Mechanical Design, Machine Design

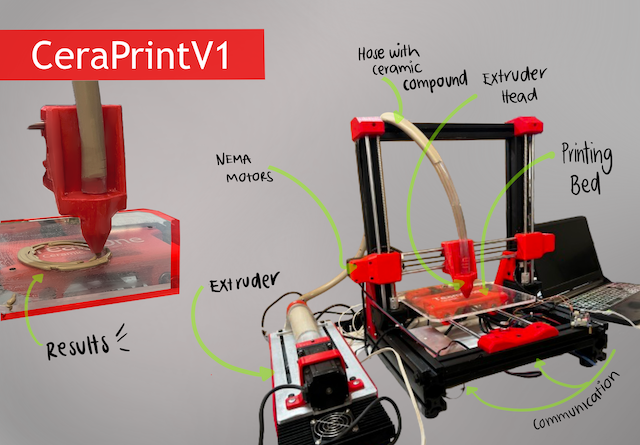

This was a tough, but interesting week. As a team, we created a ceramic 3D printer, which despite being a challenge, turned out to be successful. Although we participated as a team throughout the entire process and creation of the machine, these were my contributions.

Team Practice

Here its the link of our team practice.

Desing of the structure

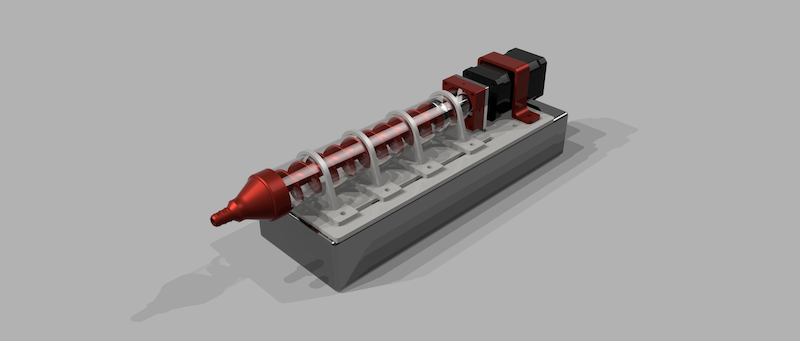

For the design of the machine's structure, one of my colleagues created their design in SolidWorks, as well as the components. Therefore, I structured it in Fusion 360 with the materials to be used in order to visualize everything necessary before the machine's production.

Design of the extruder

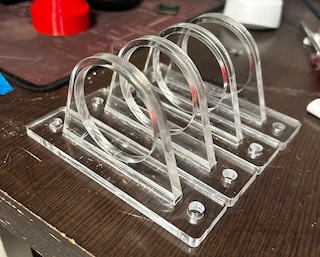

For the design of the extruder, my contribution was designing the supports for the extruder base for better grip, as well as rendering and composing the various elements in Fusion 360.

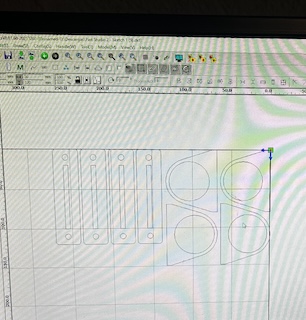

The design of the supports was done in Fusion 360, and they were cut using laser cutting technology on 6mm acrylic.

3D model of the machine

I designed the complete 3D model of the machine for a better digital visualization of our ceramic printer.

As well as that of the components in an exploded view of the 3D model.

.png)

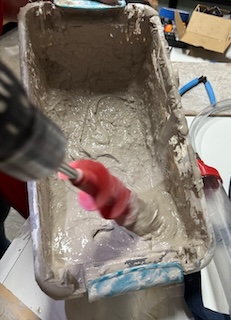

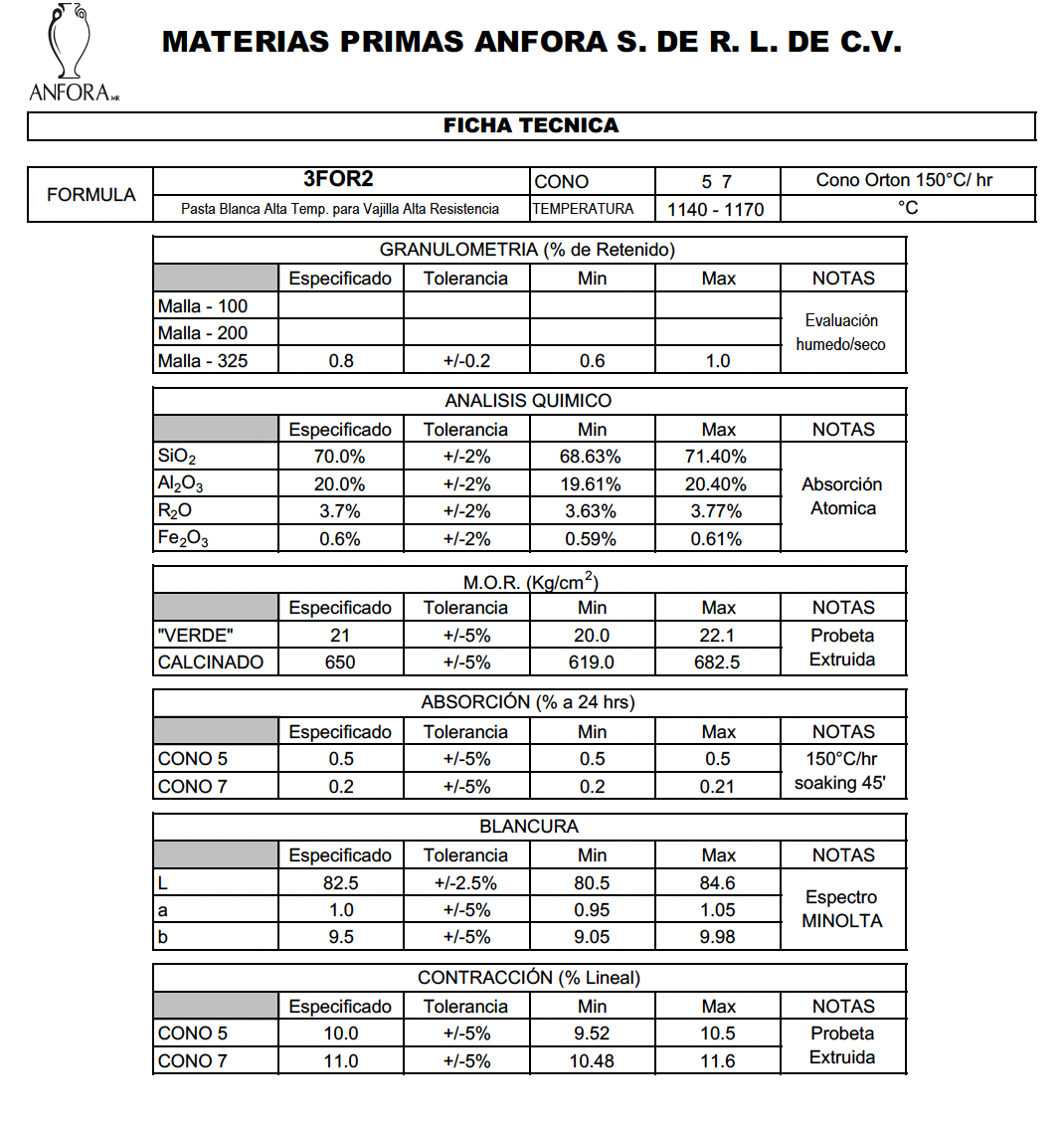

Ceramics and mixing tests for the use of the extruder

I obtained a ceramic, specifically a line ceramic suitable for industrial use. Using the ceramic datasheet and various tests I conducted, I arrived at the specific mixture consistency for the machine.

Sheet and group page design

I designed a sheet with the main components of the pages, as well as all the documentation for the group page.