Applications and Implications

Assignments

Propose a final project masterpiece that integrates the range of units covered, answering:

- What will it do?

- Who's done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

Your project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, embedded microcontroller interfacing and programming, system integration and packaging.

Where possible, you should make rather than buy the parts of your project.

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

All the important links are Here

Learning outcomes

Individual Assignment

What will it do?

My butter lamp chamber project, inspired by the traditional Bhutanese butter lamp case, combines traditional elements with modern technology. In this chamber, a butter lamp is placed, and as the flame's heat rises, it naturally causes a prayer wheel at the top to spin. In addition, my design includes an NTC thermistor sensor situated below the chamber's lid where the heat goes up to the prayer wheel. When the heat from the butter lamp surpasses a predetermined threshold,this sensor activates the DF MINI player (an MP3 player module), which plays prayer sound files. As the butter lamp burns, the prayer wheel spins just like the typical butter lamp case, and prayers are played automatically, resulting in a unique and exciting experience that combines tradition and technology.

Who's done what beforehand?

LED butterlamp

This new design combines the charm of a traditional butterlamp with modern LEDs, mimicking a real flame's gentle flicker. It's safe and easy to use in small spaces or indoor areas where real flames aren't allowed. This mix of old and new respects the cultural importance of light-offerings while making them safer and more practical. There are two types: one with LED light and prayer recitations, and another that simply stays lit, giving options for different uses and preferences.The light is rechargeable and smokeless, which is energy-saving and LED Light Decor.

What will you design? and What parts and systems will be made?

Physical Components

| Image | What I am designing | How I will make my design tangible and where I have designed it |

|---|---|---|

|

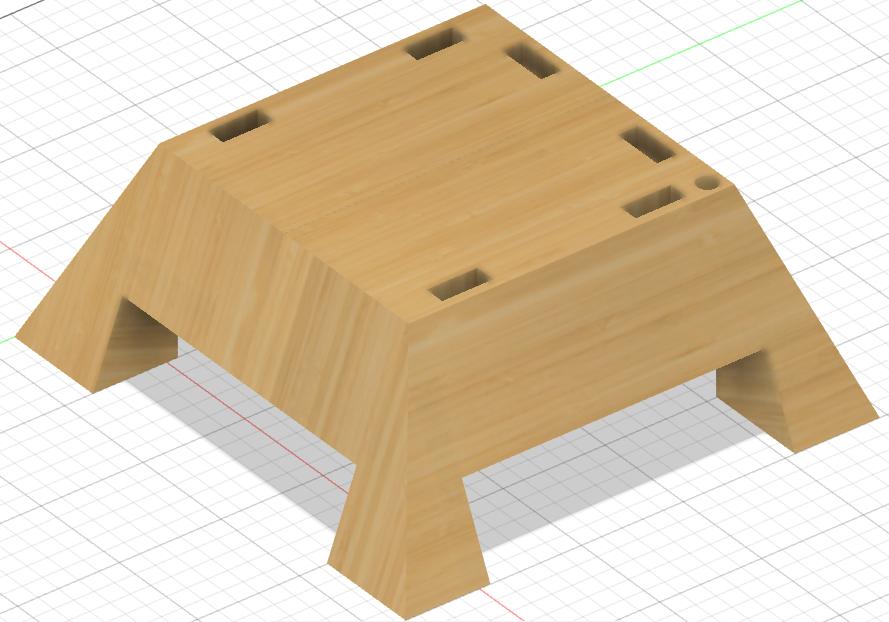

Base (which holds the overall design and where my circuit board, DF player, and speaker (resonance) will be placed) | I have designed the base in Fusion 360. The base is going to be laser cut or 3D printed. I will try to make both ideas physically to confirm which is better. For now, I feel that the idea of 3D printing it is better for aesthetic appeal. I have already laser cut one prototype of the base with cardboard material and I don't like the layered texture on it. I sliced it using the software Slicer for Fusion 360 to slice my design into 9 sections and then glue them. |

|

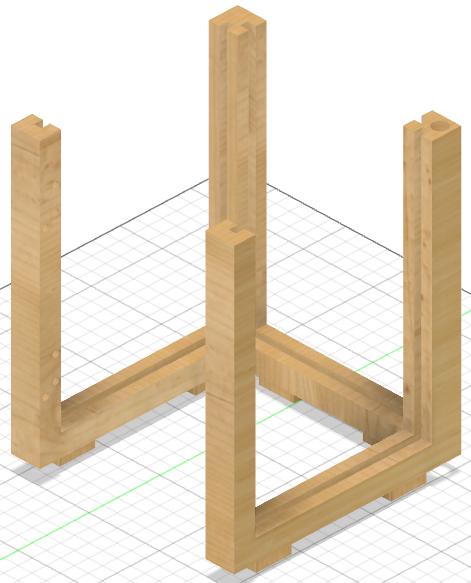

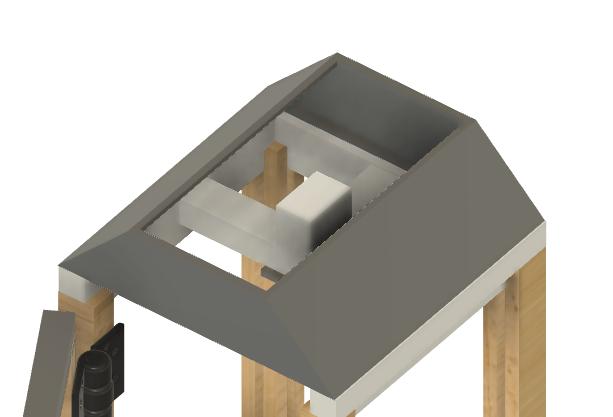

Structure which holds the glasses (the enclosure, (connected to the base) is the enclosure where the butter lamp will be placed). | I have designed the structure in Fusion 360. This is the structure with slots where my glasses are going to be placed. Its is the main structure where all the roof, the prayer wheel and the structure holding the NTC thermistor sensor are going to be placed with pressfit joints. I plan to 3D print it. |

|

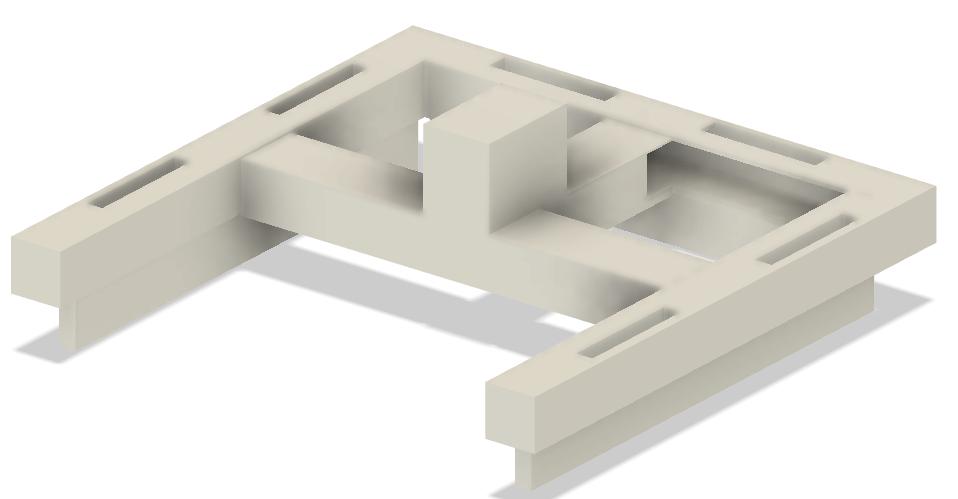

Structure above the glass enclosure (this is the structure which is going to hold the NTC thermistor holder, prayer wheel pivot and the roof) | I have designed the structure in Fusion 360. This is the structure that has a intricate design on the bottom face, since it is holding the NTC thermistor holder in place and need spaces for the wires to pass. I plan to 3d print it(If it doenst melt form the butter lamp's heat.) |

|

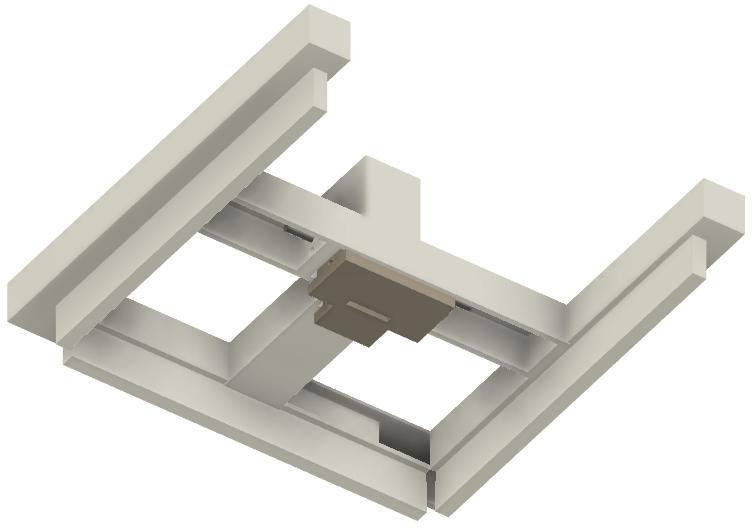

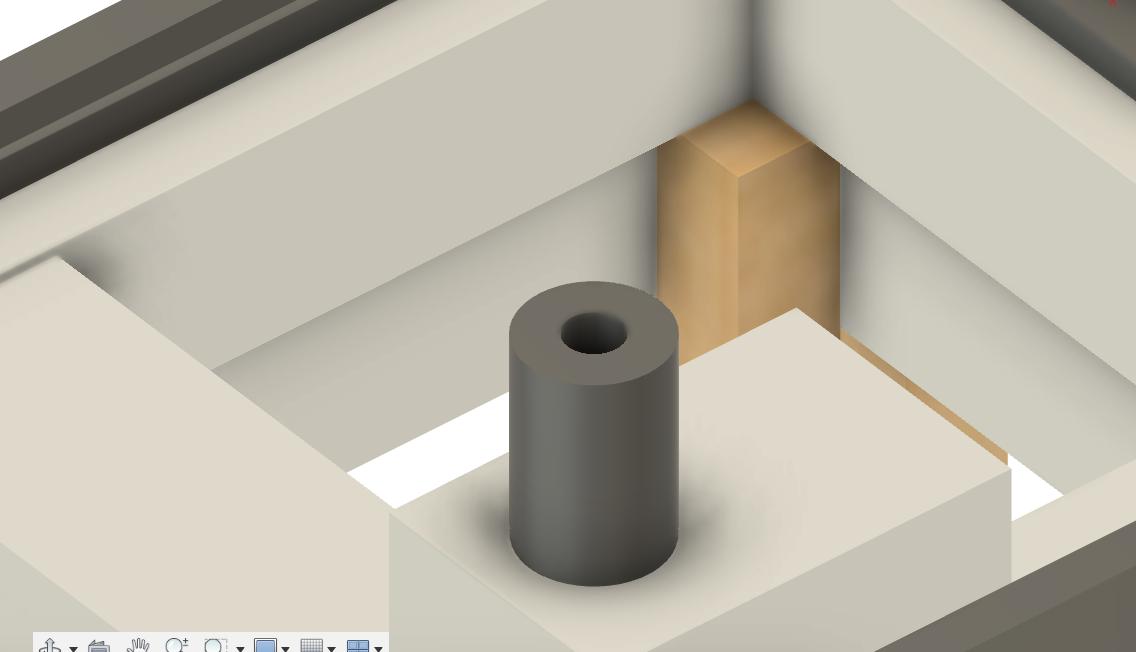

NTC holder(the gray one, this is a structure that has enough space in the middle of the holder to let the NTC thermistor through. It is stuck to the structure above the glass enclosure) | I have designed the structure in Fusion 360. This is a structure that is attached to the structure above the glass enclosure with the simplest lock. It has a small hole in the middle with the width size of the NTC themistor. I plan to 3D print it(if it doesnt melt from the butter lamp's heat.) |

|

Hinges(These are the hinges that join my door with my glass enclosure) | I have designed the hinges in Fusion 360. These are hinges I have designed in week 2 during the Computer Aided Design and I will be using the same design for my door. I plan to 3D print it. |

|

Roof (This is the roof or a lid that is hollow which lets the hot air rise up to the prayer wheel.) | I have designed the roof in Fusion 360. The lid is the overall closing of my full final project enclosure. It is hollow in the middle that lets the hot air from the buttr lmap's flames rise up and direct it to the prayer wheel to spin it. It wil be fixed to the structure above the glass enclosure with the press fit idea. I plan to 3D print it |

|

Prayer wheel pivot(this is the structure that holds the support needle of the prayer wheel.) | I have designed the pivot in Fusion 360. The pivot is going to be right above the structure above the glass enclosure. There is usually a support needle for the prayer wheel that holds it up and supports free movement of the prayer wheel. This pivot is going to be laser cut. It will be sliced using the Slicer for Fusion 360 |

|

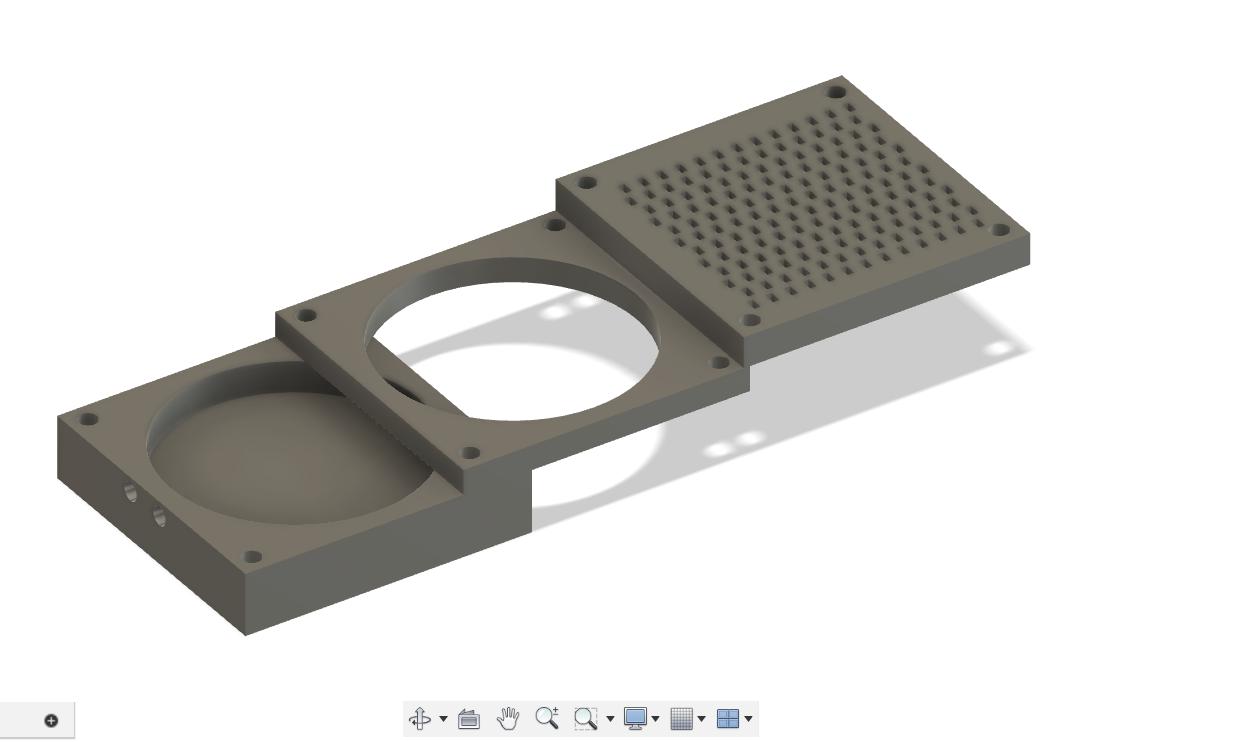

Resonance Chamber(this is an enclosure where my speaker will be placed to amplify the prayers) | I have designed the Resonance chamber in Fusion 360. The Resonance chanber has three parts. The enclosure is of an idea by CUIDEVICES.COM Here is why each layer is important according to CUIDEVICES.COM The speaker is protected by the hole pattern and spacing in the front cavity, which also allows for sound transmission and pad movement. The middle section of the enclosure provides a balanced environment for sound resonance, optimizing audio quality.The rear cavity prevents sound leakage and interference, ensuring clear audio quality. I plan to user the CNC machine or laser cut it. |

What materials and components will be used?

The Materials and Components that will be used

| Materials and Components (Physical Components) | What for? |

|---|---|

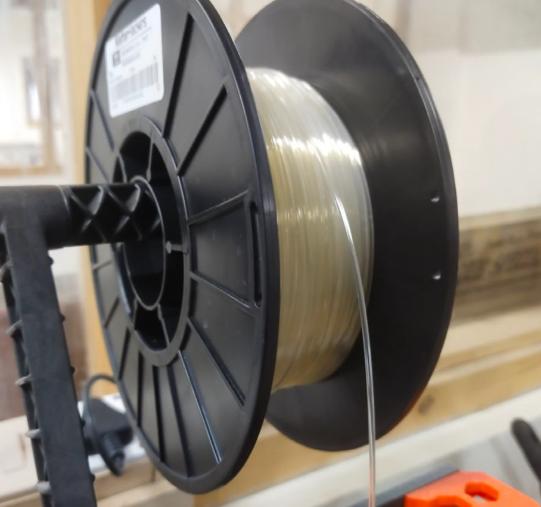

PLA and XT Filament

|

For my 3D printed components:

|

CardBoard

|

For my laser printed components:

|

What materials and components will be used?

The Materials and Components that will be used

| Materials and Components (Electronics) | What for? |

|---|---|

| XIAOESP32C3 | Microcontroller |

| NTC Thermistor Sensor | Input Device(To sense a strike in the temperature and trigger the DFplayer mini) |

| DFplayer Mini | Output Device(To be triggered to play prayers) |

| Speaker | Output Device(To play the prayers) |

| 1 lED and a 1K resistor | Hello LED | Pin Socket 1*07 | For connecting XIAOESP32C3 | PTH 3 pin socket | For my NTC thermistor sensor | PTH 4 pin socket | For my DFplayer mini | 1k ohms | For my DF player | 2 buttons | Volume Control | Glass | 5mm for my glass enclosure |

BOM

| Components | Purchase | Amount No. | Price | Total |

|---|---|---|---|---|

| Xiao ESP32C3 | seeedstudio.com | 1 | $4 | $4 |

| PTH Socket 2PIN | robu.in | 0.2 | $0.35 | $0.07 |

| PTH Socket 3PIN | robu.in | 0.3 | $0.35 | $0.11 |

| PTH Socket 4PIN | robu.in | 0.2 | $0.35 | $0.07 |

| FHeader 5PIN | robu.in | 0.5 | $0.35 | $0.18 |

| FHeader 3PIN | robu.in | 0.4 | $0.35 | $0.14 |

| DFplayer Mini | robu.in | 1 | $3.33 | $3.33 |

| FHeader 4PIN | robu.in | 0.2 | $0.35 | $0.07 |

| 1K Resistor | robu.in | 2 | $0.00 | $0.01 |

| Tactile Switche Square Push Button / Tact Switch SMD Micro Switch | robu.in | 2 | $0.31 | $0.62 |

| ColorFabXT filament | robu.in | 1 | $25.00 | $25.00 |

| Single Sided Copper Clad Laminate PCB Circuit Board 8x12 | robu.in | 0.5 | $15.99 | $8.00 |

| 1-1/4-Inch Coarse Thread Drywall Screw Phillips Drive | robu.in | 15 | $0.00 | $0.01 |

| USB plug C-type | robu.in | 1 | $5.00 | $5.00 |

| Others (soldering tin, dupont cables) | robu.in | - | - | $5.00 |

| NTC Thermistor module | robu.in | 1 | $4.20 | $4.20 |

| Mini speakers | robu.in | 1 | $2.30 | $2.30 |

| Prayer wheel | robu.in | 1 | $1.80 | $1.80 |

| Cardboard | robu.in | 0.2 | $4.50 | $0.90 |

| Glass | robu.in | 2.5 | $1.85 | $4.63 |

| SD card | robu.in | 1 | $6.84 | $6.84 |

| Total | $72 | |||

Where will they come from?

Components(Input and Output)

Rest not included in the list is already available in the lab

| Already Availabale in the lab | Bought from robu.in and amazon.com |

|---|---|

| NTC thermistor sensor | DFplayer mini |

| Speakers | SD Card |

How much will they cost?

Total cost of components(bought)

| Components | Cost(USD) |

|---|---|

| Df player | $7.49 |

| Sd Card | $6.84 |

| Total = $14.33 | |

What processes will be used?

| 3D PRINT(Original Prusa i3 MK3S and MK3S+), (Additive manufacturing) | LASER PRINT(Epilog Edge), (Subtractive manufacturing) | Milling(SRM-20) |

|---|---|---|

|

|

|

What questions need to be answered?

How will it be evaluated?