanned me and the mesh turned out to be very good, I was curious to 3D print

the result!

For processing, I used PrusaSlicer

and MeshMixer.

For the print to be stable, I designed a small square base using Fusion360 and exported

it as .stl file. Then, on Prusa, I opened my scan and tried to manipulate it, making

sure

that the bottom surface of the feet is flat and leveled.

For this, I rotated the perspective 180°, used the function "place on face",

selected the bottom surface, then performed function "cut". The print was scaled down to

20%,

ending up with the dimensions of 67 × 21 × 17 mm.

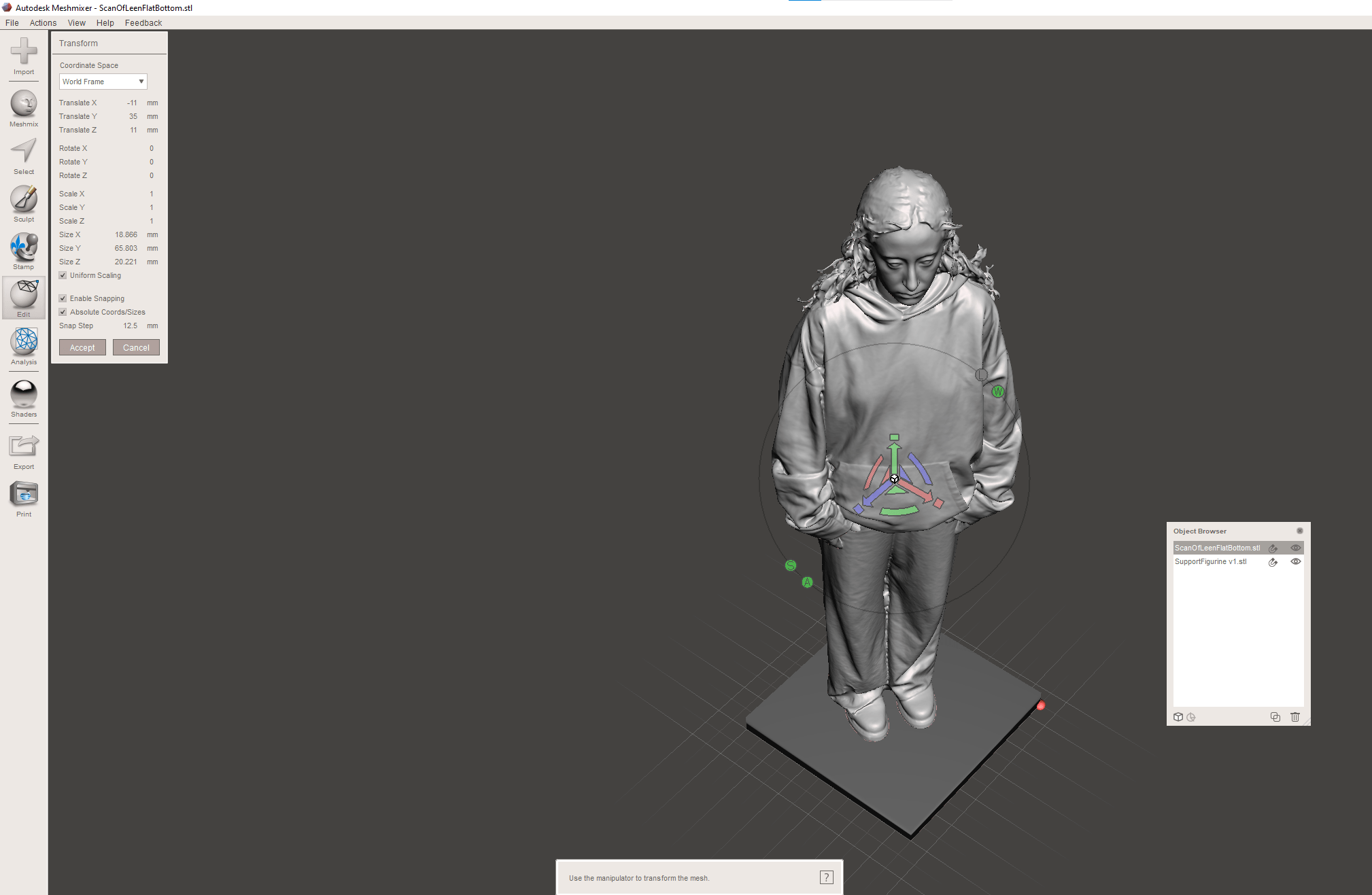

Then, I saved the new version of the scan and reopened it in MeshMixer

to combine the base and the figurine into one .stl file.

First, I dragged and dropped both files. Then I went to Edit >

Transform in order to select the right coordinates for the figurine

to be placed right on top of the base.

After placement was checked from every angle, both the base and the figurine

were combined using the combine function.

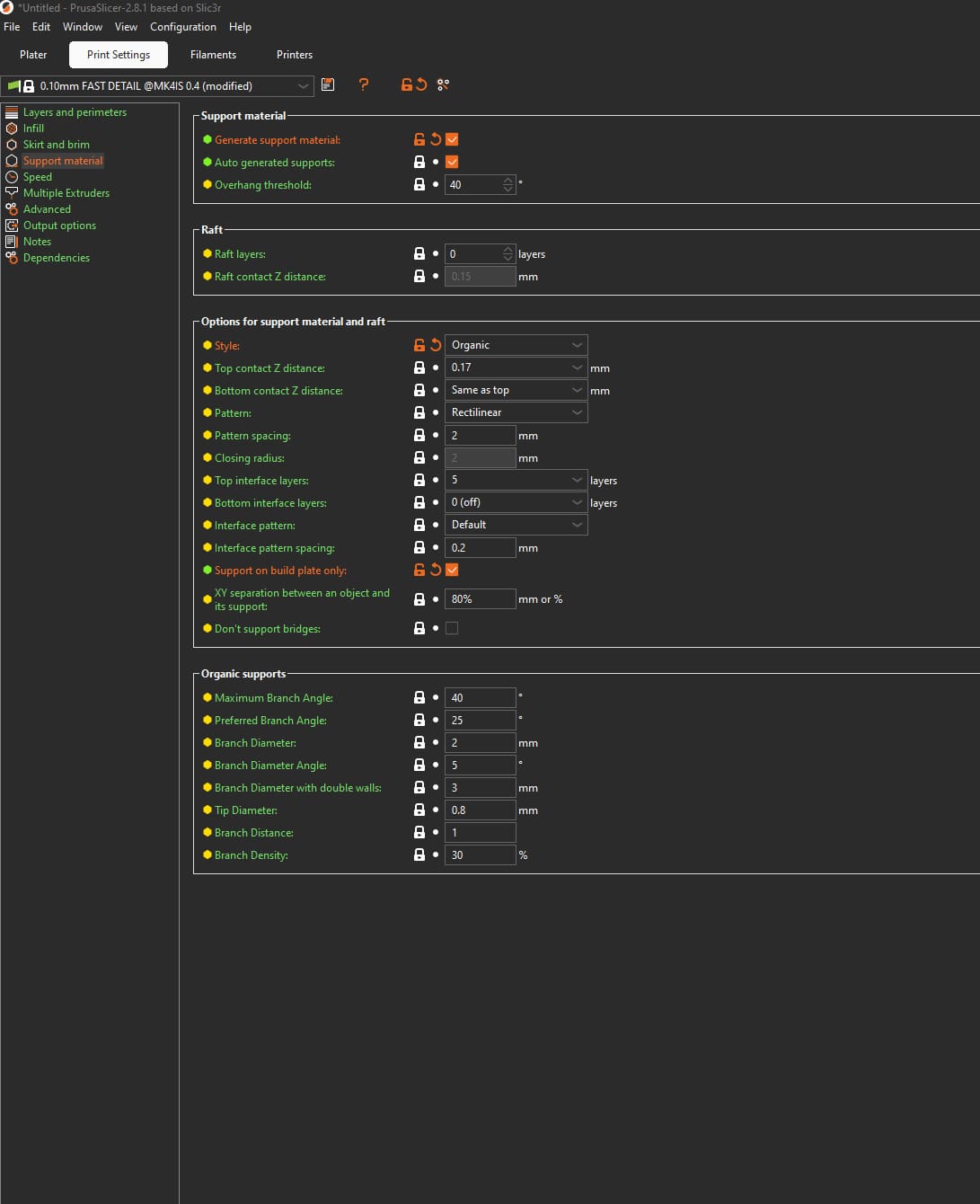

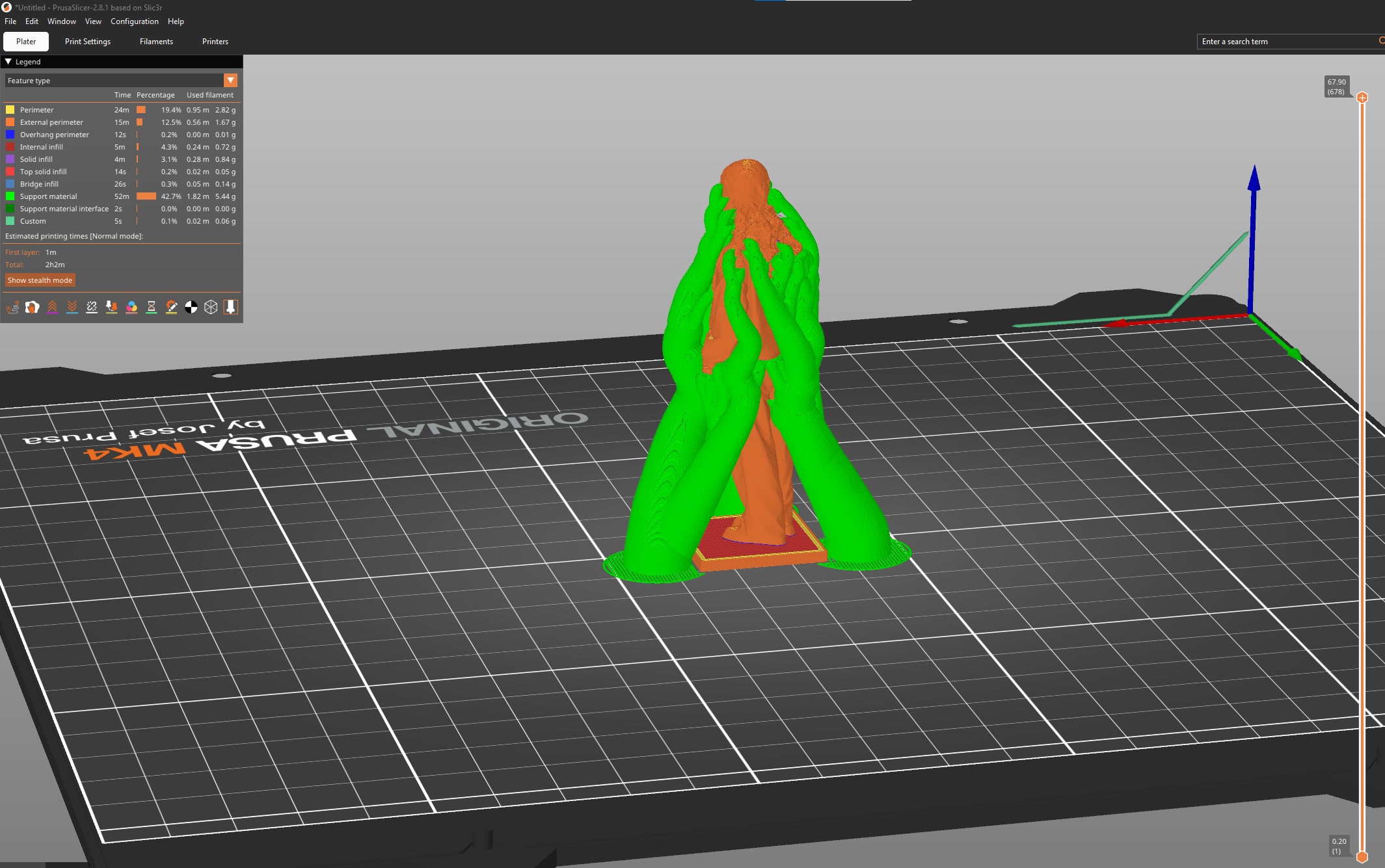

Finally, to set the printing setting, I went back to PrusaSlicer. First, I switched

from "Beginner" mode to "Expert" mode to be able to manipulate more settings.

Since I learned from my struggle with the normal support, I knew more confidentyl how to

approach the printing settings for my miniture!

Therefore, I went to "print setting" and ticked on

generate support material, set the style to organic,

and ticked on Support on build plate only.

Finally, the print was ready for slicing. Printing time was 2 h 2 min.

Figurine Attaching .STL File Problem

While trying to upload the original mesh with 100% resolution, I hit the soft limit

for the GitLab repo storage (941 MB).

I reset my repository by cloning the old version from my repo locally, then adding

slowly from the fresher local version folder, pushing and committing step by step.

Now, only the STL file for the figurine was left.

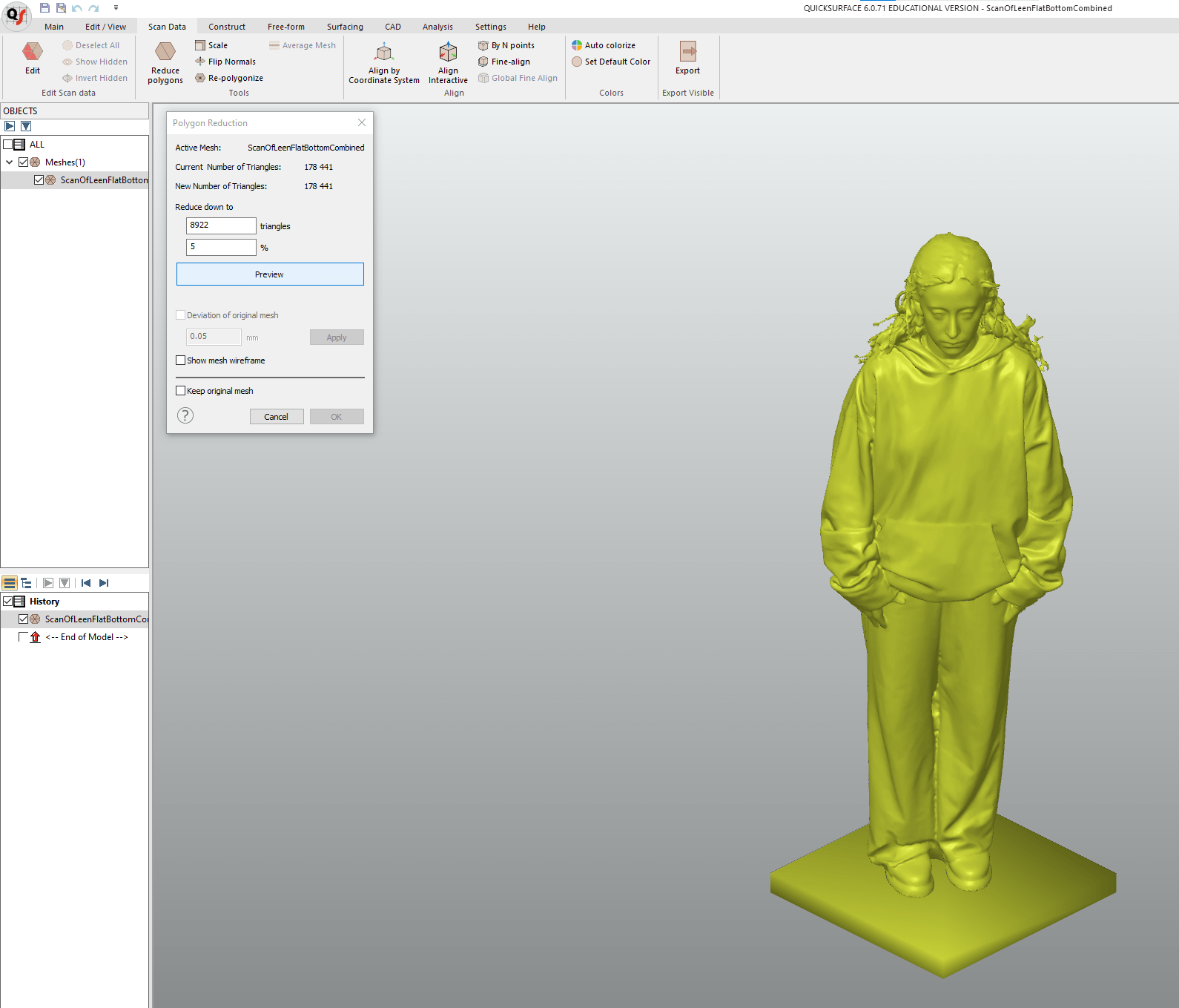

Therefore, I had to use QuickSurface to

reduce the mesh down to 5% (8.5 MB). The only downside is that it’s not open-source,

but we have it in the lab PCs so why not use it to serve the purpose!

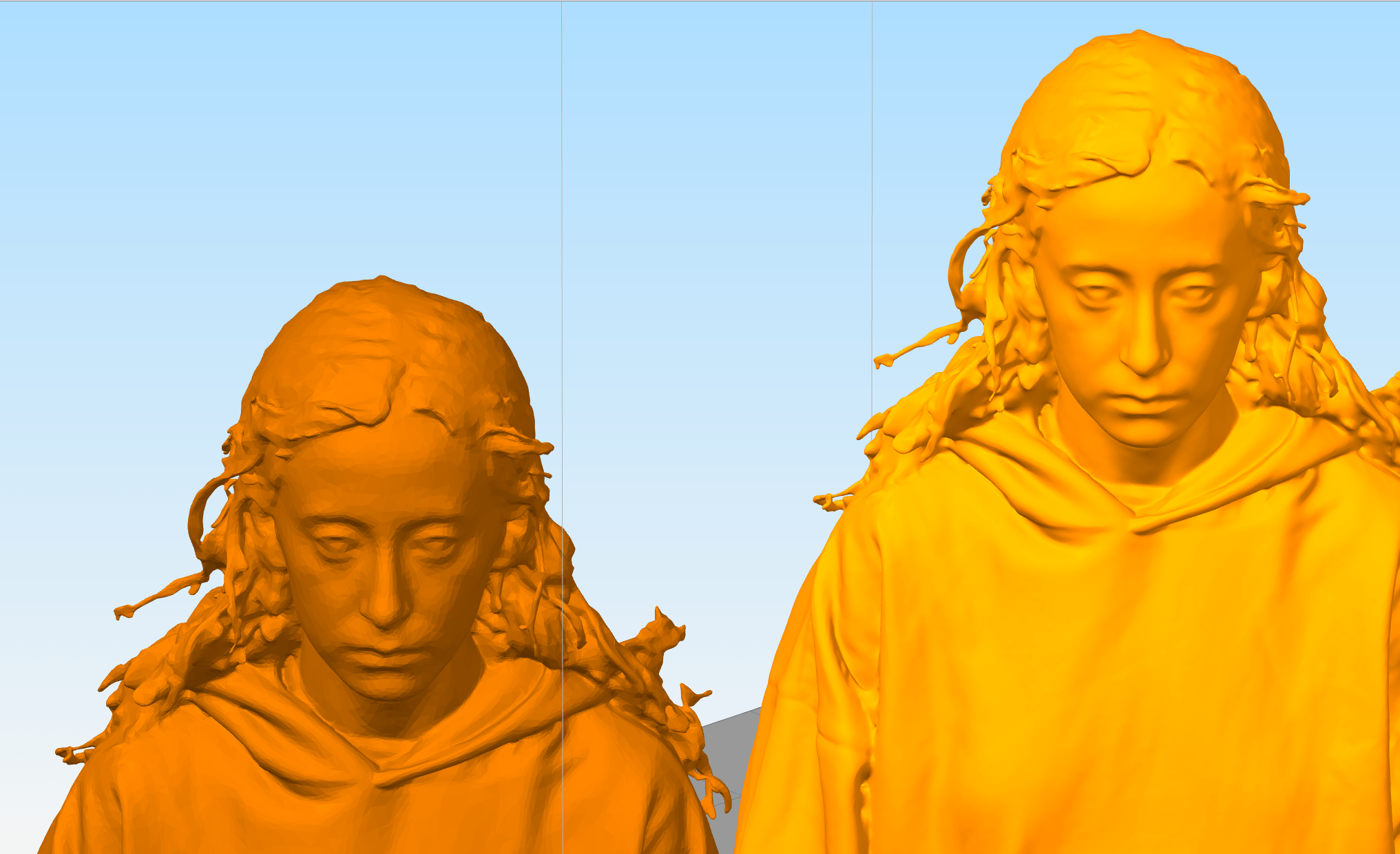

For comparison between the old and new mesh, I opened both STLs in

Slic3r. If we zoom in,

we see the triangles being more rough in the reduced version.

However, for 3D printing, the difference will not be visible.

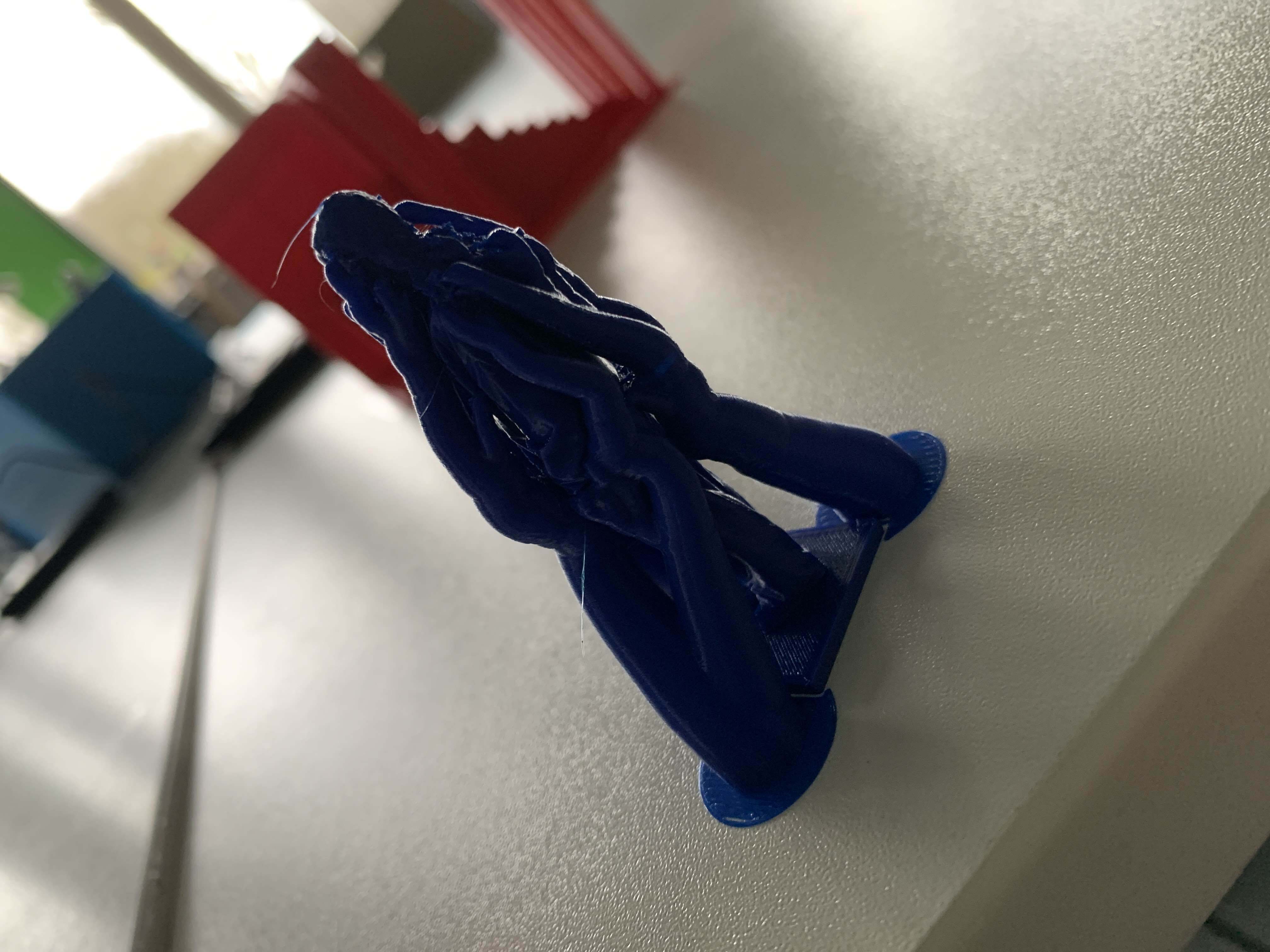

Leen Miniature before removing Support Material

Leen Miniature Figurine after removing Support Material

All I can say is that it took a long time and maneuvering with pliers to remove

all the support material. I will try next time to have a design that requires less

support!

Reflection: Advantages and Limitations of 3D Printing

Advantages: 3D printing offers design flexibility, which enables

printing of intricate geometries and complex structures that traditional subtractive

methods

cannot easily achieve. Additionally, it minimizes material waste by forming objects

layer

by layer and supports rapid prototyping.

Limitations: On the downside, 3D printing is often a slow process compared to other techniques such as laser cutting, and the printed objects often require post-processing. Additionally, the selection of filament depends on the mechanical properties of the printed objects that serve the function you desire!

Limitations: On the downside, 3D printing is often a slow process compared to other techniques such as laser cutting, and the printed objects often require post-processing. Additionally, the selection of filament depends on the mechanical properties of the printed objects that serve the function you desire!

Reference: Xometry. (n.d.). Subtractive vs. additive manufacturing.

From Link

Files

Figurine.3mf

Figurine.stl

SupportFigurine.f3d

Spherebox.f3d