Output Devices

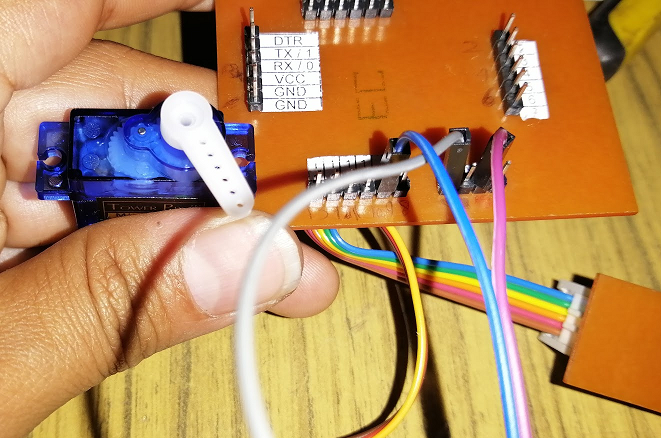

In this activity I used a Fabduino PCB Board with a servomotor SG-90 to control the angle of movement.

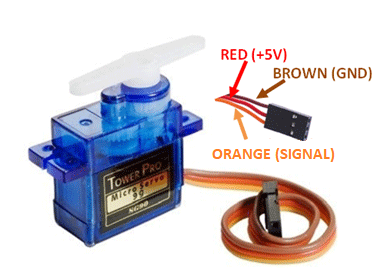

Servomotor SG-90

This analog micro servo will rotate up to 180 degrees (90 in each direction). You can expect it to operate the same as standard versions, but this micro servo is much smaller and can fit into tighter spaces. Its lightweight (9g) design will still output a high amount of power. This servo will work with any servo library, code, or compatible hardware.

Specifications

Product Name: Pro 9g mini servo(S version)

Manufacturers ID: TPSG90S

Size: 0.866”x0.48”x1.142”

Weight: 9g

Products Torque: 8.96lp/inch(4.8V) 1.6kg/cm

Reaction speed: 0.1sec / 60degree (4.8v)

Operating voltage: 3.0V-7.2V

Temperature: 0-55 degrees

Action Dead: 10us

Gear Media: Nylon

Mode: Analog

Pin Configuration

1. VCC: It has a power supply of 3.5V to 5.5V.

2. Ground: The module usually connects to the ground of a circuit.

3. Signal: Controlled by PWM.

Once the servo motor is connected, the Arduino Nano can send pulse signals to the servo motor to control its position. A servo motor is controlled by sending a series of pulses through the signal line. The width of the pulse is what determines the angular position of the servo, which can typically rotate up to 180 degrees, as it has physical limits. Generally pulses with 1ms duration correspond to 0 degrees position, 1.5ms duration to 90 degrees and 2ms to 180 degrees.

While the duration of the pulses required to control a servo motor is typically standardized, the minimum and maximum pulse durations may vary depending on the specific brand or model of the servo motor being used.

Fabduino

I used my Fabduino board to do this assignment, that can be found in Assignment 08 Electronics Design.

Previuosly designed in other assignments.

Components used

01 Fabduino PCB Board

01 Servomotor SG-90

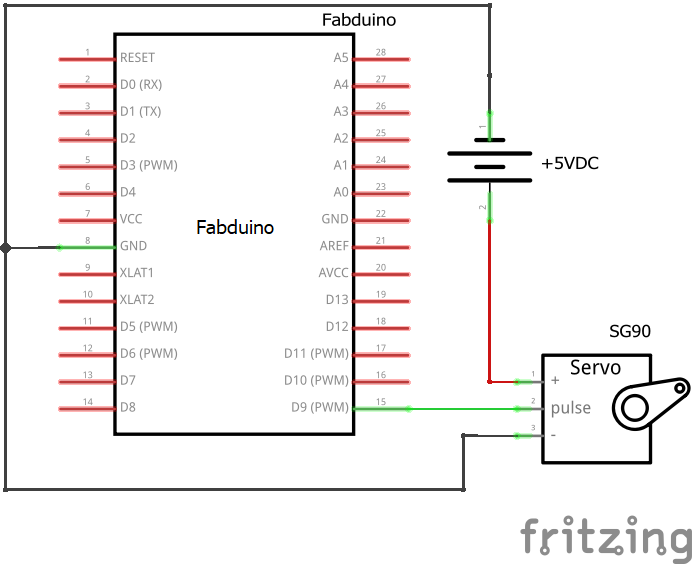

01 External Power Supply

Jumpers

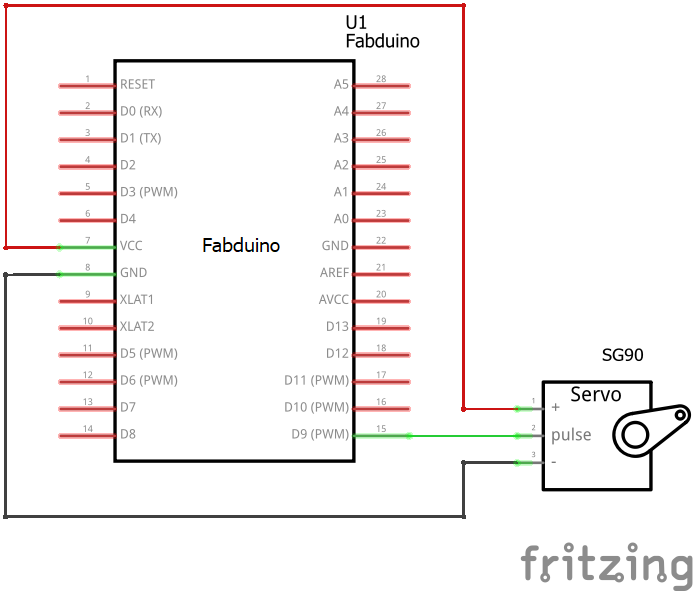

So, I made the next circuit to test the servo motor.

Schematic Circuit

I used PWM pin (pin D9) and VCC and GND.

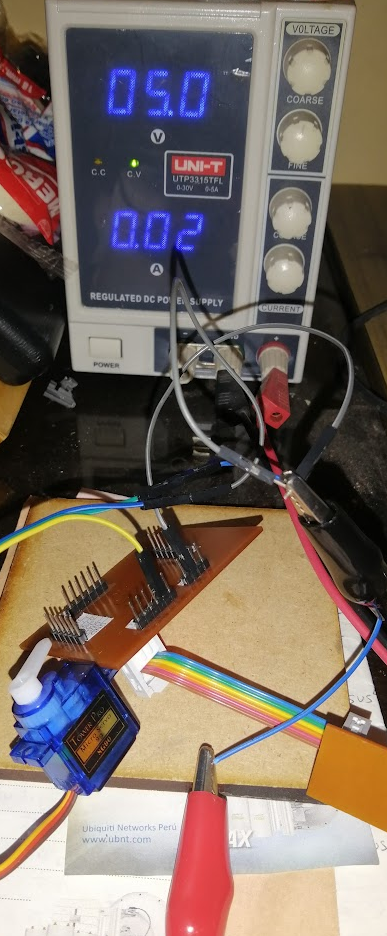

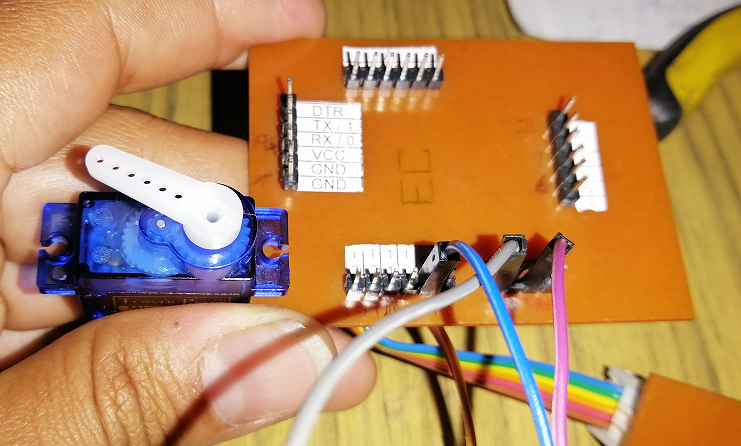

Next, I've tested with a external power supply

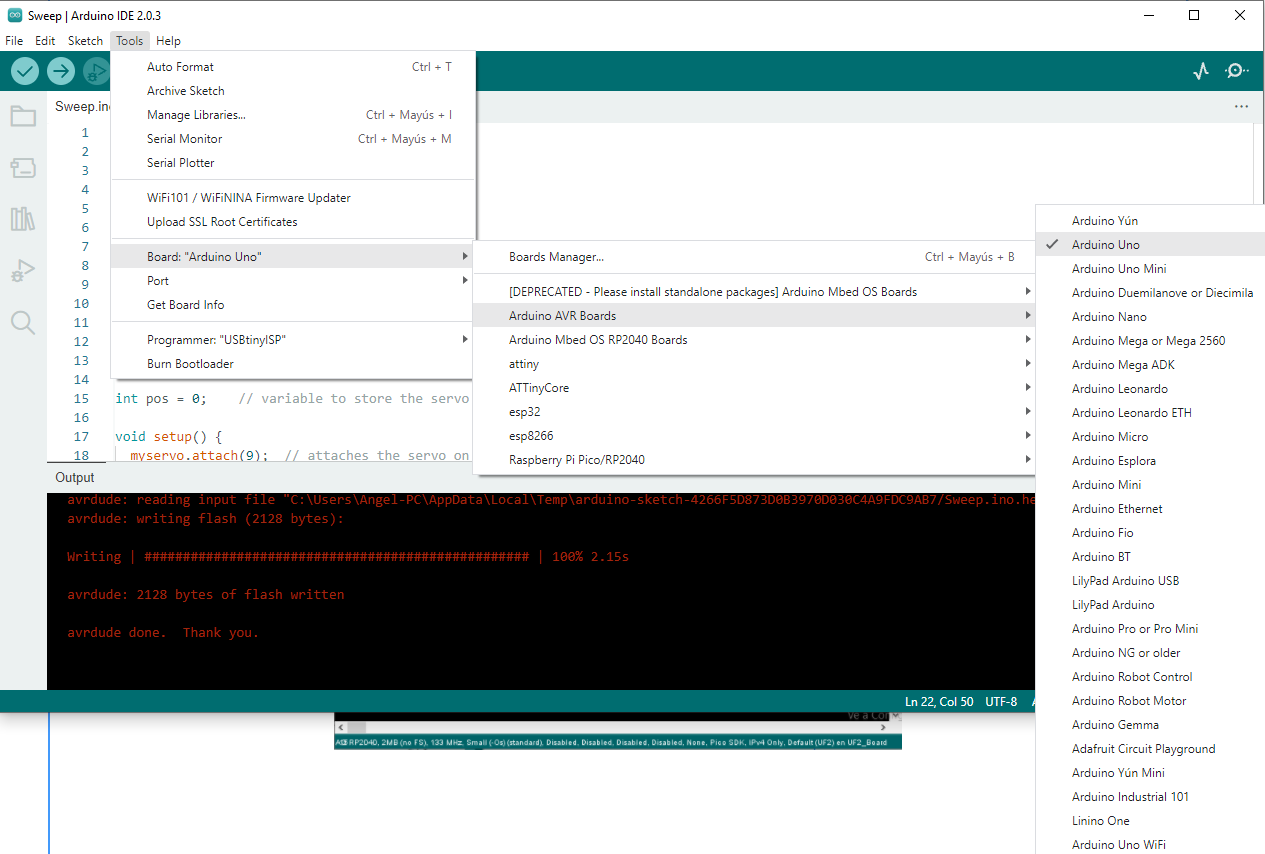

Programming the PCB Boards

In the programming IDE we must select the board Arduino UNO and program using FabISP

Test Code / Firmware

//I've used as reference the arduino code from git repository (for controlling a servo motor)

//https://github.com/arduino-libraries/Servo/blob/master/examples/Sweep/Sweep.ino

/* Sweep

by BARRAGAN

This example code is in the public domain.

modified 28 May 2015

by Michael C. Miller

modified 8 Nov 2013

by Scott Fitzgerald

http://arduino.cc/en/Tutorial/Sweep

*/

#include <Servo.h>

Servo myservo; // create servo object to control a servo

// twelve servo objects can be created on most boards

void setup() {

myservo.attach(9); // attaches the servo on D9 pin Fabduino to the servo object

}

void loop() {

int pos;

for (pos = 0; pos <= 180; pos += 1) { // goes from 0 degrees to 180 degrees

// in steps of 1 degree

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(15); // waits 15ms for the servo to reach the position

}

for (pos = 180; pos >= 0; pos -= 1) { // goes from 180 degrees to 0 degrees

myservo.write(pos); // tell servo to go to position in variable 'pos'

delay(15); // waits 15ms for the servo to reach the position

}

}

Testing

In this test I used a servomotor SG-90, angles from 0 to 180 degrees in a loop. The Servo.h library was used.

Servomotor connected at 0 degrees.

Servomotor connected at 180 degrees

Testing with a external power supply to measure the DC current. The average value is 0.03A (30 mA) at 5V, I mean 150mWatt.