19. Project Development

As the time to deliver my final project approaches, I dedicated this week to keep track of what I already have, what I should modify and what should stay from the original idea. At this point, I think some tasks helped me to be more realistic and grounded about the possibilities and time I have left.

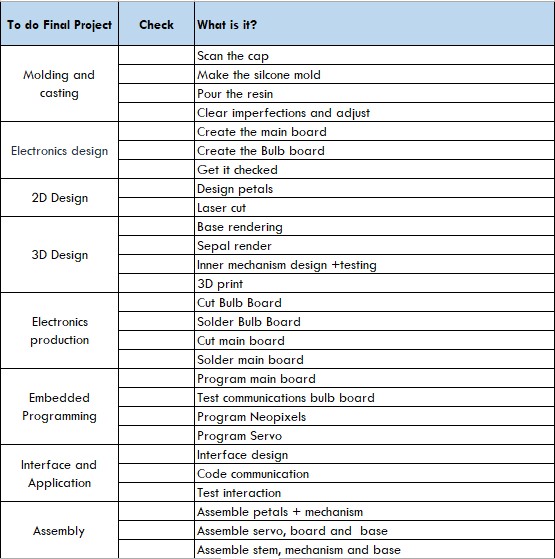

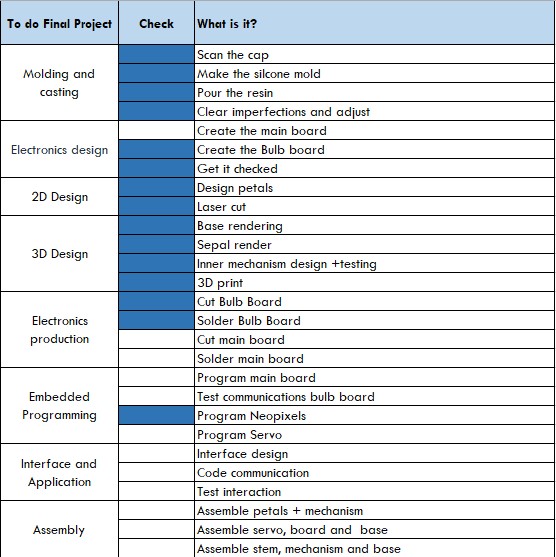

The planning

After considering my previous ideas on the project and the schedule I proposed from week 11, now it's time to get serious and be more specific with what comes next. As I divided already my project in 3 sections already, now I had to subdivide the tasks I defined on my plan from Week 17 Also, I renamed some of the steps and separated them by phases that I named as the weeks they belong to in the FAB.

What tasks have been completed? & What tasks remain?

I decided to start with the design so far, that's what made me most confident. Also, I started working with what I believe could require more time or mistakes. Here's the checklist so far:

0.Prototyping and testing

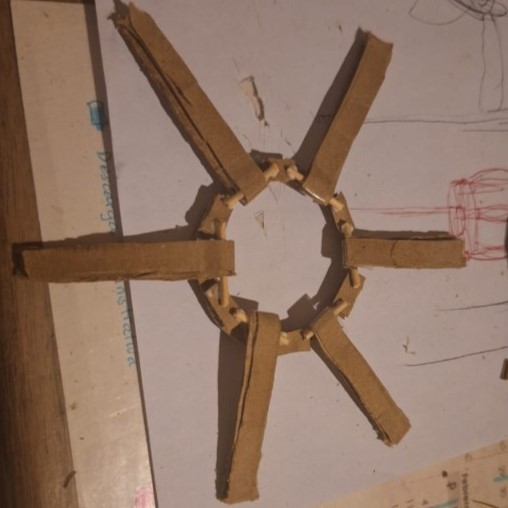

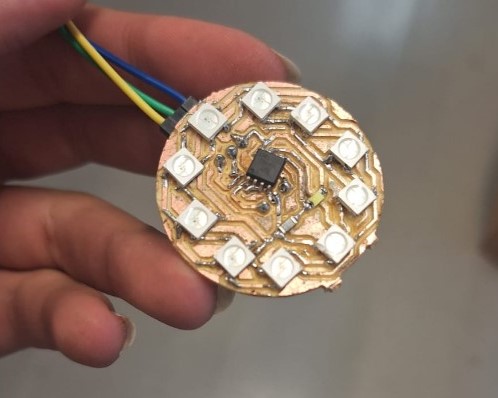

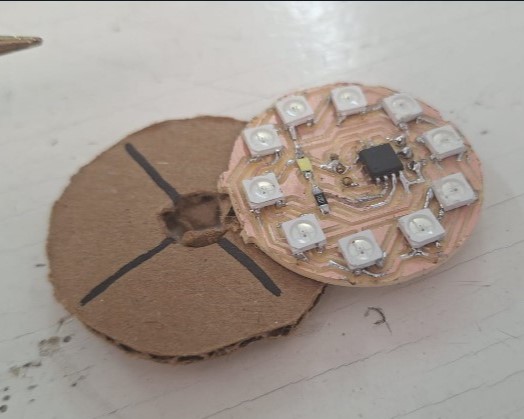

Before starting to make the main pieces of everything, I spent a week designing what I considered the key pieces of the flower. I Started from making a prototype for the Bulb Board, where I drew some neopixels, a small microcontroller and glued some pins. Note:The position and design changed, this was just a visual representation for the size. Then I also made tests using toothpicks and crepe paper to build the mechanism and petals. I tried it with a plastic easter egg to imitate the sepal.

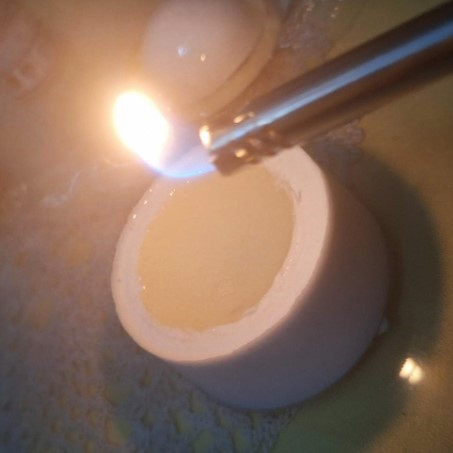

1.Molding and casting

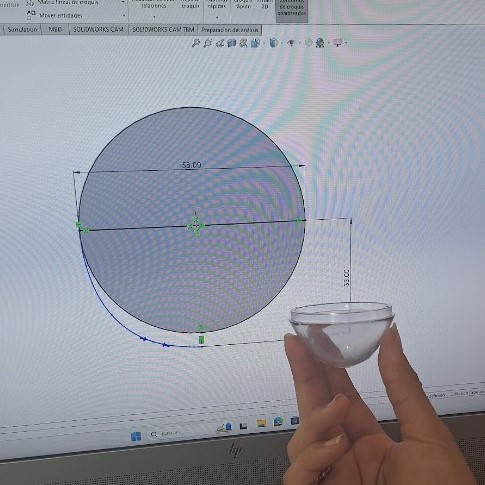

This is the very first thing I did for my project. The idea came up as the first task to

complete

since I had clear from the beiginning that I needed something to emulate a light bulb

for my

project. As I chose to have a Neopixel board to be my light source, then I first

wanted

to

state the measurements and dimension of a cap to distribute the light better.

So that, I made some tests for molds using silicone: first a flat circle, then

the half of a sphere. Finally, I decided to use a Styrofoam sphere to get more texture.

I let

the silicone dry 24 hours around it before demolding.

The next task ahead was to prepare the resin mixture and pour it in the mold, I used clear resin, since it has a nice light refraction index.I used a lighter to get rid of bubbles and it took about 36 hours to dry completely, so I gave it enough time and demolded carefully.

2.Electronicss design and production

As I had the base measurements for the center of the flower and had the resin cap as a reference, I could design the Bulb board, which consisted in a board that holds 10 neopixels and a microcontroller.If you wish to see more of the process, it's fully documented on Week 9 here are some pictures and also a comparission to the prototype.

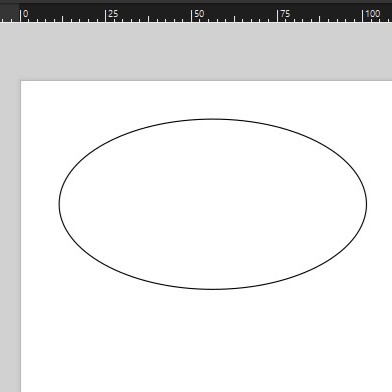

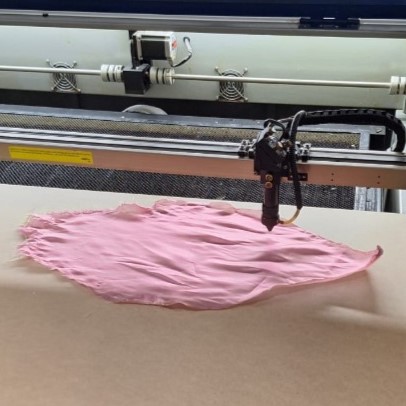

3. 2D Design

Another part I already started is the 2D design, mostly related to the petals sizes and shapes, here I defined the petals had to be longer and like an oval, so I could hide them to the mechanism later.Also I tested the volume I coild get from different fabrics, deciding to go with tule and organza definitely.

3. 3D Design

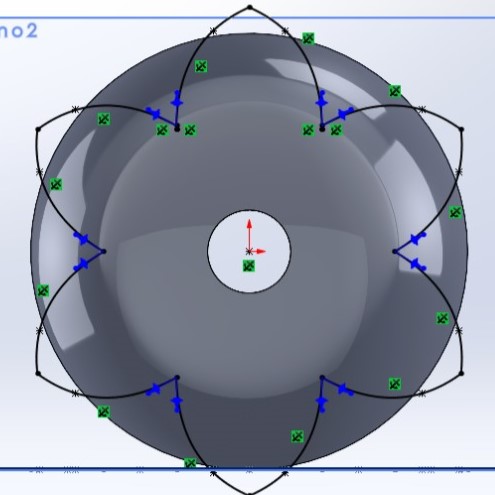

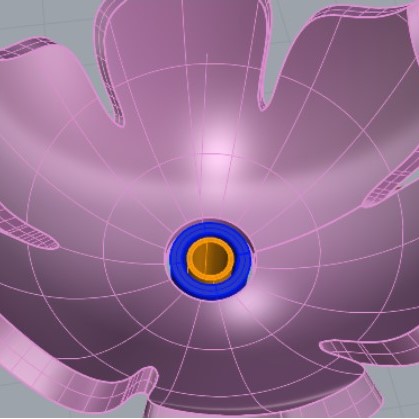

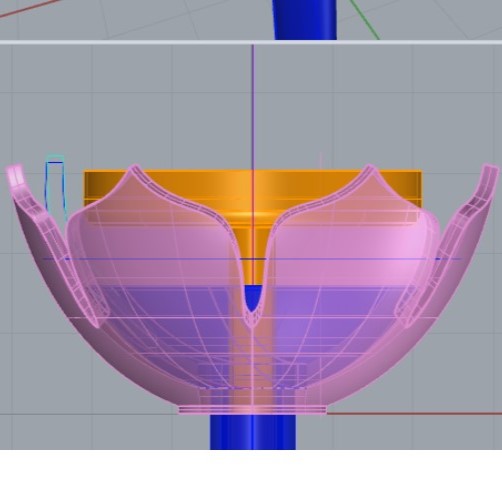

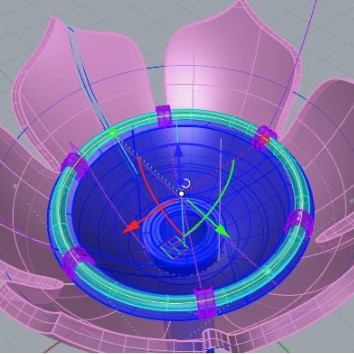

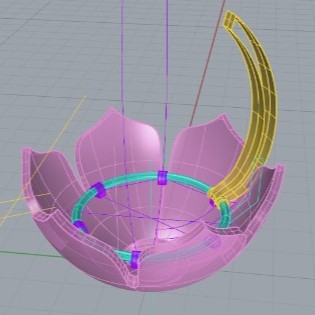

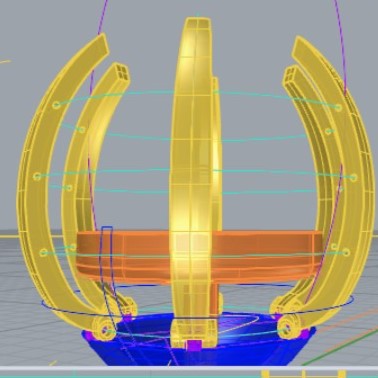

About the 3D design, I invested some time to get the render of the sepal and mechanism as

soon as possible. This, to make sure it was functional before looking for pieces for the

stem, because there are some aluminum profiles that may fit but the best choice could depend

on the mechanism behavior.

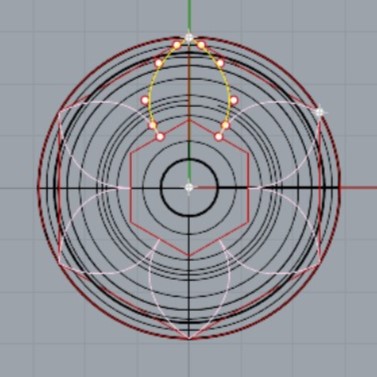

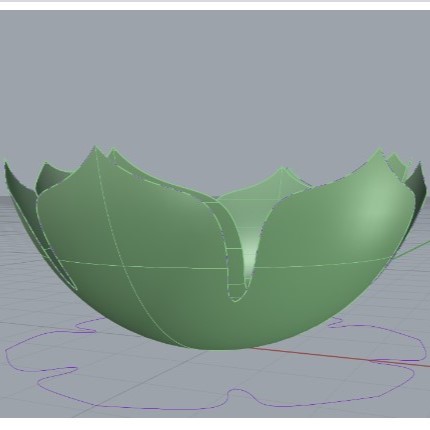

I used SolidWorks first, to try to get the best design, but as the shape is more

organic, I ended up using Rhinoceros, since it is more flexible to organic shapes

and allows free modeling before defining the measurements, something not so viable using

Solid.

Here are some more descriptions of the pictures and design process:

- First attempt to model in Solid parting from the Easter egg I used for the prototype.

- Attempt to prokect the petals on the structure on solidworks (unsuccessful).

- Flat drawing of petals in Rhinoceros.

- Attempt to project and wrap petals over the structure of the sepal (successful).

- Pipe structure for the stem and inner moving mechanism to rise up and down.

- Lateral view of the structure including the piece to hold the PCB

- Movable base with holes for the rotation mechanism.

- Arms to attach the petals.

- Testing distance span of movement.

4. Embedded Programming

I have already tested some simple codes on the modules I needed for the project, first on the servomotor and then on the neopixel board. But as the main board is not ready yet, I ran some example codes from arduino to get them working. At some point I realized my Bulb board overheated and desoldered some pins I had to fix.

What has worked?

I strongly bekieve that starting from a prototype that I took seriously and had base

measurements for proportions was a lifesaver. Since I already had measurements as a

reference, I could set the base to design the maing project from something solid and not a

random base measurement. Also, this allowed me to keep proportion between the elements of

the system.

Other thing that has worked well is waiting before joining anything in a permanent way, this

has allowed me to modify things and check any corrections that I required

What has not worked?

I would start with keeping the idea of two separate boards with two separate

microcontrollers. Despite I could use the Attiny45 to test the neopixles during

week

9, I believe it could have been more practical to keep a board without a microcontroller

and

just neopixels, so that I could program directly with a single wire for signal, one for

ground and one for power. I thought about this because those are less steps to reach the

same goal.

Also, trying to print the 3D design on ABS hasn't been successful yet, I tried without

knowing the parameters to print in this material so I have two options: a)Research a bit

more about how to print on ABS or B)go back to a material I'm already familiar with.

Considering timing and practicity, I think I will go with option B, so I risk less

mistakes.

Here you can see the failed attempts:

What have I learned?

So far, I've learned to optimize resources and time a little bit more. At the beiginning of

my workflow I was not very practical and took too much to finish simple tasks as if time

wasn't important and I could do it right at the first try, now I anticipate that and work

more aware of time, material resources and practicity.

Also, I learned to manage the process better, since at first I had a blockage because I

didn't know what to do first. Writing down tasks is really useful, and also you can

get to manage everything better after knowing for sure what you have to do.

I just recommend: