Machine Design

Assignment 10 - Fab Academy Barcelona

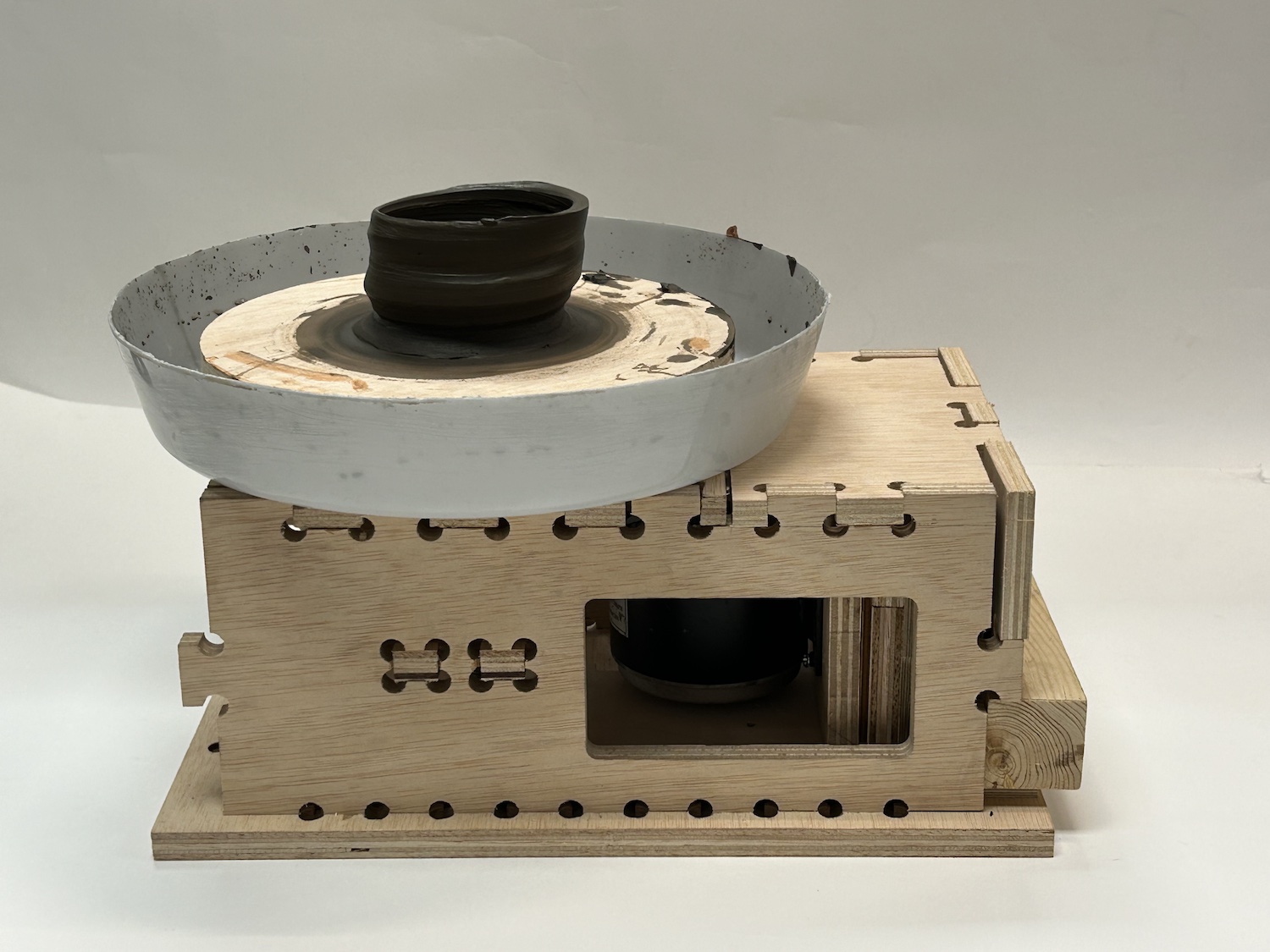

Building a Pottery Wheel

Group Work

This week we were introduced to machine and mechanical design. We reviewed different ways to actuate and automate a mechanical device. The main work was a group assignment. My group decided to create a pottery wheel.

The page documenting the group assignment work can be found here.

My Contribution

I was travelling during the group project, so unfortuantely I mostly contributed from afar. This included:

- Creating & maintaining master project plan (see below and on group page.

- Leading documentation both before and after group work - I was the main owner of the group page linked above.

- Collecting, reviewing, and commenting on design plans, photos, videos, etc. I sent design files, my feedback, and documentation back to team in Barcelona so they could incorporate into the work in the lab.

Project Plan

As lead on project management I created and maintained the progress to the below plan. Table HTML coded with help of ChatGPT.

| Phase | Date | Task | Details | Status |

|---|---|---|---|---|

| Design | 3 April | Preliminary Design Discussion | Discussion on design requirements and constraints | Completed |

| Design | 3 April | Create Detailed Design Plans | Include a stable frame: A box with a top; Design bearings and mechanical parts | Completed |

| Design | 3 April | Specification and Dimensioning | Detail specs for motor, shaft, bearings, flywheels, pulley, wheel, etc. | Completed |

| Initial Testing | 3 April | Test Drill Holes for Shaft and Bearings | Ensure mechanism is centered to prevent wobbling | Completed |

| Initial Testing | 4 April | Enclosure Fit Test | Test for snug fit of box joints fingers | Completed |

| Initial Testing | 5 April | Motor Torque Requirement Testing | Test motor with more torque if necessary | Completed |

| Construction | 4 April | Bridge Design and Fabrication | Width: 80mm, Length: 415mm, Height: 15mm; include pockets and holes for shaft | Completed |

| Construction | 5 April | Enclosure Cutting and Assembly | Start and complete the cutting, and assemble the box | Completed |

| Construction | 5 April | Mechanical Assembly | Assemble shaft, gear, mount to base and frame; install motor | Completed |

| Assembly & Integration | 8 April | Assemble wheel & box | Integrate mechanism and enclosure / box | Completed |

| Assembly & Integration | 9 April | Electronics Setup | Install and test speed control electronics | Completed |

| Assembly & Integration | 9 April | Test 3D Printed Bearing | Test leveling of the wheel plate with a 3D printed bearing holder | Completed |

| Assembly & Integration | 9 April | Final Testing and Adjustments | Comprehensive testing of electronics, and mechanical adjustments | Completed |

| Assembly & Integration | 9 April | Final Review and Quality Check | Review the project for any final adjustments | Completed |

| Launch | 10 April | Final Presentation | Present the final version of the pottery wheel for global class | Completed |

| Launch | 10 April | Documentation | Complete and push documentation on group site | Completed |

Key Learnings

These include:

- We did a good job allocating tasks based on availability, expertise, and interest. This allowed for smooth project execution.

- Clear communication is especially important when some of the team (like me) is remote.

- Regular testing at each phases helps identify issues early - it's better to test and learn quickly than churn on designs that might be thrown away.

- Components (like gears, motor, power) need to match requirements (e.g. speed and torque needed for wheel).

- Documenation is especially important when working in a group to keep everyone on the same page.