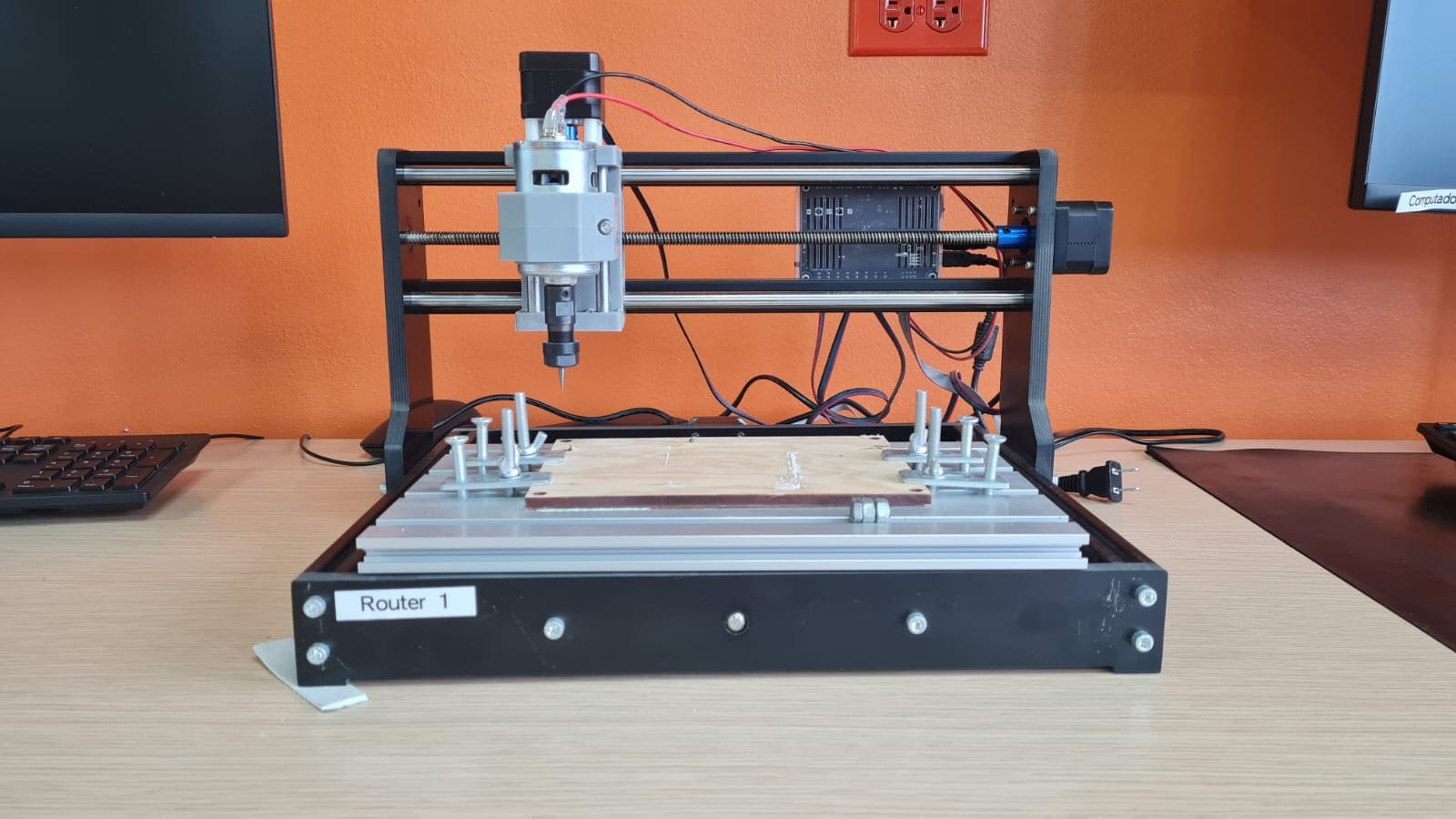

New week, new assignments, I'm starting week #8 of Fablab Academy and this week is about Electronics production. In week 04. we had the opportunity to work with a PCB board and we had to solder some components. Now we have to design our own PCB board and it would be best to do it considering the final project. So for this weeks assignments were using the CNC router. So let´s begin with this week assignments and hope for the best.

This week assignmets are:

Group assignments:

Individual assignments:

| Machines/Equipment | Software | Components |

|---|---|---|

|

|

|

CNC router

Is a subtractive manufacturing process that uses a rotary tool to remove material from wood, expanded polyurethane foam, plastic, and soft metals. A CNC router typically has a gantry-style construction where the spindle travels left and right along the x-axis and back and forth on the y-axis. It is not designed for high-speed cutting of complex geometries in hard metals. Are generally less stiff than standard CNC mills and when harder metals are being cut. It must also be noted that routers have limited travel along the z-axis, they cannot create deep holes and slots.

It works by moving a tool to specific x, y and z coordinates throughout the machine's available working area. A router or high-speed spindle with a cutting tool then removes material at the desired locations. Different cutting tools can be used depending on the material and the feature being machined. These tools can be manually or of a more advanced machine, an automatic Tool Changer can swap out tools.

Data from: CNC router

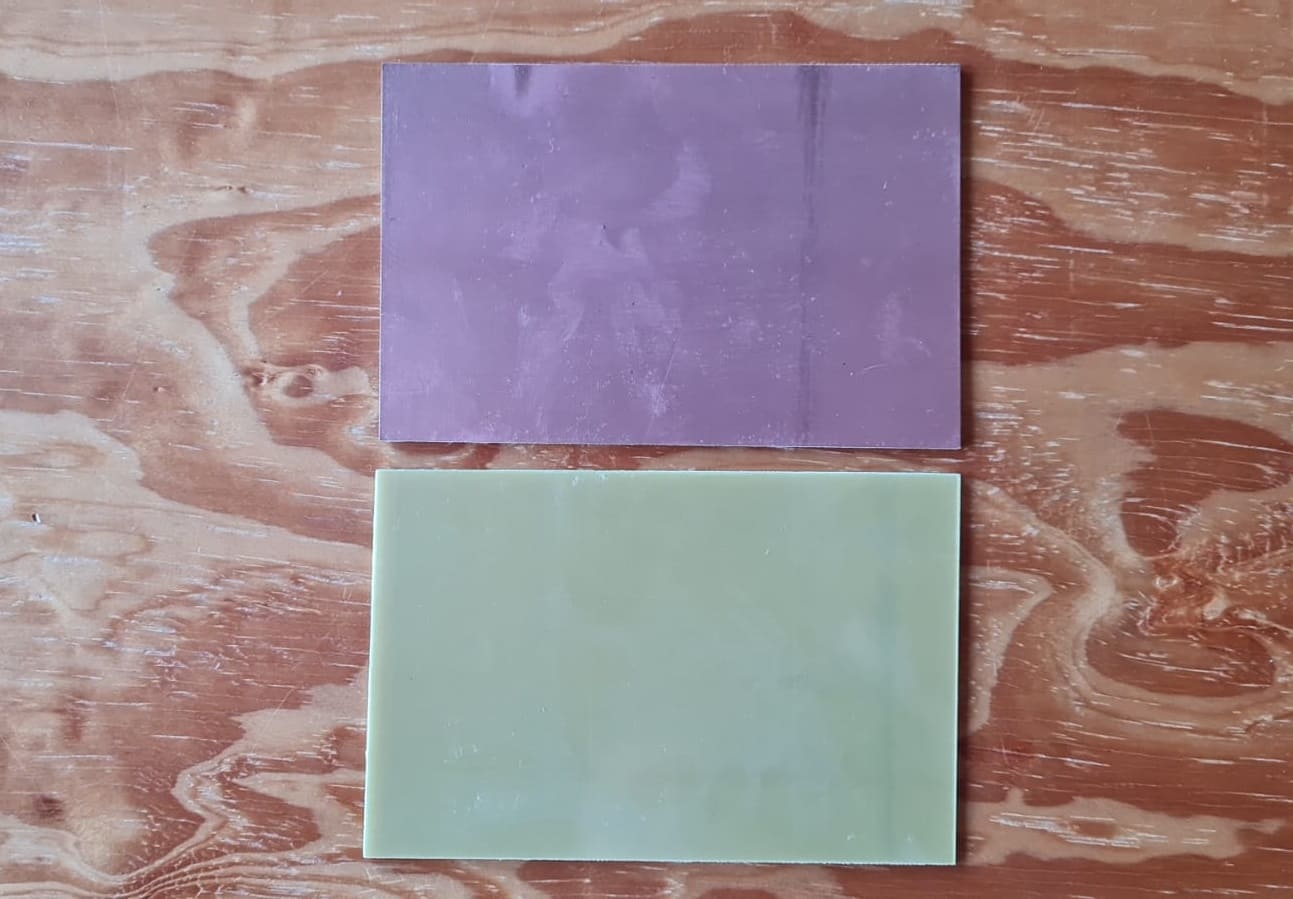

Board

A standard printed circuit board (PCB) relies on a base layer typically made of fiberglass. While this material operates well in normal conditions, it often sustains damage in high-power applications. Metal core circuit boards, such as copper core PCBs, offer the durability and conductivity you need for high-temperature uses.

Copper core circuit boards are a type of metal core PCB. With their layered design using a copper base, these PCBs offer superior thermal conductivity.

Data from: PCB boards

Soldering station

Is an electrical device used for soldering tasks. It comprises soldering tools connected to the control unit, desoldering tools, soldering tip cleaners, holders, stands, and other accessories. The control unit consists of temperature adjustment knobs, display areas and an electrical transformer.

Data from: Soldering station

Soldering tin

Is ideal for applications where there are delicate temperature requirements for soldering. When tin is added into the wire, it provides a lower melting temperature. A lower melting temperature for solder is required when the parts being joined can be negatively impacted at higher temperatures.

Is commonly used for electronics where heat sensitive components will begin to melt, crack, or warp at varying high temperatures. It also provides good electrical properties as well as mechanical strength. The solder ensures that electronic components are joined securely to contact points. Since the tin lead wire is lightweight, it won’t put any unnecessary stresses on components.

Always ensure that proper ventilation and personal protective equipment is used when using tin lead wire for soldering. Lead is considered hazardous. So, the tin lead wire materials that are not used should be disposed properly in approved containers.

Data from: Soldering tin

ShopBot CNC

Autodesk Fusion combines CAD, CAM, CAE, and PCB into a single, integrated cloud software platform. It includes all the tools that you need to go from design to manufacturing, seamlessly.

With Autodesk Fusion, you'll be able to:

Data from: Fusion 360

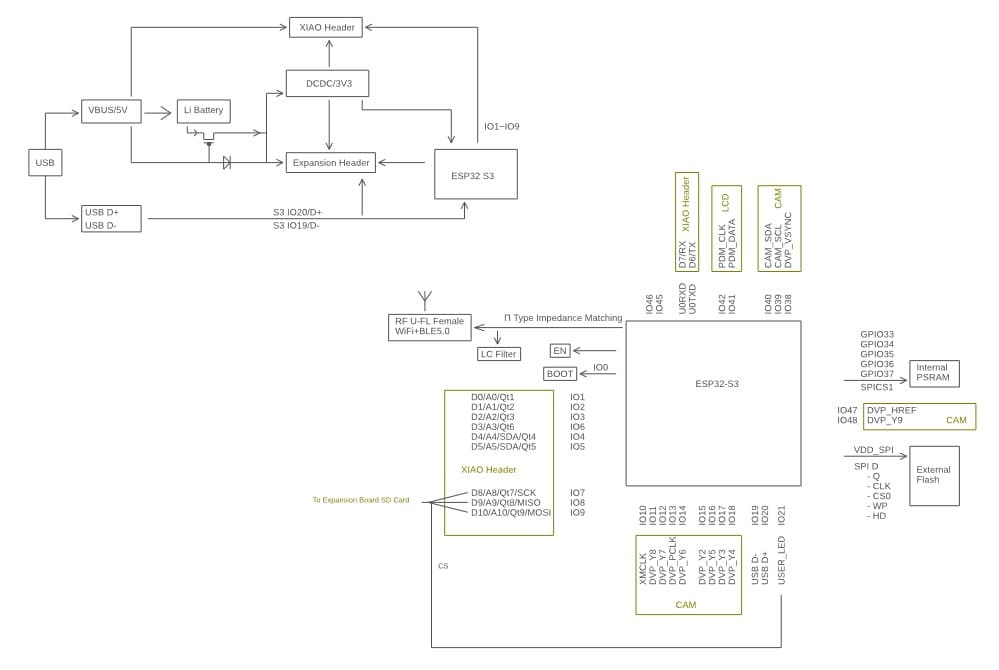

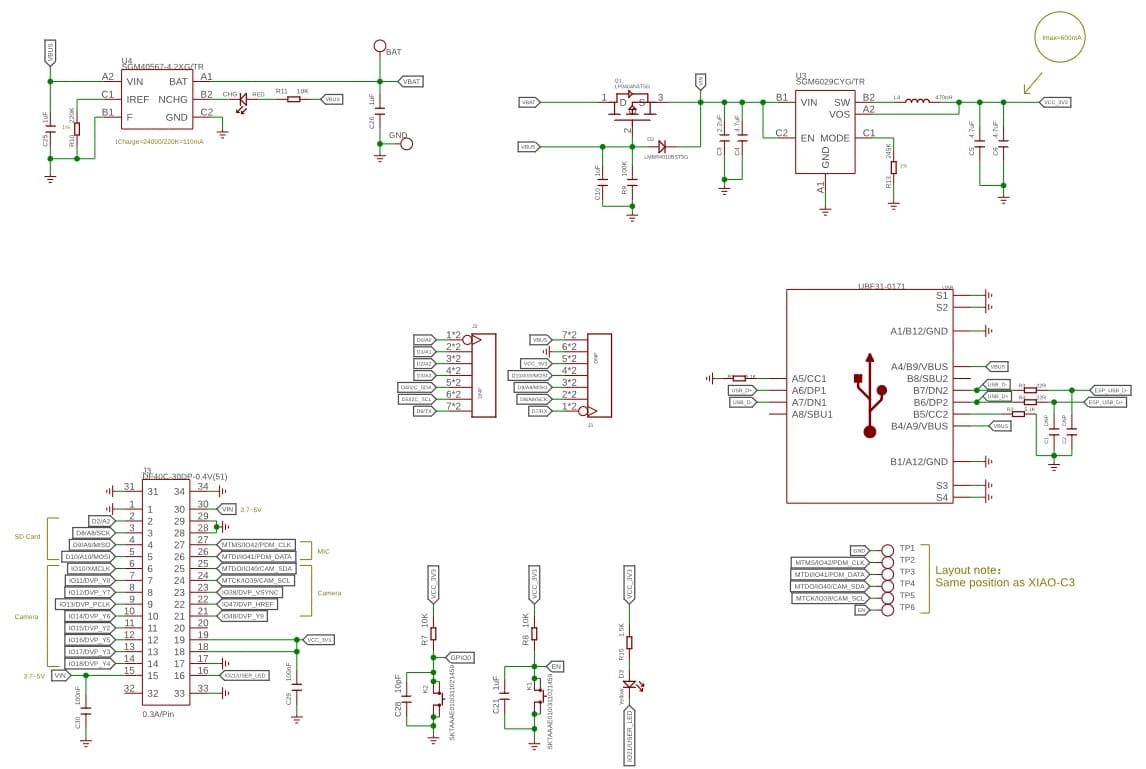

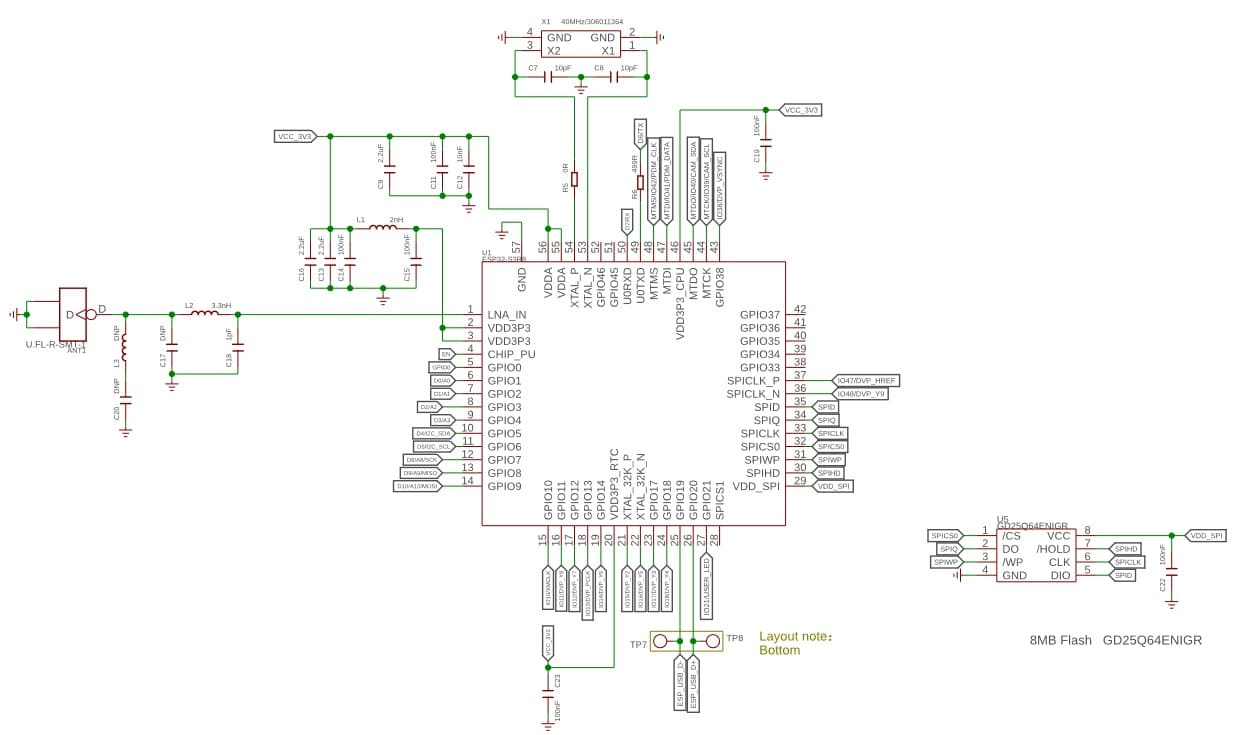

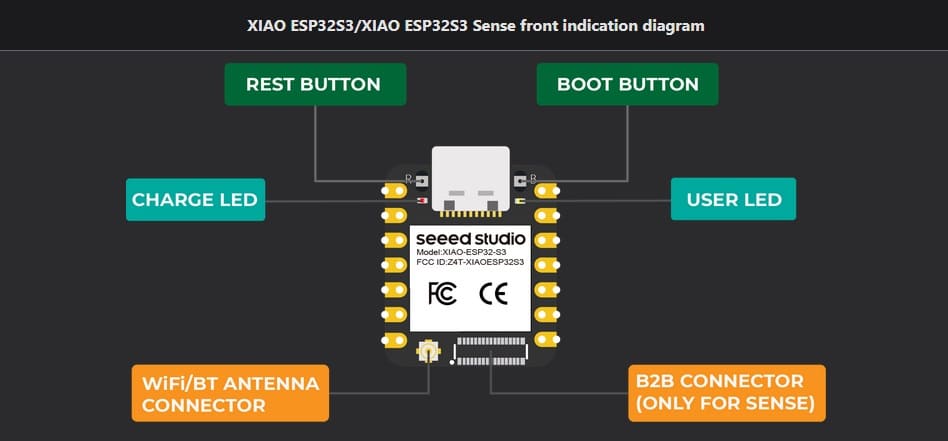

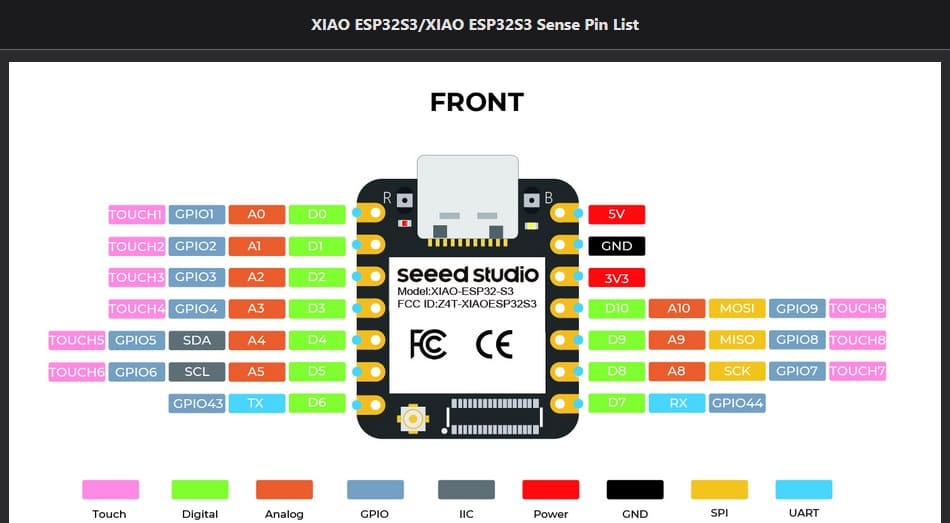

Is a diminutive development boards, sharing a similar hardware structure, where the size is literally thumb-sized. Integrates camera sensor, digital microphone and SD card supporting. Combining embedded ML computing power and photography capability, this development board can be your great tool to get started with intelligent voice and vision AI.

Data from: Xiao ESP32S3

RGB LED stands for Red Blue Green Light Emitting Diode, which refers to the three hues of light that are generated in these LED strip lights. The LED strips use a combination of different brightness levels in each of the three colours to generate a full spectrum of colour.

Data from: RGB Led

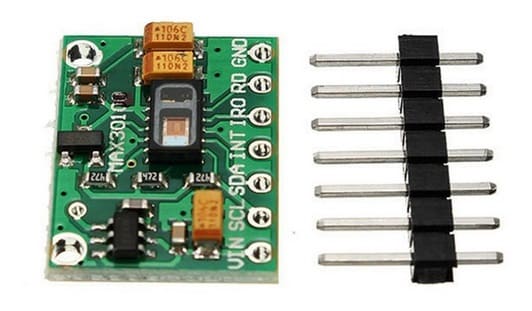

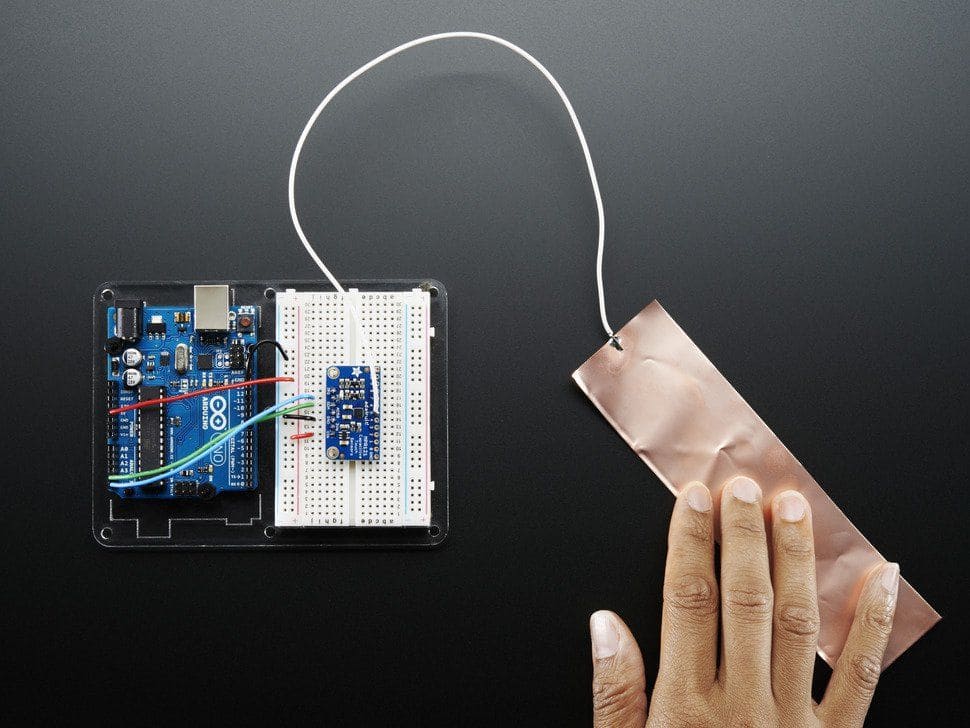

Is an integrated pulse oximetry and heart-rate monitor module. It includes internal LEDs, photodetectors, optical elements, and low-noise electronics with ambient light rejection. It provides a complete system solution to ease the design-in process for mobile and wearable devices.

Data from: Max30102

Is a non-contact sensor that detects the presence of an object (often referred to as the “target”) when the target enters the sensor’s field. Depending on the type of proximity sensor, sound, light, infrared radiation (IR), or electromagnetic fields may be utilized by the sensor to detect a target.

Data from: Proximity sensor

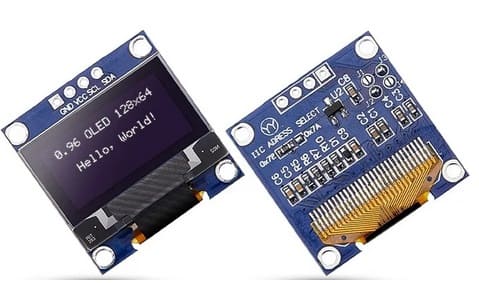

The SSD1306 display is an OLED that is controlled by the SSD1306 micro-chip driver, which acts as a bridge between the display matrix and the microcontroller. Despite the size, these displays are very functional and capable of displaying complex images.

Data from: LCD screen

HC-SR04 stands for High-Conductance Ultrasonic Sensor consists of a transmitter and receiver. The sensor measures how far things are without touching them and it uses sound waves to get the measurements right. It can work well when things are between two to four centimeters away. So, it’s good for things that are around two to four centimeters away.

Data from: Ultrasonic sensor

Is a basic, low-cost digital temperature and humidity sensor. It uses a capacitive humidity sensor and a thermistor to measure the surrounding air and spits out a digital signal on the data pin. It's fairly simple to use but requires careful timing to grab data. The only real downside of this sensor is you can only get new data from it once every 2 seconds.

Data from: DHT22 sensor

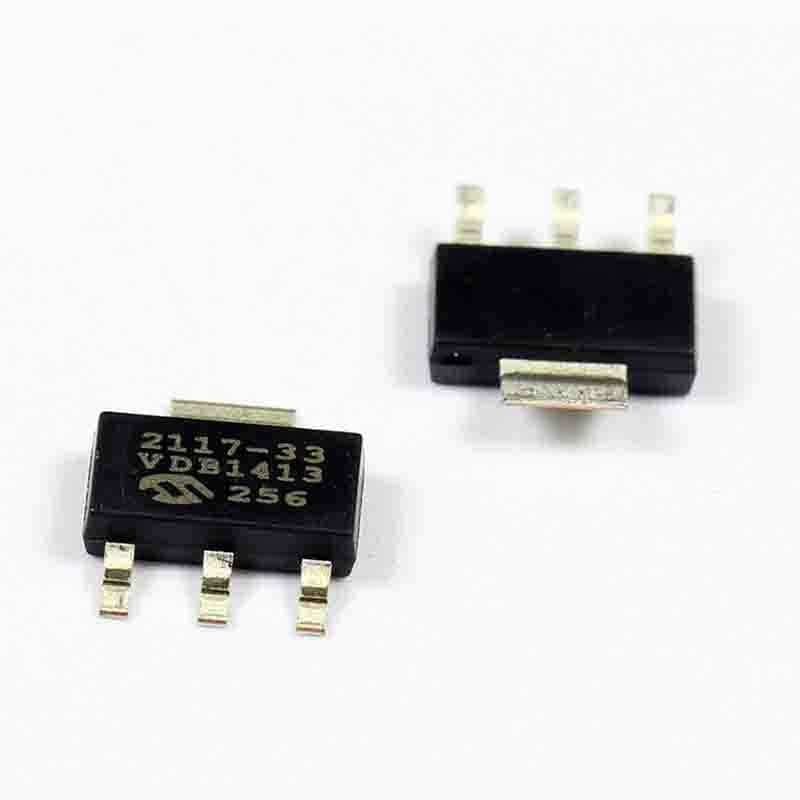

Is a fixed, high accuracy (typically ±0.5%) CMOS low dropout regulator. Designed specifically for battery-operated systems, the TC2117’s CMOS construction eliminates wasted ground current, significantly extending battery life.

Data from: Voltage regulator

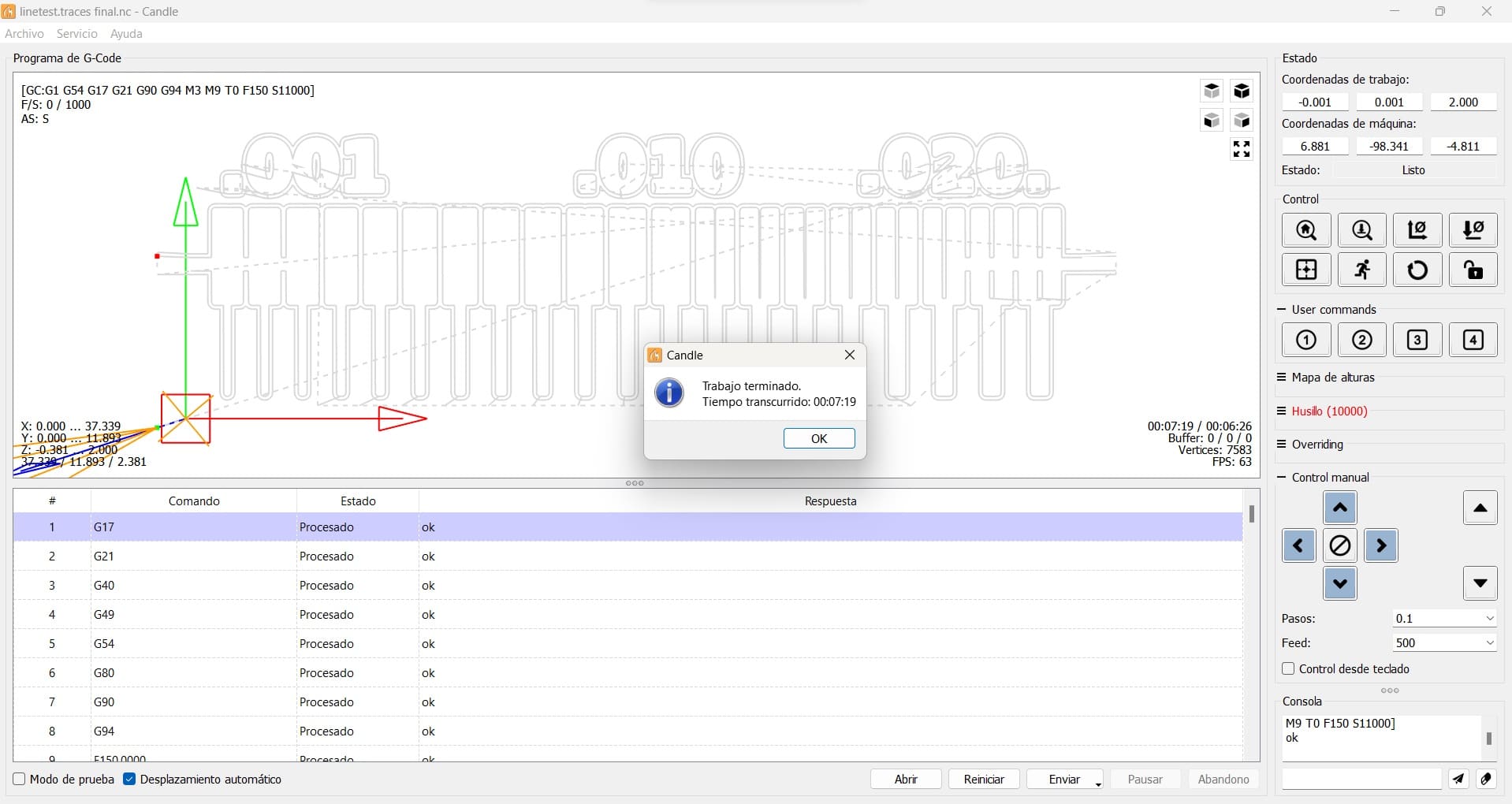

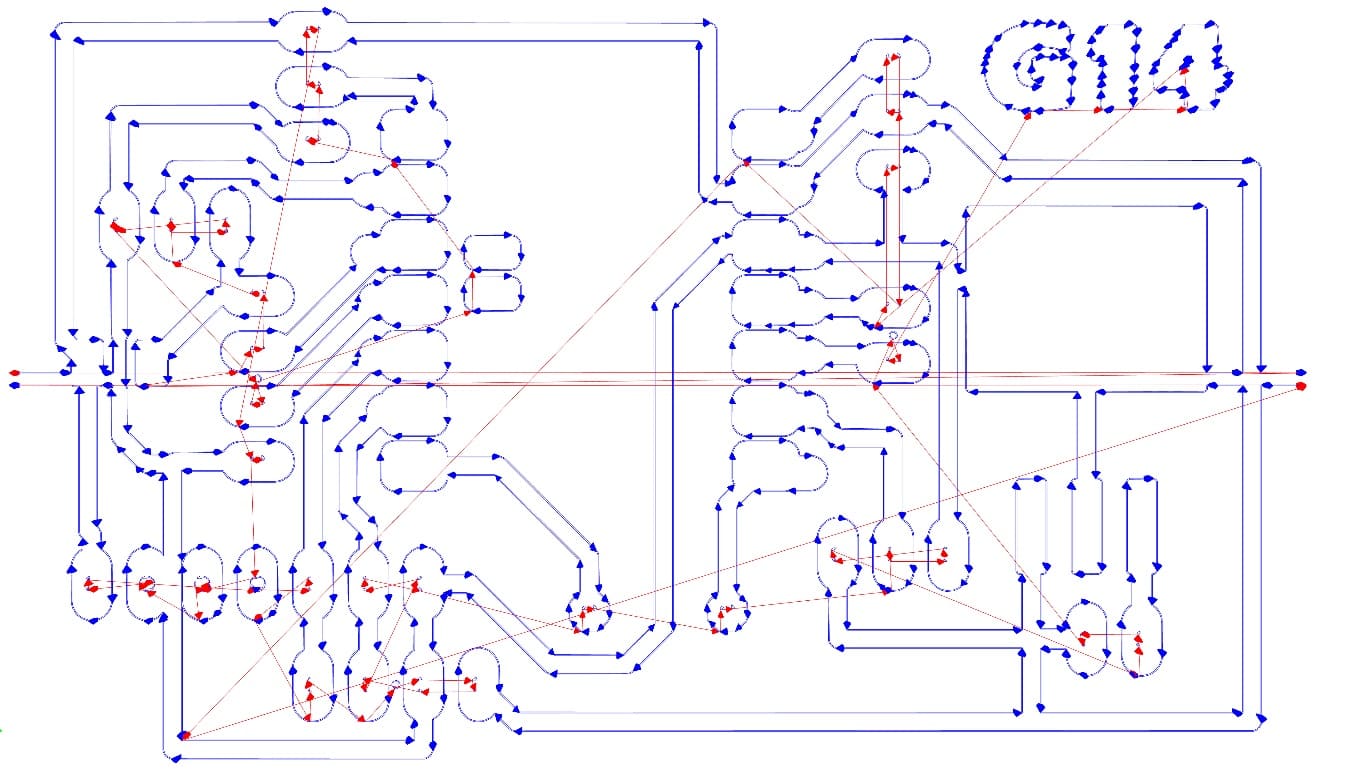

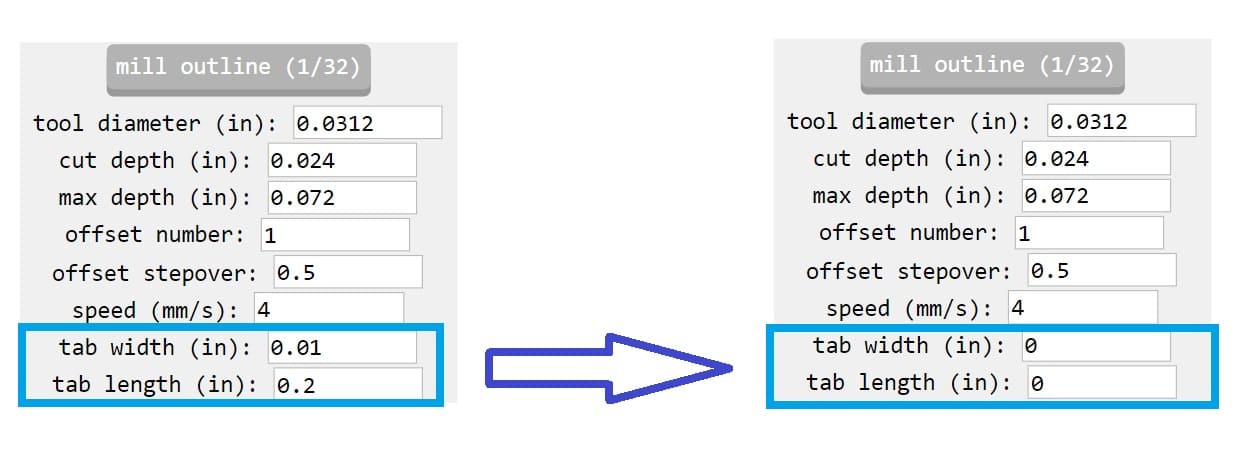

In this initial part i'm using the .NC files of the fabmodules.

Based on the results less than 0.013 in. the traces won't be made.

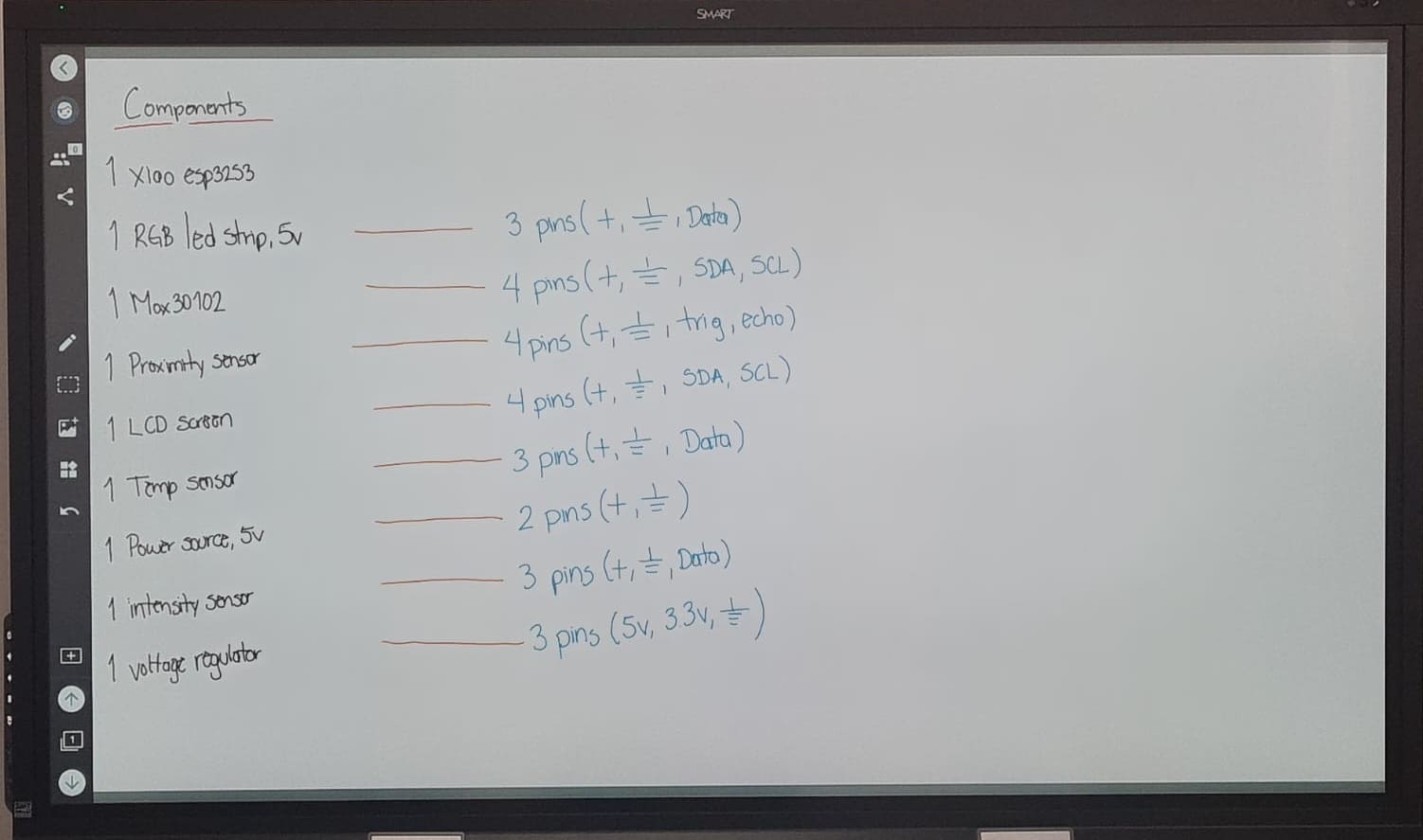

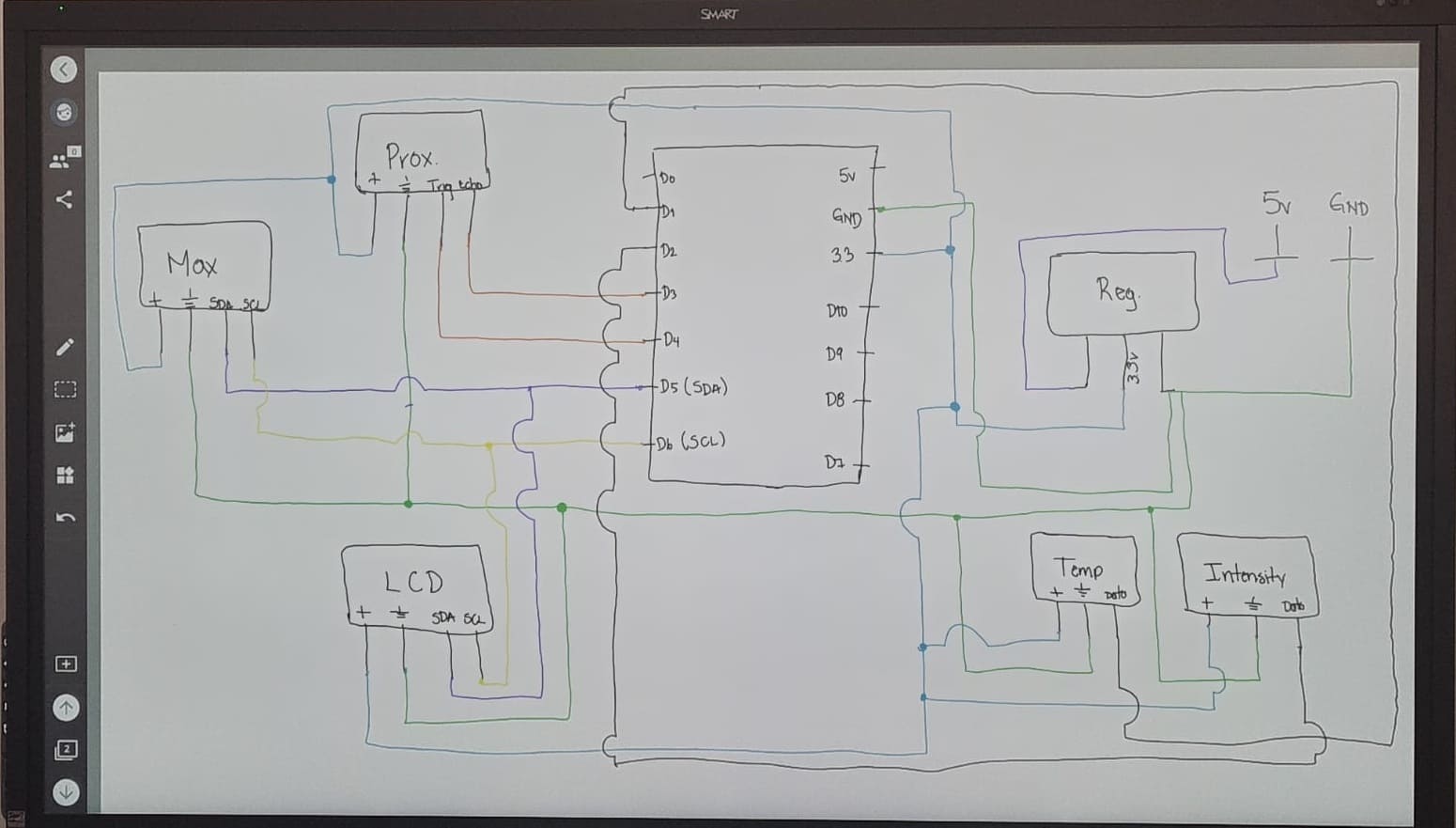

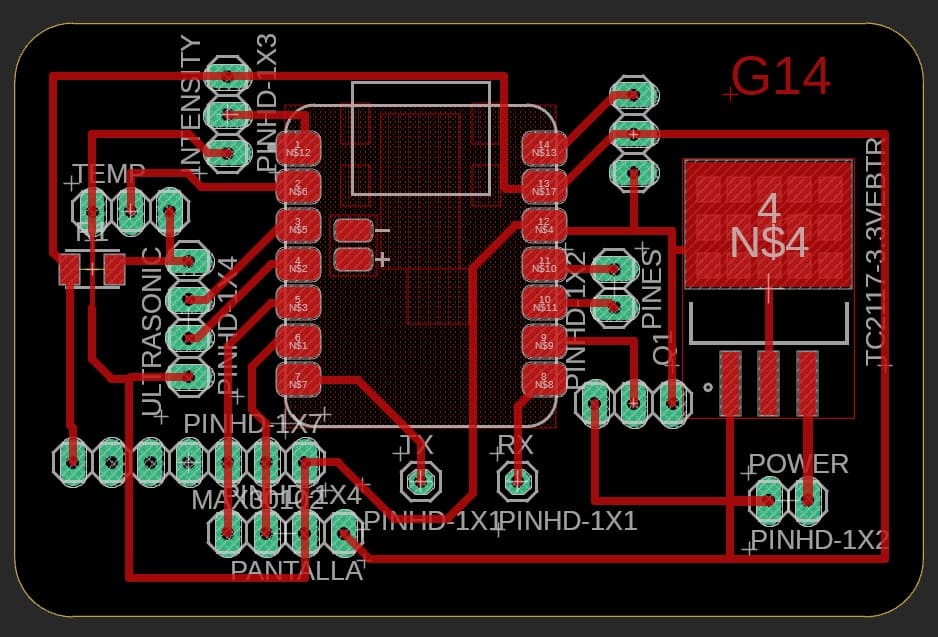

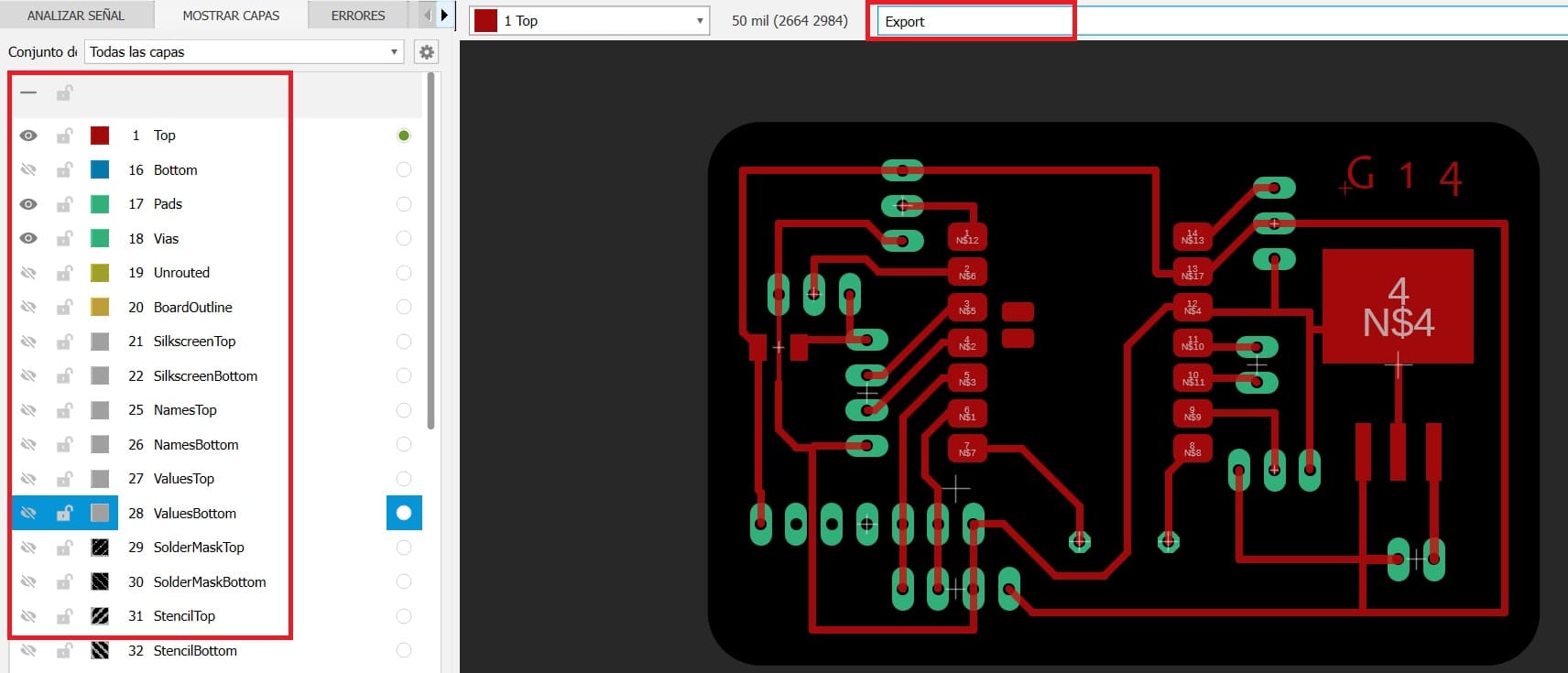

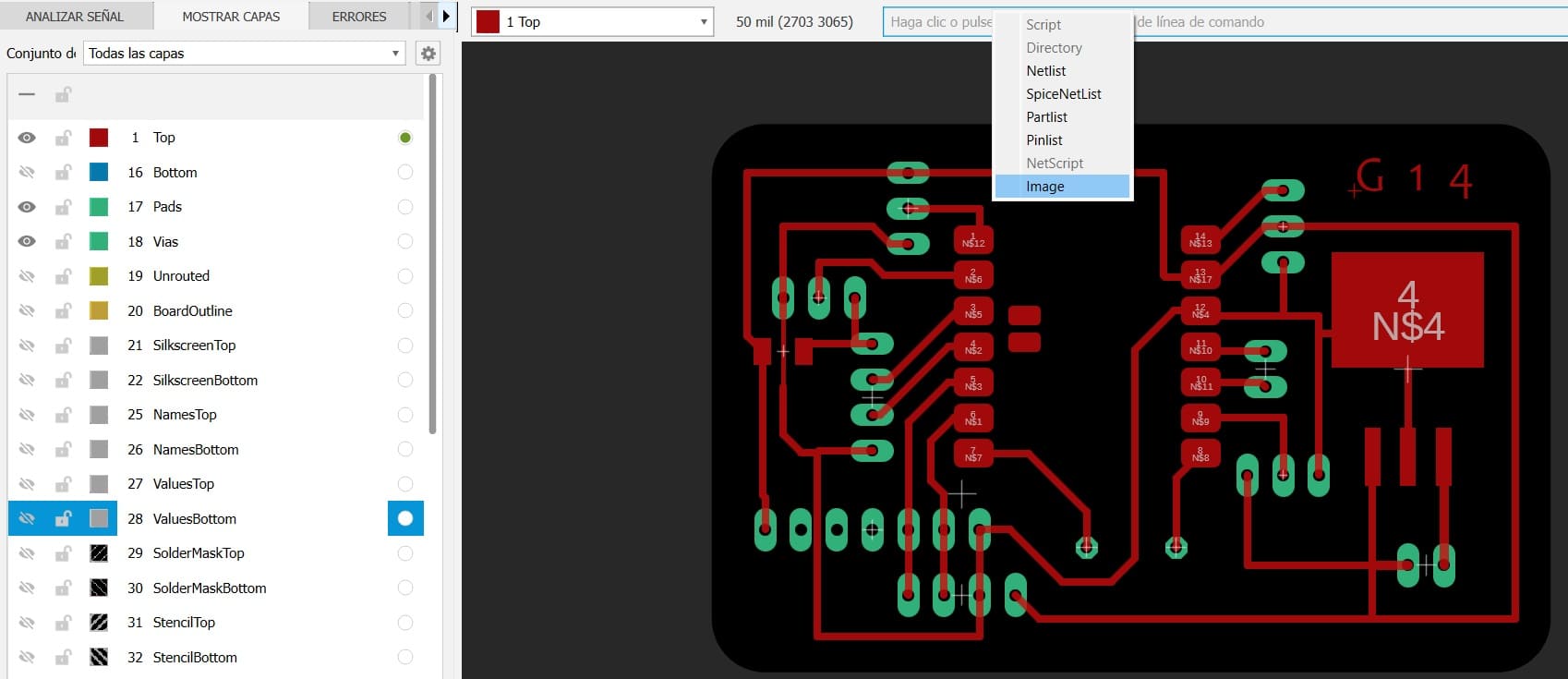

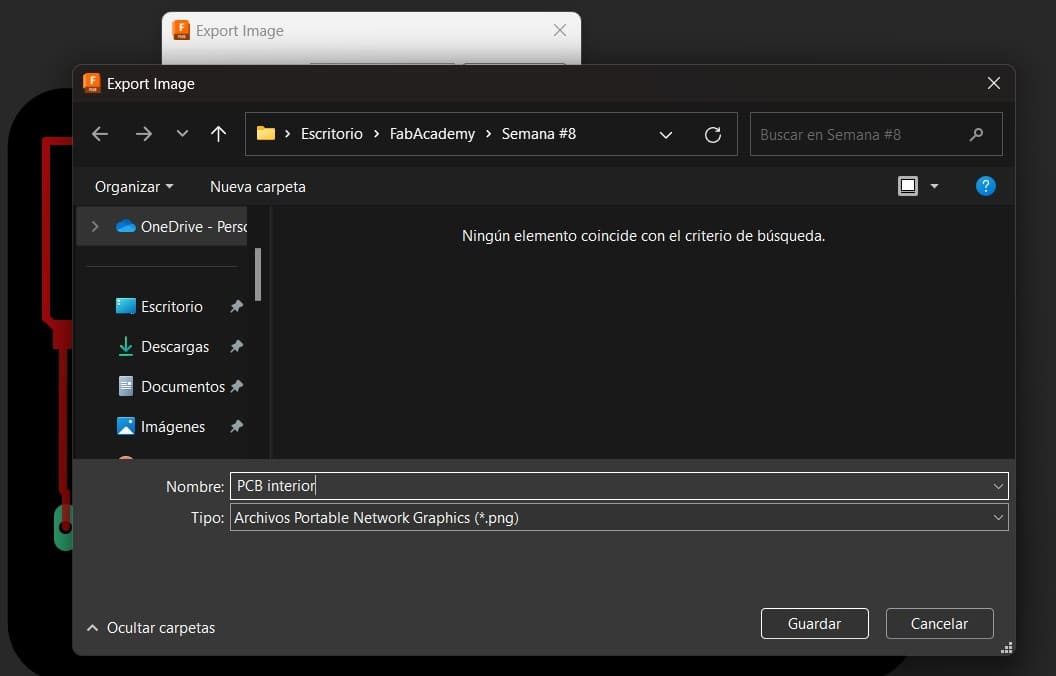

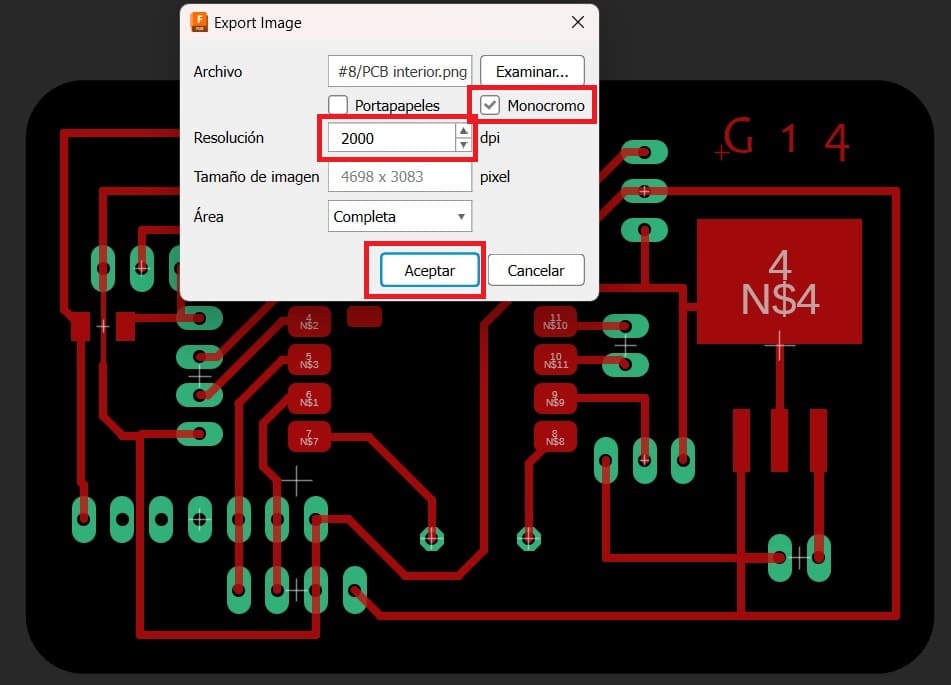

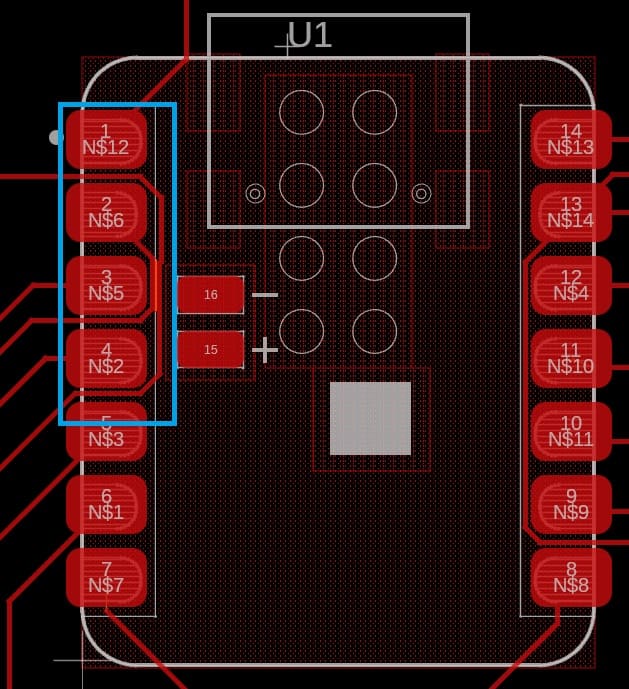

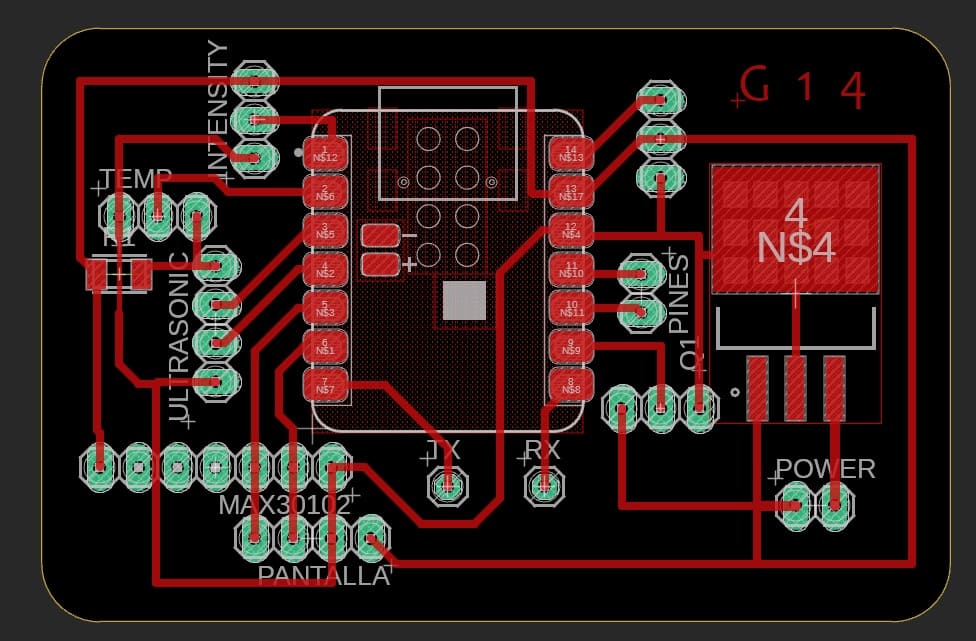

For my first task, I started desinging the PCB board. for this, I use Fusion 360, i've never done this before.

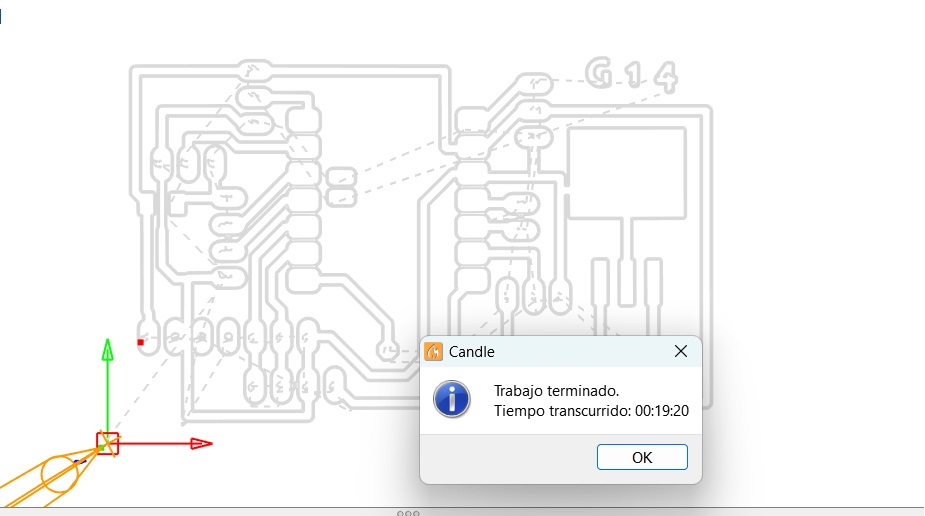

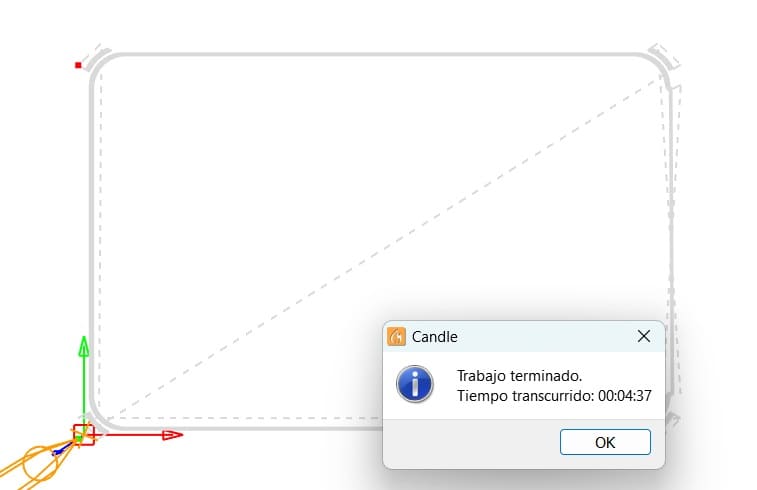

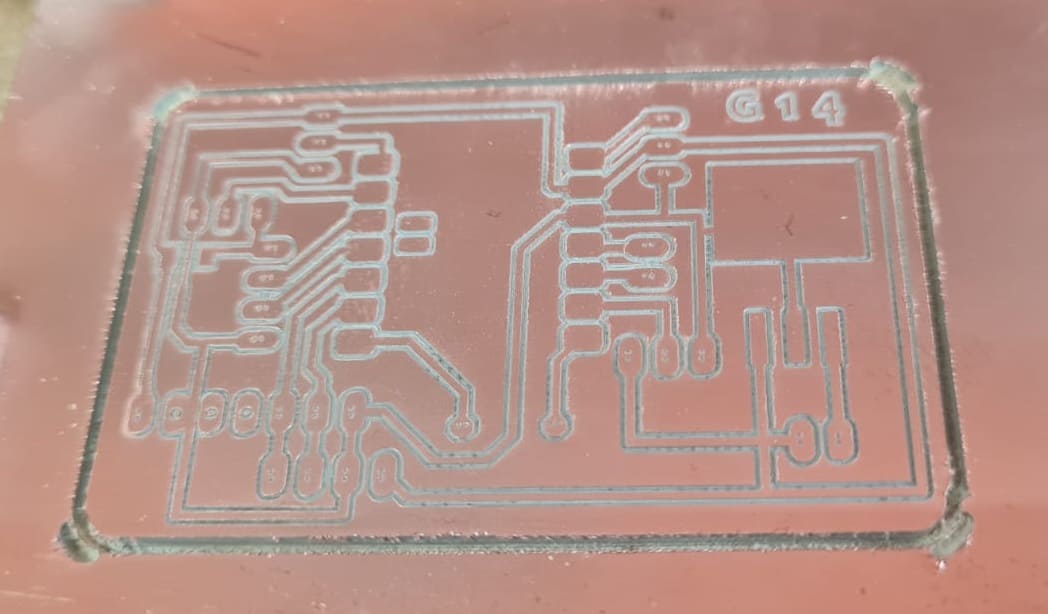

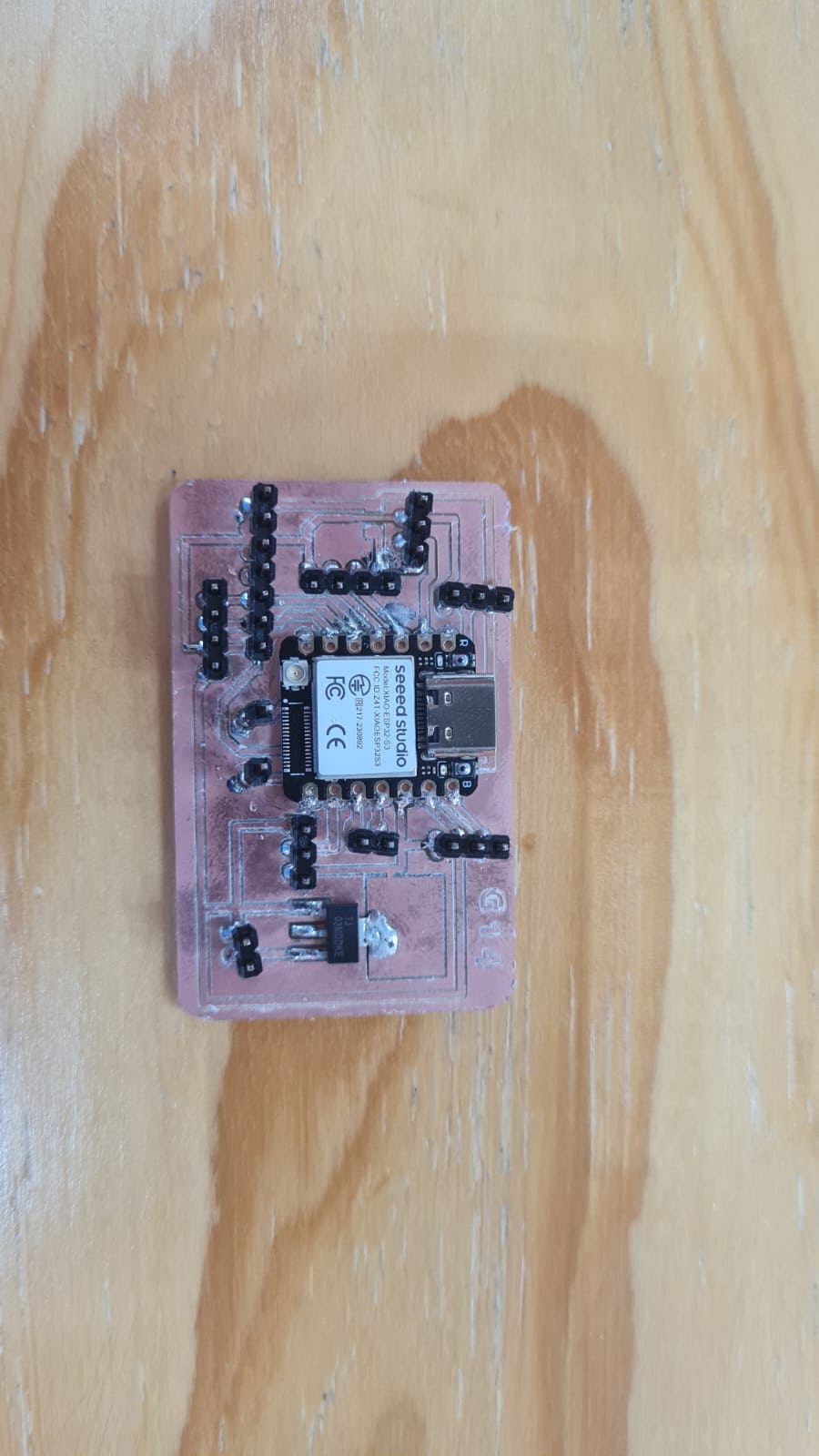

So, lets begin our engraving process of the PCB board. As usual, lets hope for the best:

So, I had some problems this week. I think this was one of the hardest weeks, not because of the assignments but of specific tasks I had to do. For example:

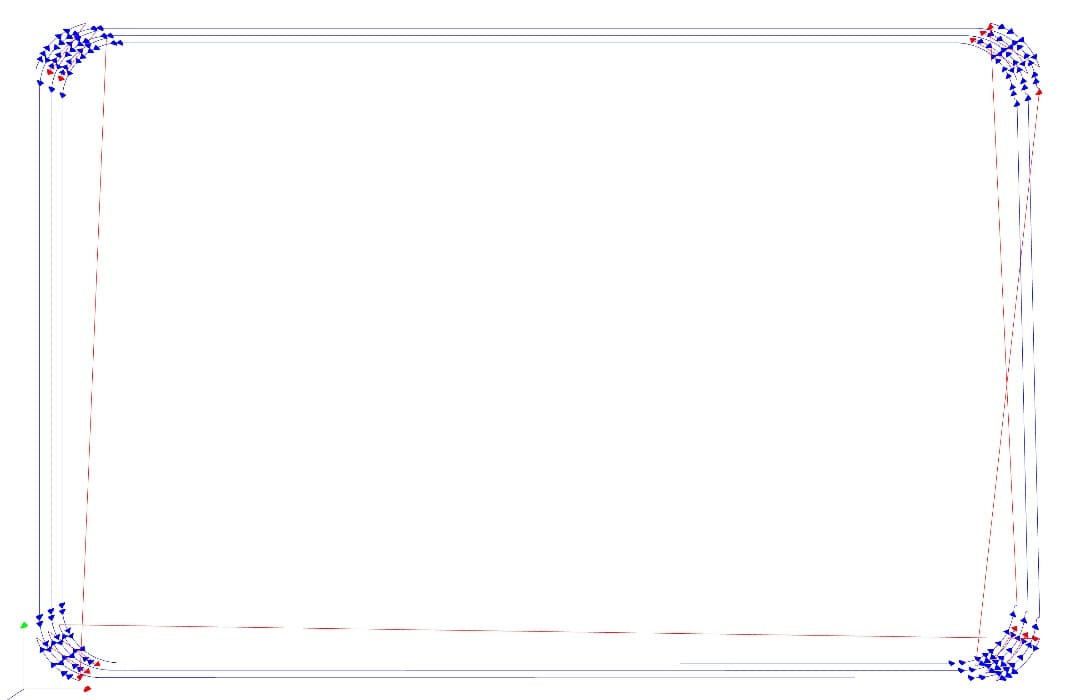

Another problem (P.I.C.N.I.C error) was with PCB exterior:

In this part you can download the files that I use for this 7th week assignments.

What did I learn in this week?