Group assignment: do your lab's safety training and characterize your lasercutter's focus, power, speed, rate, kerf, joint clearance and types

Vinyl Cutter

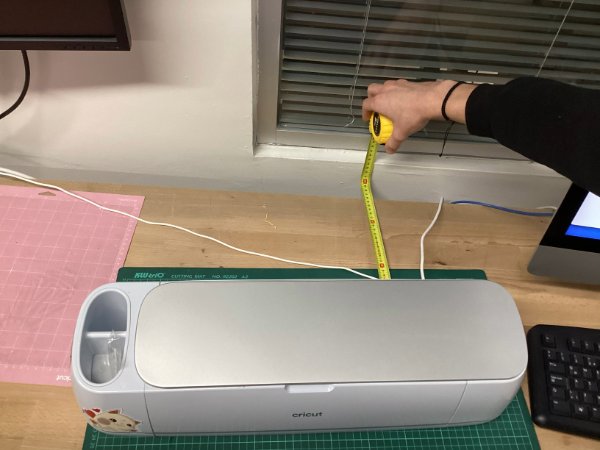

My Setup

Equipment Used:

- Cricut Maker 3 (connected via USB for stability)

- iMac running Cricut Design Space

- A2-sized cutting mats (green and pink grip)

- Measuring tape for alignment

- Weeding tool for detail work

Materials Used:

- Smart Vinyl (Removable) for flexible application

- Various colors of vinyl for different designs

Step-by-Step Process

1. Setting Up the Workspace

Connected the machine to my computer using a USB connection.

2. Measuring and Preparing the Machine

Measured available workspace and checked the blade installation.

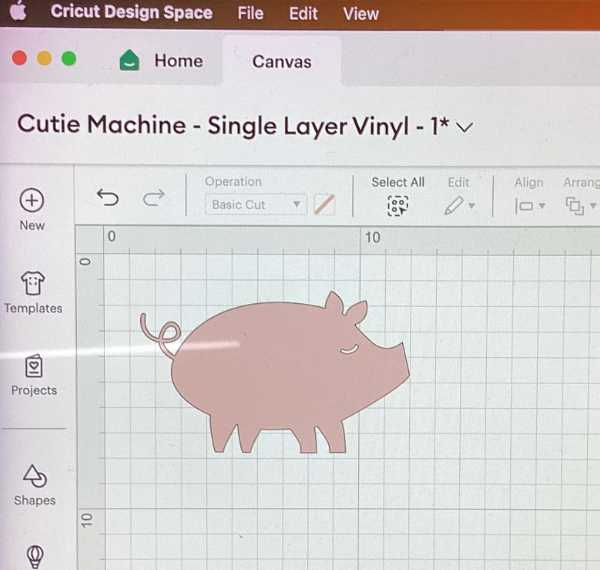

3. Creating and Preparing the Design

Designed and adjusted dimensions for Hisar FabLab Logo and other shapes.

4. Loading the Vinyl Material

Aligned vinyl properly and loaded it into the machine.

5. Executing the Cut

Started the cutting process and monitored progress.

6. Weeding and Challenges

Used the weeding tool and encountered peeling issues with Hisar FabLab Logo.

7. Failed Attempt - Peeling Issue

Failed to peel Hisar FabLab Logo due to cutting depth issues.

8. Successful Vinyl Application

Successfully applied a Ghost Sticker and Pig Sticker.

Laser Cutter

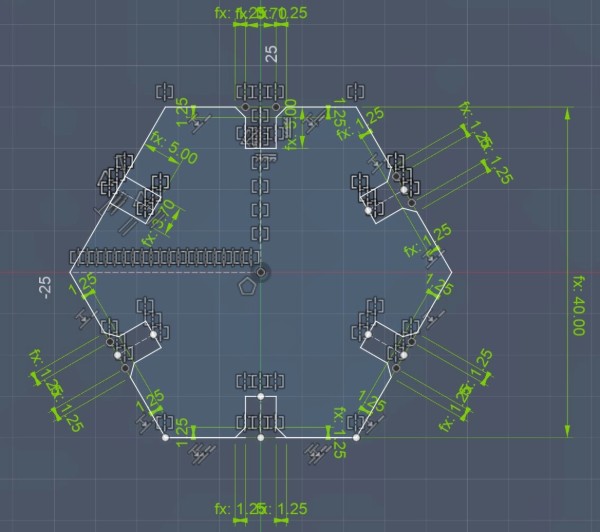

The Design of the Puzzle Piece on Fusion360

I wanted to have a simple puzzle piece that uses chamfered joints. The key element of the design is going to be the modularity of it. You can built interesting shapes using these pieces.

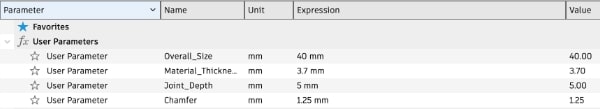

Kerf & Joint Clearances

When laser cutting, the laser burns away a small amount of material—this is called the kerf. If you design a slot to be the exact same width as your material, the final cut will be wider than expected.

In your case, you were cutting 4mm thick material, but instead of making the slot exactly 4mm wide, you set it to 3.7mm. This is because the laser removes about 0.15mm on each side, meaning the final cut would actually be around 4mm wide—giving you a snug fit.

If you had left the slot at 4mm, the laser would have cut away extra material, making it about 4.3mm wide, which would be too loose. On the other hand, if the slot was too small, forcing the parts together could break them.