Group assignment - Computer controlled cutting:

As part of our group assignment, we conducted safety training for our lab activities. Additionally, we characterized our laser cutter's key parameters, including focus, power, speed, rate, kerf, joint clearance, and types.

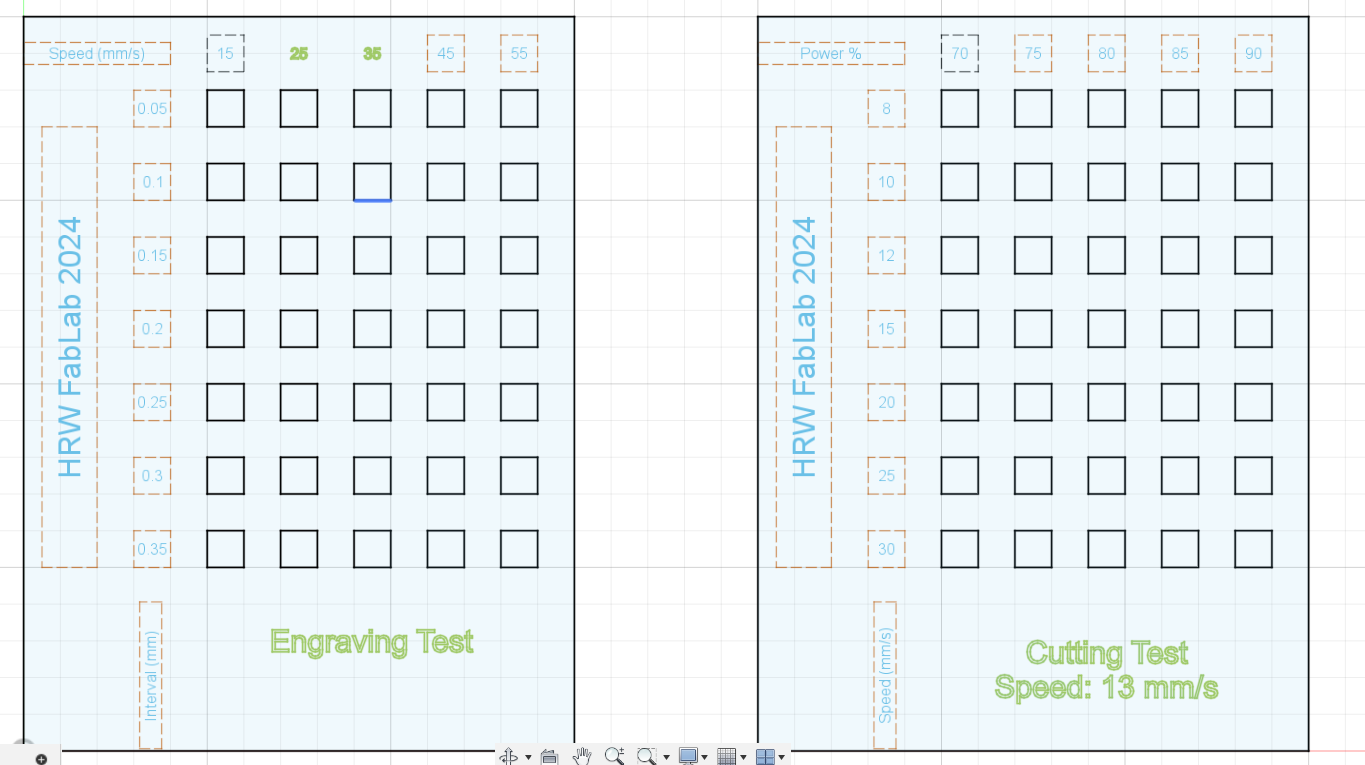

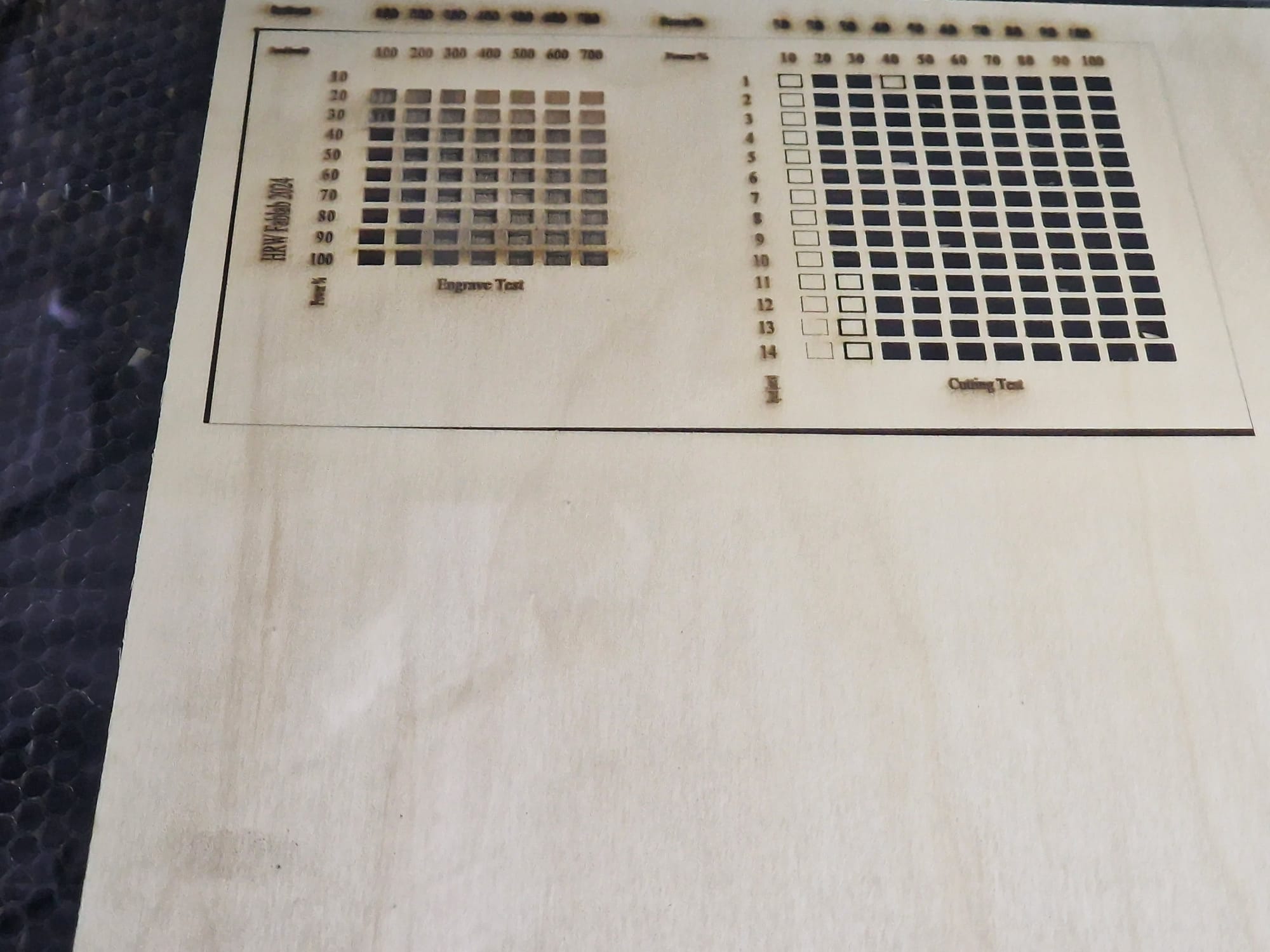

For the power, speed, rate characterization, we employed a 2D-sketch in Fusion 360. Our testing encompassed a range of speeds and power values for both cutting (speeds from 1 to 14 mm/s and power from 10 to 100%) and engraving (speeds from 100 to 700 mm/s and power from 10 to 100%).

After thorough experimentation, we determined the optimal values for engraving to be 600 mm/s for speed and 30% for power. Similarly, for cutting, our findings indicate that the optimal values are 12 mm/s for speed and 30% for power. These optimized parameters not only enhance the efficiency of our laser cutter but also contribute to achieving the desired results with precision.

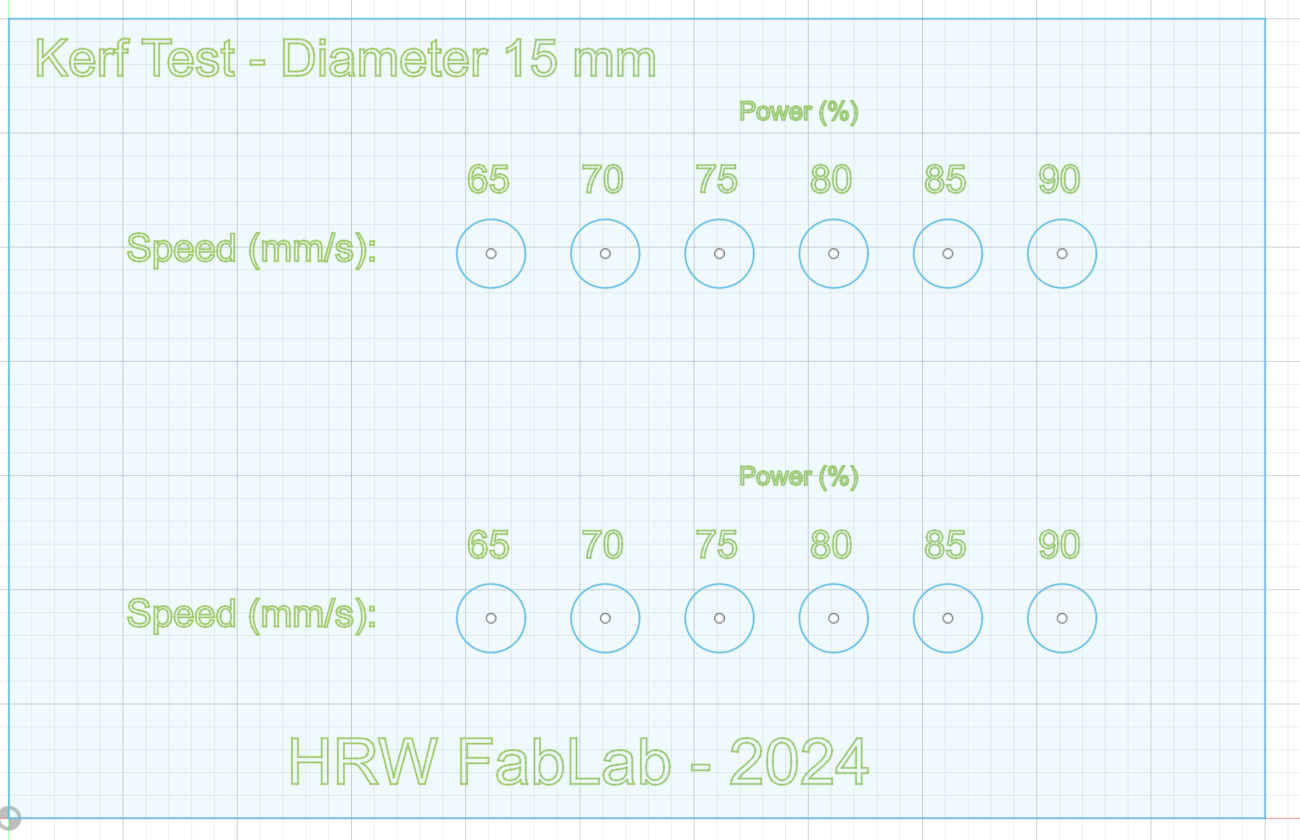

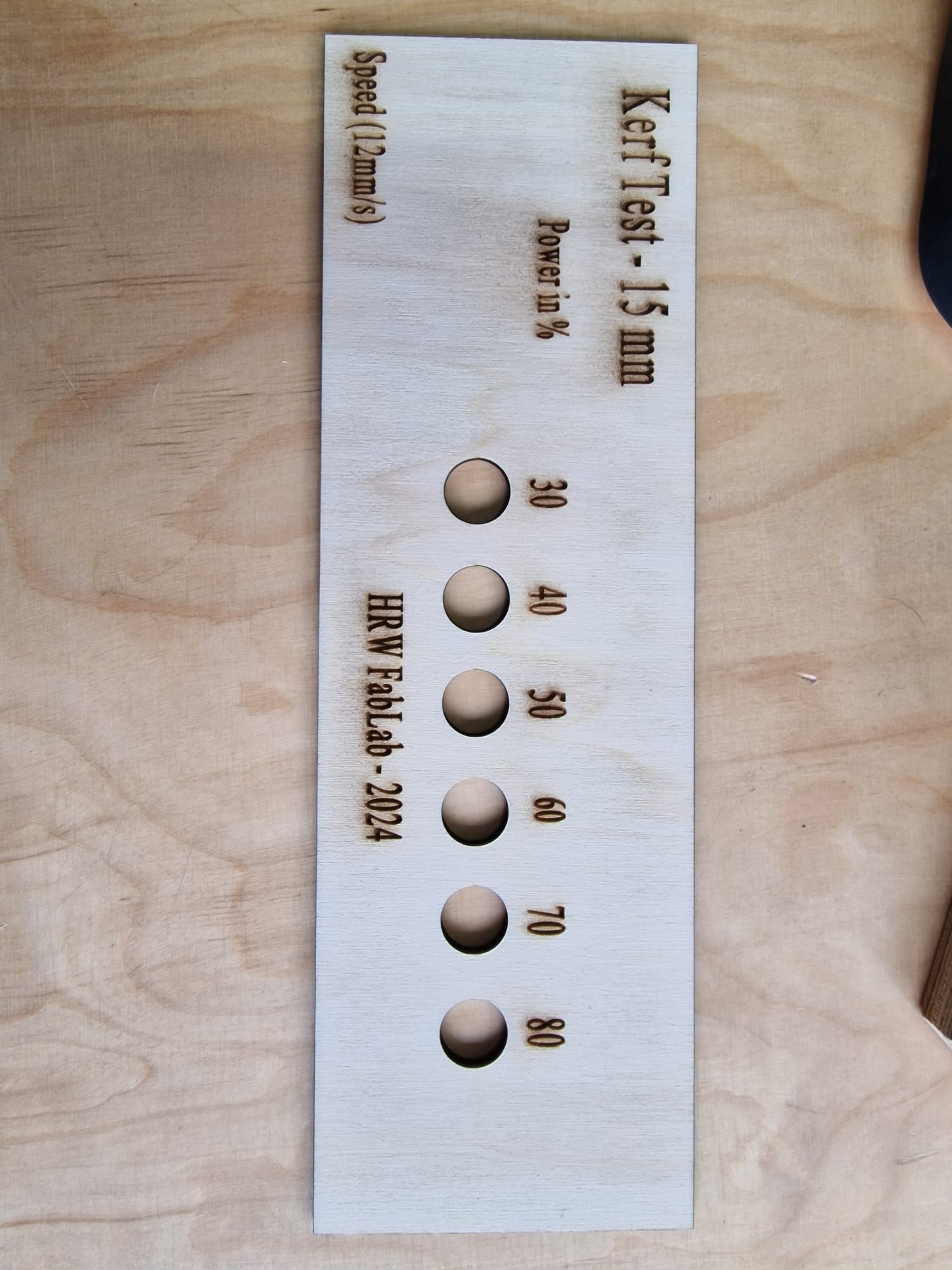

Characterization of Focus and Kerf

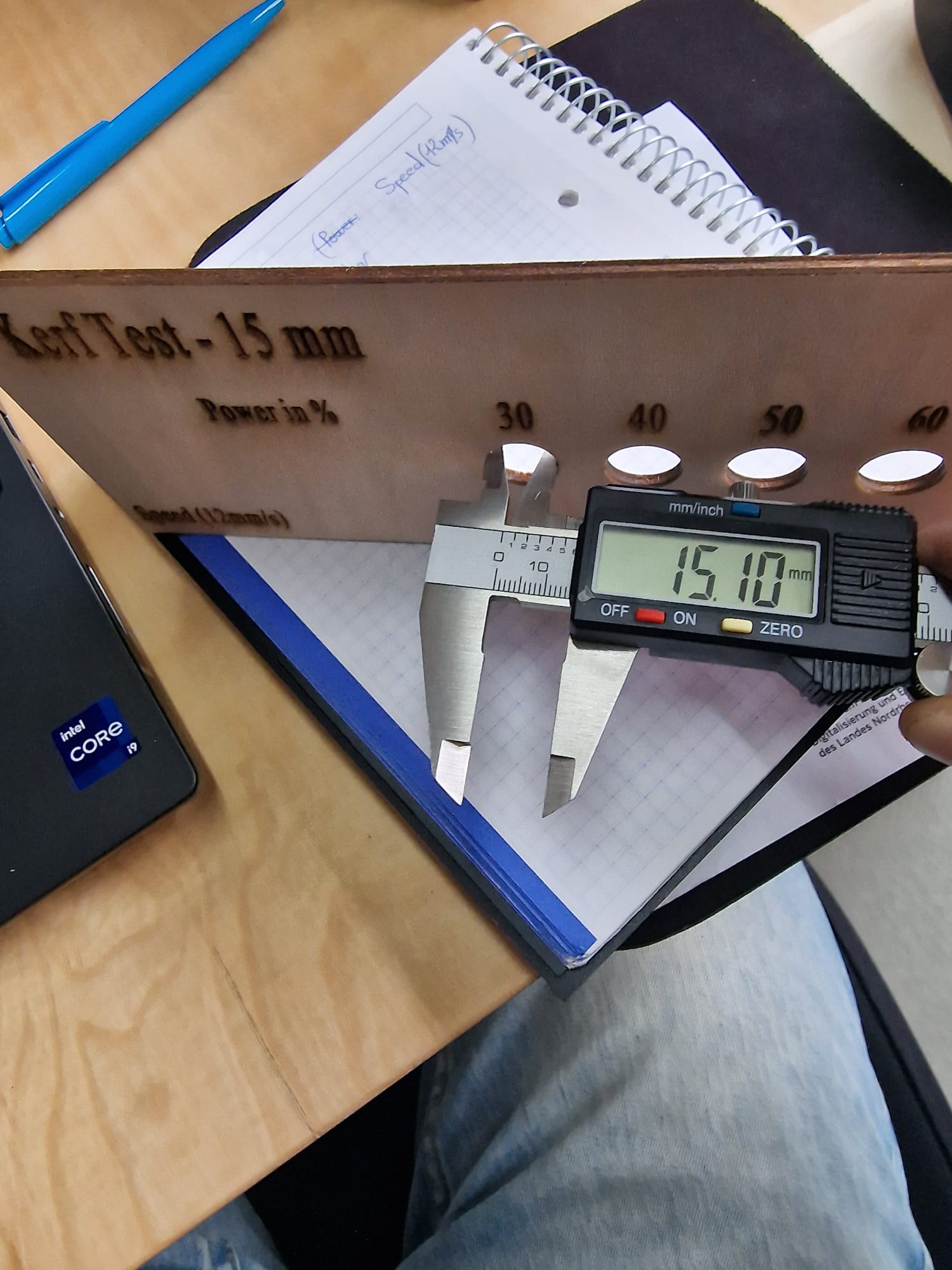

Continuing our group assignment, our focus extended to the characterization of focus and kerf by utilizing a specific template. Within this template, we incorporated circles that underwent cutting with power settings ranging from 30% to 80%, maintaining a consistent speed of 12 mm/s. The results were meticulously recorded in a table, providing a comprehensive overview of our findings.

Results:

- For 30% power, the resulting circle diameter was measured at 15.10 mm.

- At 40% power, the circle diameter slightly increased to 15.12 mm.

- With 50% power, the circle diameter expanded to 15.14 mm.

- At 60% power, the circle diameter further increased to 15.16 mm.

- With 70% power, the circle diameter measured 15.18 mm.

- Finally, at 80% power, the circle diameter reached 15.20 mm.

This systematic testing approach enabled us to observe the nuanced effects of varying power levels on the cut diameter of the circles. Such insights are pivotal for refining our laser cutting parameters, ensuring that our focus and kerf dimensions align with our project requirements.

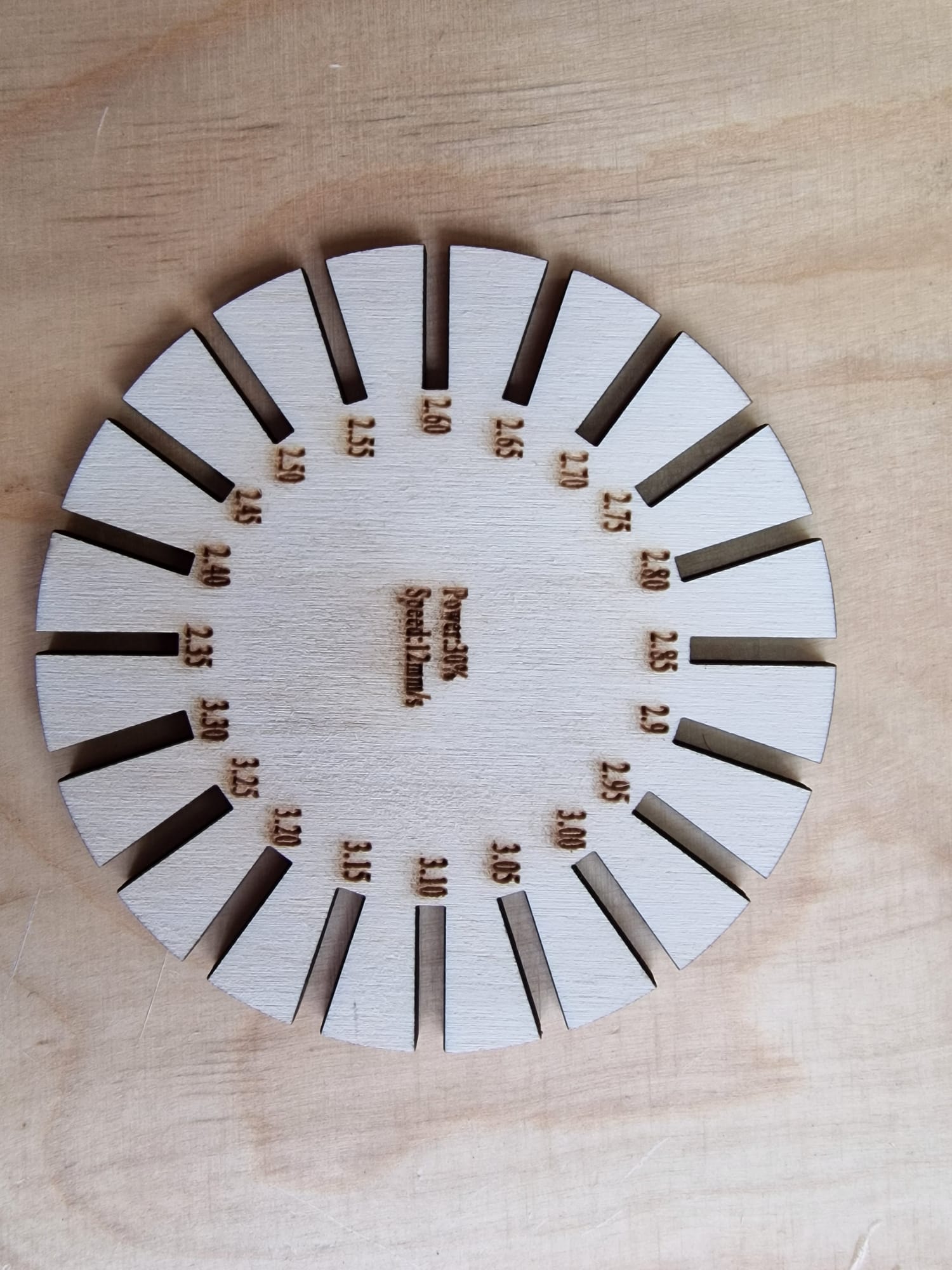

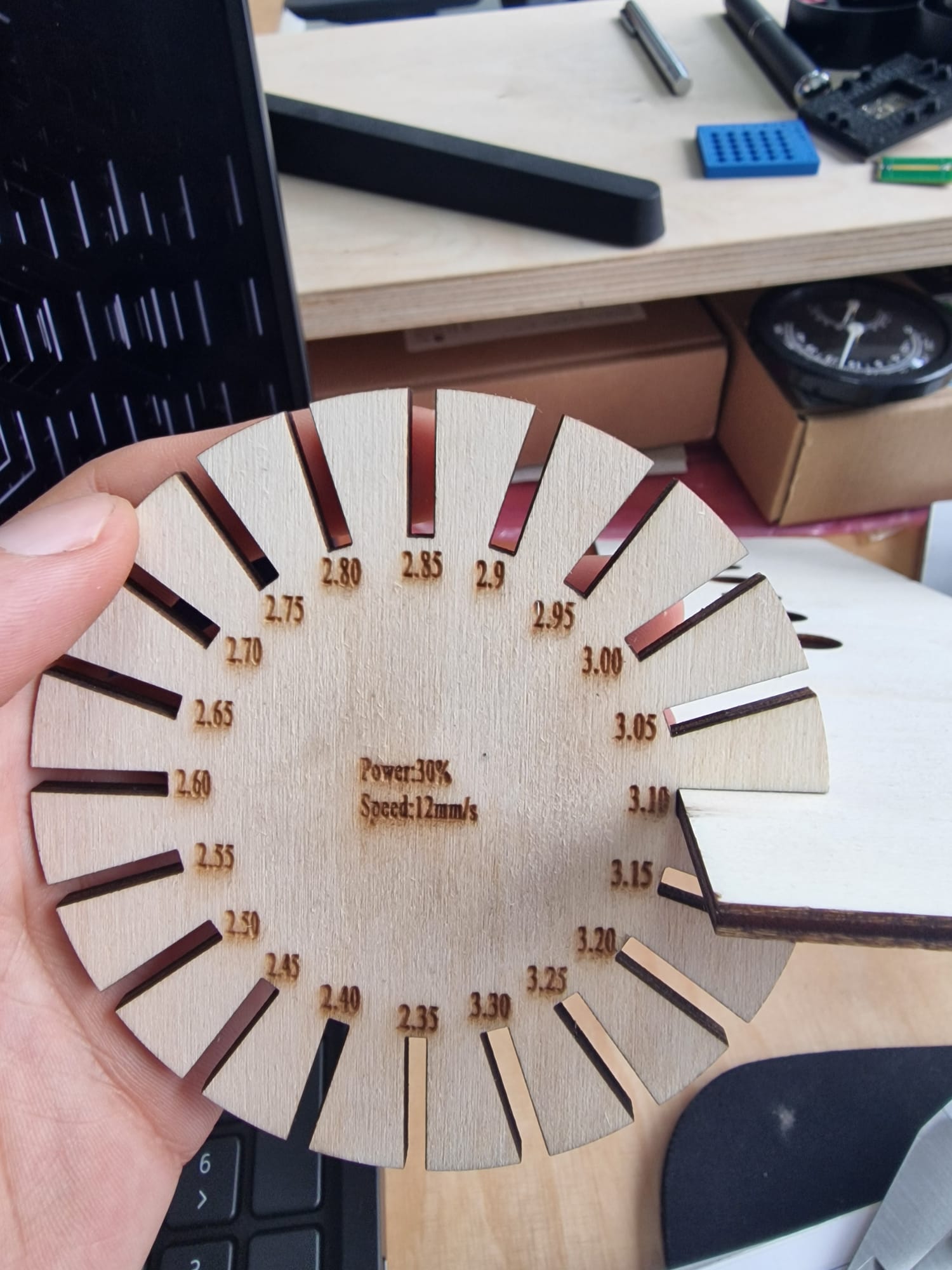

Joint Test

For the joint test, we employed a gear-like template to examine various gap widths ranging from 2.35 to 3.30 mm. The goal was to identify the optimal cutting parameters, specifically a power setting of 30% and a speed of 12 mm/s.

The results revealed that the most suitable joint gap width for achieving a reliable press-fit construction was determined to be 3.10 mm. This width was found to provide an effective and secure connection.