moulding and casting

Molding is the act of creating the cavity / form that carries a negative or reverse impression of an original model.Molds can be made of a rigid material, such as plaster or plastic resin or more commonly, a flexible material such as rubber.

The material to use should be chosen considering the material of the model, the material to be used to make castings,

and whether there are any undercuts.

casting is the act of pouring liquid material into the cavity of a mold. After a period of time, this liquid will cure via

chemical reaction or cooling. The solidified part is also known as a casting, which is ejected or broken out of the mold to

complete the process. Casting materials are usually metals or various cold setting materials that cure after mixing two or more

components together; examples are epoxy, concrete, plaster and clay.

as we use different mould materials we deal with safety issues in a group assignment we focus on safety datasheet https://fabacademy.org/2023/labs/rwanda/Group_Assignment/molding_casting.html group page

for this assignment i have started design through CAD softawe (solidworks) i had an idea for making sledge hammer

i started making sketch and determines the length of my material as i have used wax,

so i have designed my mold according to wax size that i have

the idea of the object came from nowhere, which i started making sketch, and the first sketch is all about masking with the size of material

.png)

besides the sketch i drew the circle and then i add something as a corner on it

.png)

then i add inside small circle, after sketching i clicked on extrude on top from tabs to make solid part

.png)

from the extruded part i drew sketch from the face of the part like a hexagon draw given fillet to corners

.png)

then after i used the extruded cut tool to cut from solid part

.png)

.png)

and also i have added half circle on the other face to cut from the object

.png)

so the following step is to make mold, i have used assembly design process

i saved what i made in part so i opened new design in assembly,

.png)

the technics here to make mold is easy

i clicked on assembly new part then i have made a part like a box that is larger than my design

the box actually has the same size with my mold the wax i have used

the box are two pieces both up and down sides, though i have designed two boxes in assembly to make mold from them

.png)

when done making boxes the following step is to make a mold

fist select one part of the boxes and open it as edit

from tabs click insert >> molds >> cavity then i am asked to choose the solid part to make mold from

.png)

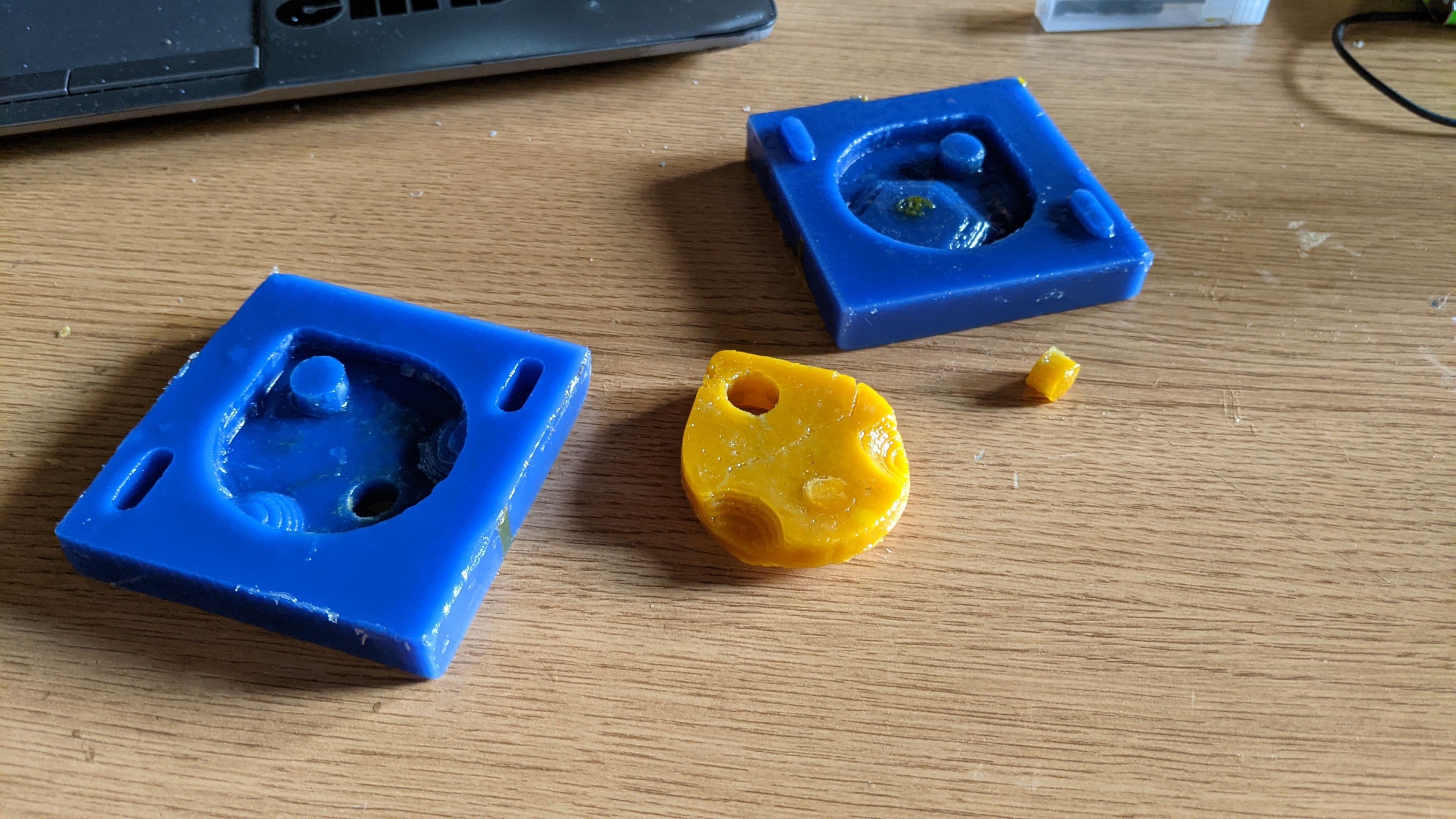

for making successfull mold i had to and two knobs to avoid molding process splitting aside or aligning them correctly

.png)

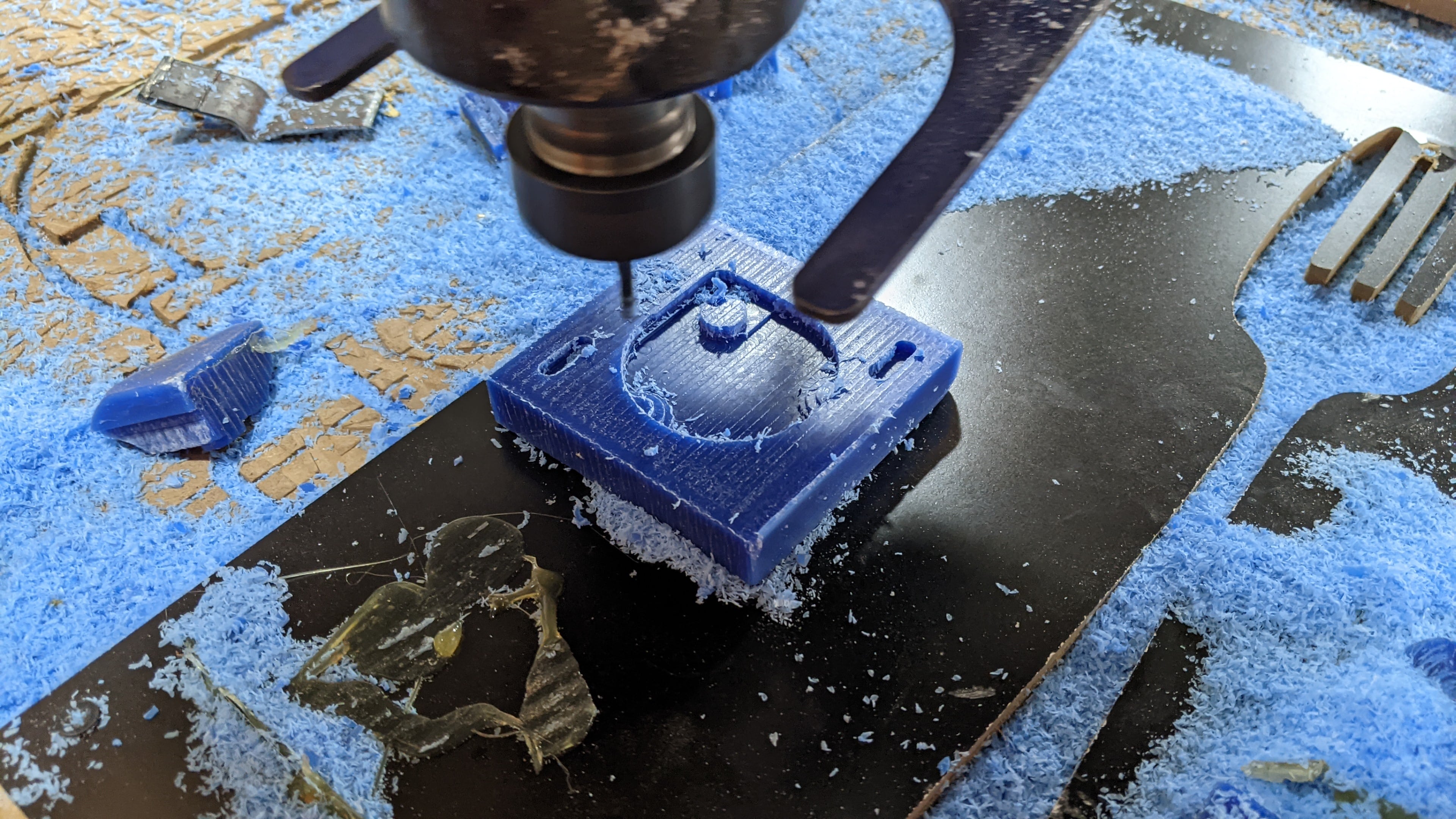

on one side they are two holes and the otherside there're tknobs so that they fit each other

.png)

preparing for molding

opened vcarve softaweto prepare for tool and machining.png)

.png)

sending work on cnc machine refer to this ink how to start cutting from cnc machine it is a work i have done in recent week link HERE

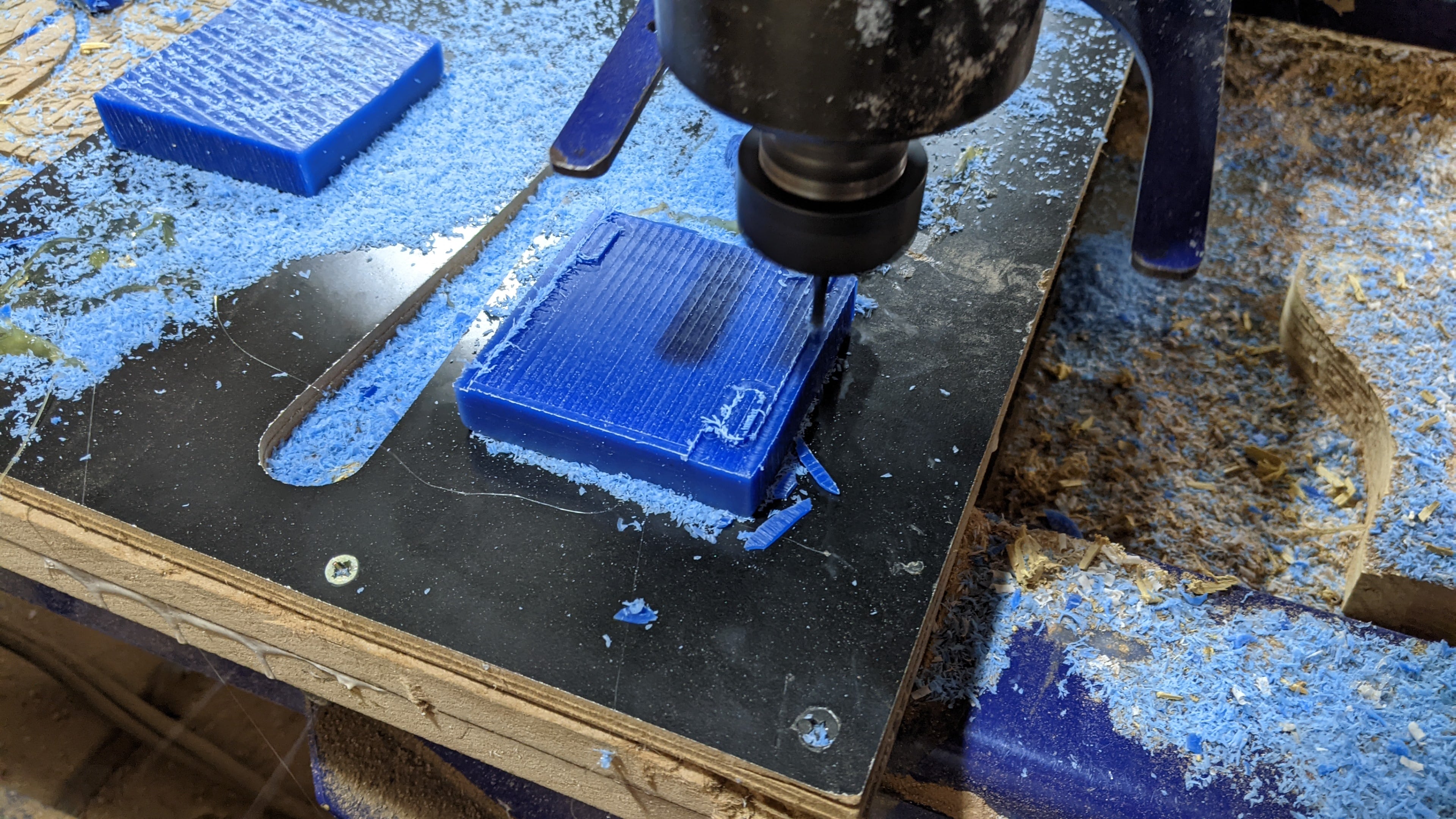

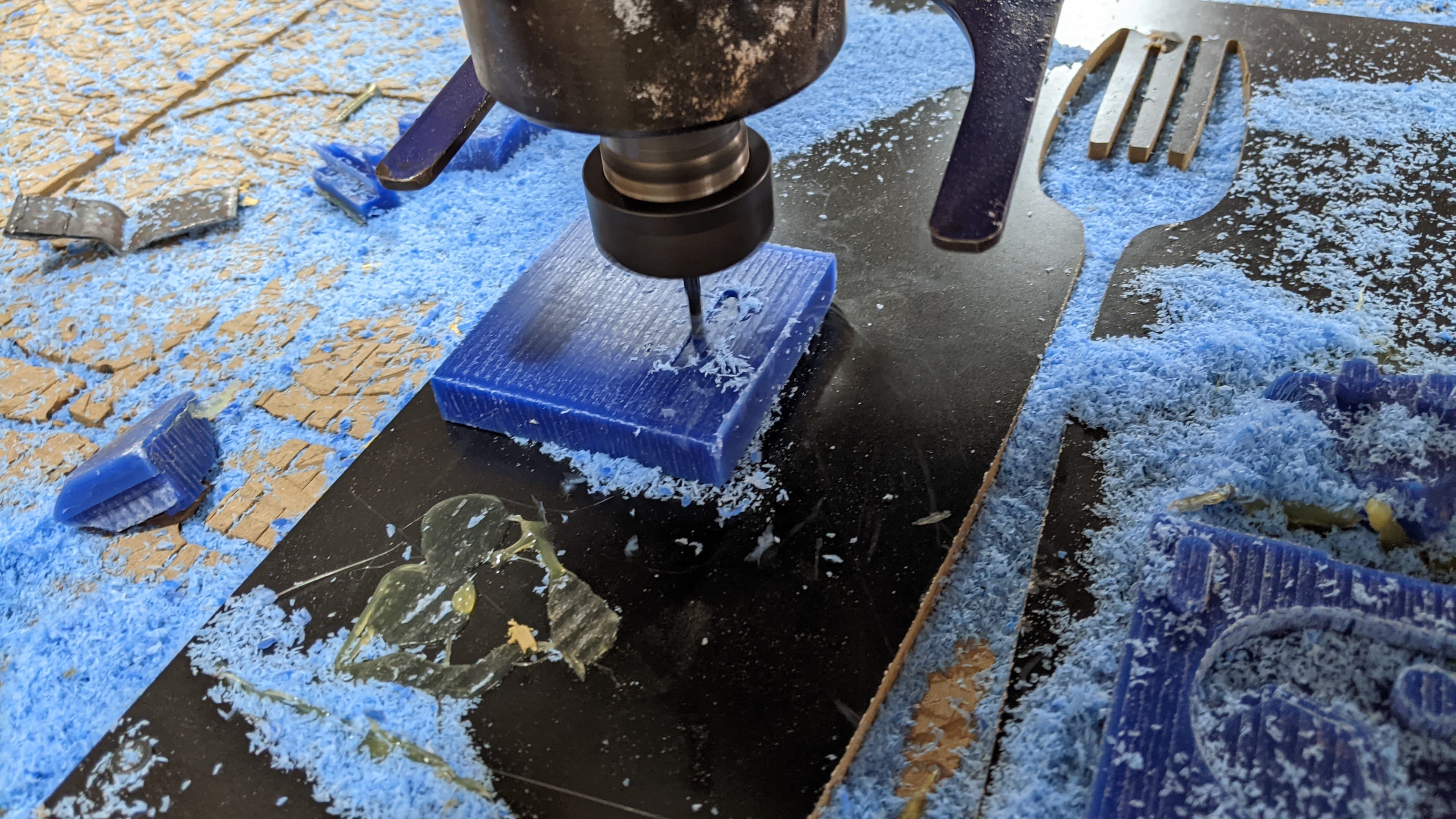

starting curting the part one

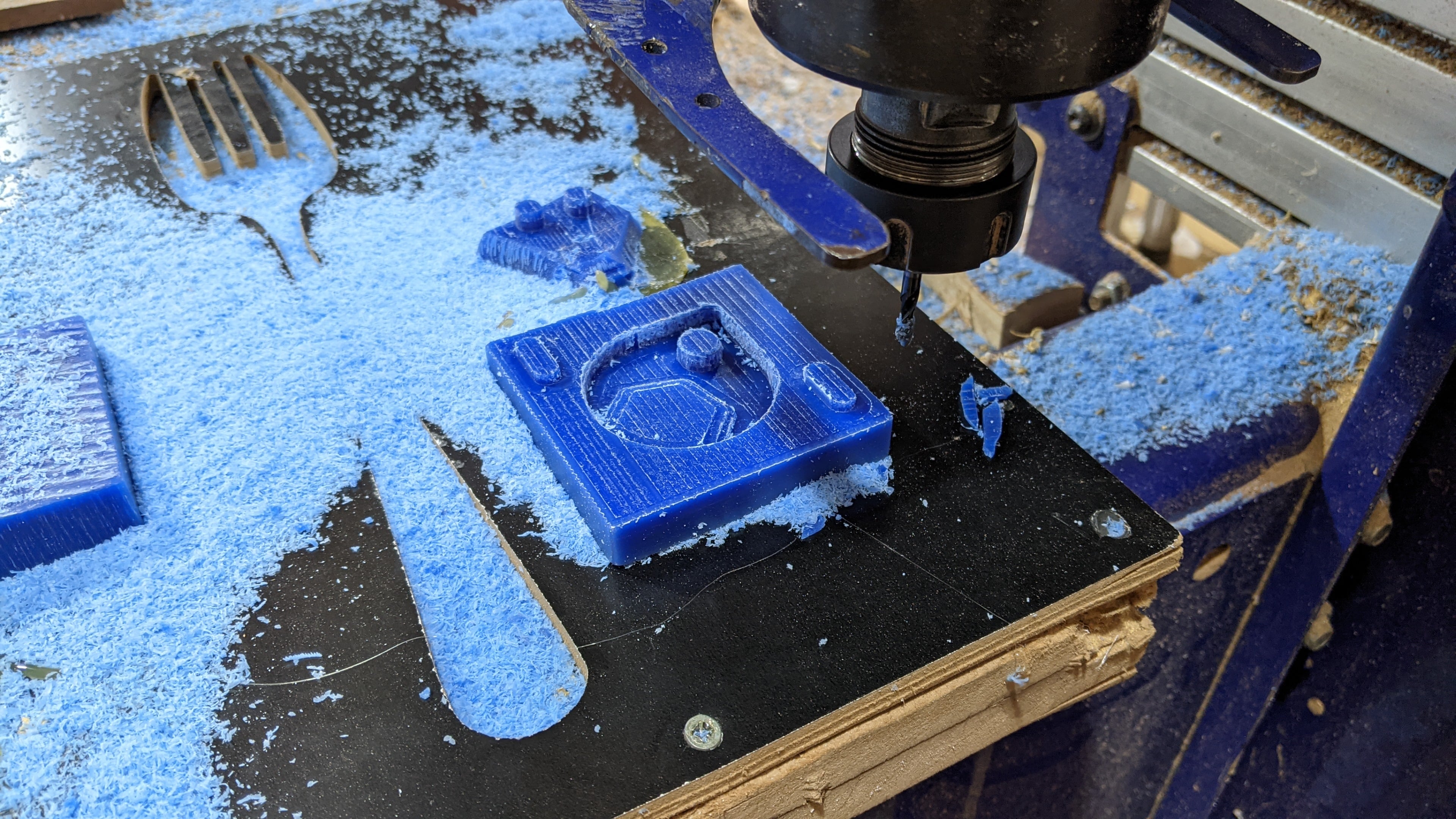

starting to cut the second part of the mold

preparing for materials to be used

in our lab we have used the beewax as we have it around

bee wax is good material that has properties suitable for molding

follow the given link explains all about beewax wax learn more about beewax

we have used the oven to melt the beewax

after making mold i realized that i have to avoid honey wax may stick to honey wax so i tried to use kitchen oil

to protecting it from sticking on material

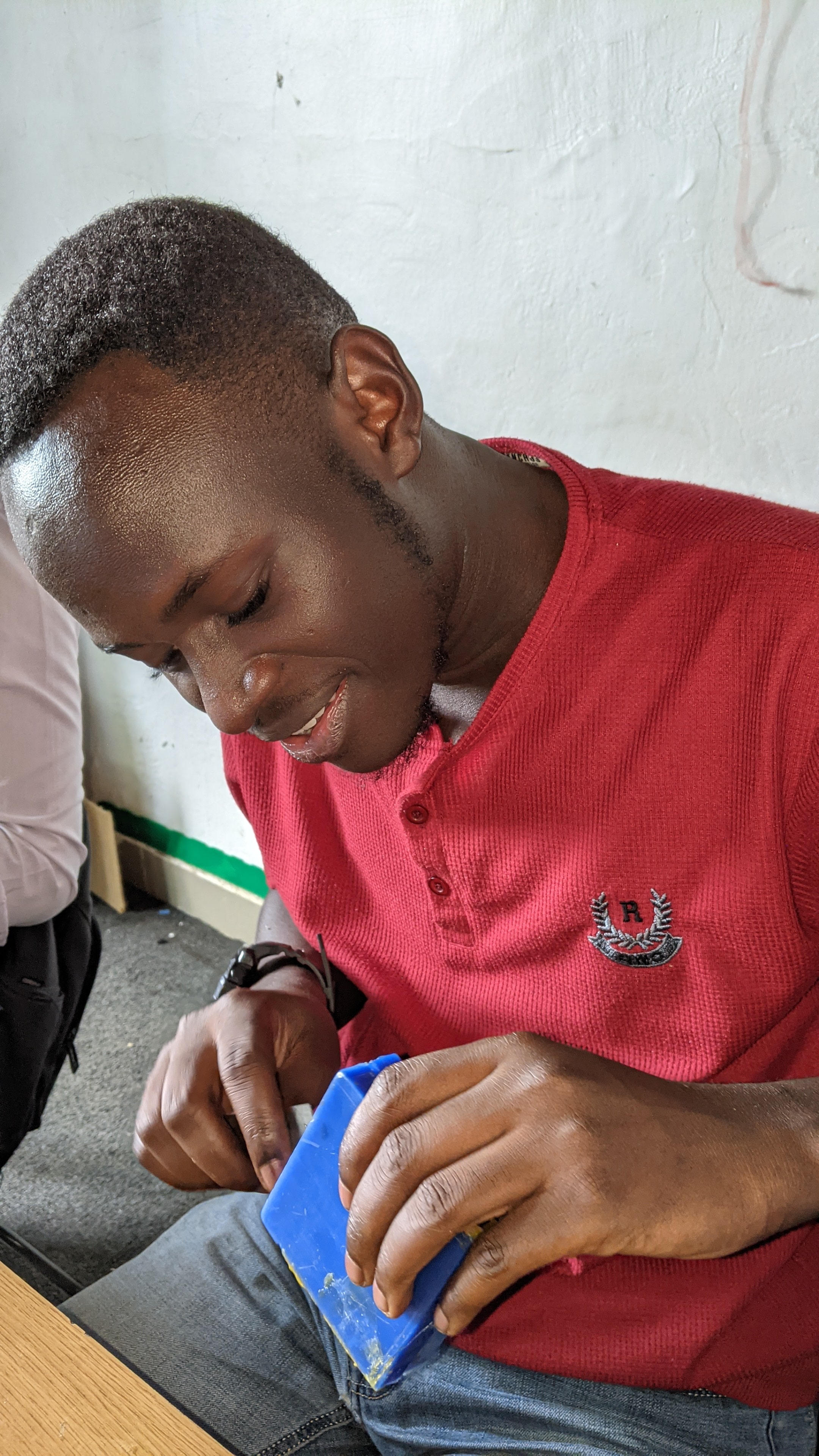

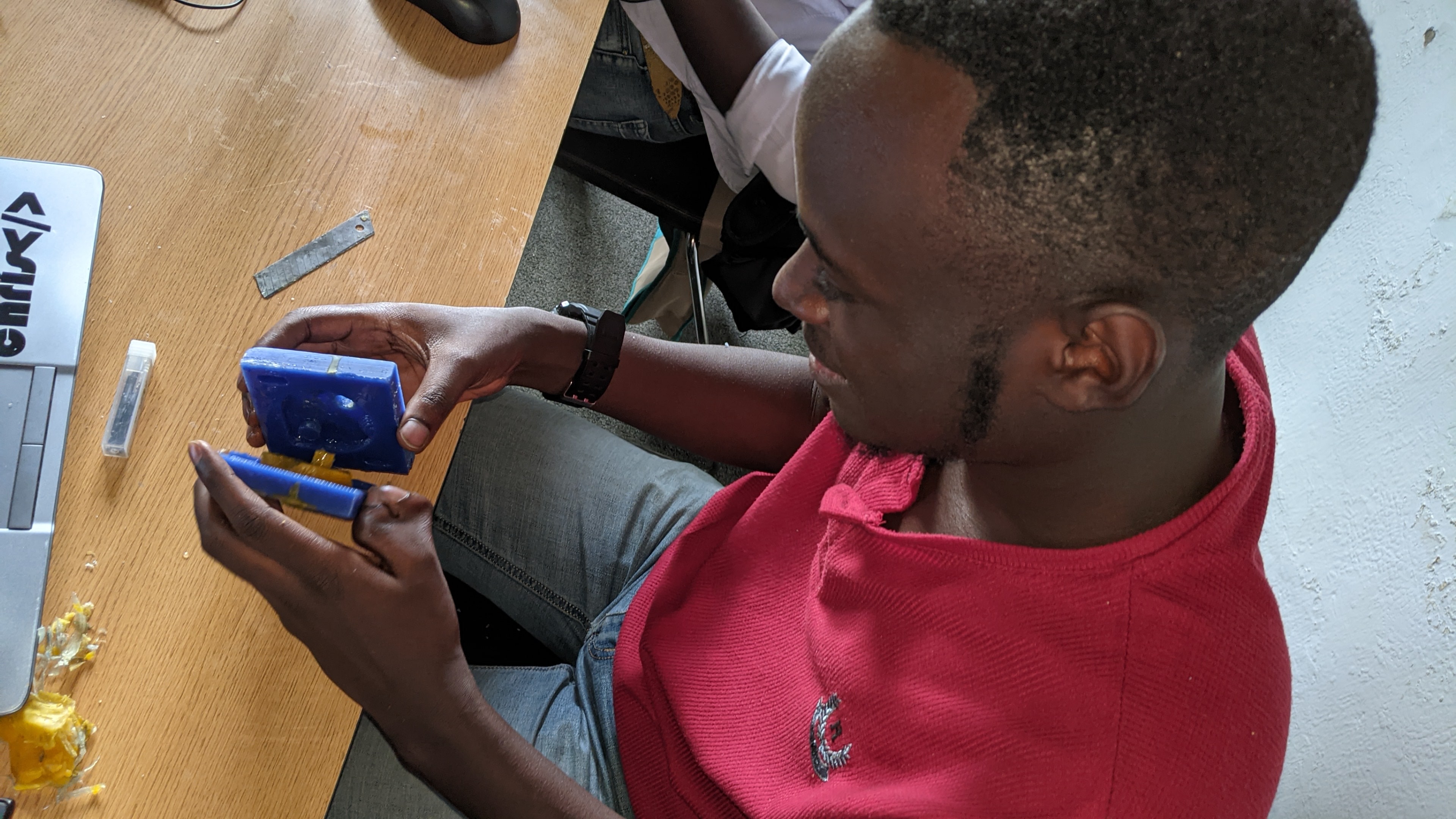

after waiting for 20min i started separating two parts of mold using cutting knife

excited! i opened the material separately ended

the final result i have got was as i expected but the other side was having some rough particle because mould did not fill well enough