6. 3D Scanning and printing¶

This week I designed a paramatric 3dprinted shelf you can make out of trash.

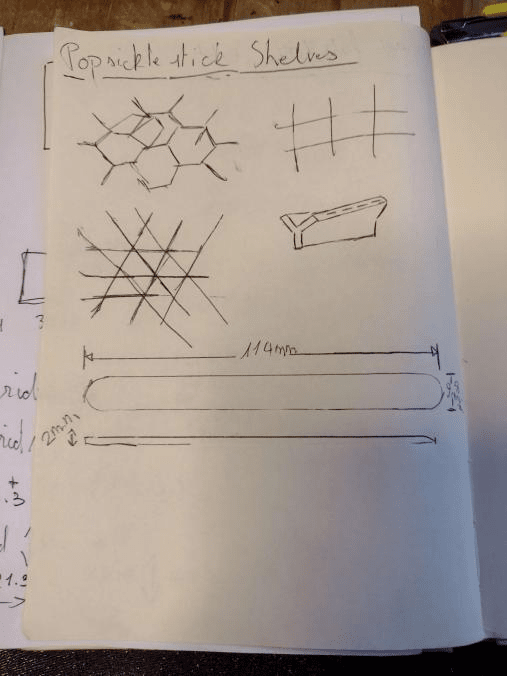

Step 0: Idea, Goal and Research¶

The goal of this idea is to be able to recycle popsicle sticks into a fun shelving system. But also make it so the prints are parametric enough to be able to create different designs.

Measure a bunch, write it down. Let it simmer, draw a few. I started with taking measurements of a popsicle stick, i like using callipers for my measurements, but I also need to realise these dimensions don’t need to be that precise and the printer will add another few steps in which i can clean up the sizing.

Step 1: 3D Model¶

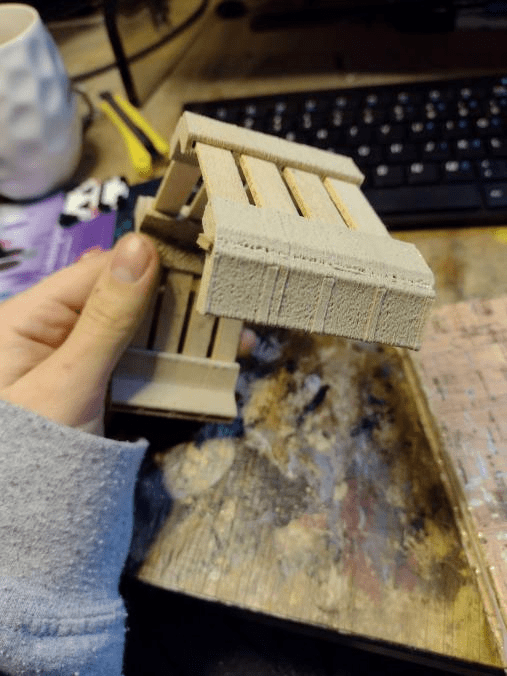

This 3D Model has been made three times over, one in Microsoft 3DBuilder, one in Autodesk fusion360 and another one in the same program but this time parametric. The reason for this is honestly just, because I’m trying to make small spirals, make the versions better over a few iterations.

This is the original version that was made in 3DBuilder, and it had no tolerances, I had to shave the popsicle sticks to be able to plug them in.

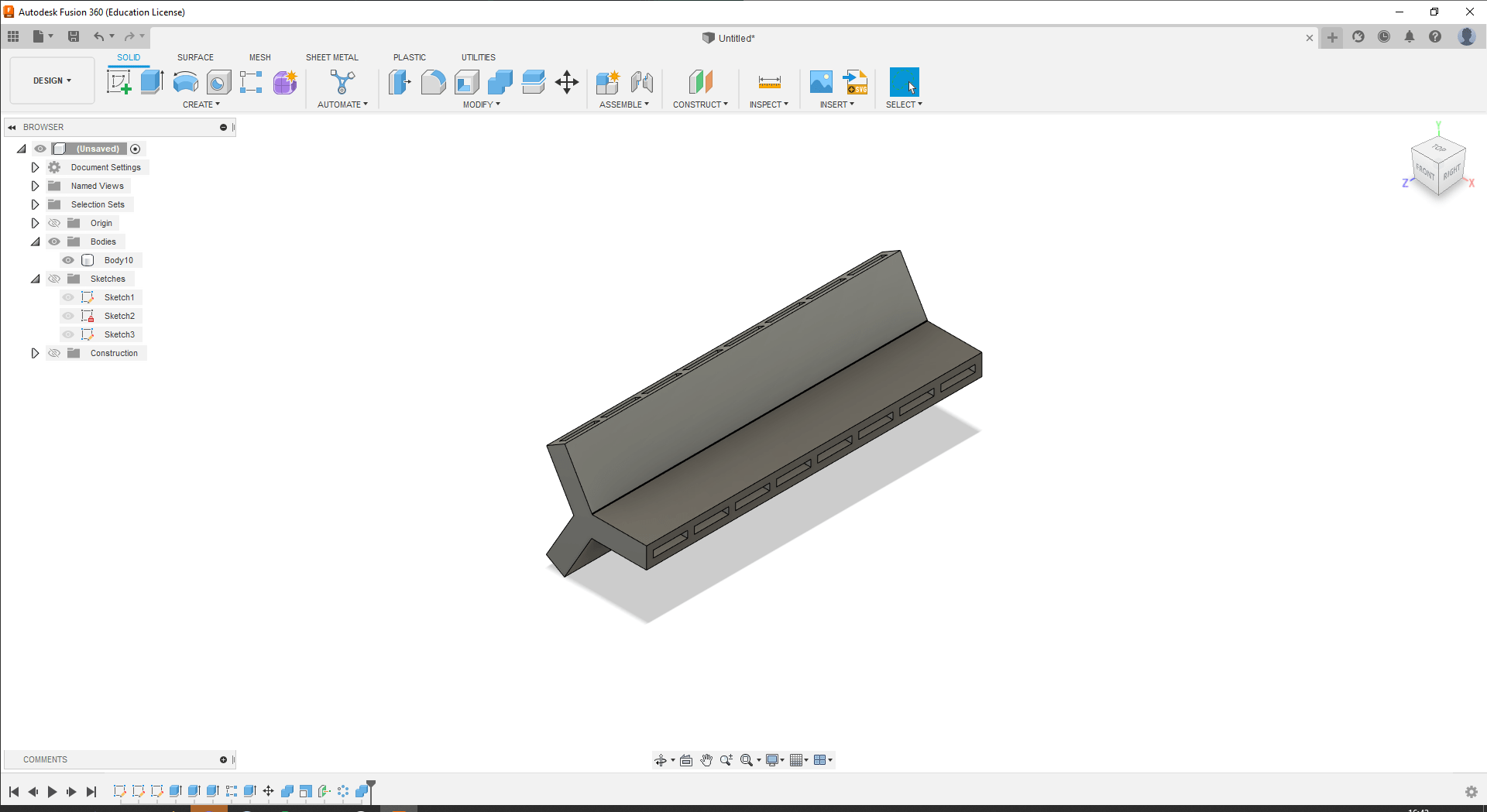

Fusion 360 Parametric¶

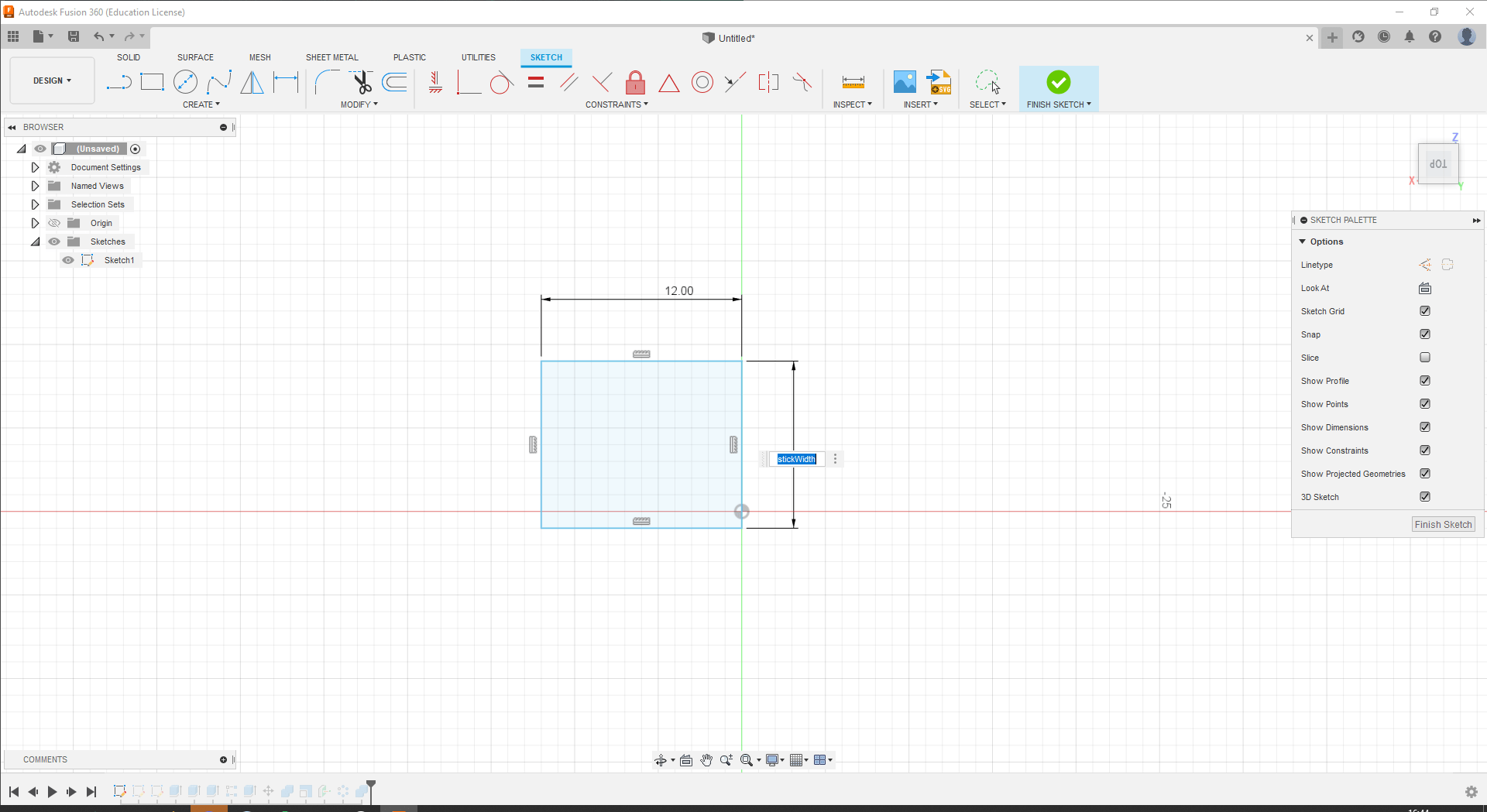

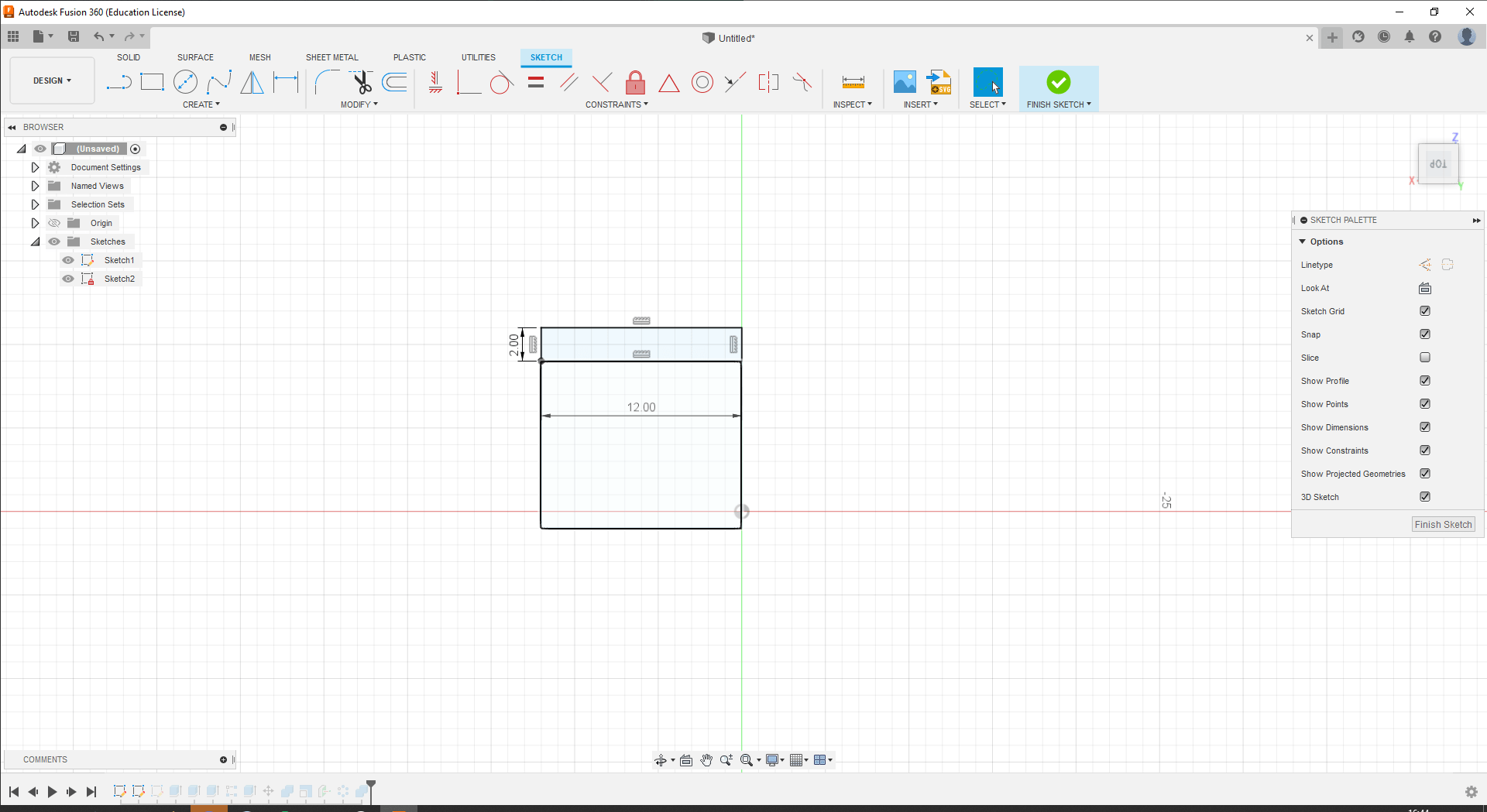

Just like IRL we start of with a sketch.

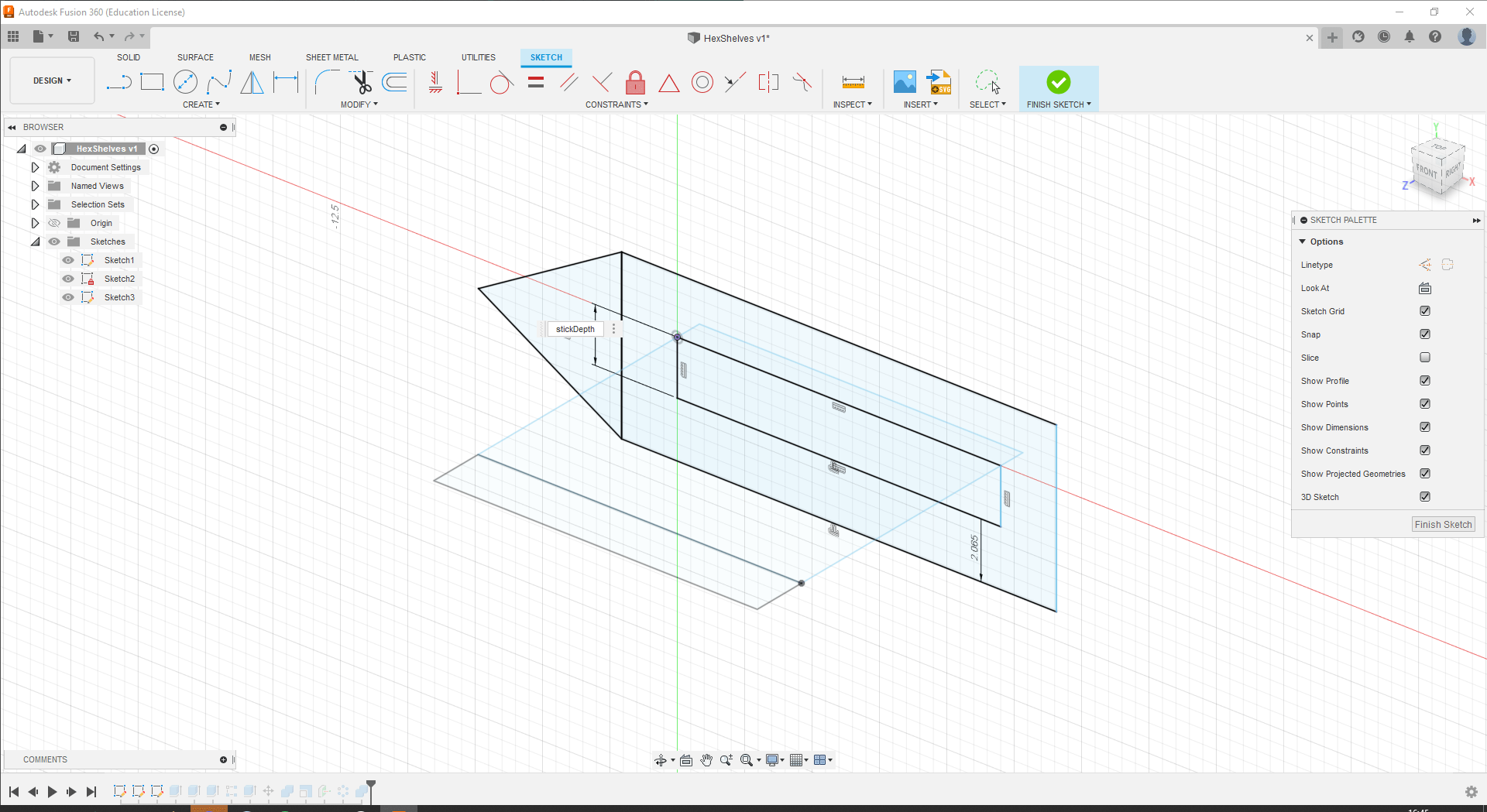

But unlike IRL I’m making another sketch in 90 degrees on top of the first one.

first sketch is the hole i want to add the popsicle stick in

second sketch is square to this one and it shows the side of the object, with a hole added aswell do note here that i deviated from the initial sketch already and planned to only make a hexagon version, i don’t think a square version would be as sturdy.

3D Models¶

final thoughts¶

Different directions or ideas? I like the hex version for sturdyness, but I’m sure a square version would dazzle me too. Look at this beauty though.