Week 15: Wildcard Week

Checklist for this week:

- ☑ Documented the workflow(s) and process(es) you used

- ☑ Described problems encountered (if any) and how you fixed them

- ☑ Included original design files and source code

- ☑ Included 'hero shot' of the result

Task for this week

Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it. Possibilities include but are not limited to wildcard week examples.

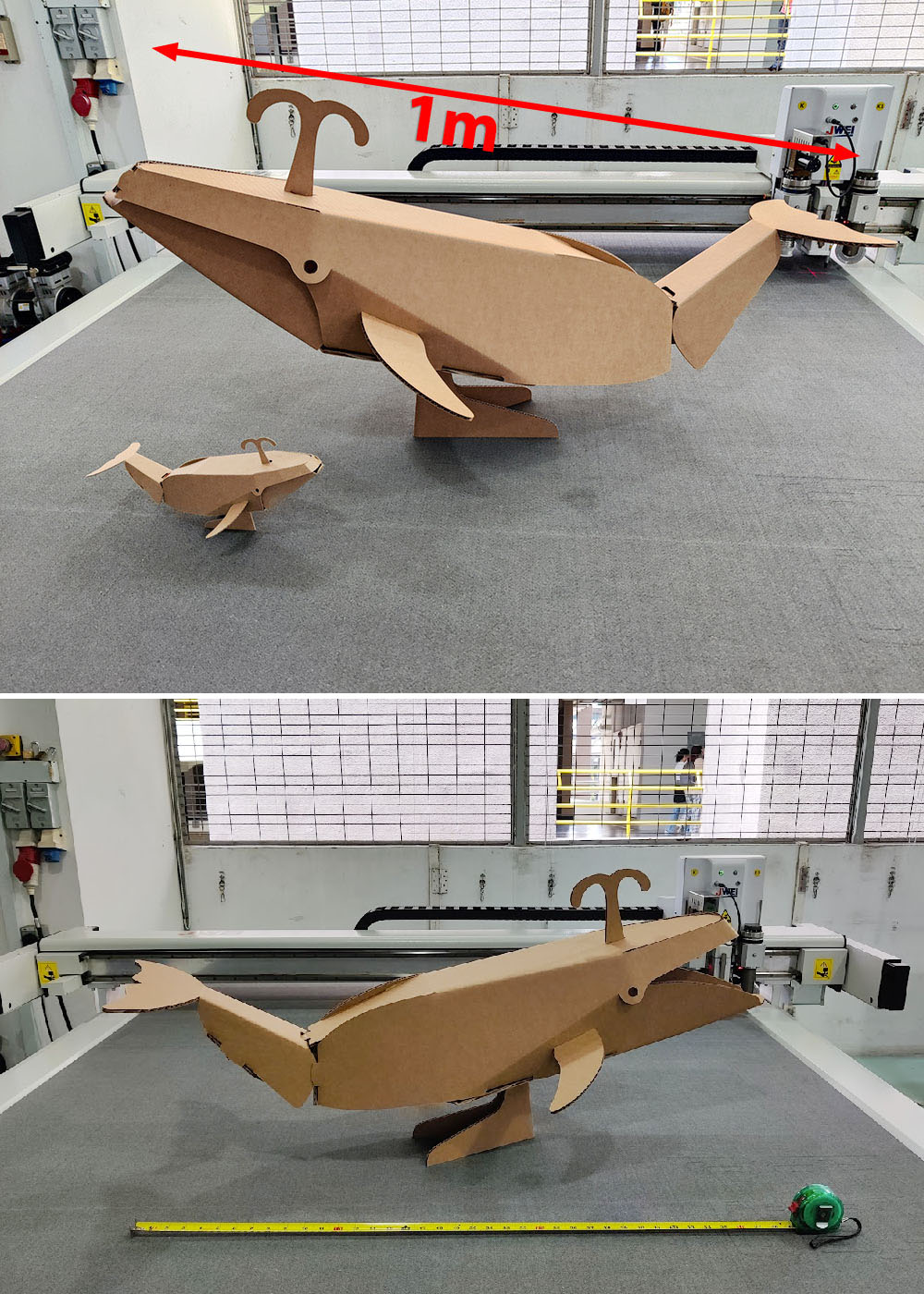

The Tiny

I absolutely adore wildcard week- it has been the most delightful week thus far, although not necessarily the easiest. Amidst the exhilarating rush to complete the project featuring an impressive 8-meter cardboard whale and seven additional sculptures, I also took on the ambitious task of crafting 1000 sets of mini cardboard whales to engage the younger audience. While a static sculpture would be appealing, I aspire to transform it into an automata, adding an extra layer of intrigue. Though the construction process may involve some complexity, particularly for the moving parts, it serves as a delightful challenge for participants to tackle and conquer.

Throughout the Global Open Time from last saturday, the community has displayed remarkable kindness and provided me with a multitude of inspiring ideas to further enhance the whale project.

The Process

The process involved the creation of a 3D digital model, followed by its conversion into 2D templates, and eventually bringing it back to life in 3D physical form.

To initiate the process, a low-resolution polygon 3D model was crafted using Blender 3D. As there are numerous YouTube tutorials available on this topic, I won't delve into the specifics. However, I did document a time-lapse video during Week 3, showcasing the creation process in Blender. Once the 3D model was completed in Blender, it was exported as an OBJ file.

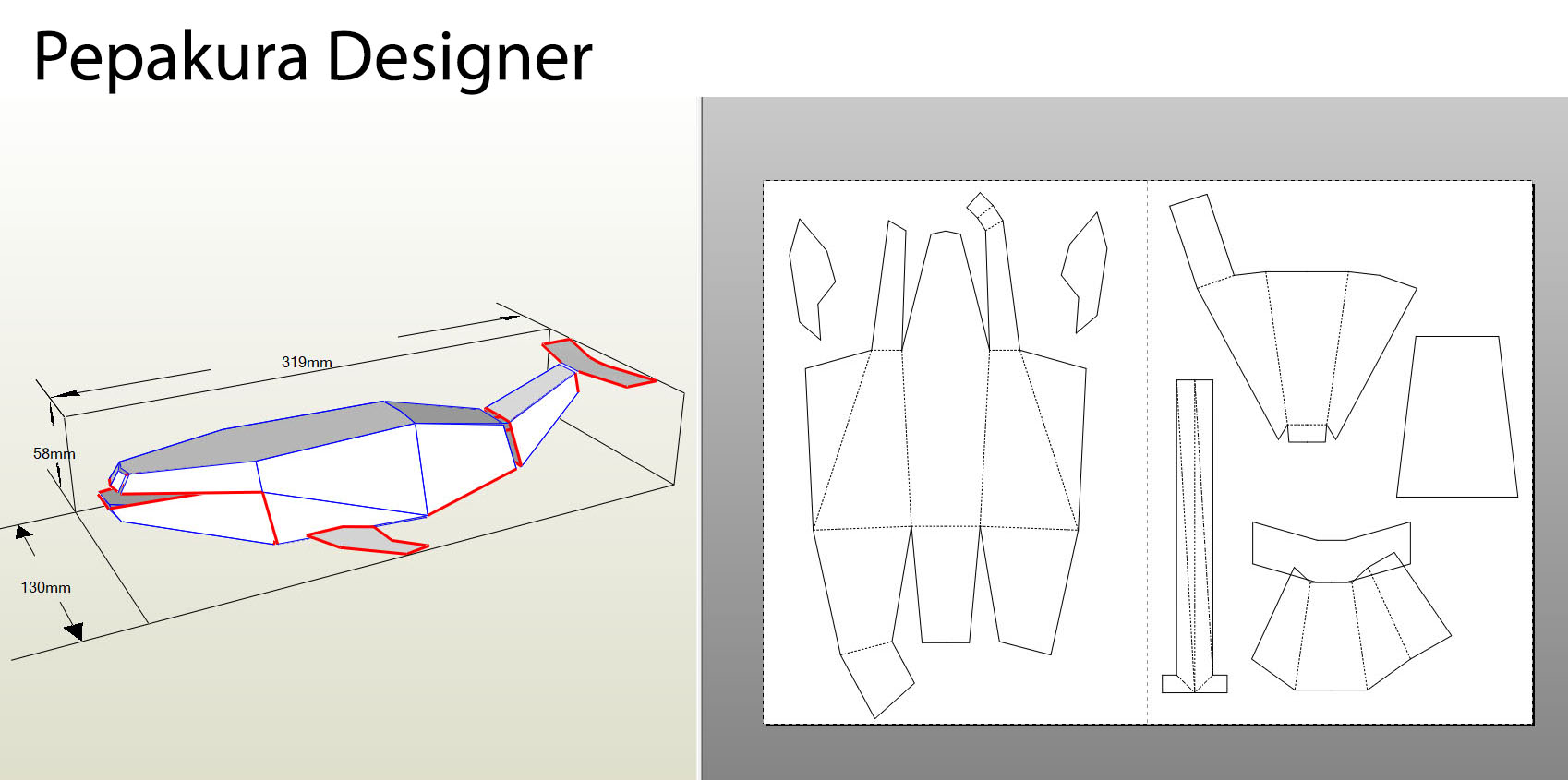

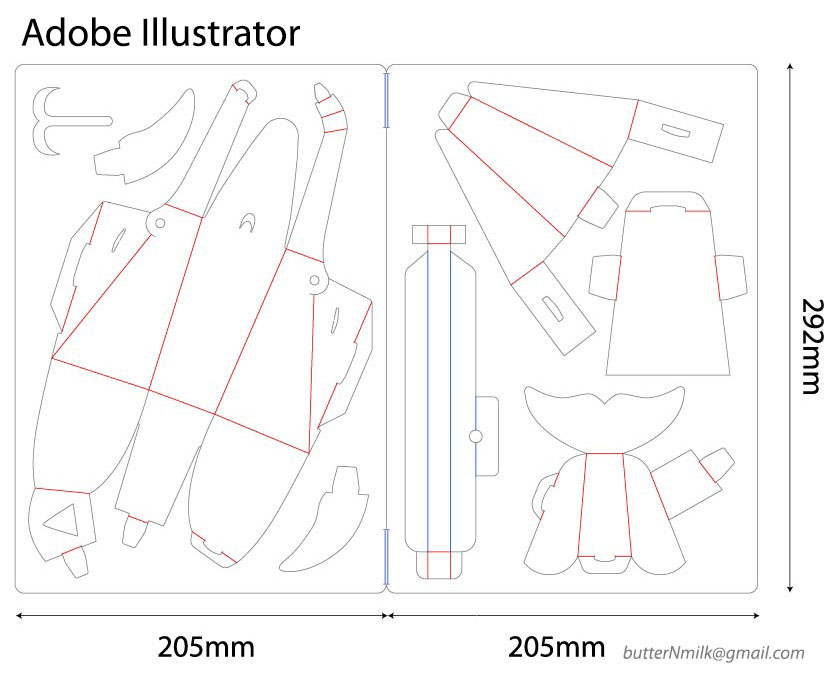

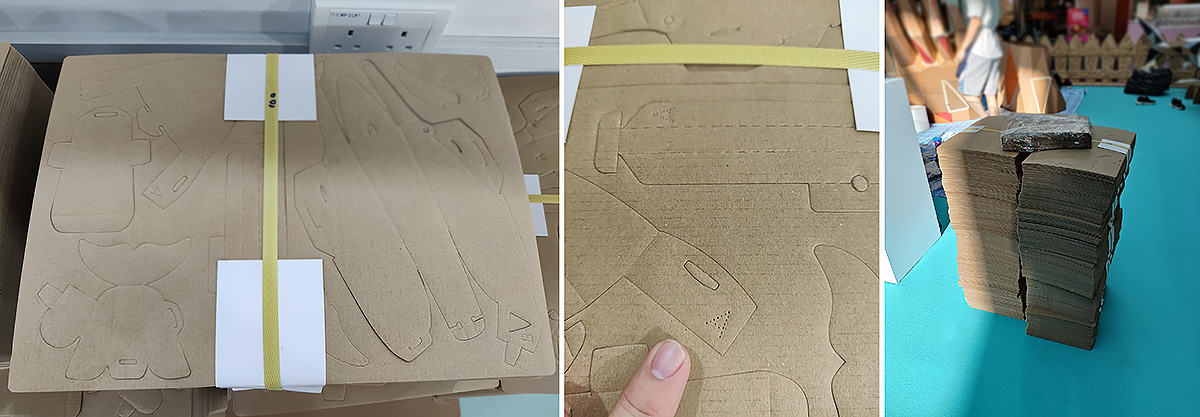

The OBJ file was then imported into Pepakura Designer for the purpose of unfolding the model. This step yielded a preliminary version of the mini whale templates. Subsequently, the templates were rearranged in Adobe Illustrator before proceeding with the cutting phase. In illustrator, I included tabs to eliminate the need for adhesive when assembling the mini cardboard whale.

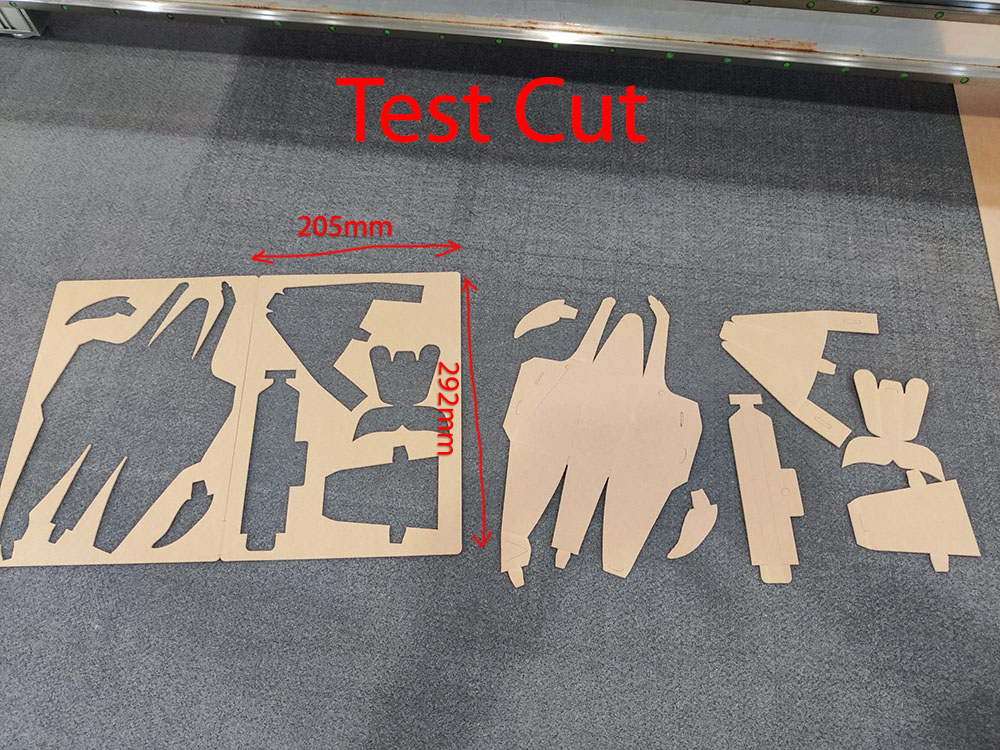

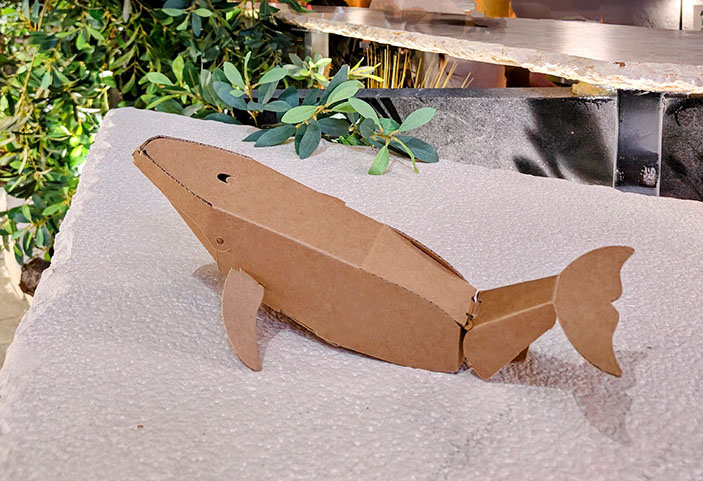

The next step involved attempting to cut out the templates using the Jwei Flatbed cutting machine. To expedite the process, I utilized masking tape to join the edges, enabling me to have the first 3D cardboard prototype in my hands as quickly as possible. Following that, I created several more mini whales with slight variations, resulting in no fewer than five initial prototypes of different sizes.

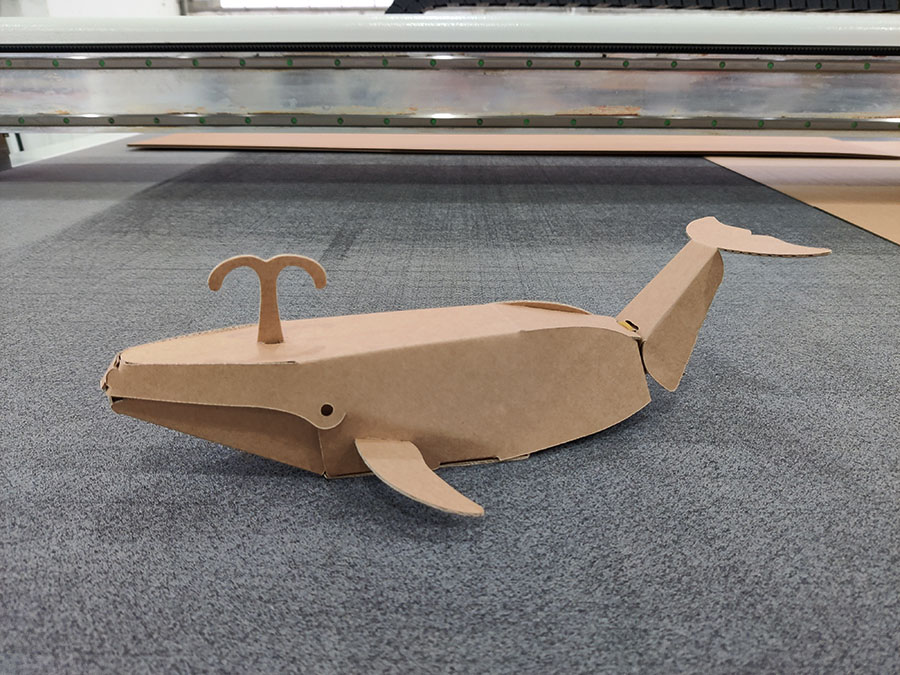

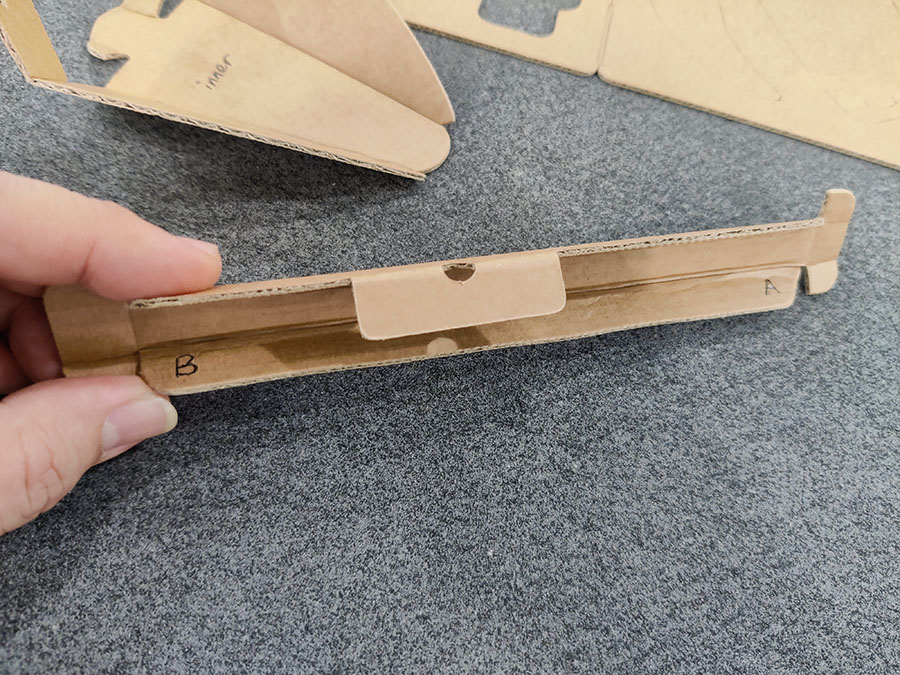

The image below showcases the mini whale after undergoing five or six iterations. A shaft was implemented to facilitate the opening of the mini whale's mouth using a rubber band.

The Challenge

One of the most significant hurdles I encountered was ensuring the proper functionality of the moving part, specifically the mouth. Determining the ideal length of the shaft proved to be critical, and although I could estimate it within the 3D software, testing it in real life presented an entirely different challenge. To find the optimal measurement, I resorted to cutting several shafts of varying lengths. It was crucial for the mouth to close perfectly and not excessively stretch when fully opened. To achieve this, I employed a rubber band to smoothly return the mouth to its original position.

Hero Shot of Mini Cardboard Whale

Instruction Video

Below is the instruction video for the 1000 participants over 3 weekends.

We updated the instruction videos in following week and mass-produced the mini whales in thousands. To watch the instruction video on Youtube: https://for.edu.sg/whale or preview a low-resolution video below.

The flatbed cutting machine could be used for making functional furniture on campus. (project back-dated to April 2022)

Links to working files

- Mini Whale Blender File (3D) (.blend)

- Mini Whale Pepakura File (.pdo)

- Mini Whale Illustrator File (.ai)