Week 12: Molding and Casting

Assignment of the week:

Group assignment:

Review the safety data sheets for each of your molding and casting materials

Make and compare test casts with each of them

Compare printing vs milling molds

Individual assignments

Design a mold around the process you'll be using, produce it with a smooth surface finish, and use it to cast parts.

Learning outcomes:

Design appropriate objects within the limitations of your process

Demonstrate workflows used in mold design, construction and casting

Requirements for the assignment:

Linked to the group assignment page and reflected on your individual page what you have learned

Reviewed the safety data sheets for each of your molding and casting materials, then made and compared test casts with each of them

Documented how you designed and created your 3D mold, including machine settings

Shown how you safely made your mold and cast the parts

Described problems and how you fixed them

Included your design files and ‘hero shot’ of the mold and the final object

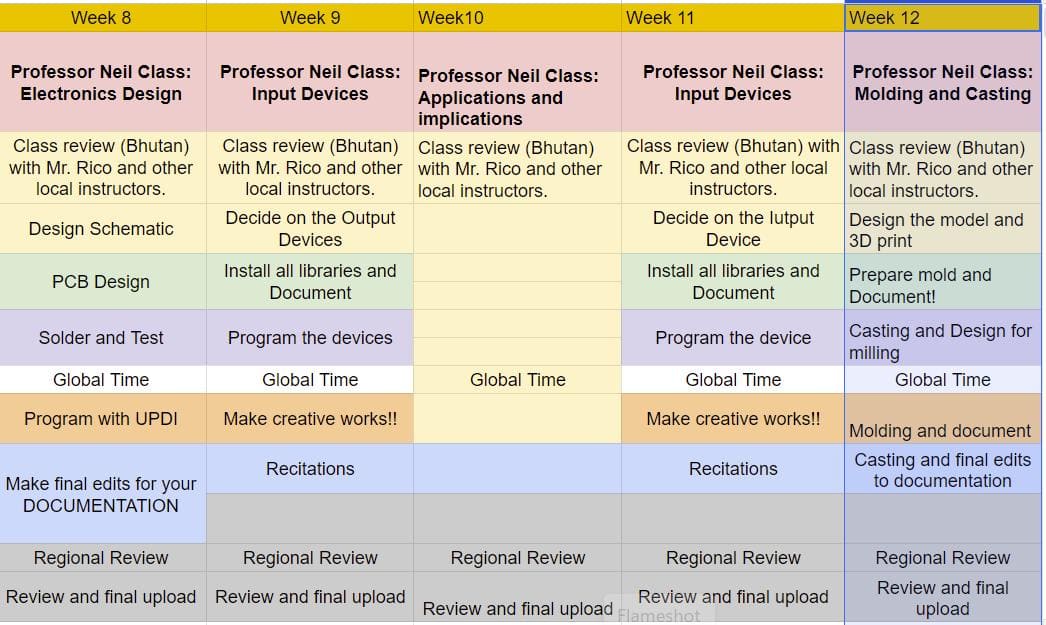

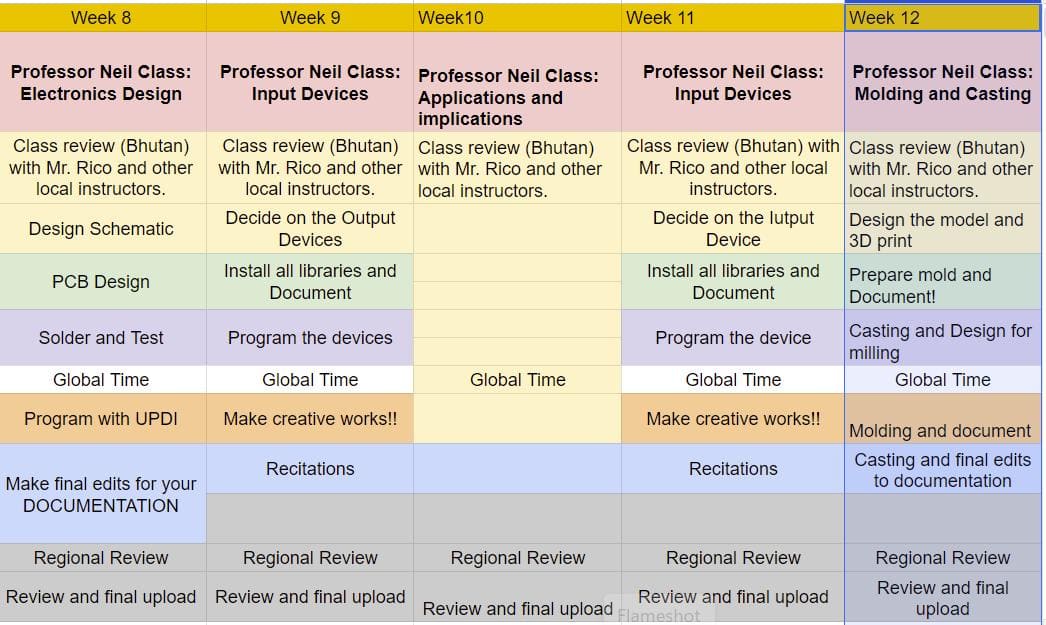

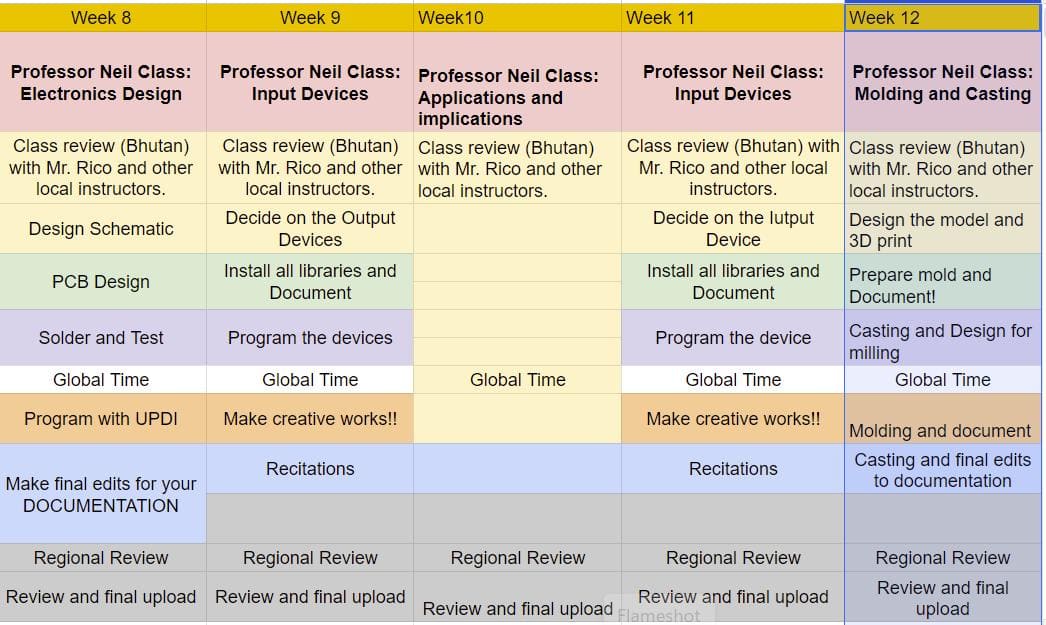

Here comes another schedule for another week!!

Group Assignment:

Learning Highlights:

- Safety First: Reviewing safety data sheets is crucial before handling any molding and casting materials. It includes wearing appropriate protective gear, working in well-ventilated areas, and understanding potential hazards and first-aid measures.

- Material Characteristics: Different molding and casting materials have unique properties such as viscosity, curing time, hardness, and compatibility with other substances. Understanding these characteristics helps in selecting the right material for specific applications.

- Mixing and Handling: Proper mixing and handling techniques are essential for achieving desired results. This includes following recommended mix ratios, curing times, and post-curing processes for optimal performance.

- Molding and Casting Techniques: Various molding and casting techniques like injection molding, slip casting, and die casting offer versatility in creating different types of molds and final products. Each technique has its advantages and limitations.

- Comparison of Printing vs Milling Molds: Both 3D printing and milling offer unique advantages and drawbacks in mold creation. 3D printing allows for intricate and detailed designs but may result in textured finishes, while milling produces smoother outcomes but is limited by the size of the drill bit.

- Design Considerations: Designing molds requires considering factors like mold complexity, detail level, surface finish, and the intended use of the final product. Choosing the right technique depends on balancing these factors to achieve the desired outcome.

Conclusion:

The exploration of molding and casting techniques, along with the comparison of printing vs milling molds, provides valuable insights into the versatility and considerations involved in these processes. Safety precautions, material properties, mixing techniques, and molding methods all contribute to successful mold creation and casting. Understanding the strengths and limitations of each approach allows for informed decision-making based on project requirements and desired outcomes. Whether opting for 3D printing for intricate designs or milling for smoother finishes, careful planning and execution are key to achieving quality results in molding and casting endeavors.