Holow screw on spikes for final project

List of task this week

- Model (raster, vector, 2D, 3D, render, animate, simulate, ...) a possible final project

-

Compress your images and videos

-

Post a description with your design files on your class page

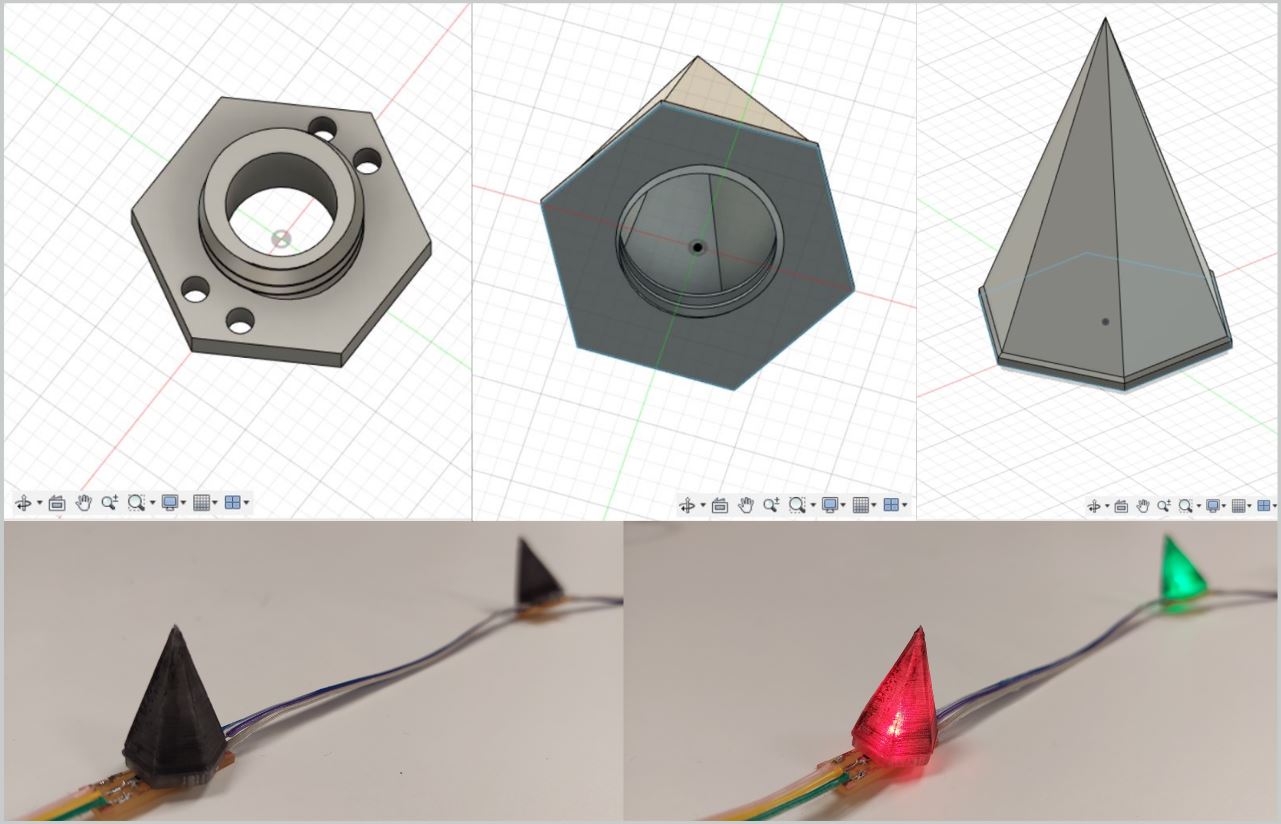

Bottom of spike modeled in Fusion 360

My knowledge of fusion 360 is pretty limited I have really only done one project in it before,

but my coworkers use it allot so I decided that it would be my pick for 3D modeling.

I used the Create Sketch tool and picked the “floor” phase, I used the Polygon and made it a 6

corner one so it would be a hexagon and made it 16.166mm on the wide side. I right clicked on the

hexagon and selected push/pull and pulled it up 2mm. Sketched a circle on top of the hexagon and

made it a diameter of 8.485mm and pulled it up 3mm. I sketched another circle on top of the last

one but made that one a diameter of 6mm down to the bottom to make a hole through. To put threading

on the cylinder and made sure to take a screenshot of the settings there so I would have them later

when I make the top. I made the threading by going to create and selecting thread and selecting the

cylinder part and pulled it in 4.433. I made little circles on the hexagon and pulled down to make

holes. At the end I sketched a center rectangle on the bottom and pulled 1.5mm up to make space for

the led. A coworker pointed out that I should make different components for different parts, so I made

it so the bottom was one component and put the spike in a separate component.

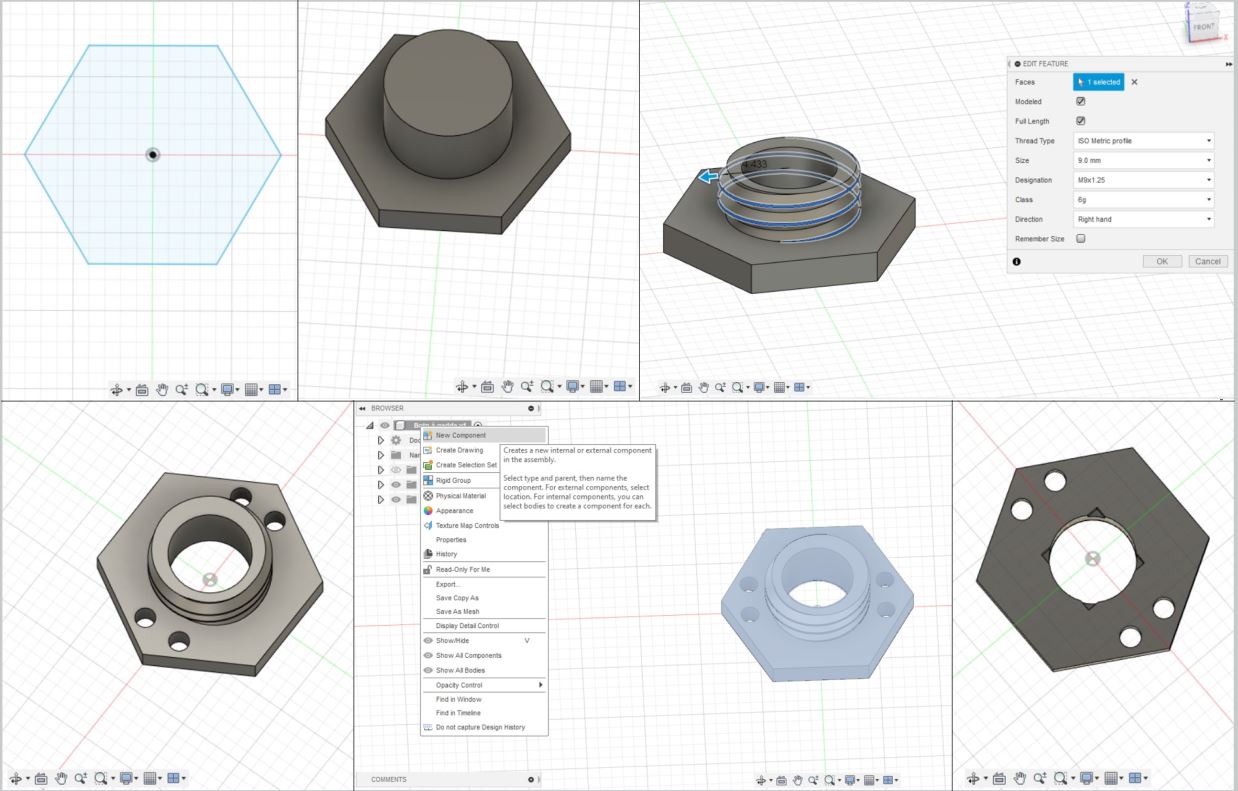

Holow spike modeled in Fusion 360, screw part

I tried to make the spike all in one go but was not successful, I realized that the roof tool fills even if you

have two walls so I did the screw part separate and then the hollow spike separate.

So, after my first attempt failed I started with the screw part first. I went in to sketch and made a hexagon,

pulled up just like described above. I sketched a circle and pulled down. Put threading on the inner cylinder and

made sure to take a look at the screenshot of the settings and make them the same. I didn’t want there to be a base

and then a spike so I used the chamfer tool to adjust the sides so when I put the spike on it would not be in the way.

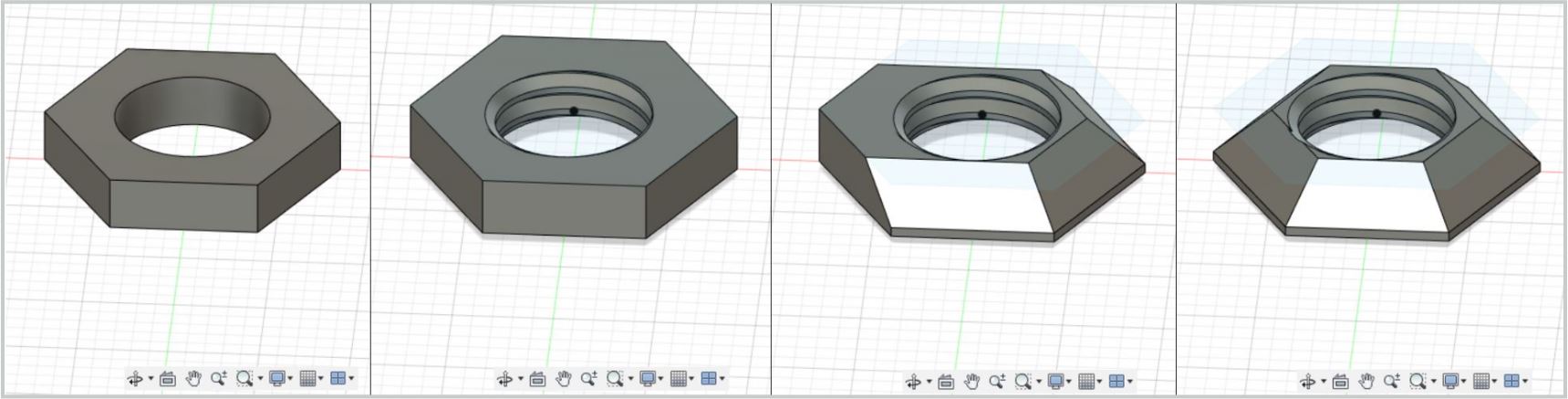

Holow spike modeled in Fusion 360, spike part

To make the spike I went in to sketch and made a hexagon and a line from the middle of the hexagon to 21mm height, selected

both went into create and used the tool loft. Made another one the same way only a little smaller to take out of the bigger

one to make 0.5mm thick walls.

Having both parts of the spike I used the tool combine

Trying Gimp to editing images

I used to just use Inkscape to get photographs ready to raster in the laser but a colleague of mine

always uses Gimp so I decided to try that.

I opened Gimp and dragged in an image. I went into Colors and selected Colorize and took the

saturation down to 0 to make the image black and white. I went into colors and selected Brightness-contrast,

there I changed the brightness and contrast until I thought It was extreme enough to raster onto wood.

To do a little more I played with the filters to get a feeling for that, here are some of my favorites.