WildCard.

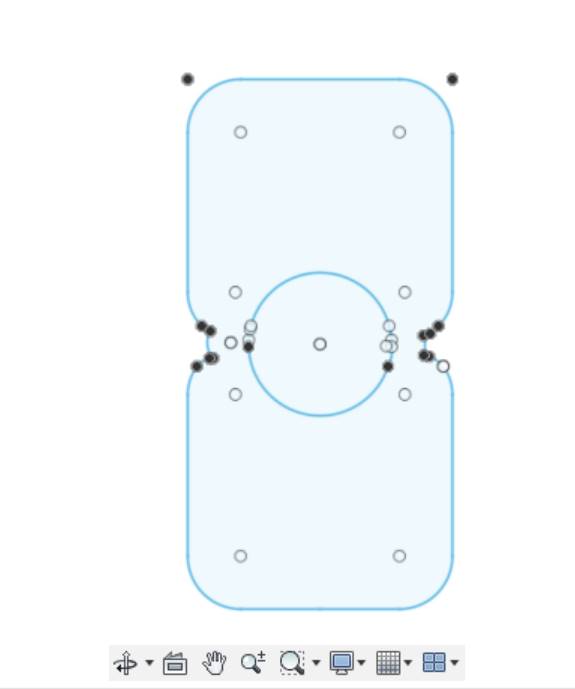

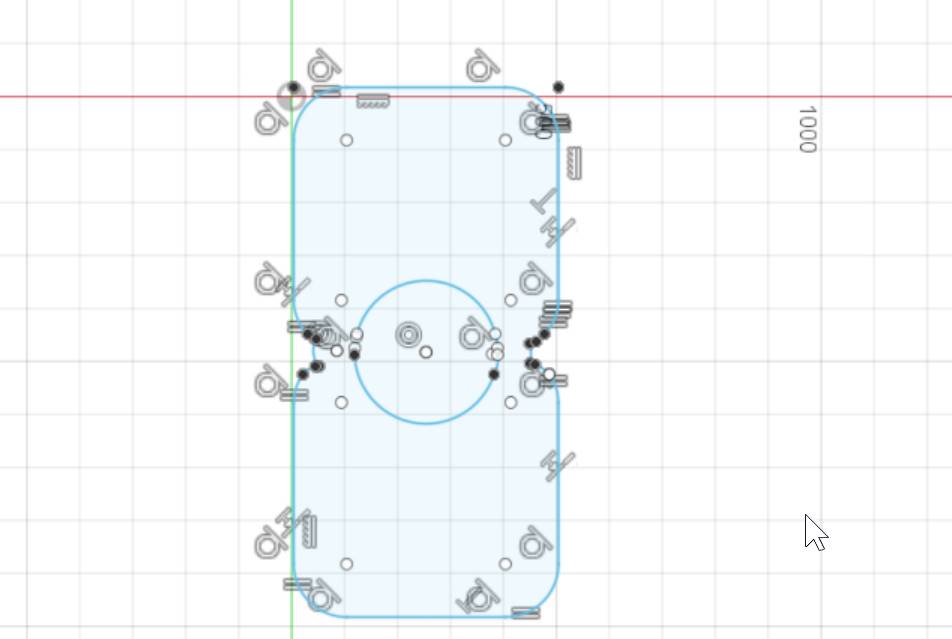

A zund is a digital cutting system used for precision cutting of materials like a paper, card board and fabric. Basically, the Zund uses four software to manufacture, i.e., Cut server, Cut Editor, Cut Manager and Cut Queue. so for the wild card week all 6 of us were given choice to choose between any of the heavy machines and for my vest zund was the perfect machine to cut the fabric. so firstly i just designed on fusion 360 and then exported the file as DXF file since the machine could read only DXF files. below here is the designed on fusion 360

Application

The Zund is best used for cutting materials that cannot be cut on the laser cutter or CNC such as; plastics, or foam rubber that release fumes, highly flammable materials like foam-core and cardboard, or textile materials. A secondary benefit of the Zund is that because it uses blades and does not produce heat like that generated by the laser cutting process, there are no burned edges on materials. The Zund can also be used for more unusual materials such as wax, metal mesh, corrugated plastic, plastic films, fabric, foam and felt. Because force is exerted by the blade moving during cutting (unlike the laser cutter), smaller features may not come out as cleanly or detailed as they would on the laser cutter. In general, the Zund is suited to larger features.

The upper design on fusion is simple since I just measured the dimension on my body size and the calculated it times 2 since I had to have two of the same size for putting the components.

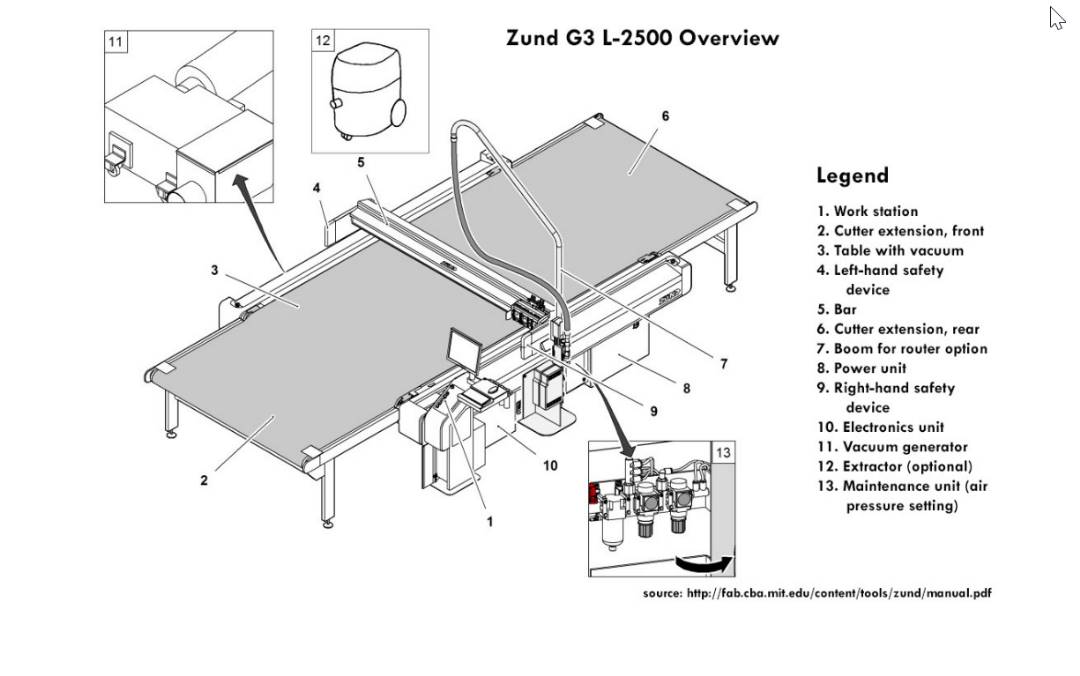

Below here is an over view of zund machine.picture source. Here.

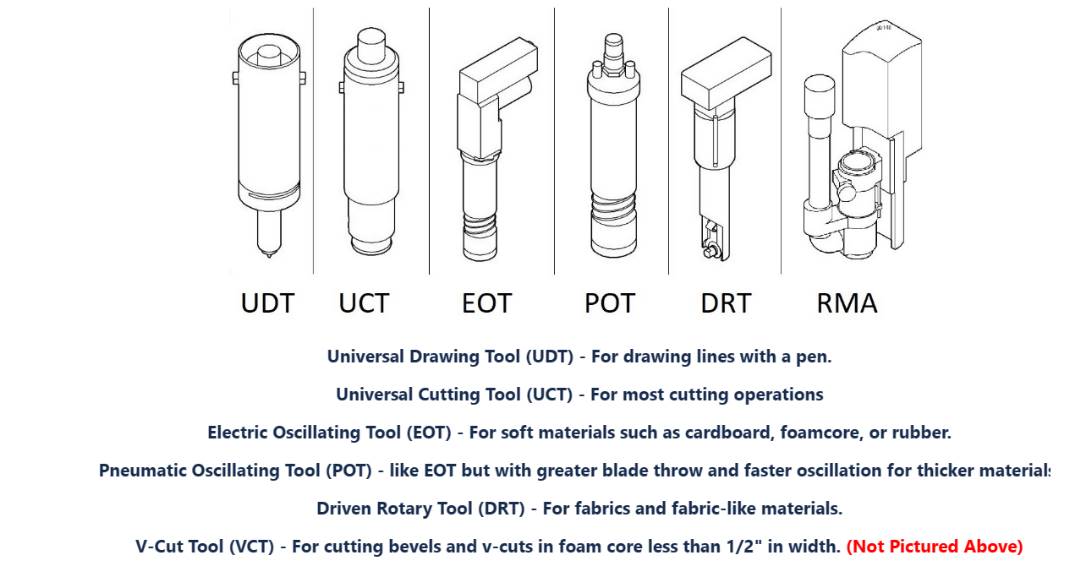

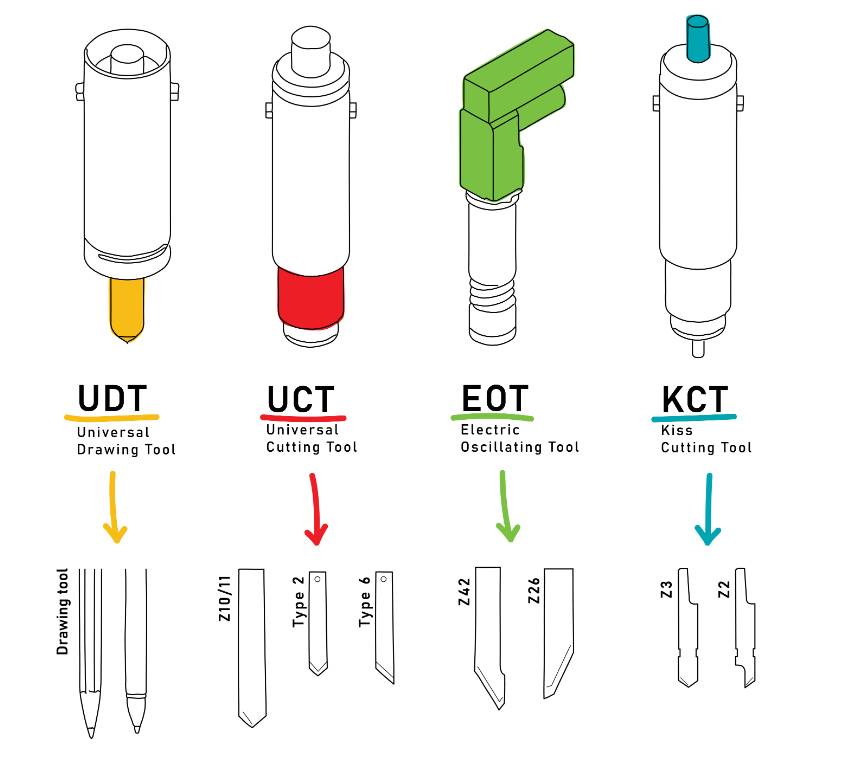

Zund different types of blades.

Light Barriers & Emergency Stop(Safety measures.)

The Zund has safety features to prevent injury during operation. The main feature is a series of 'light barriers' that are projected from one end of the gantry to the other on the front and back side of the cutter. If these beams are broken by someone reaching into the operating area, or if a piece of stock lifts up unexpectedly, the cutter will immediately stop operation. To continue the operation after everything is cleared from the table, press 'OK' then 'Online' to continue the cut from where it stopped. While the light barriers are a soft stop, the red emergency stop buttons are a hard stop. When the emergency stop is pressed the operation immediately stops, cancels the current job and disengages the tools. To continue from an emergency stop the button must be twisted to be released, then follow the instructions on screen. The tools will re-engage and require initialisation and the job will need to be restarted from the PC. If something begins to go wrong during the cut, such as the stock moves unexpectedly, the operation can be paused by pressing any of the grey directional buttons on the console or 'online'. The job can then be resumed by pressing 'online' once the issue is resolved.

Let us see the Workflow.

Since sewing so difficult for me, doing it manually was very frustrating. After Sir Rico visited here in Bhutan he helped me to learn how to sew. and this was the design I sew on the sewing machine as weel as on the zund using fusion.Now let us see how to cut on zund. Thinley helped me to use the machine since he was the zund expert in the lab. So before that you need to turn on the machine. Press F1 and the you can see the light blink on the machine saying online.

;;">

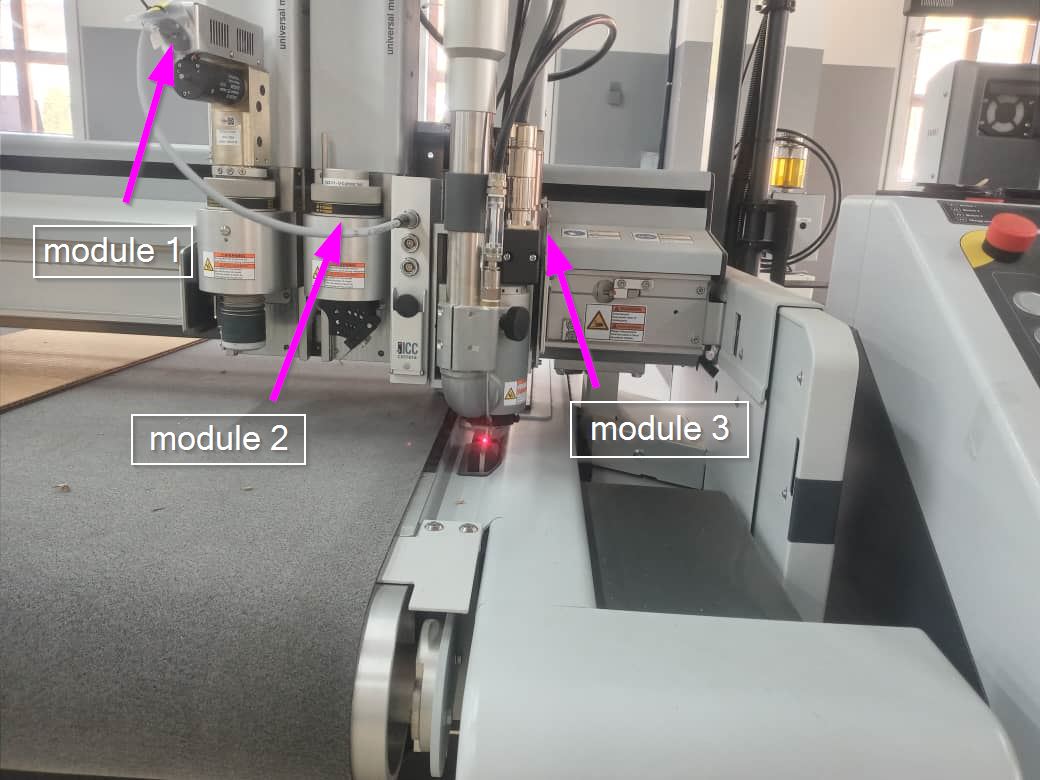

After that turn on the pc while the machine is initializing. Below here we can see that there are 3 types of module and each module has different types of blades. 1 for card-bord, 1 for fabric and 1 for Acrylic.

Below here is the job controller for zund which has it own app.

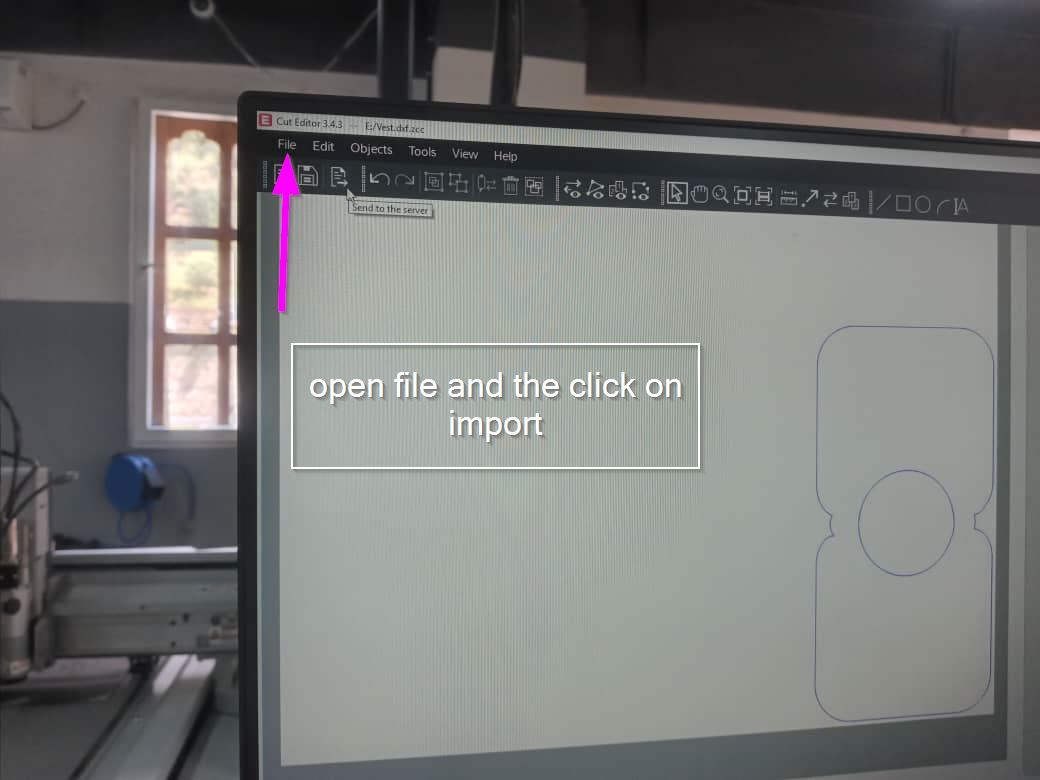

Next import your design like how you normally import design files on other machine, remember the design file should be in DXF file even if you design on any soft ware thats fine but the design file should be DXF file for the machine to read it. Go to file and the you will get a drop down and then select import option like other normal machine.

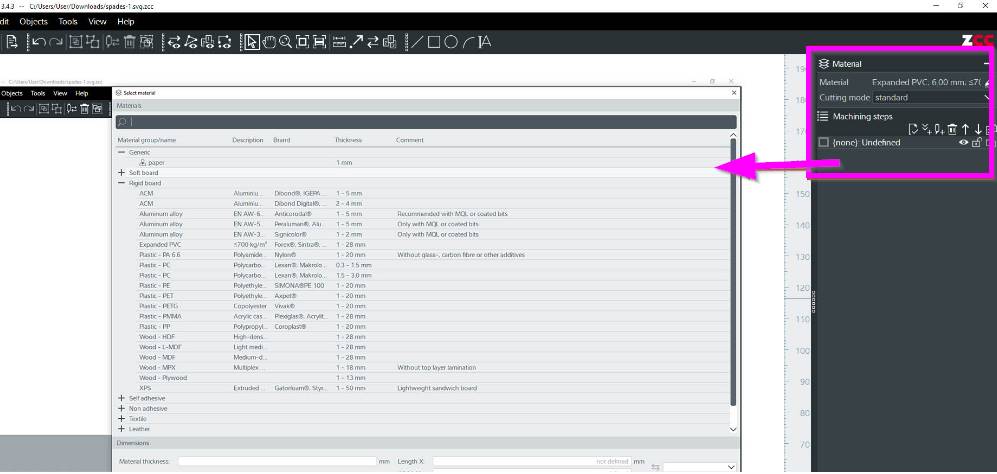

After that select the material type from the right corner

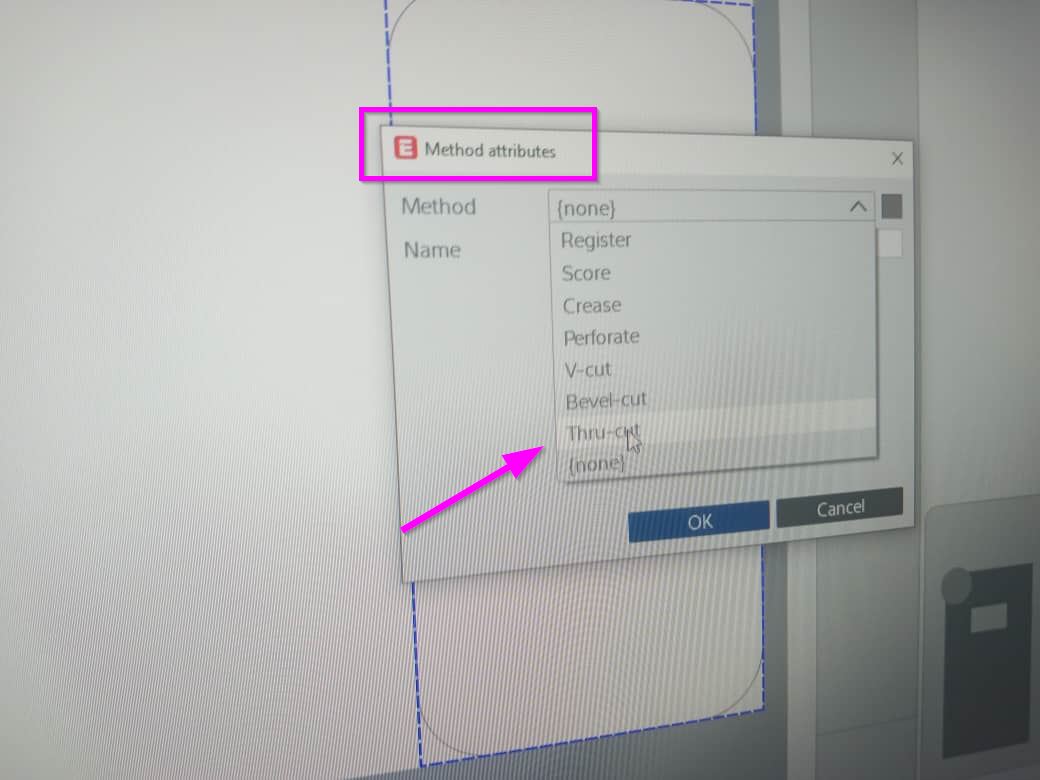

And the select the material attribute for my design it was through cut since it was just to cut the fabric.no engraving and all.

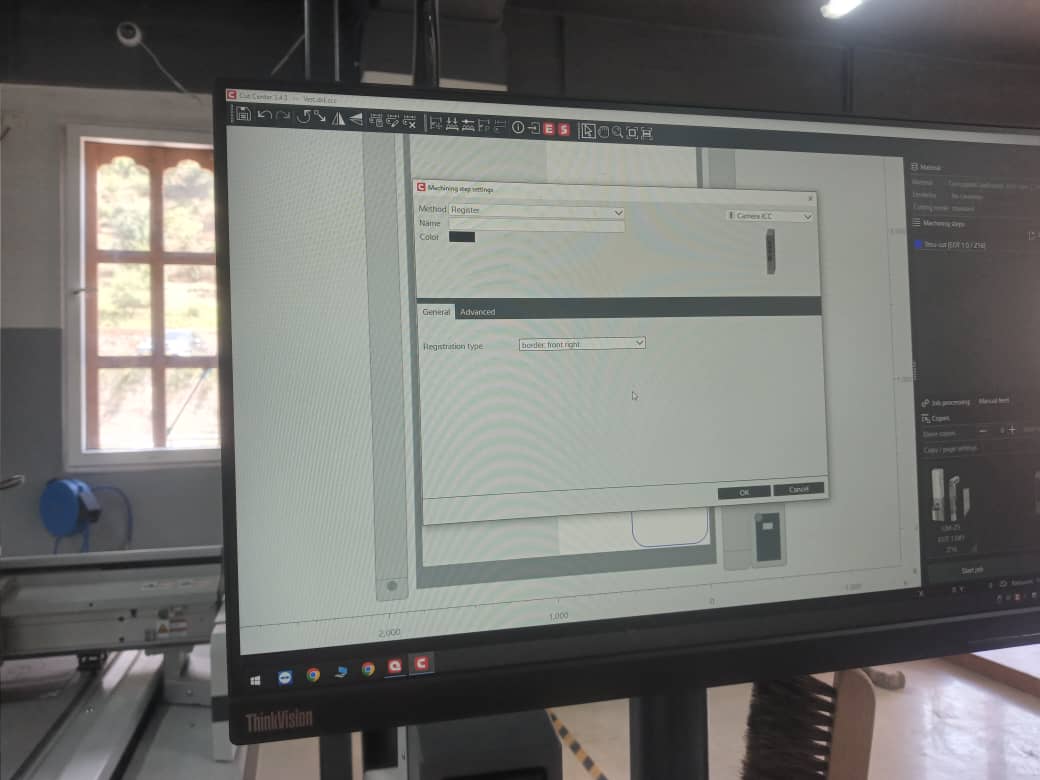

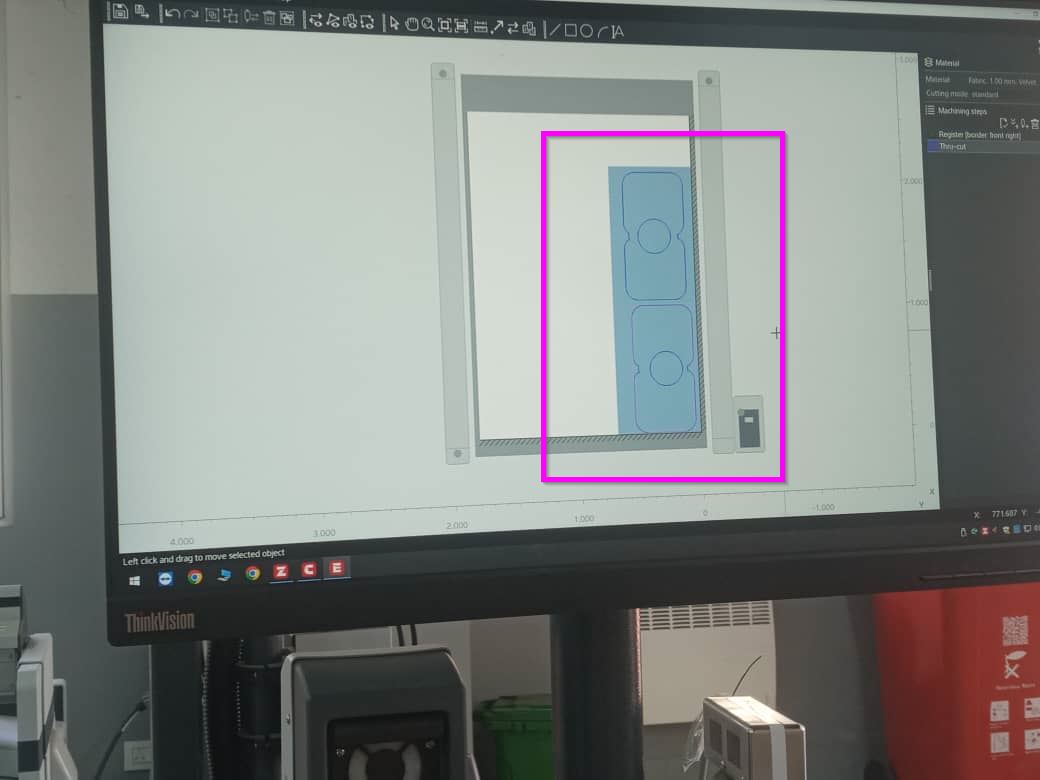

Now choosing blade and machining setting up for my fabric vest i didn't had to change any setting since it was just to thru-cut. No engraving or any patches needed to be added,patches were used for the routing since to avoid sucking of the small design by the vacuum.(Method>register, color>black,camera>ICC)

Below here shows when you send the design to the job controller to cut

Th e machine sets auto z , we dont have to do it manually

Below here is the video of how zund works.

Before cutting on the fabric I just did a test cut on the cardboard.

Now after the test cut was done I just cut on fabric.

Challenges of using zund machine.

While Zund machines are highly versatile and efficient cutting solutions, there are some challenges that i encountered when using the machines.

General challenges ;

1. Material handling: Zund machines are capable of cutting a wide range of materials, but some materials may be more difficult to handle than others. Users may need to invest in specialized tools and equipment to help with material handling and ensure that the machine can cut the material effectively. 2. Maintenance: Like any machine, Zund machines require regular maintenance to ensure that they continue to operate at peak performance. Users will need to invest time and resources in maintaining their machines, which can include cleaning, lubrication, and replacement of worn parts. 3. Software integration: Zund machines are often used in conjunction with other software and hardware solutions, which can create compatibility issues and other challenges. Users will need to work closely with the Zund team to ensure that their machine is properly configured and integrated with other tools and systems. 4. Training: Zund machines are highly advanced cutting solutions, and users may require training to ensure that they can operate the machine effectively and safely. This can involve learning how to use the machine's software, understanding the cutting process, and following best practices for material handling and maintenance. Overall, while there are some challenges associated with using Zund machines, these machines can provide significant benefits to businesses across a wide range of industries. By investing in the right tools, training, and maintenance, users can ensure that their Zund machine continues to operate at peak performance and delivers high-quality cutting solutions for years to come.Challenges I Faced

To get the most out of a Zund machine, it's important to carefully consider your specific cutting needs and to work closely with the Zund team to ensure that your machine is configured properly and optimized for your specific workflow. It's also important to invest in ongoing training and maintenance to ensure that your machine continues to operate at peak performance over the long termPurposes of Zund Machine.

Zund machines are commonly used in a wide range of industries, including automotive, packaging, advertising, and textiles, to cut a variety of materials with precision and efficiency.

If you have a specific cutting need or requirement, it's worth considering whether a Zund machine might be a good fit for your business. The main purpose of Zund machines is to provide precise and efficient cutting solutions for a wide range of materials, including textiles, leather, foam, and composites. Zund machines use a variety of cutting technologies, including knife cutting, laser cutting, and router cutting, to provide versatile cutting solutions for a variety of industries, including automotive, packaging, and advertising. Zund machines are designed to handle a wide range of materials and can be customized to meet the specific needs of each user. They are known for their accuracy, efficiency, and ease of use, In a nutshell, zund machine Can even provide significant benefits to businesses across a variety of industries. Some of the specific purposes of Zund machines include cutting patterns, shapes, and designs for textiles and other materials, creating prototypes and samples, and producing high-quality finished products with precision and efficiency.Recommendations

Here are some recommendations to keep in mind:

1. Take the time to carefully evaluate your specific cutting needs and requirements. This will help you choose the right Zund machine and cutting technology to meet your specific needs. 2. Work closely with the Zund team to ensure that your machine is properly configured and optimized for your specific workflow. This will help ensure that you get the most out of your investment and that your machine continues to operate at peak performance over the long term. 3. Invest in ongoing training and maintenance to ensure that your machine continues to operate smoothly and efficiently. This will help you avoid downtime and costly repairs, and will help you get the most out of your investment over the long term. 4. Consider integrating your Zund machine with other software and hardware solutions to optimize your workflow and improve productivity. This can help you streamline your processes and increase efficiency, which can lead to significant cost savings over time. Overall, Zund machines are known for their versatility, accuracy, and ease of use, and can provide a wide range of benefits to businesses across a variety of industries. By carefully evaluating your specific needs and working closely with the Zund team, you can ensure that you get the most out of your investment and achieve your cutting goals with confidence. design file