4. Computer controlled cutting¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

To do list¶

- Group assignment:

- characterize your lasercutter’s focus, power, speed, rate, kerf, and joint clearance

- Document your work to the group work page and reflect on your individual page what you learned

- Individual assignments

- Design, lasercut, and document a parametric press-fit construction kit , which can be assembled in multiple ways. Account for the lasercutter kerf.

- cut something on the vinylcutter

Laser cutting¶

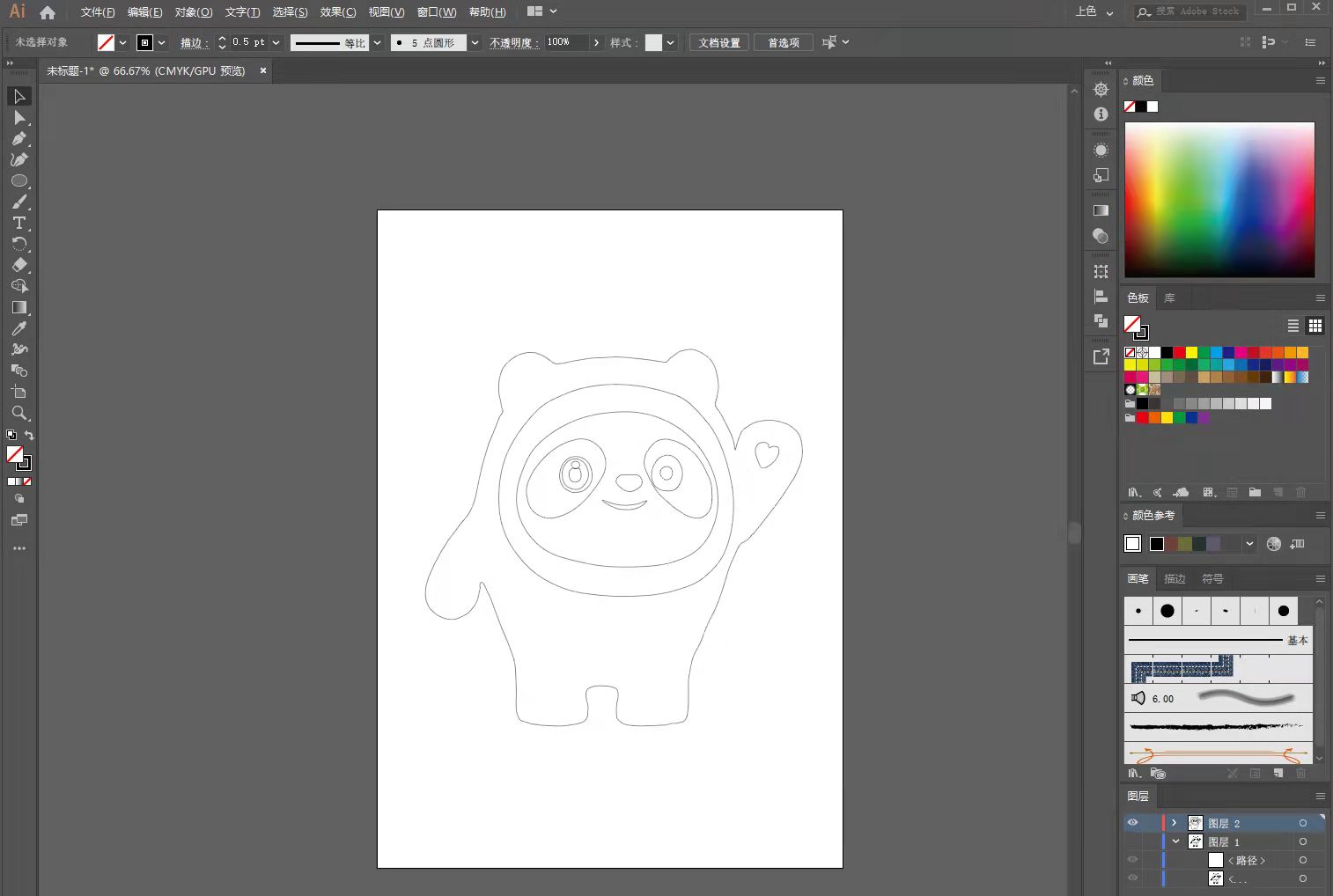

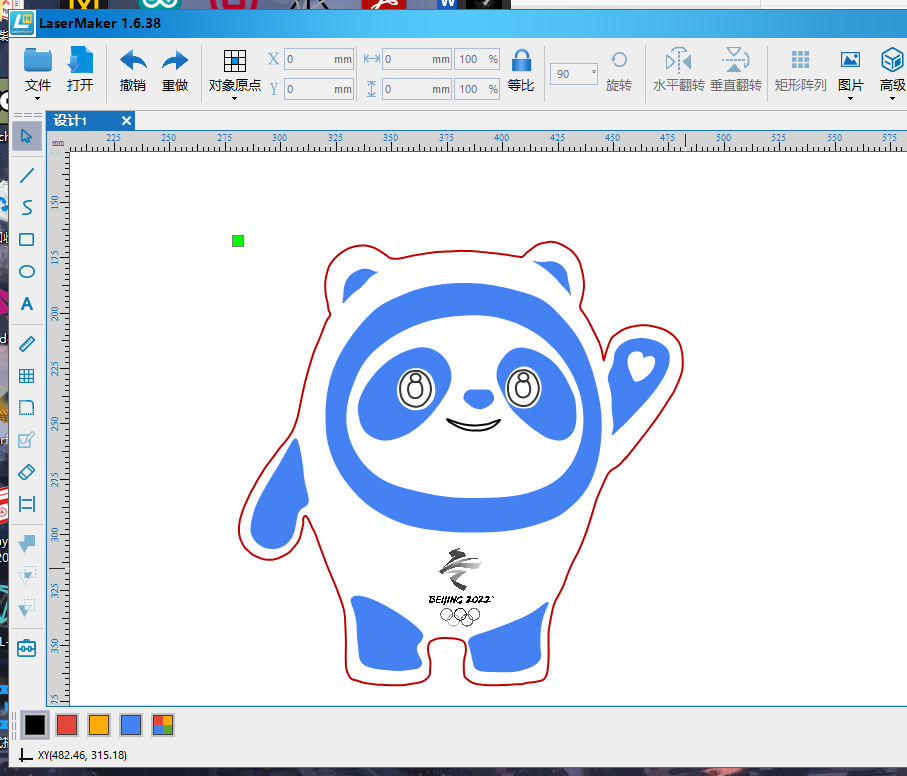

As a distance student, I have to finish laser cutting in my own laboratory. I copied Bing dwen dwen in AI and then imported it into the laser cutting machine software. In the software, there were three kinds of processing methods, including carving, line tracing and cutting.

However, there is a problem in the engraving of the picture. There is a part of the Beijing Winter Olympics logo missing. I think the color of the picture is too light to be recognized by the laser cutting machine. Unfortunately, when I realized this problem, I had moved the material and couldn’t align and engrave again. I’ll try again next time

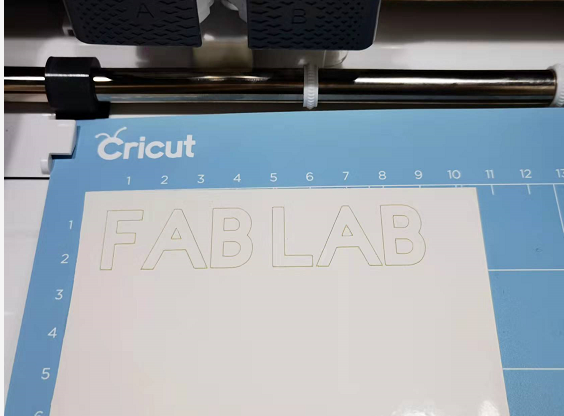

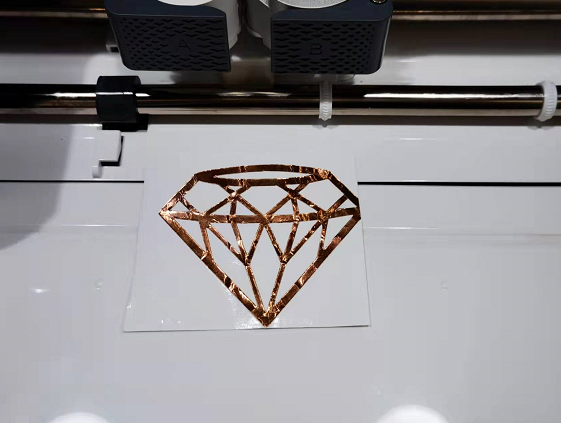

Vinyl cutting¶

I haven’t used a vinyl cutter before. Fortunately, there is a new equipment in the laboratory. I tried to cut A4 printing paper and self-adhesive paper on the machine and made some logo stickers. I also tried to cut copper tape, which is very interesting. I consider making some flexible circuits in the later stage.