Machine design

The assignments for this week:

- Group assignment :

- design a machine that includes mechanism+actuation+automation+application

- document the group project and your individual contribution

- Requirements: The requirements for the extruder, such as the type of decoration to be created, the consistency of the icing or frosting, the speed of extrusion, and any specific features needed for the cake decorating process should be defined.

- Research and Gather Information: After researching on types of plungers, piping guns, and mechanisms used for extrusion , we purchased a piping gun which could be incorporated in our machine.

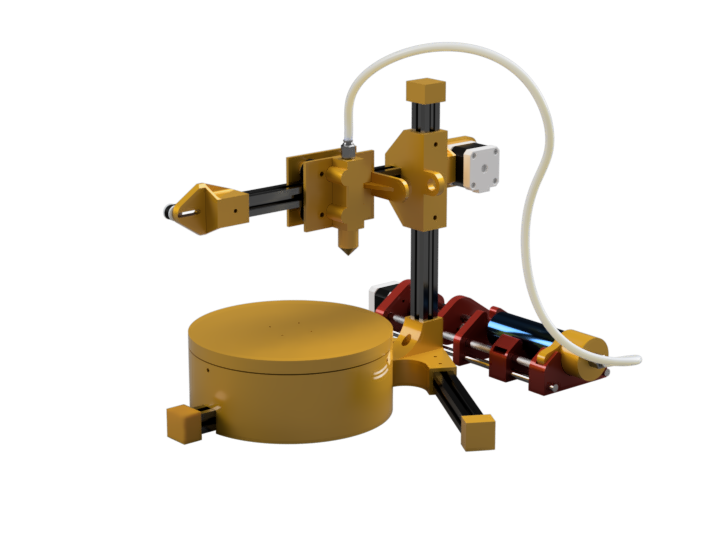

- Conceptual Design: We had a brainstorming session and developed a conceptual designs for the extruder coinsidering factors such as the type of plunger mechanism, material compatibility, ease of cleaning, and integration with the cake decorating machine. We decided conceptual designs considering how the linear actuator will be integrated into the system. Determine the mechanism for translating the linear motion of the actuator into the extrusion of icing or frosting.

- Detailed Design: We designed the parts required to support the plunger in Fusion360. The supporting structure provided a housing for the motor along with the linear actuator.

- Material Selection: We chose materials that are food-safe, durable, and compatible with the icing or frosting being used.

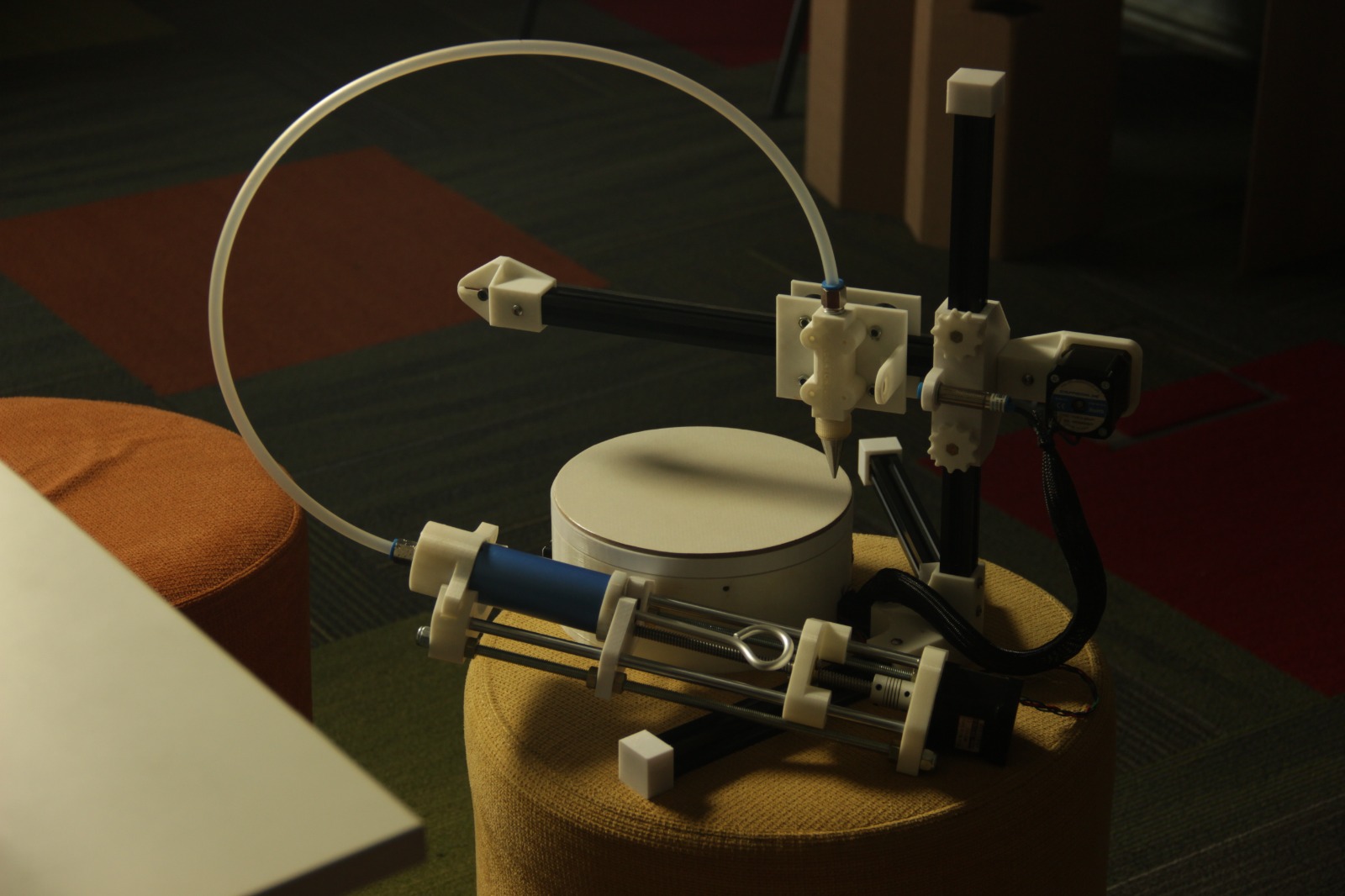

- Prototype Development: We build a prototype of the extruder using the detailed design and selected materials. and tested the prototype to evaluate its functionality, performance, and ease of use.

- Integration with Cake Decorating Machine: We integrated the extruder with the cake decorating machine, ensuring proper alignment and compatibility and Tested the integrated system to verify that the extruder operates correctly within the cake decorating machine.

- Testing and Validation:

We had to conduct thorough testing of the extruder in a real-world cake decorating environment.

Validate the extruder's performance, reliability, and consistency in producing desired decorations on

cakes.Improvements had to be made based on the test results. We initially started by using buttercream. But

because of its consistency, it was very difficult to extrude. The plunger was giving way to the buttercream. I

decided to make chocolate ganache, salted caramel and whipping cream to test the plunger.

Of the three chocolate ganache was the better option but I decided to change the consistency from 2:1 (chocolate:cream) to 1:1. This seemed like a better option. However, over time the ganache was solidifying in the pipe.

Group assignment:

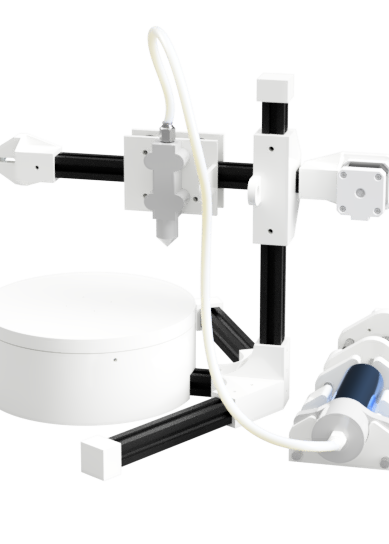

The design of the Cakerator2000, click here:

My hobby as a baker

As a dedicated home baker I always strived to create cakes that not only taste delicious but also look visually appealing. However, the process of decorating cakes has often posed challenges in terms of time and precision. Recognizing this common struggle, the team joined forces to develop a solution: the Cakerator2000!!Reasons for Developing the Cake Decorating Machine:

Shared Interest: While my passion lies in baking, we as a team share a keen interest in engineering and machine building. Combining our skills and expertise, we saw an opportunity to collaborate on a project that would integrate both disciplines and address a real-world need within the baking community.

Learning Opportunity: Developing the Cake Decorating Machine provided us with a valuable opportunity to gain practical experience in designing, building, and testing a machine from concept to completion.

Problem Solving: Identifying the challenges faced by home bakers, particularly in the realm of cake decoration, sparked our collective problem-solving drive. We saw the opportunity to leverage automation and technology to streamline the cake decorating process and alleviate some of the burdens associated with manual decoration.

Innovation: As a team, we're driven by a curiosity to explore new ideas and push the boundaries of what's possible. The Cakerator2000 represents our commitment to innovation and our belief in the power of technology to enhance everyday experiences, even in the kitchen.

Collaboration: Working as a team has been an enriching experience, allowing us to leverage each other's strengths and perspectives. Through collaboration and communication, we've been able to overcome challenges, iterate on ideas, and ultimately bring our vision for the Cakerator2000 to life.

The decision to develop the Cakerator2000 was driven by our shared interests, desire for hands-on learning, problem-solving mindset, passion for innovation, and collaborative spirit as students. We're excited to showcase the results of our hard work and creativity, and we hope that the Cakerator2000 will not only benefit home bakers but also inspire others to explore the intersection of baking and technology.

Planning

Our first step was to brainstorm about the concept and do a preliminary design. We planned and decided on our

schedule and finalised on a timeline.

.png)

.png)

.png)

This is our timeline:

.png)

.png)

.png)

Designing the Extruder

I was given the task of designing the extruder. Usually for finer decorations in cakes, we use a piping gun.