Computer controlled cutting

Introduction:

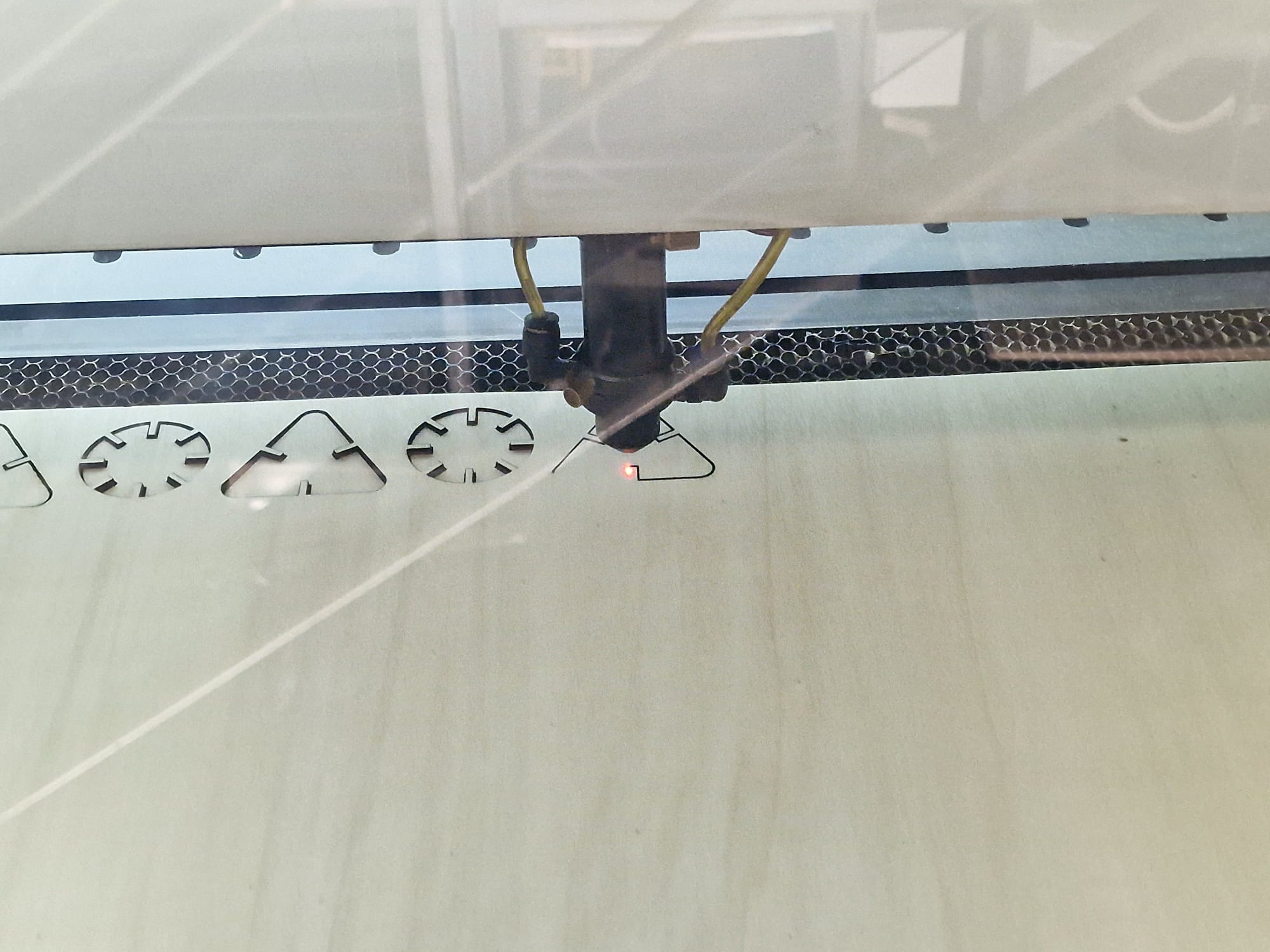

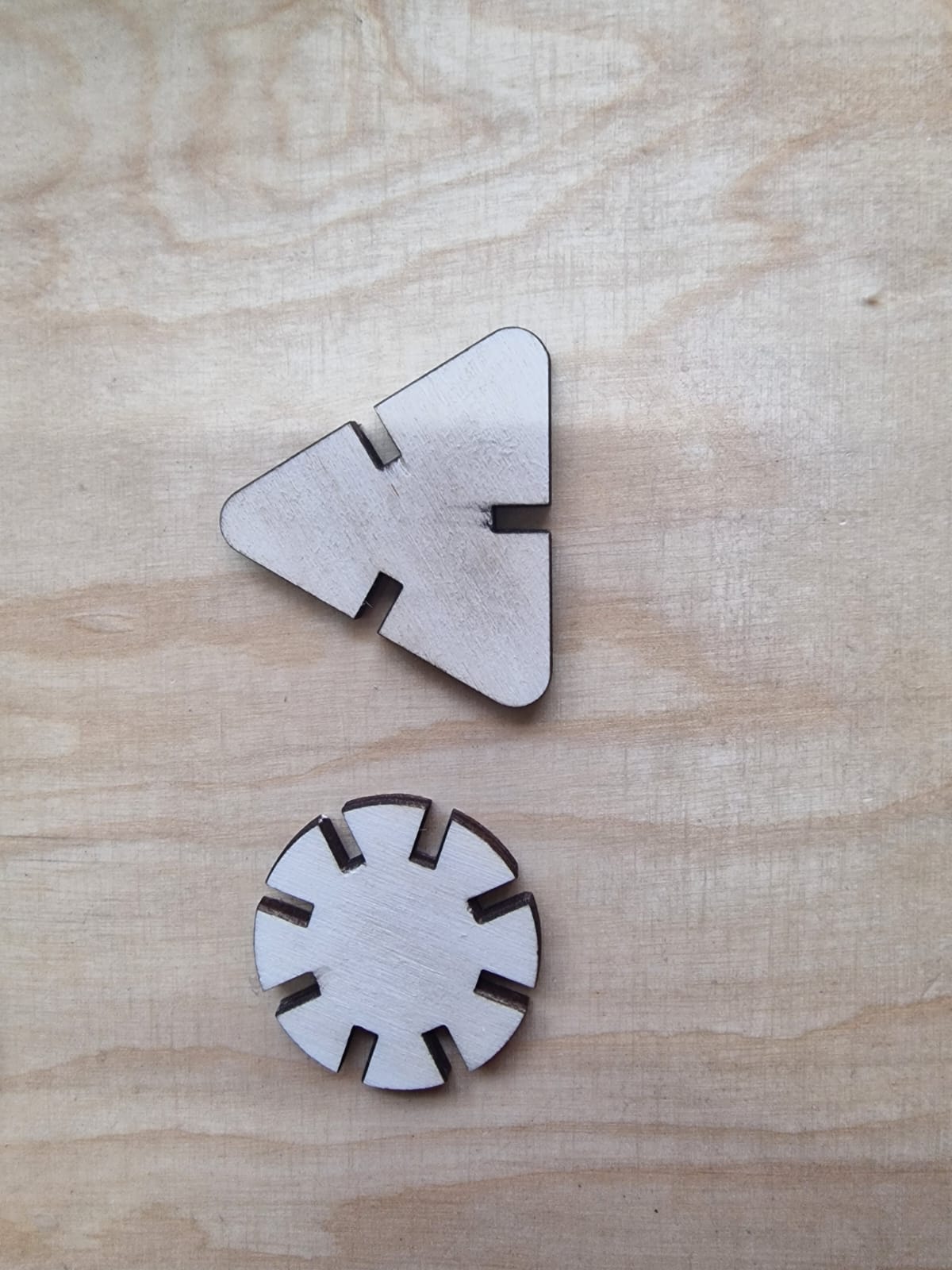

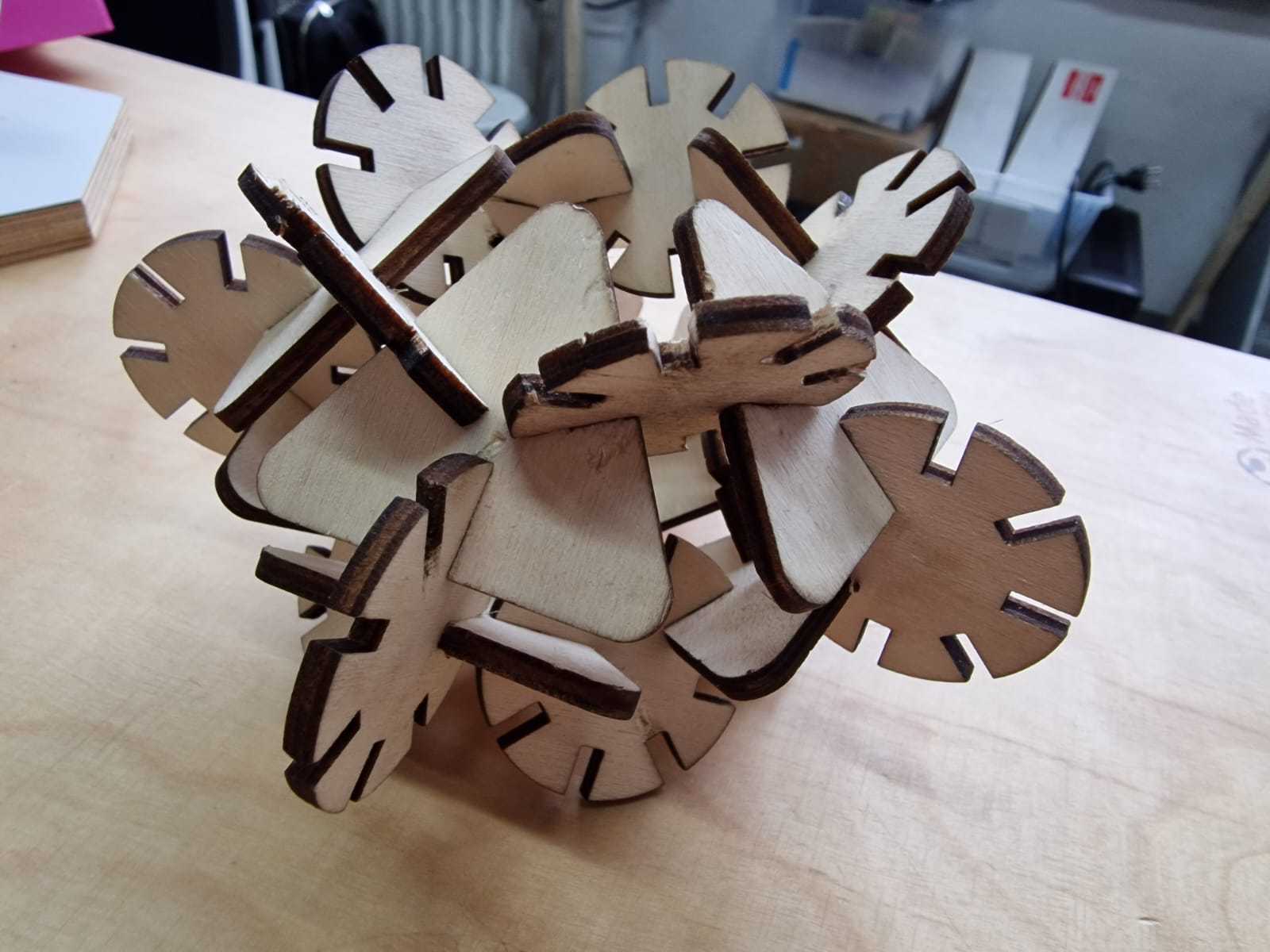

For the individual assignments, I have designed, lasercut, and

documented a parametric construction kit with the consideration of

lasercutter kerf. The objective is to create a versatile assembly system

using two fundamental geometries—circles and triangles. By strategically

introducing gaps at different positions, the components can be

fit-pressed in multiple ways to achieve a variety of constructions.

Research:

Computer-controlled cutting (also known as CNC cutting) is the process

of using a computer-controlled machine to cut, carve, or engrave

materials with precision and accuracy. This technology is commonly used

in various industries, including manufacturing, construction, and

design.

The machine used in computer-controlled cutting is called a CNC router,

which is typically controlled by software that allows the user to design

and input the desired pattern or shape to be cut. The machine uses a

cutting tool, such as a router bit or laser, to cut the material

according to the programmed design.

Computer-controlled cutting can be used on a variety of materials,

including wood, plastic, metal, and even fabric. It is commonly used in

the production of furniture, cabinetry, signs, and other decorative

items, as well as in industrial manufacturing for precision cutting and

shaping of metal parts.

Design process:

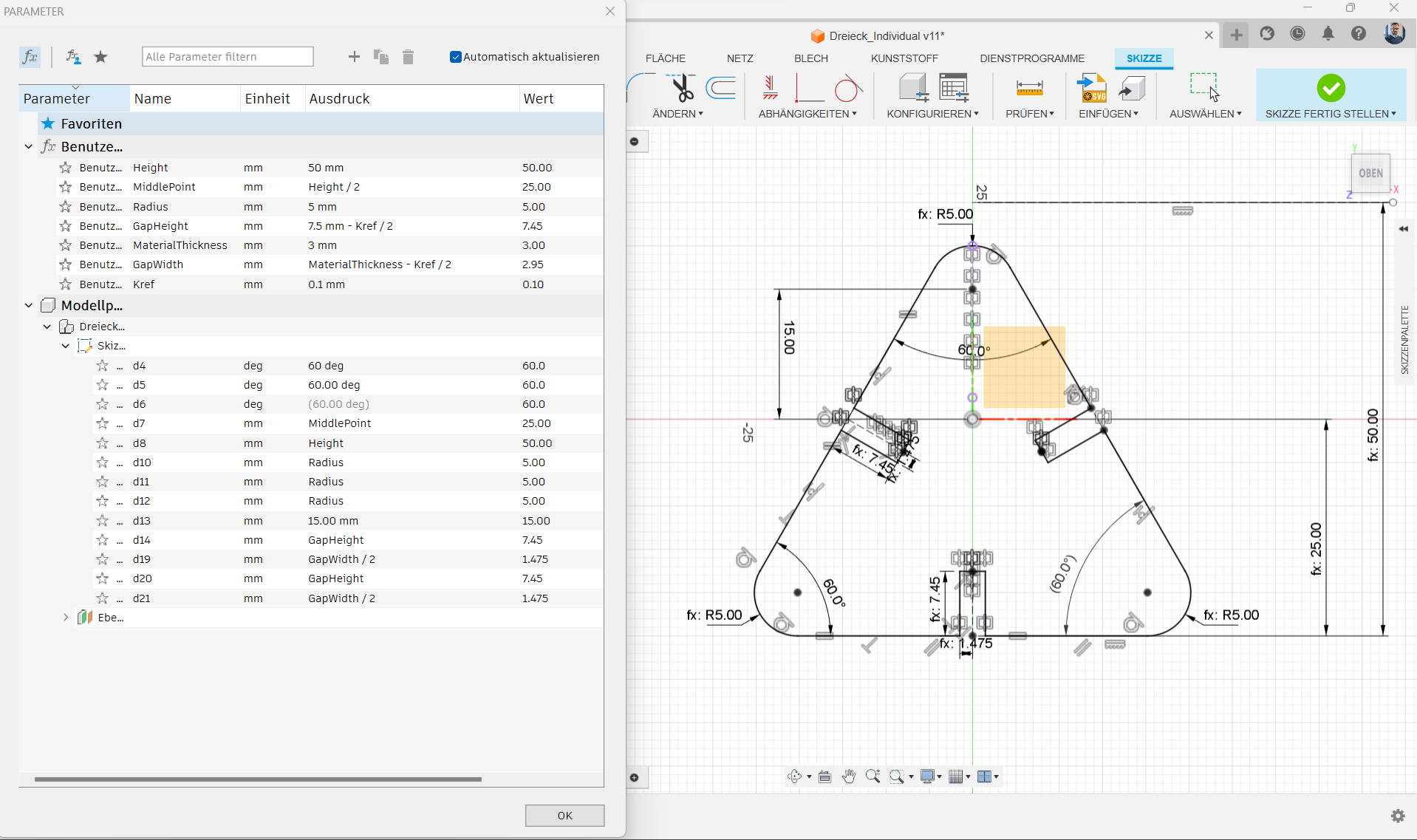

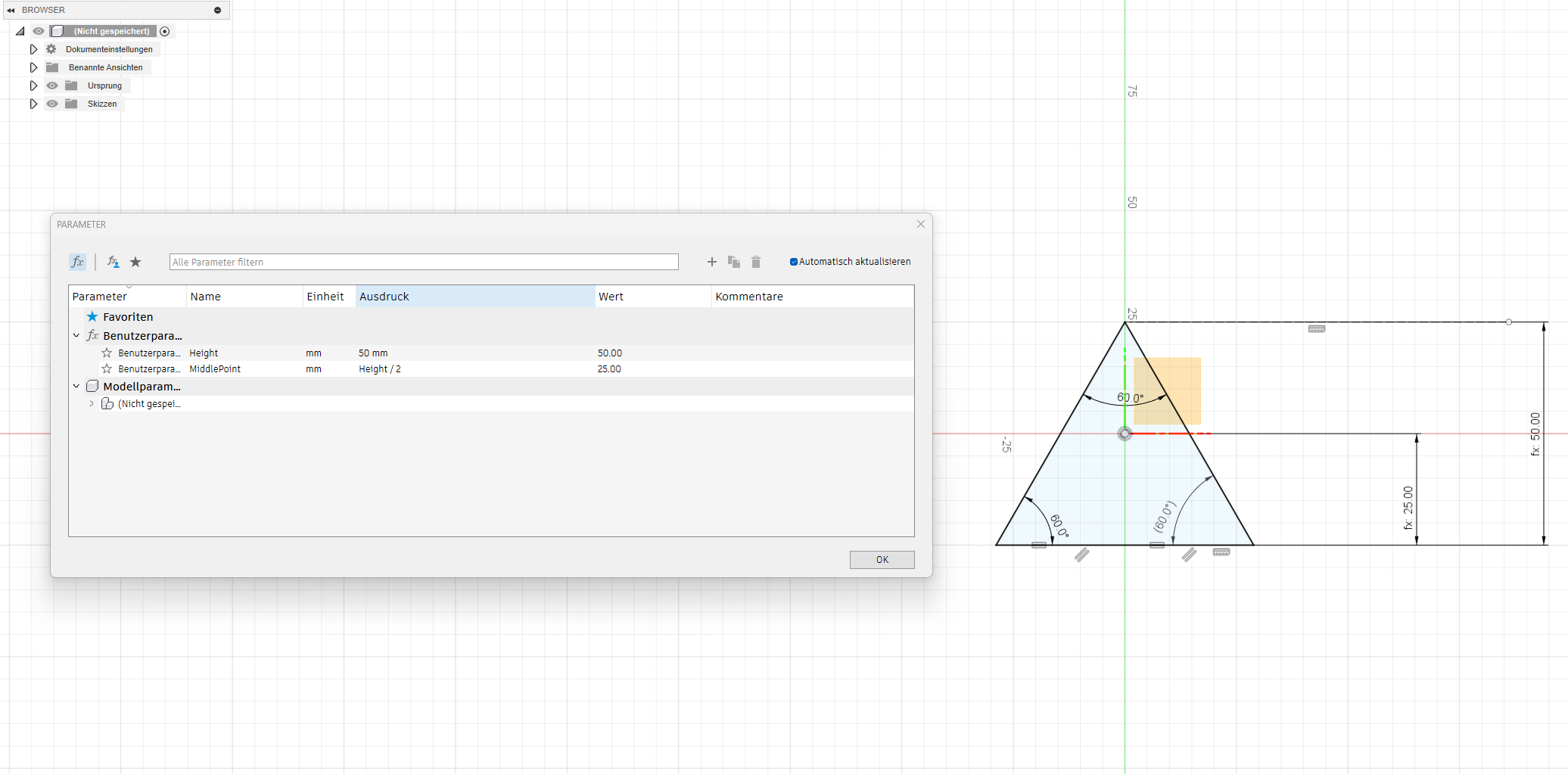

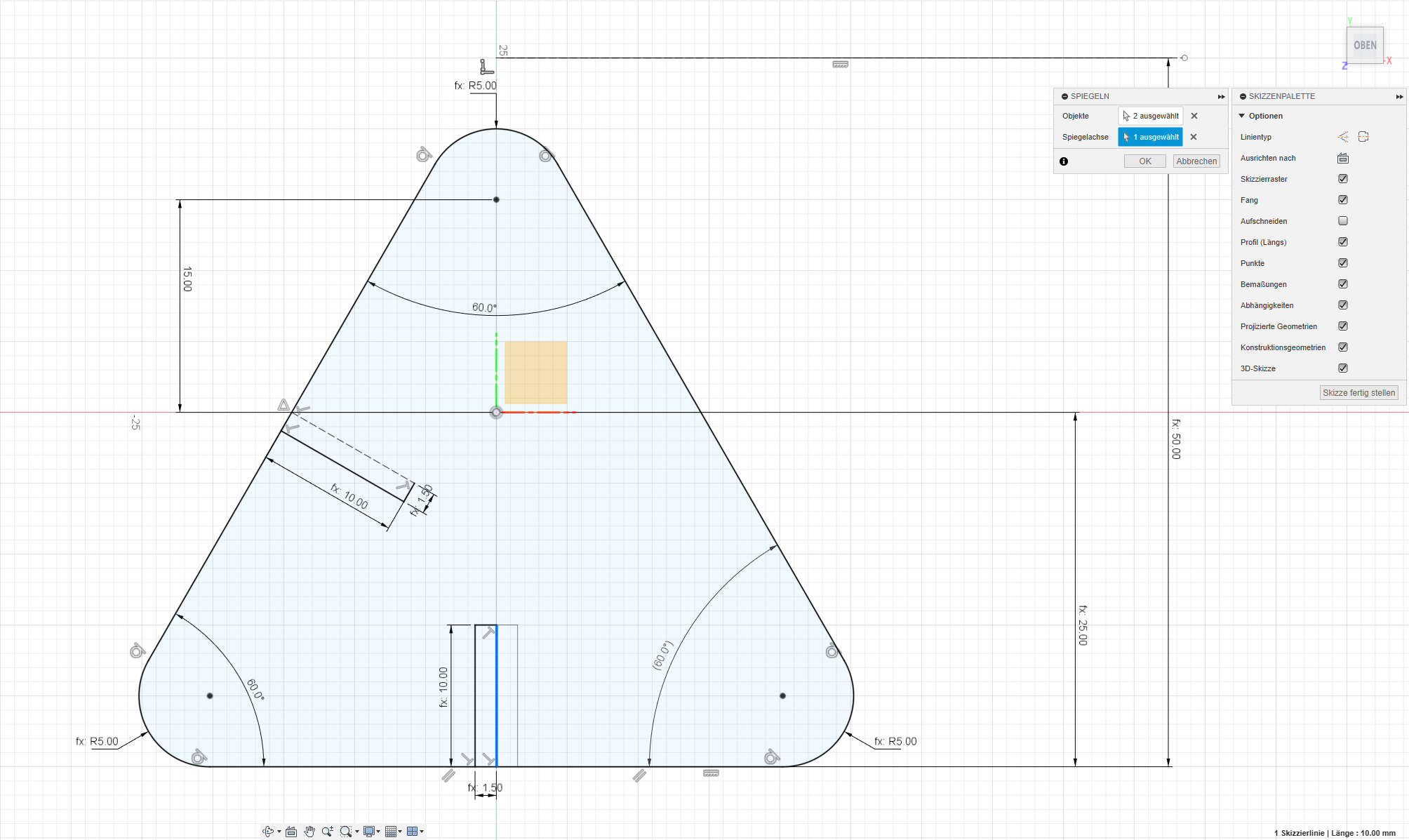

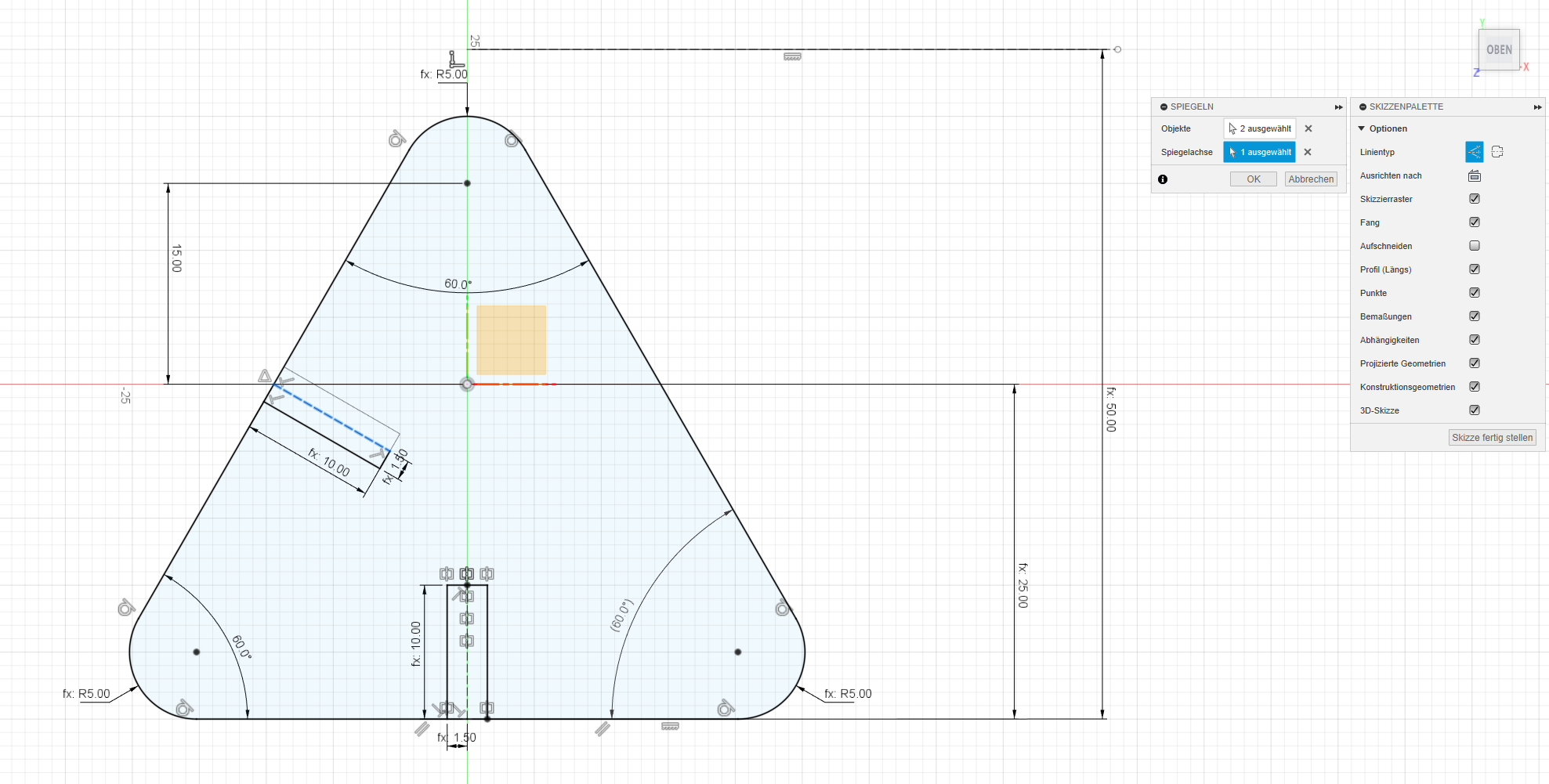

1. Triangle Design:

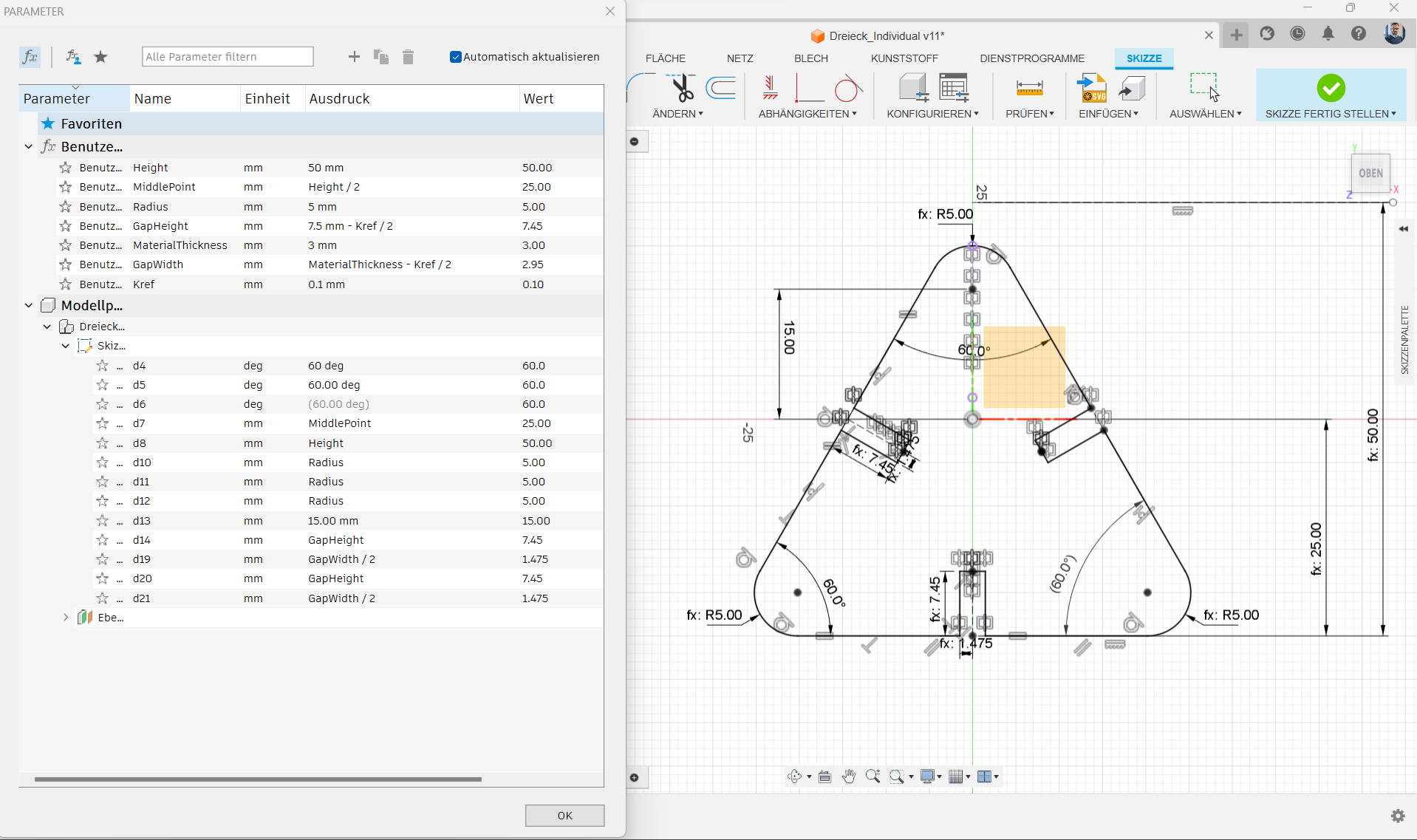

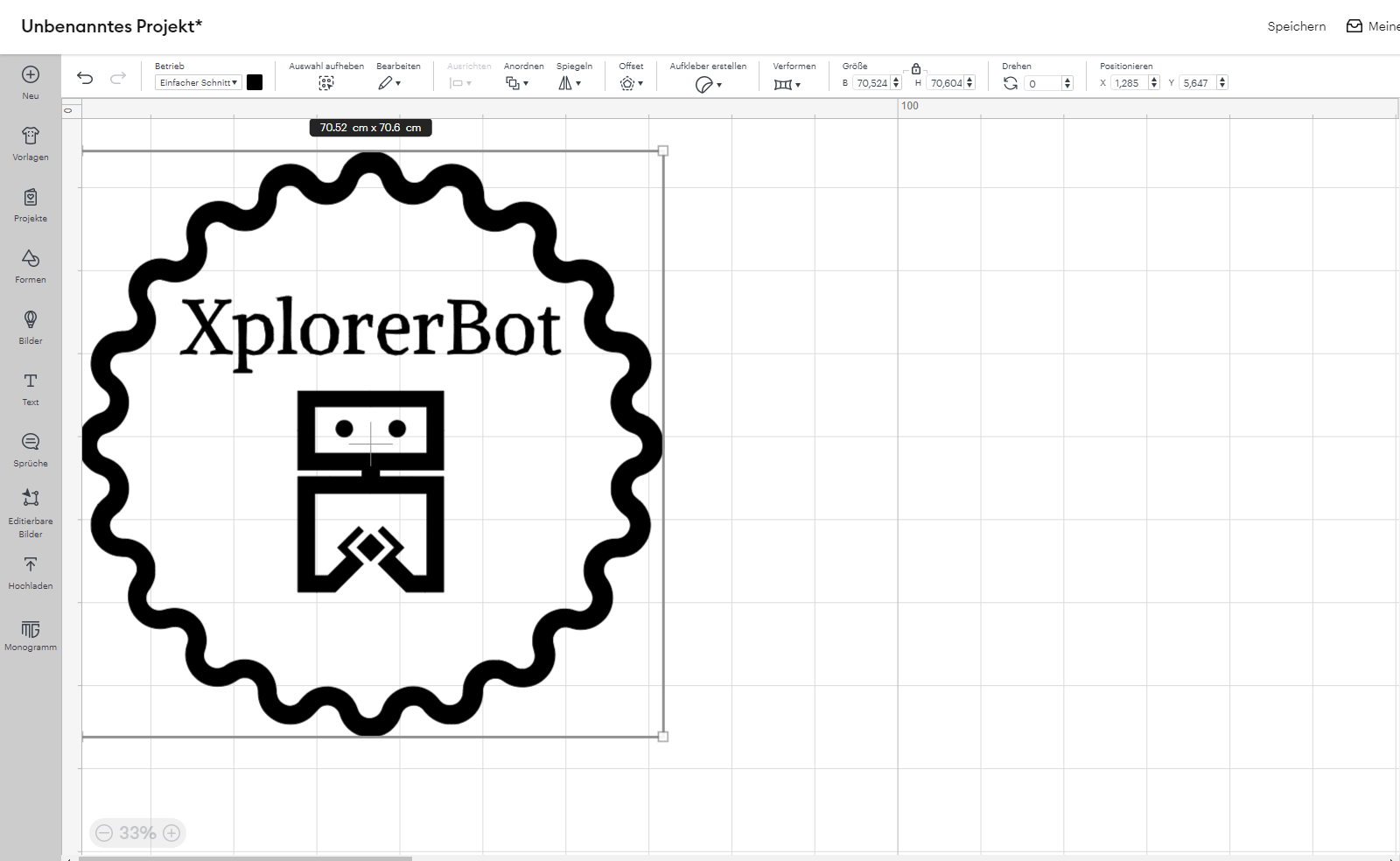

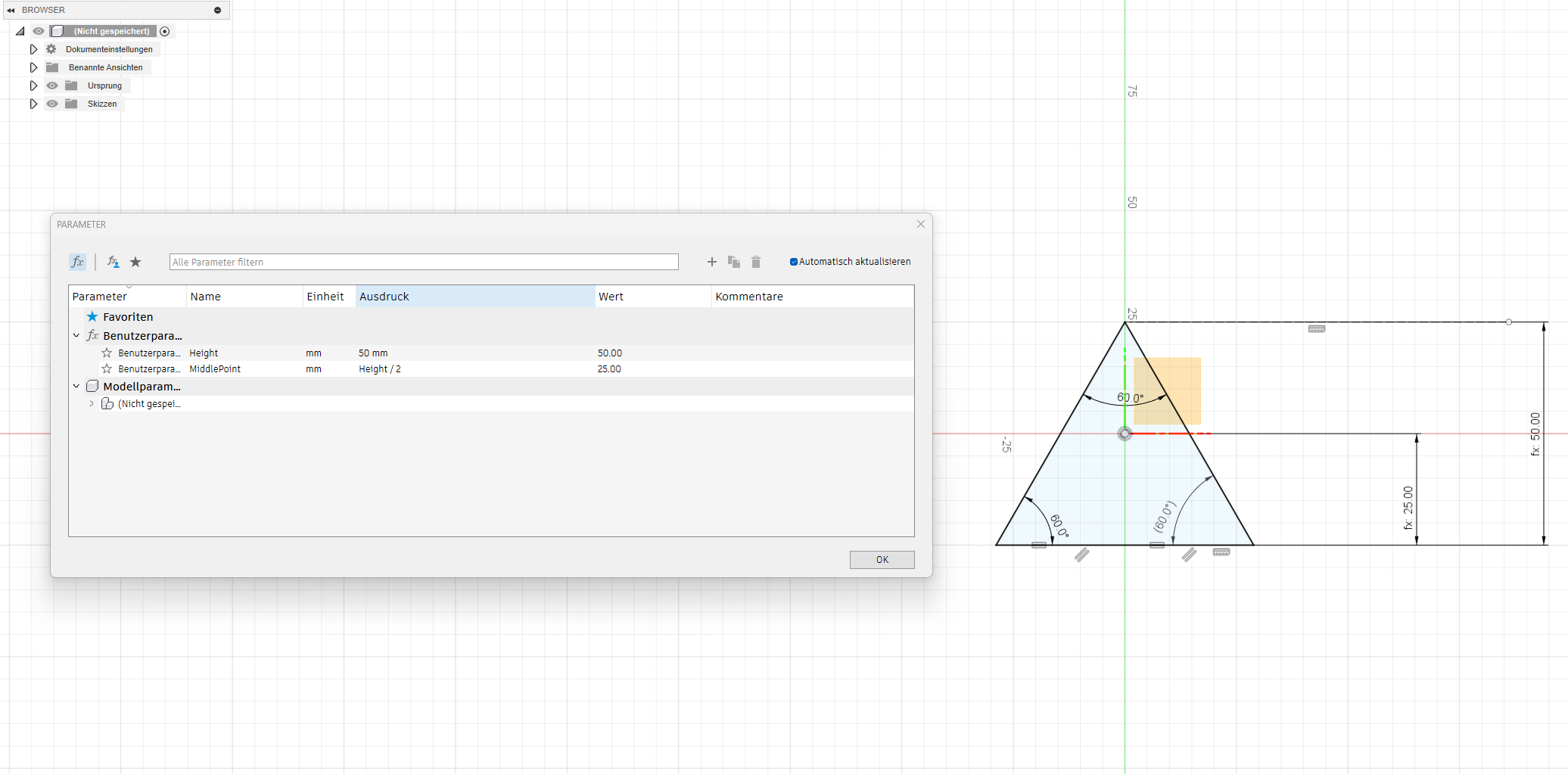

I initiated the process by sketching a triangle, defining its "height"

and "middlePoint," and establishing a mathematical relationship between

these two crucial measurements. To enhance parametric flexibility, I

utilized the user parameter function in Fusion 360, incorporating

parametric values for these measurements. To accommodate the lasercutter

kerf, I implemented the kerf value in other measures, particularly on

the external contours, keeping the initial value at "0" until the

lasercutter machine's kerf characterization.

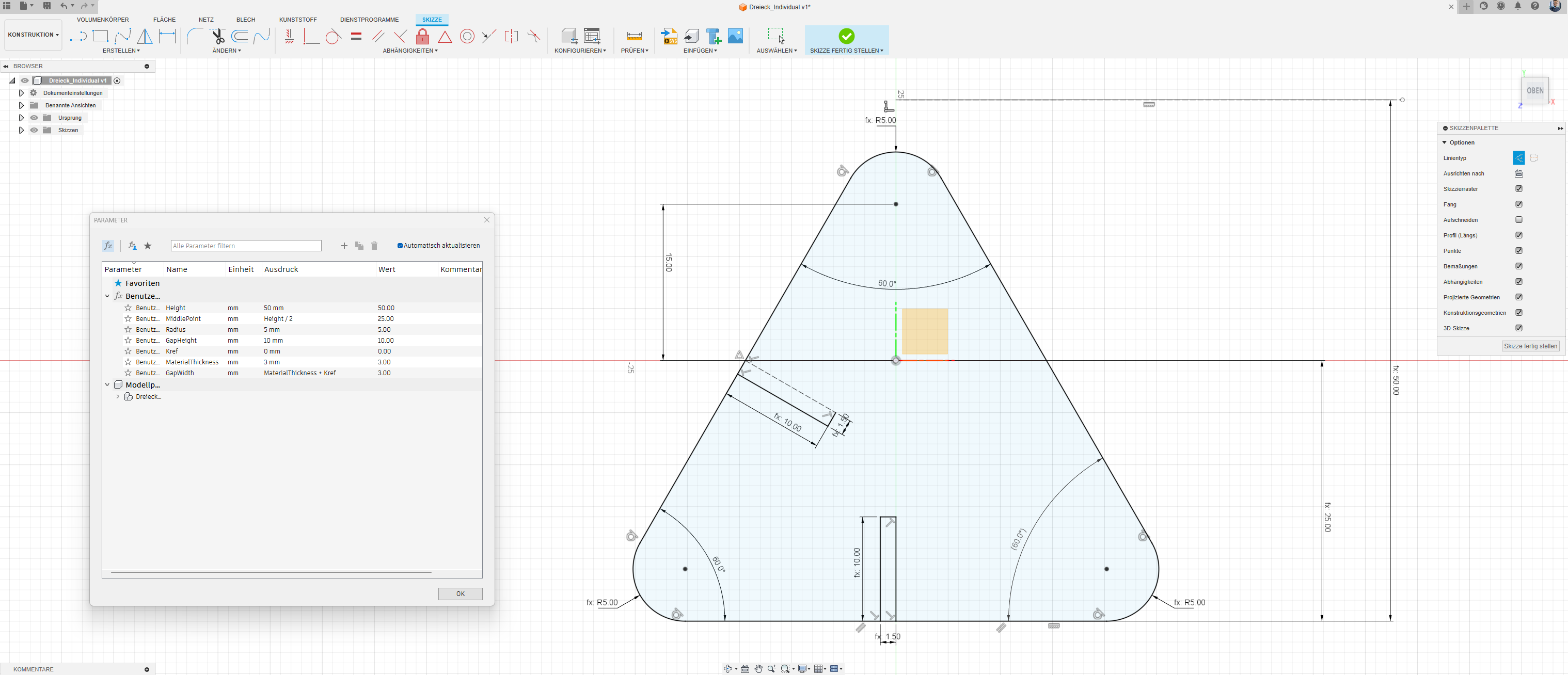

2. Corner Rounding:

To enhance user safety during assembly, I incorporated rounded corners

in the triangles. The rounding parameter, denoted as "Radius" in the

user parameters, was set at 5 mm.

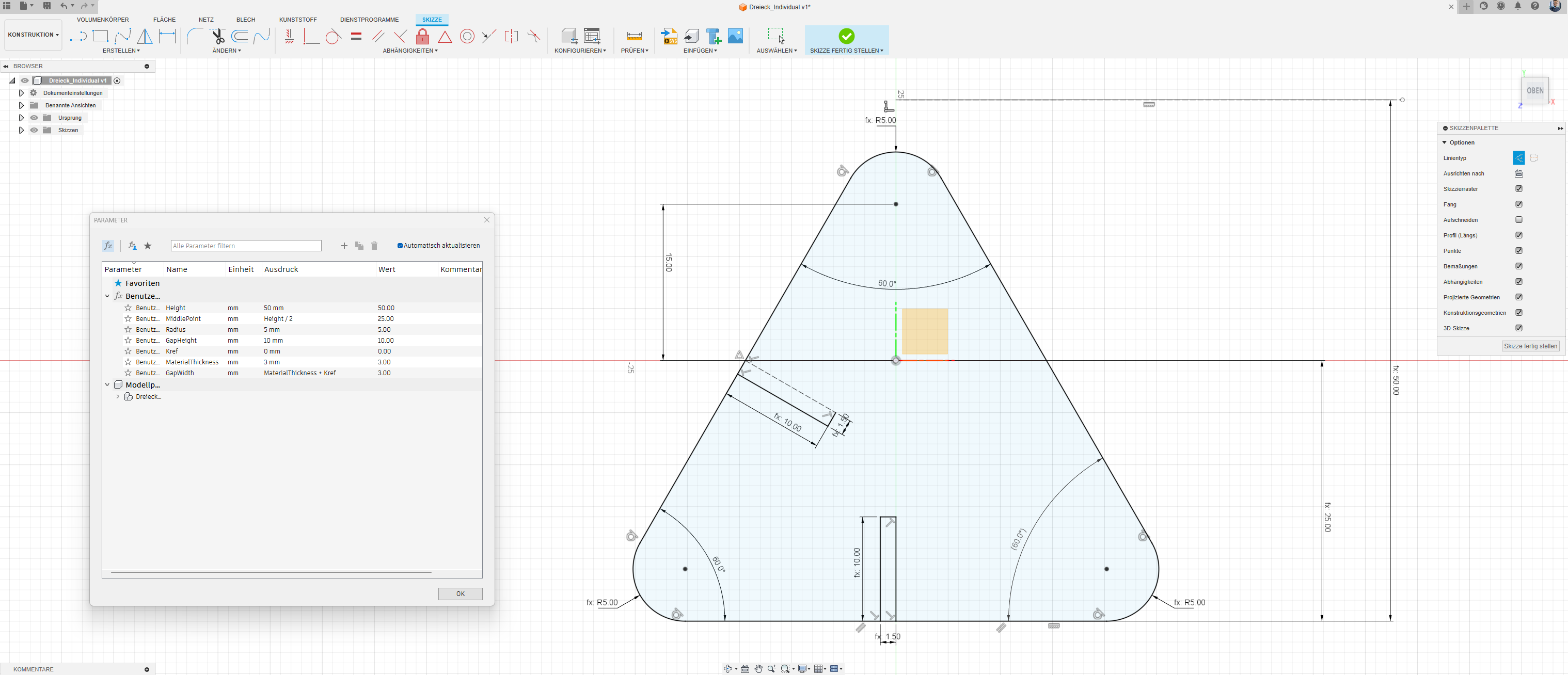

3. Rectangle Addition:

Subsequently, I introduced two rectangles—one at the center of the base

and the other on the left side. These rectangles are parameterized as

"GapWidth" and "GapHeight," with "GapWidth" aligned with the

"MaterialThickness." Similar to the triangle, considerations for the

lasercutter kerf were applied.

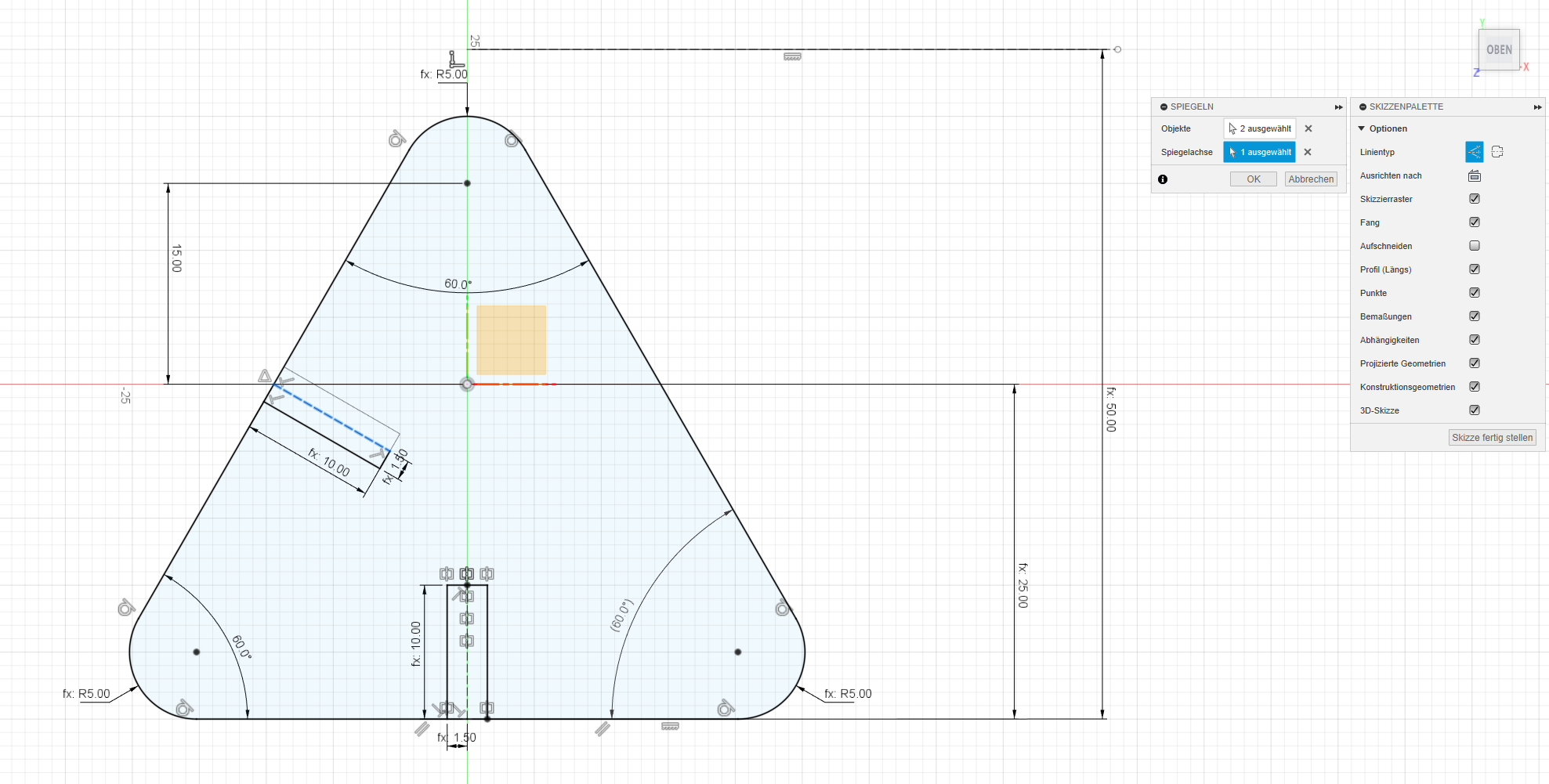

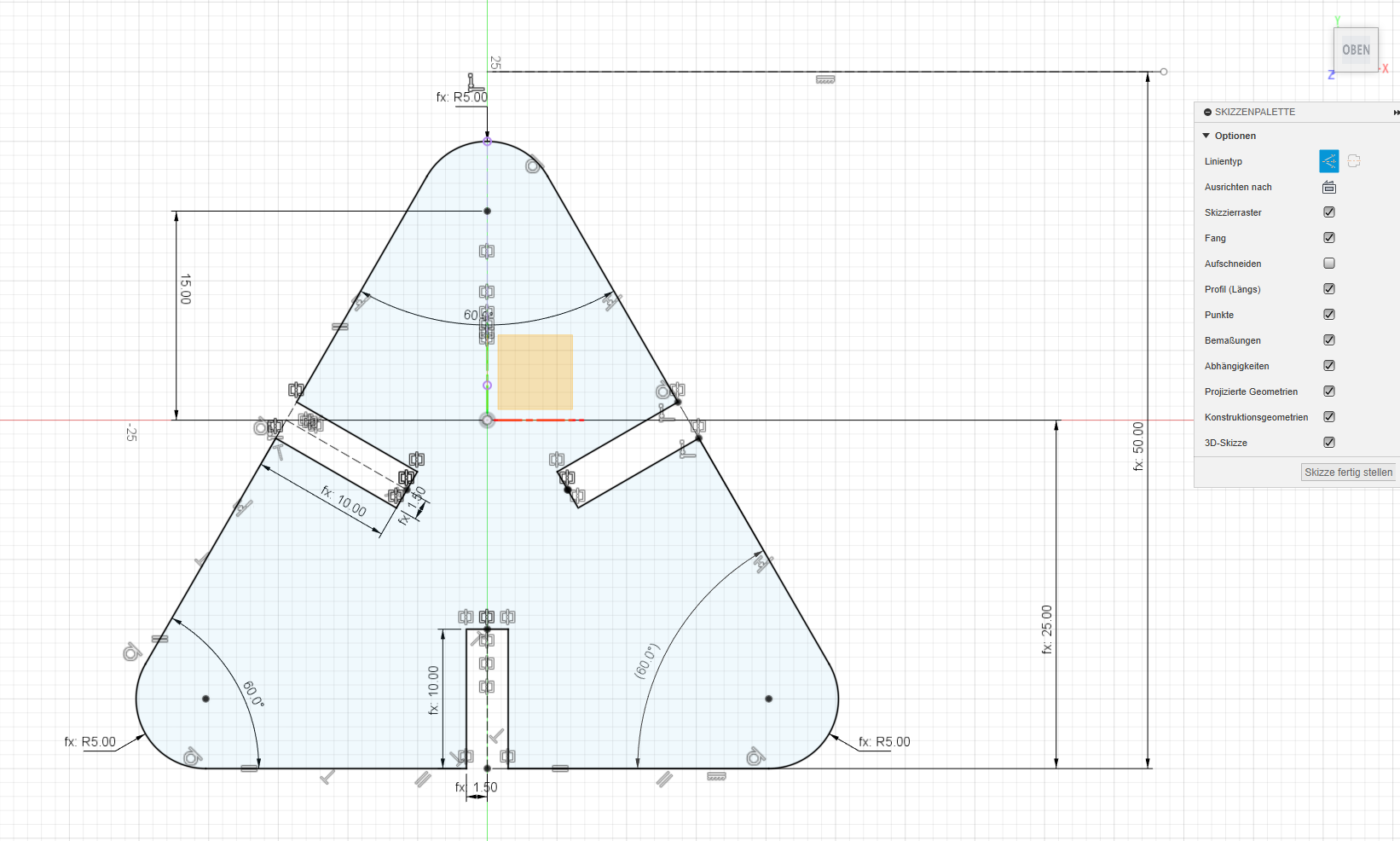

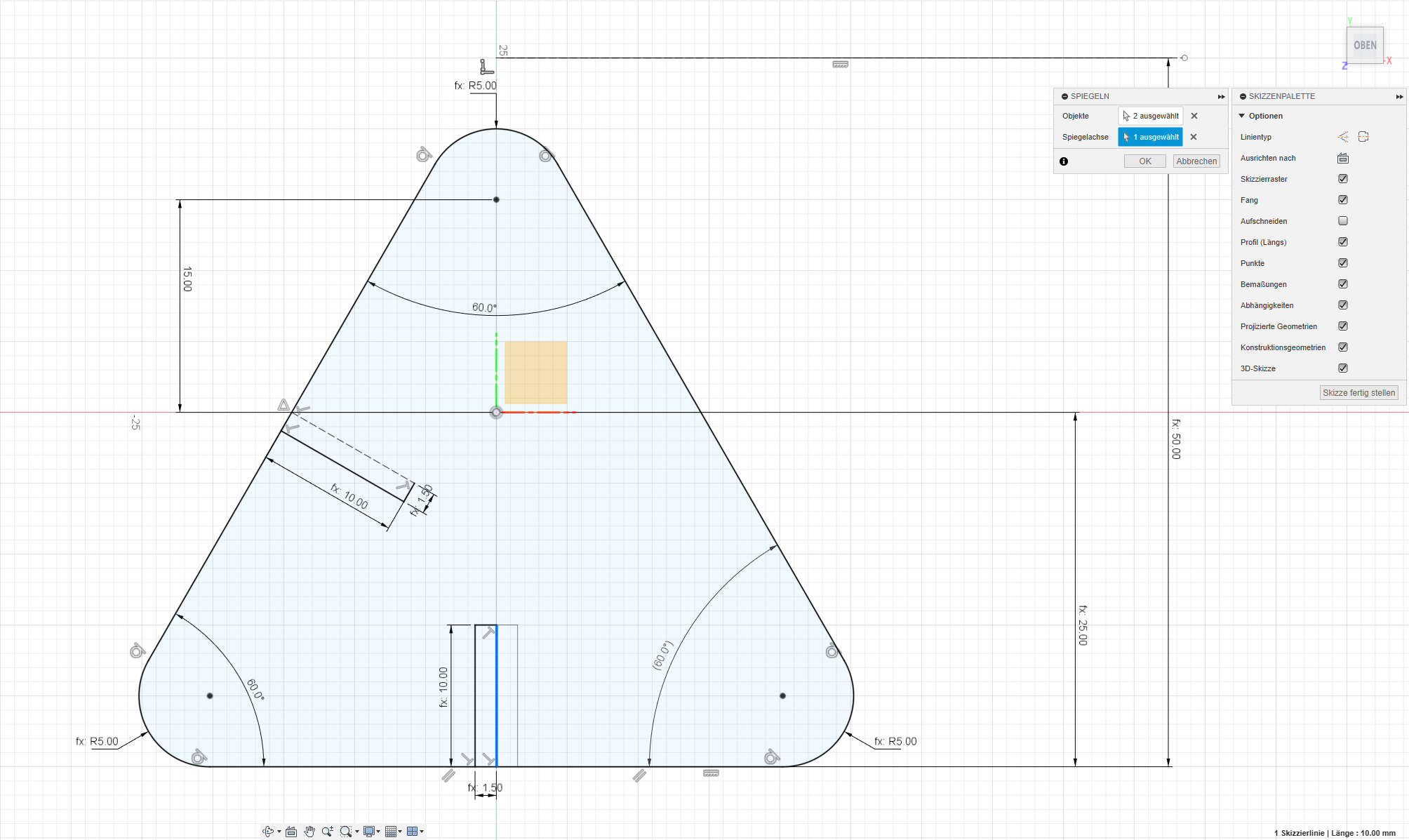

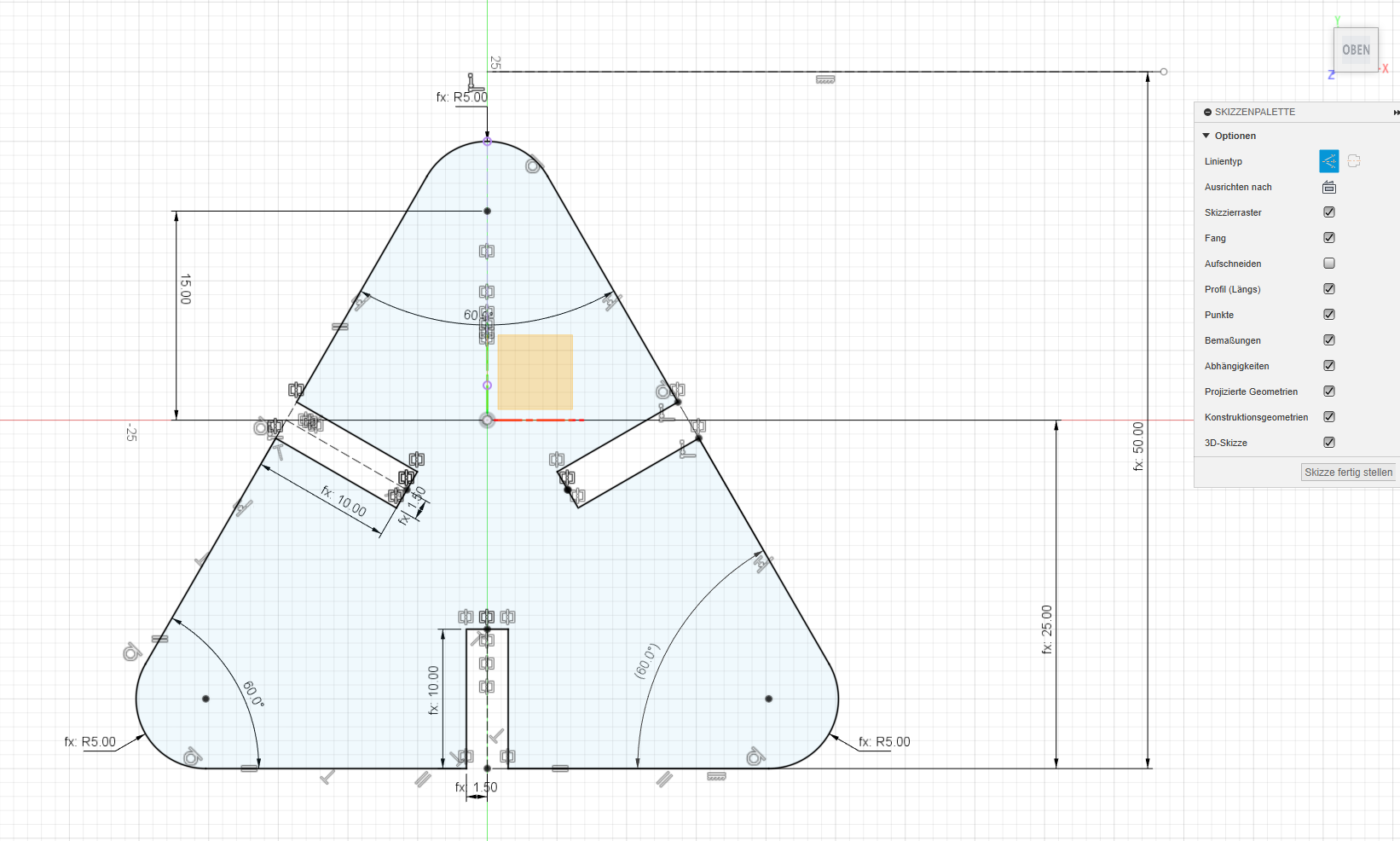

4. Mirroring:

To ensure uniformity, I mirrored the rectangles along each of the three

sides of the triangle.

5. Gap Creation:

The next step involved cutting unwanted lines, creating the necessary

gaps for the press-fit construction , with adjustments made to account

for the lasercutter kerf.

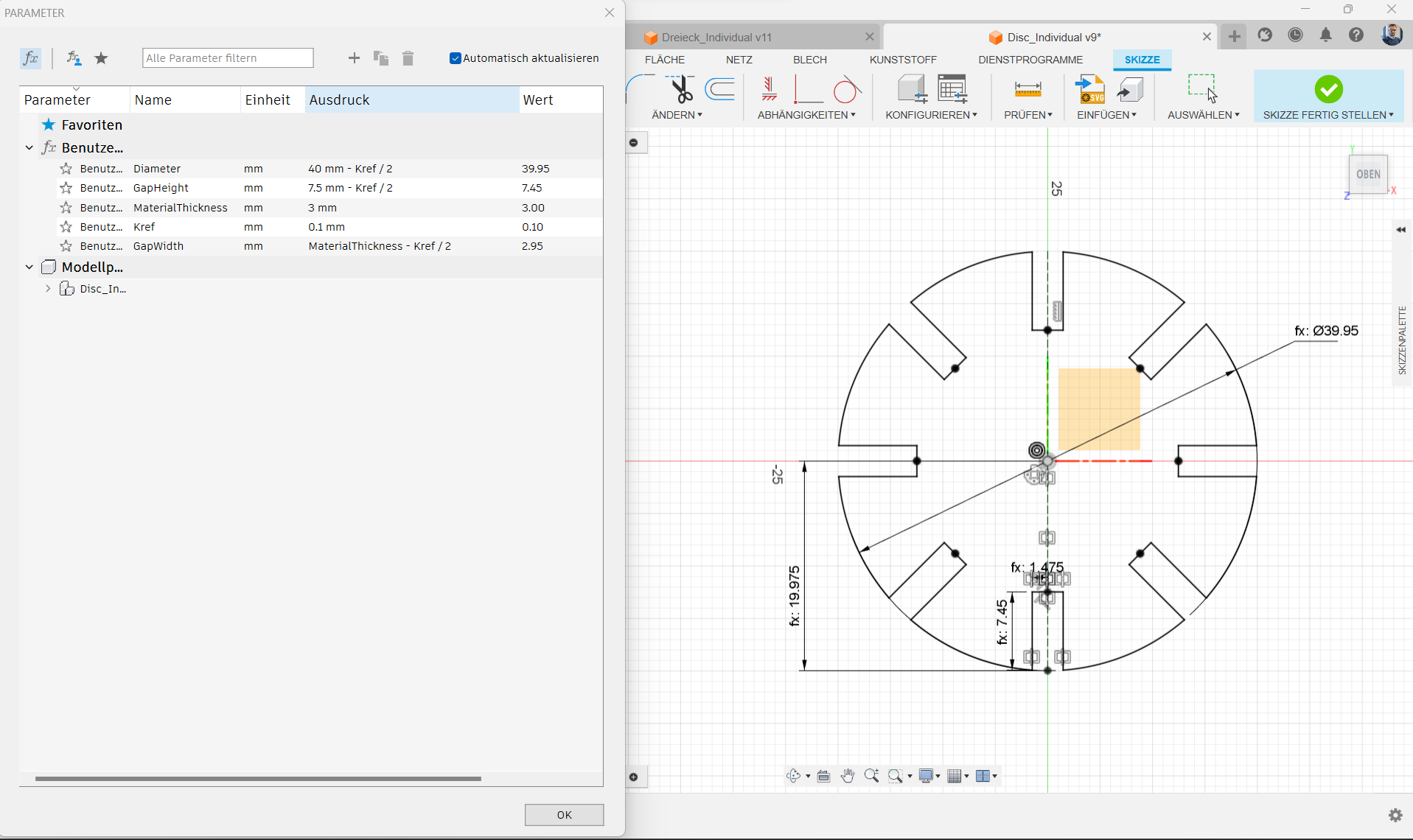

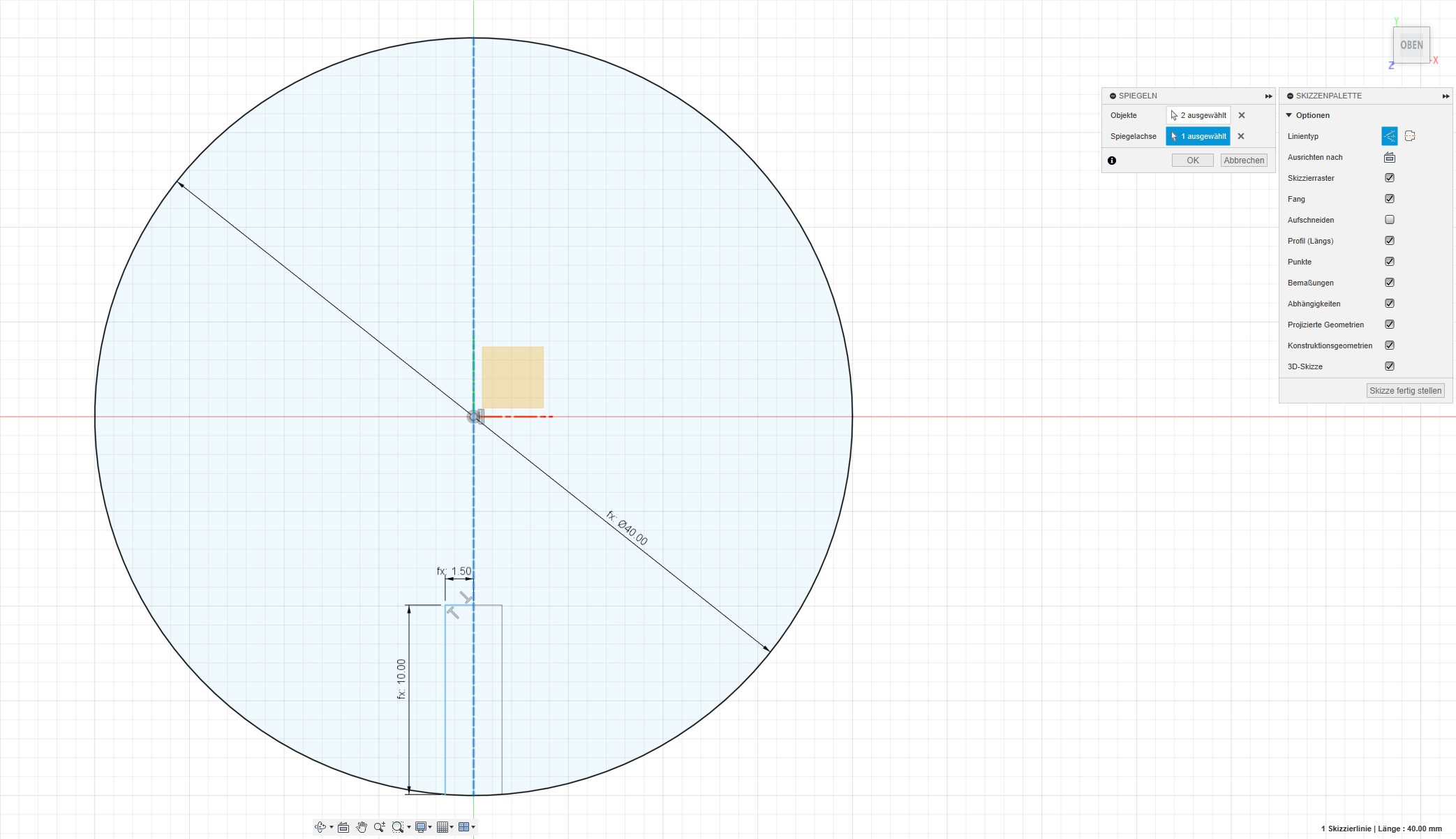

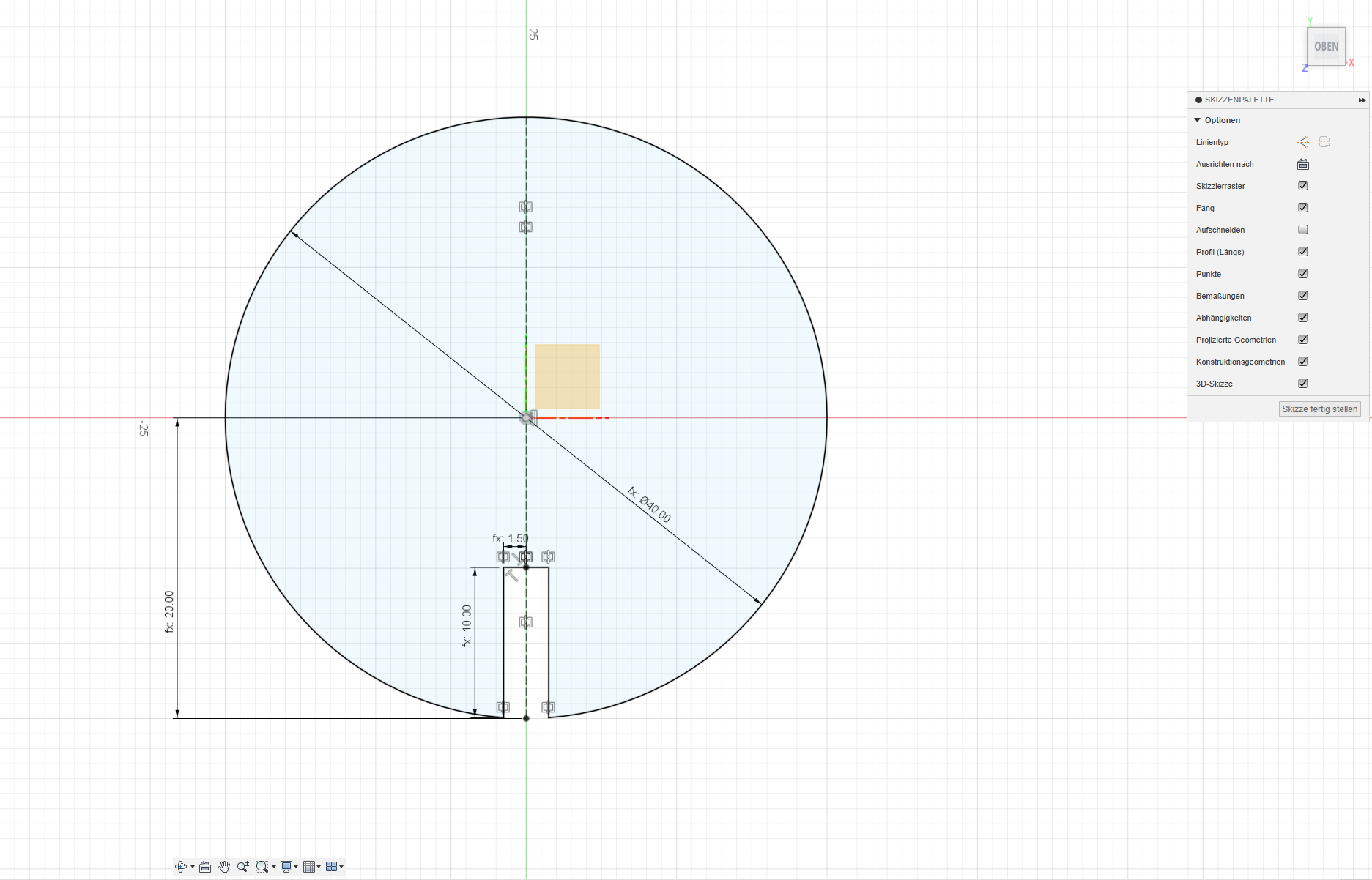

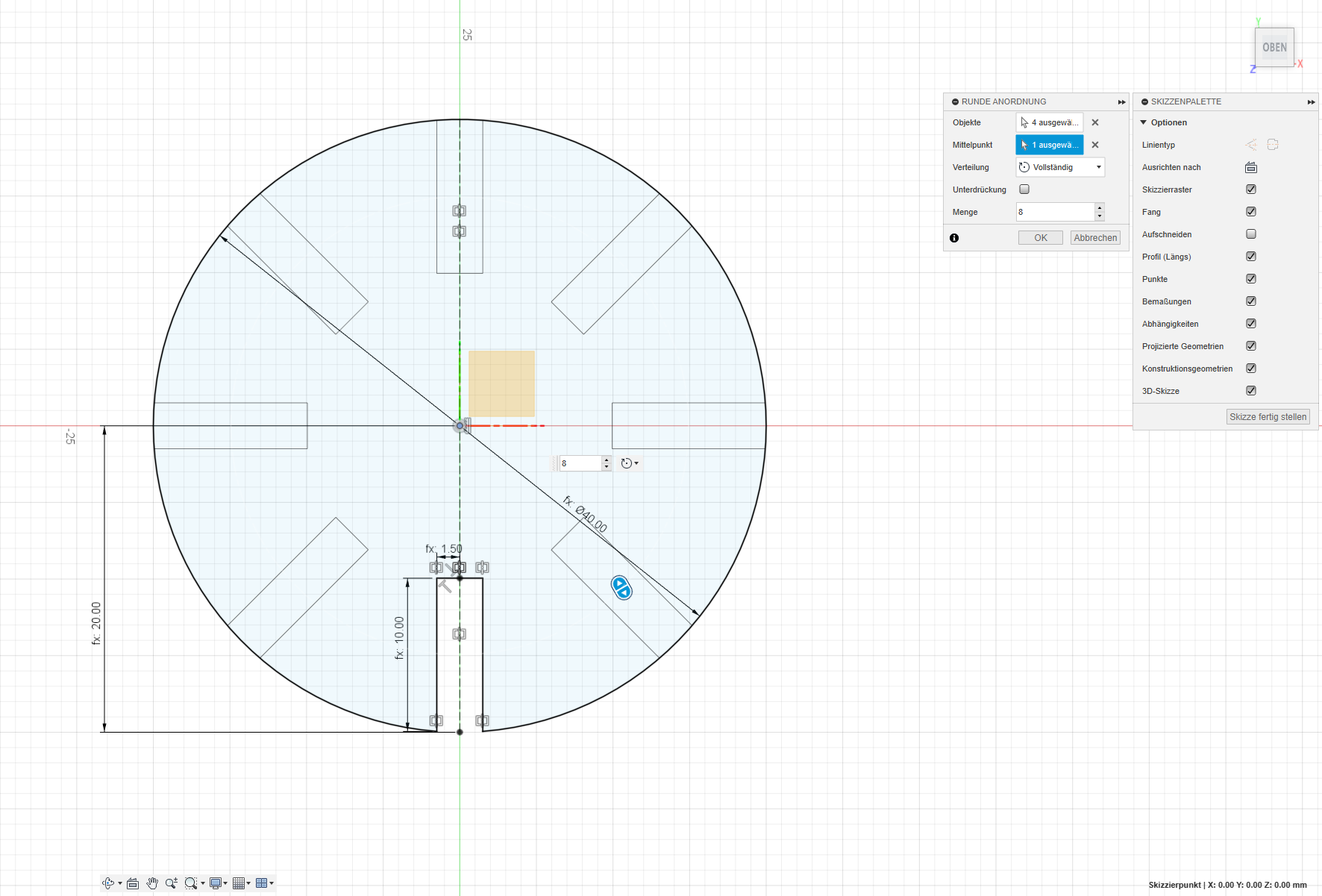

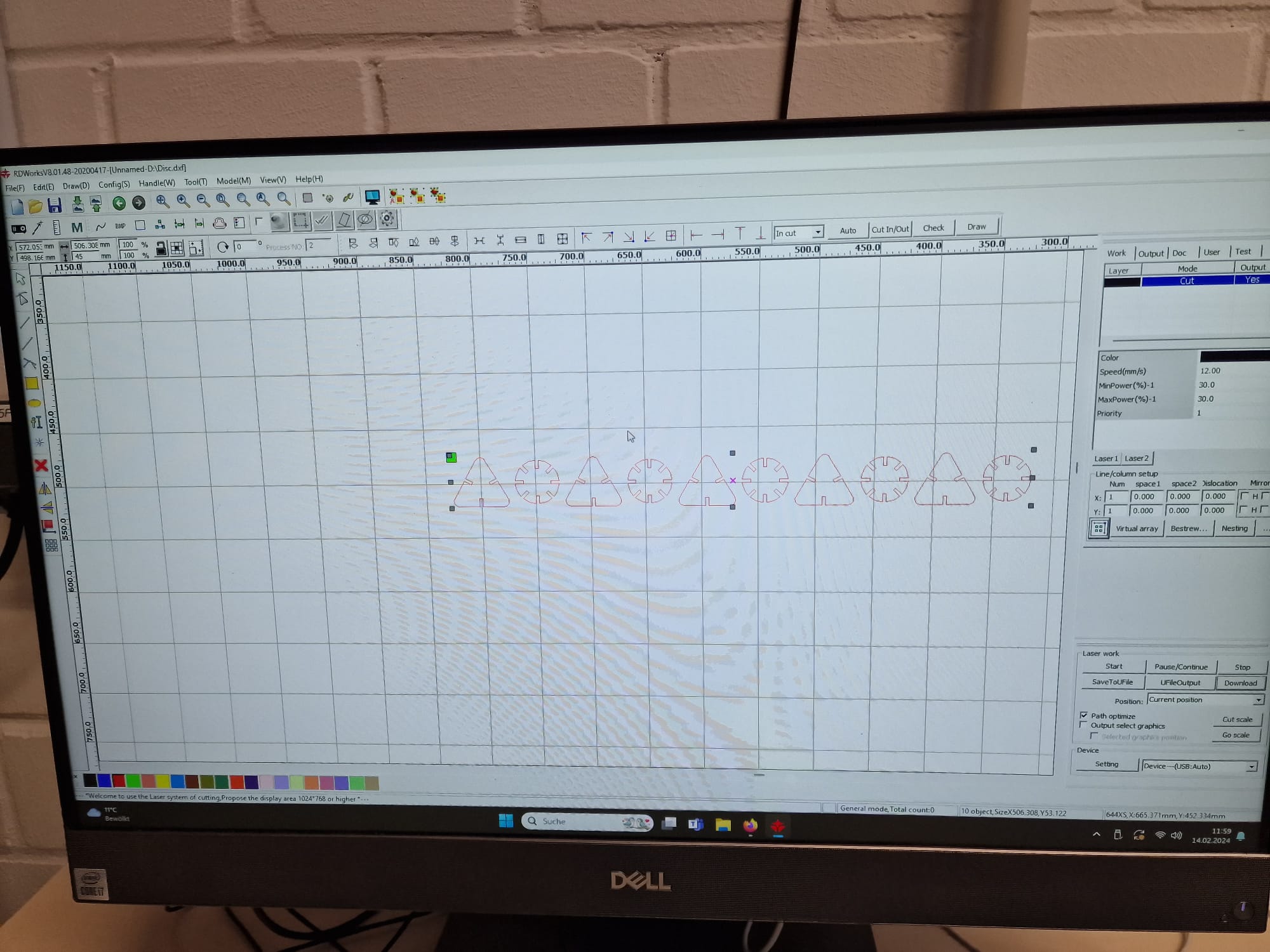

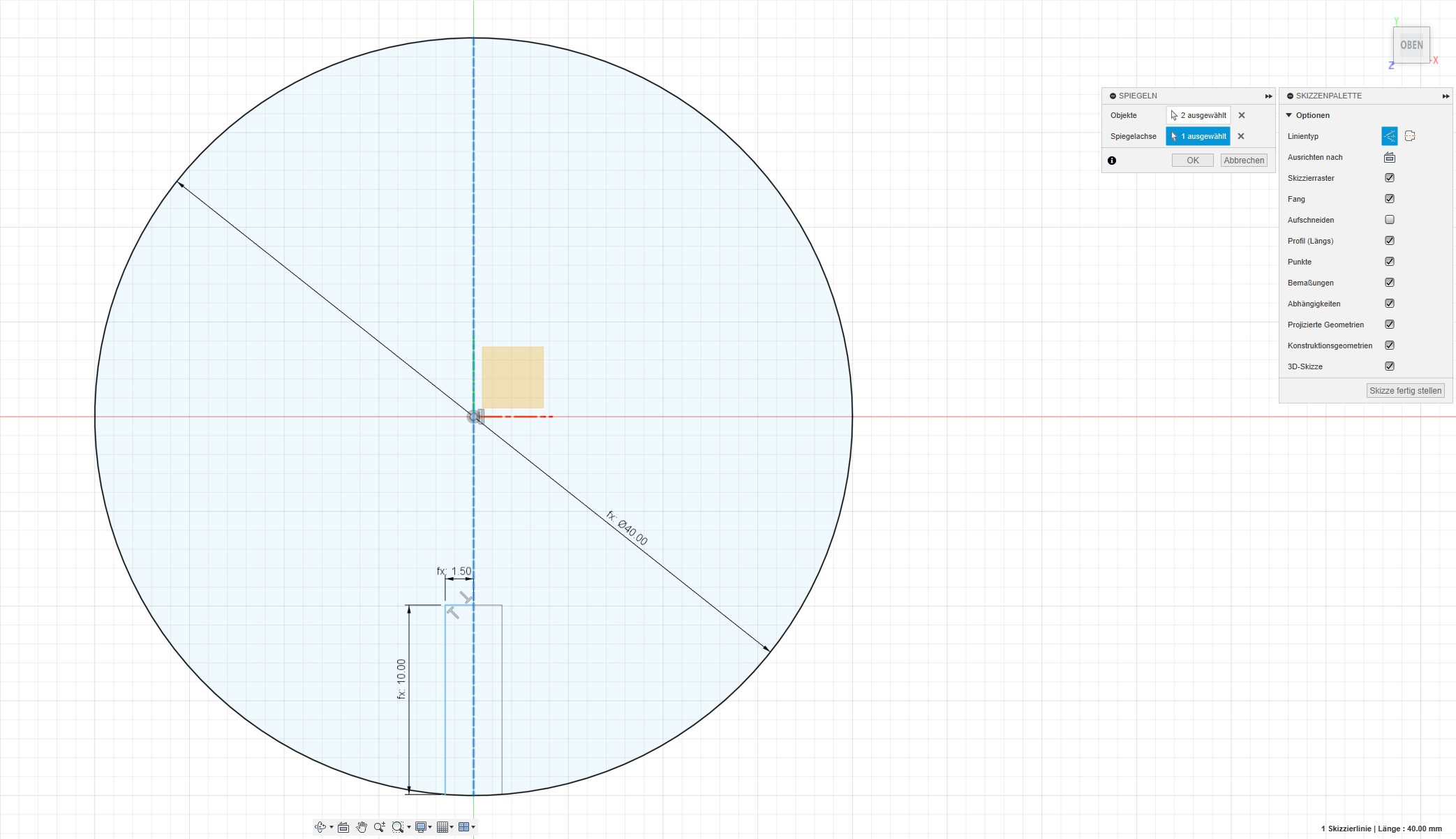

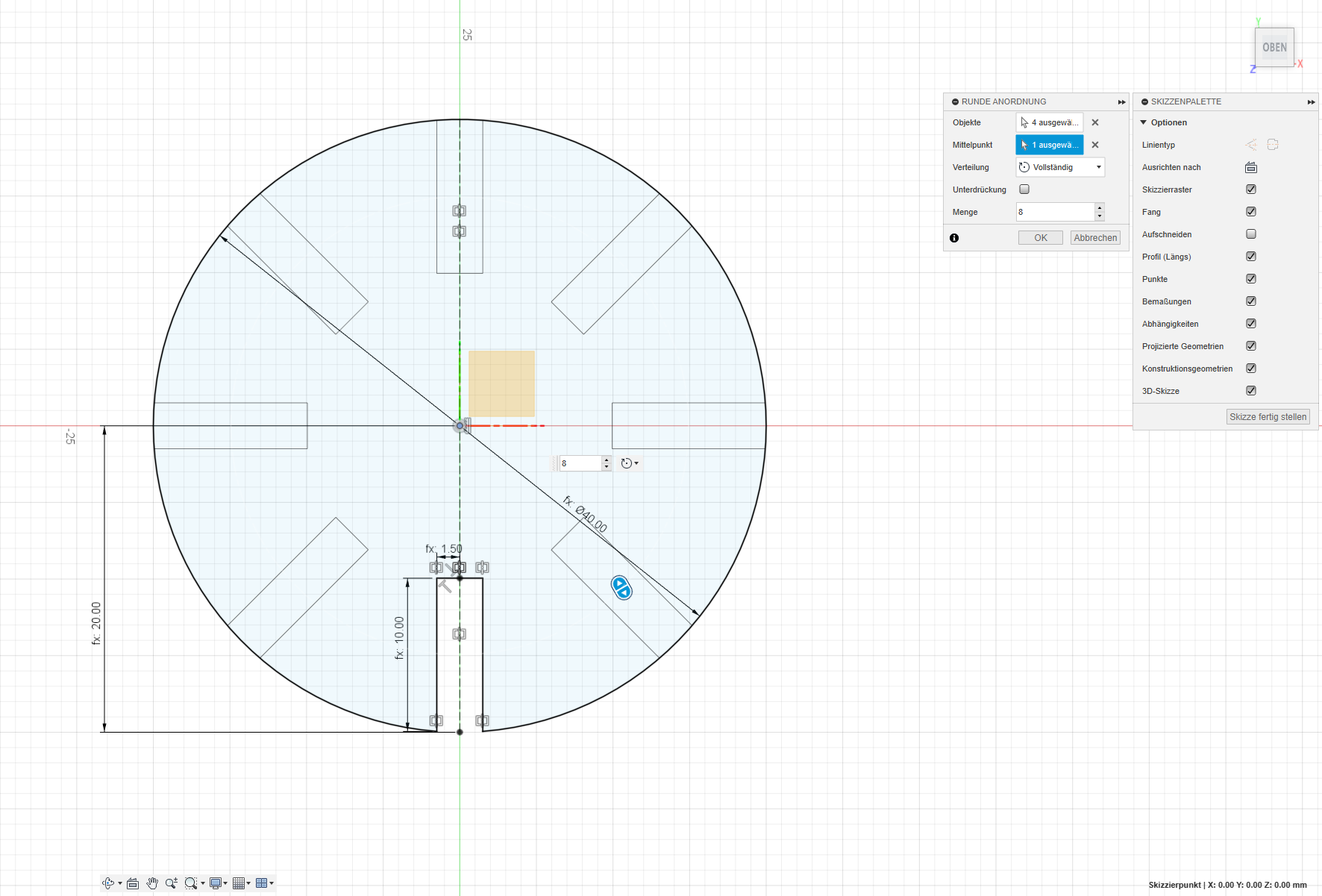

6. Circle (Disc) Design:

Replicating the process for the circular component, I set gap parameters

to match those of the triangles. Considering the lasercutter kerf,

adjustments were made to measures, especially on external contours, with

the initial value set at "0" until the lasercutter machine's kerf

characterization.

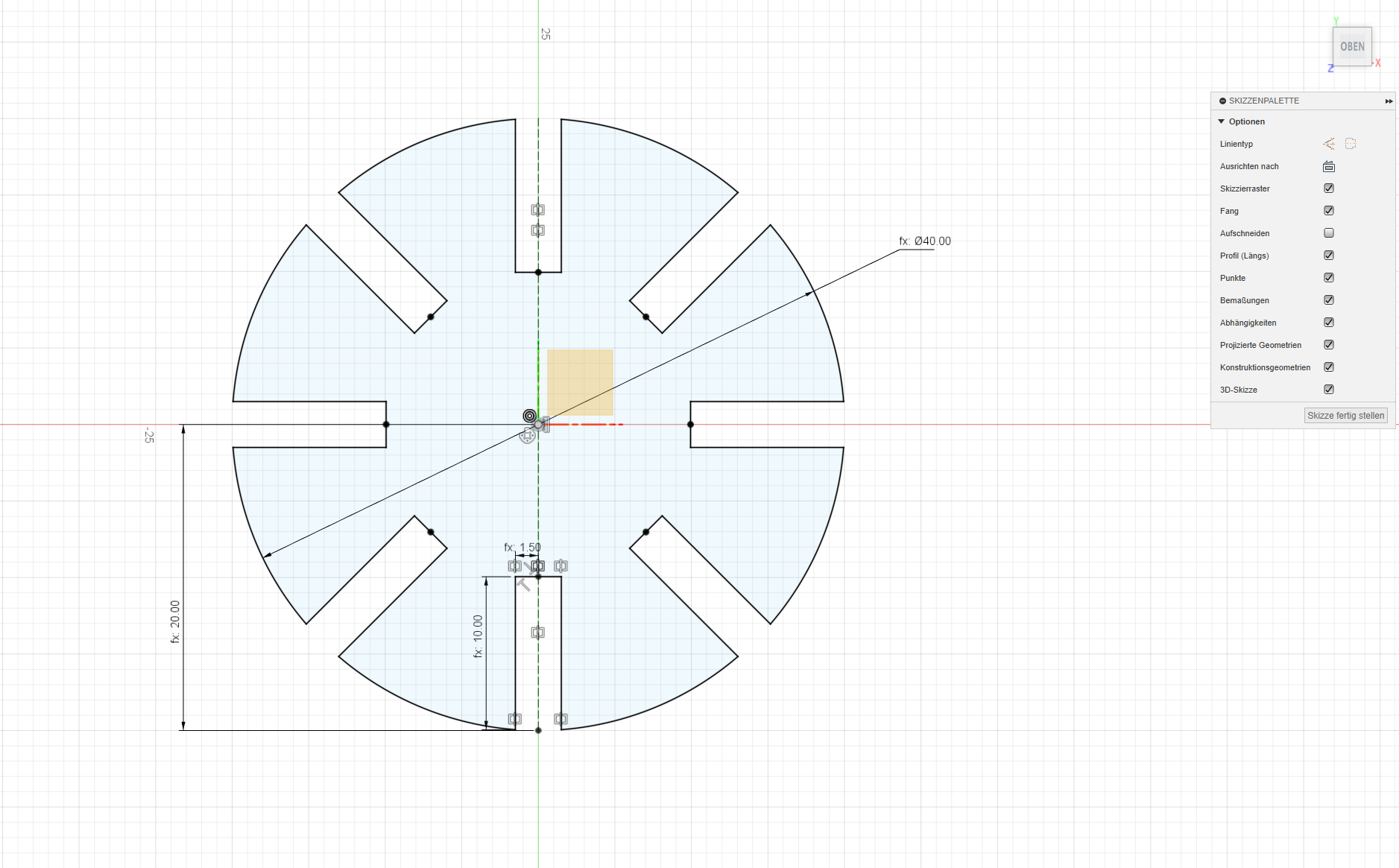

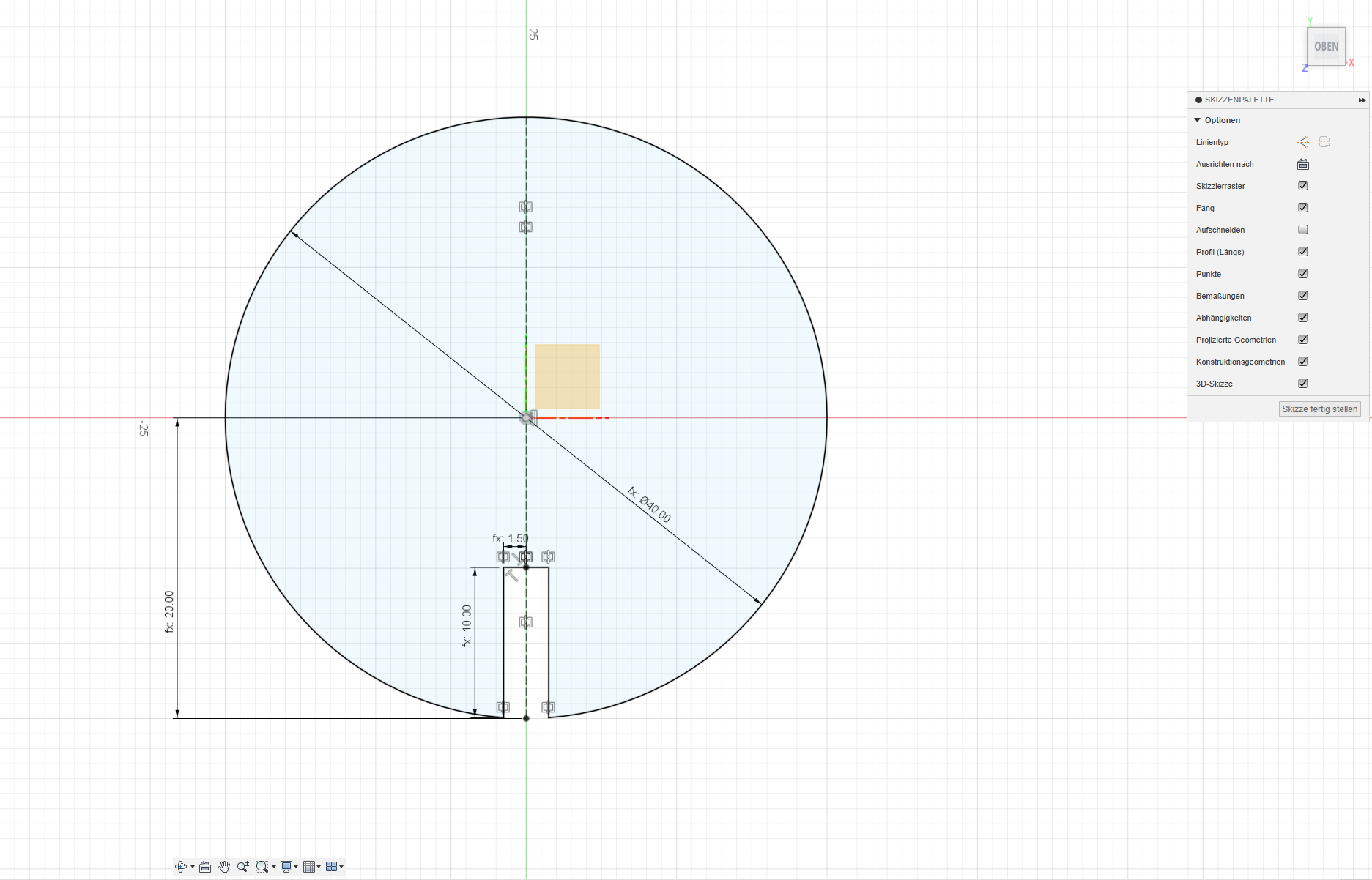

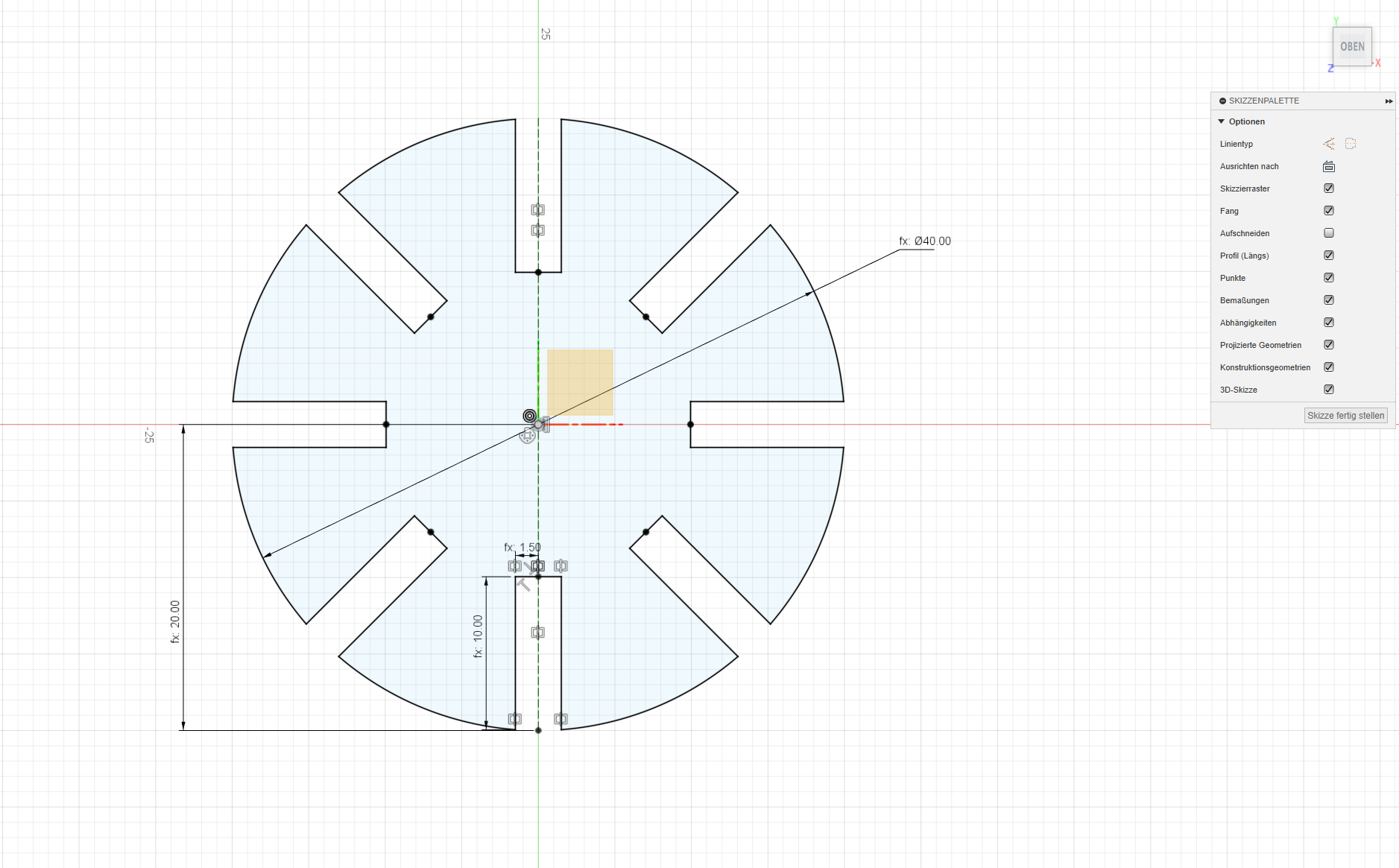

7. Gap Refinement:

Final adjustments were made by cutting away unnecessary parts of the

circle, creating the essential gaps for the press-fit construction.

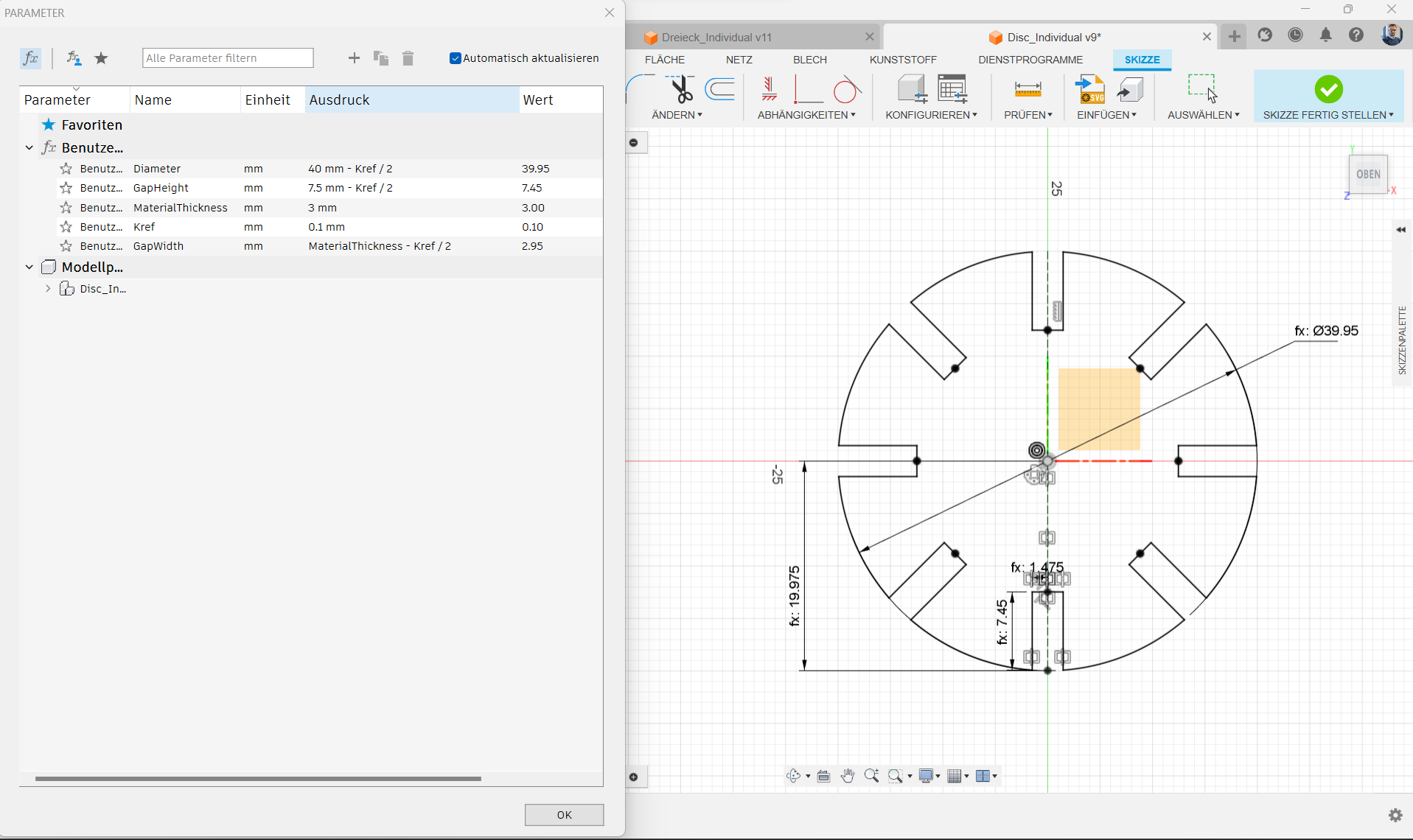

7. Finalizing the parameters for cutting: