Leen Nijim

Assignment 17

Applications and Implications

Task

Our assignment this week was to write our final project proposals. I had to answer some core questions about the project and make sure it integrates the range of skills I learned throughout Fab Academy.

Project Core Requirements

My final project should incorporate the following:

- 2D and 3D design.

- Additive and subtractive fabrication processes.

- Electronics design and production.

- Embedded microcontroller interfacing and programming.

- System integration and packaging.

- Where possible, self-made rather than bought parts and components.

Project Core Questions

Here are the main questions that my final project should be able to answer:

What will it do?

For my final project, I’d like to make an active scuba drysuit drying rack. Ideally, I’d like this rack to be modular so I can install it and use it in whichever accommodation I happen to be staying at. But at the same time it also has to be structurally sturdy enough to not collapse under continuous loading as it will act as a permanent hanging storage space for my scuba suit. Other features the rack has are:

- Smooth contours for the hanger to support the scuba suit without damaging it.

- Ventilation ducts with an electric fan.

- Humidity sensors.

- An interface with an LCD and some buttons and dials.

Who's done what beforehand?

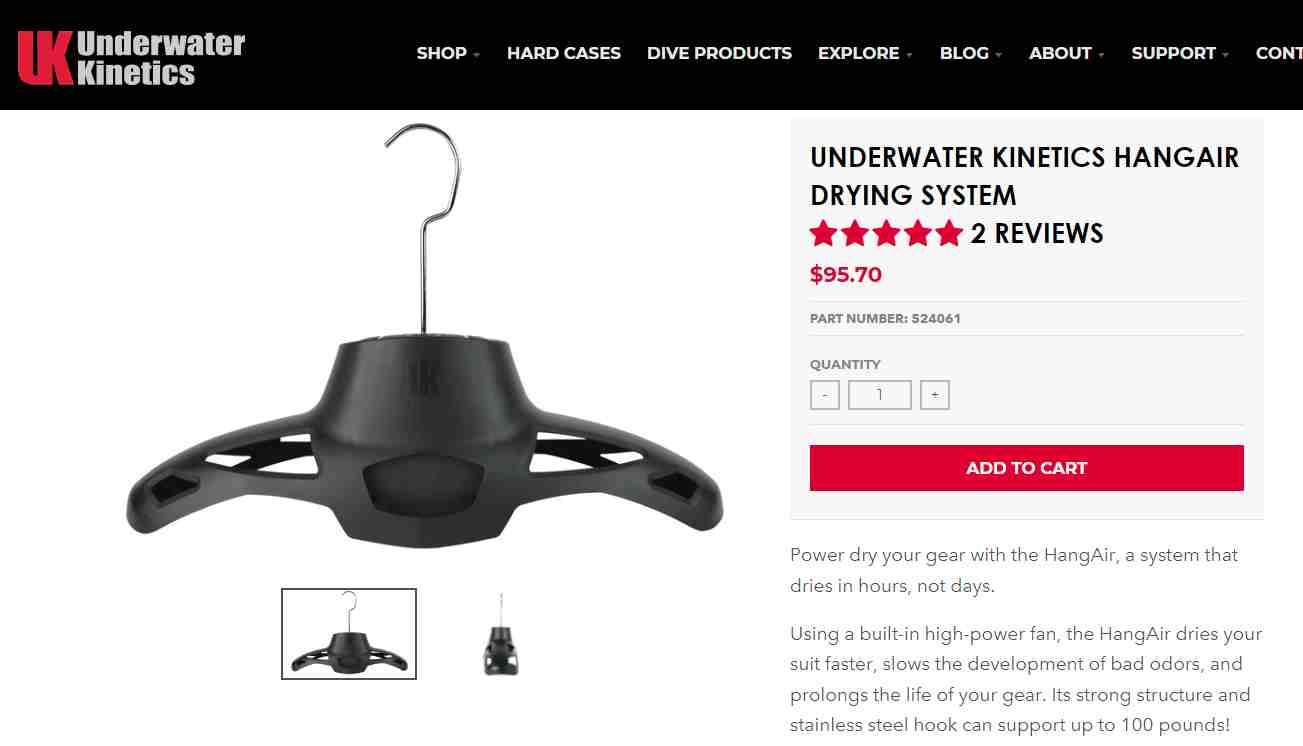

To get a rough idea about the direction I should take my system in, I did a bit of research in the Fab Academy archive as well as the internet to see whether any former student had made such a project, or if there are any existing products that I can get inspired from. Here are two products existing in the market, the first one costs almost $100 according to their website.

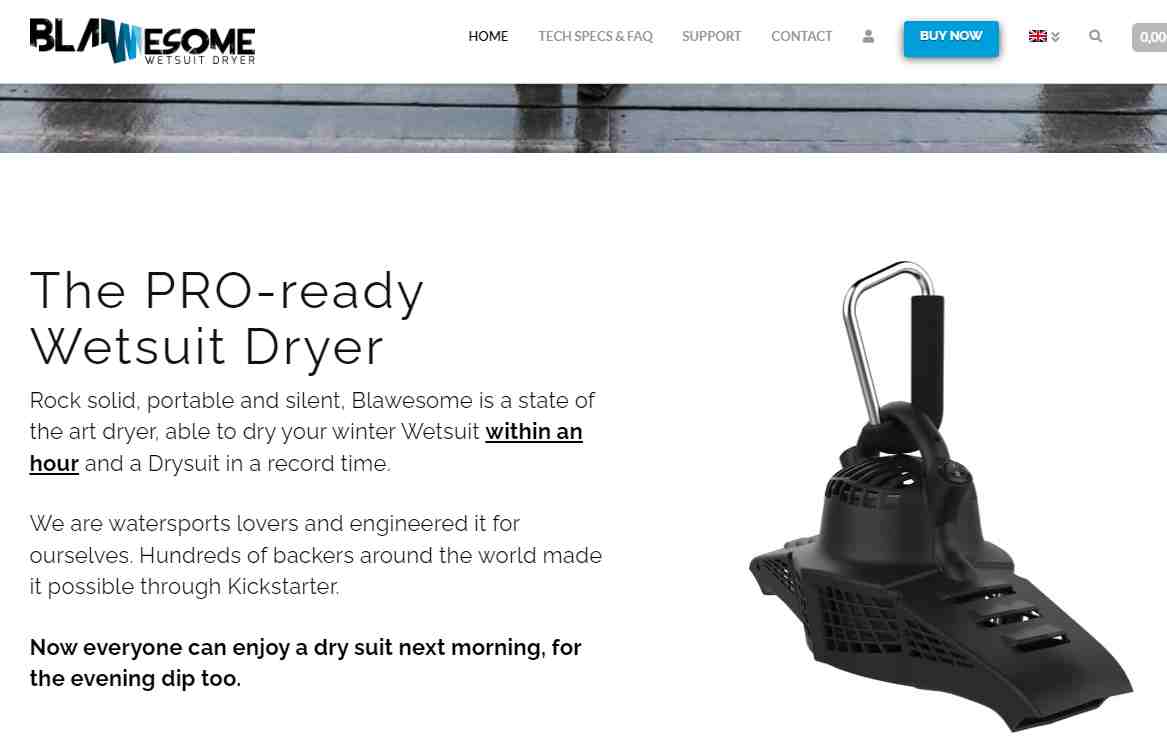

While this one costs about $180.

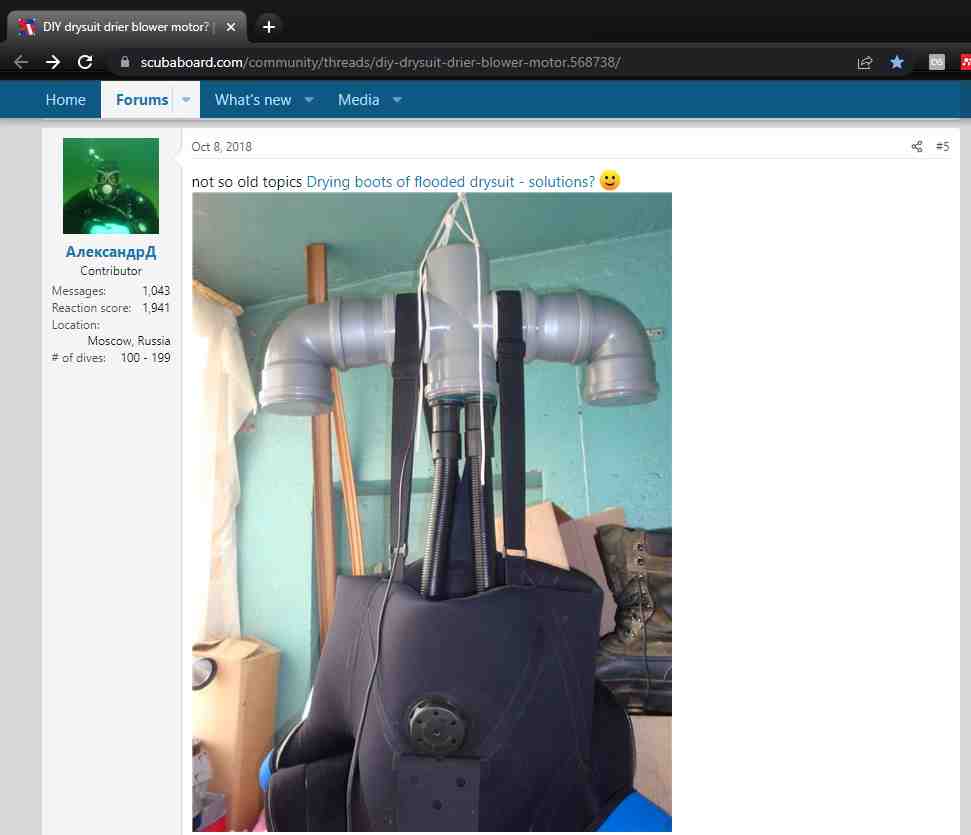

There are some DIY solutions as well that are closer to what I am attempting to design. The first one I found on ScubaBoard Forum:

And the second one on Instructables.

- Instructables.jpg)

As far as I was able to see, no similar project has been documented on the Fab Academy archive. Two former students, though, have done some related work that I looked at. Joe Zoulikian made a dehumidifier box for the filament spool mounted on a 3D printer, and Marco Wehrfritz designed a surf booties dryer.

What will you design?

Here is what I will be making:

- 3D model and render all/part of the system.

- Laser cut hookes for the hanger.

- 3D print parts like fan housing and electronics housings.

- Design and make the microcontroller board.

- Make the hanging rack.

- Prepare the peripherals and integrate them into the system.

What materials and components will be used?

Here is a rough summary of the materials and components for each part of the system:

| Feature | Material |

|---|---|

| Hooks | Plywood |

| 3D Printed Parts | PLA filament |

| Microcontroller Board | Fablab inventory electronics |

| Hanging Rack | Plywood supplied during Topic 8 week |

| Output Devices | LCD from Fablab inventory, and fan repurposed from an old project in the lab |

| Input Devices | Humidity sensors and button from Fablab inventory |

| Drysuit Hanger | Polypropylen plumbing pipe connectors |

Where will they come from?

Here is a summary of where my system components will be acquired from:

| Feature | Source |

|---|---|

| Plywood | Fablab inventory |

| 3D Printed Parts | Filament from here |

| Microcontroller Board | Fablab inventory |

| Hanging Rack | Plywood supplied from here |

| Output Devices | LCD from Fablab inventory, and fan repurposed from an old project in the lab |

| Input Devices | Fablab inventory |

| Drysuit Hanger | PP pipe connectors from here |

How much will they cost?

Here is a rough estimate of how much my project will cost:

| Feature | Cost |

|---|---|

| Plywood | repurposed scraps |

| 3D Printed Parts | 9€ |

| Microcontroller Board | 13€ |

| Hanging Rack | (125€ covered in Topic 8) |

| Output Devices | 6€ + repurposed from the lab |

| Input Devices | 12€ |

| Drysuit PP Hanger | 9€ |

What parts and systems will be made?

Here are the parts I will make:

- Hanger hooks.

- Microcontroller board and electronics.

- Fan housing and mounting part.

- Electronics housing boxes.

- Hanging rack.

What processes will be used?

| Topic | Feature Description |

|---|---|

| Computer-Aided Design | 3D model and render all/part of the system |

| Computer-Controlled Cutting | Lase cut hooks for the hanger |

| Electronics Production | Make a microcontroller board |

| 3D Scanning and Printing | 3D print parts like fan housing and electronics housings |

| Electronics Design | Design the microcontroller board |

| Computer-Controlled Machining | Make the hanging rack |

| Embedded Programming | Program the microcontroller board |

| Output Devices | Connect LCD and fan motor to the microcontroller |

| Input Devices | Connect humidity sensors, dials and buttons to the microcontroller |

| Networking and Communicatios | Use I2C to communicate between LCD and microcontroller |

What questions need to be answered?

Here is what I still need to do for the project:

- Design and cut hanger hooks.

- Design and 3D print fan housing and mount.

- Design and make microcontroller board.

- Connect and program input and output peripherals with microcontroller board.

- Take care of wiring and system packaging.

How will it be evaluated?

I would like my project to be evaluated in terms of functionality, usability, reliability, and growth potential. It needs to successfully function as a scuba suit dryer, and be easy to use in terms of hanging the suit on it and controlling the system. And it has to function reliably for longer operation hours, and I need to be able to service/maintain it easily, as well as be able to expand its functions, exchange single components, and disassemble it and transport it.