Computer Controlled Cutting

-

Group assignment:

- Design, lasercut, and document a parametric press-fit construction kit, which can be assembled in multiple ways. Account for the lasercutter kerf.

- Cut something on the vinylcutter

-

Individual assignments:

- Characterize your lasercutter's focus, power, speed, rate, kerf, and joint clearance.

- Document your work to the group work page and reflect on your individual page what you learned.

Vinyl

I started by selecting the image that I was going to put on the slicer. The picture is the Huando Institute sales logo.

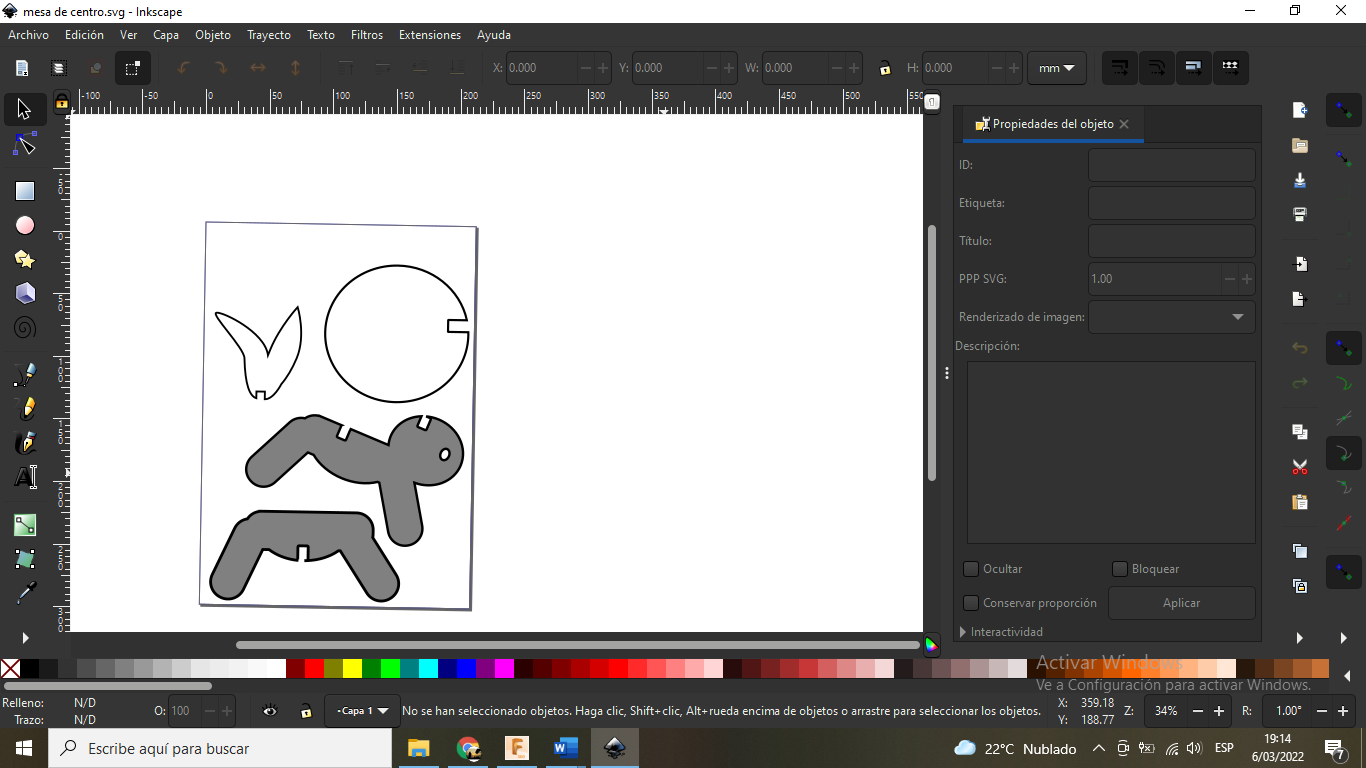

This image was made in Inkscape, the image is saved in my file to be used when we have our machinery in the institute. Both images were converted to their respective bitmap.

These images will be used to cut out and be decals and then used for various images.

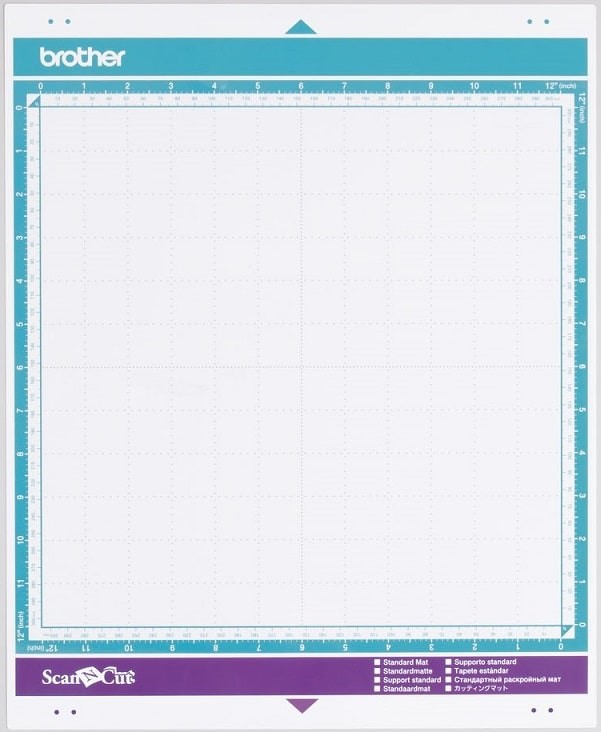

The PMSUB, will provide us with a machine to be able to make our designs to cut vinyl, it also allows us to scan a drawing and cut it instantly using different materials.

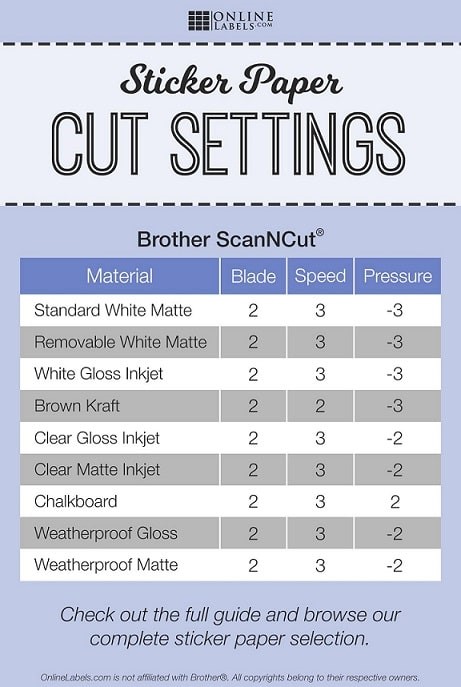

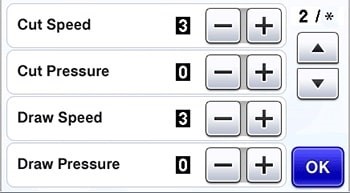

Some configurations for different types of grid mat.

I will use a standart size.

Well, in this part, I have learned that the machine that performs vinyl cutting... will cut all the lines of the image, even if the lines are canceled by other lines.

For best result, the drawn image should have only the outer lines and they should be connected and there should be no loose spaces.

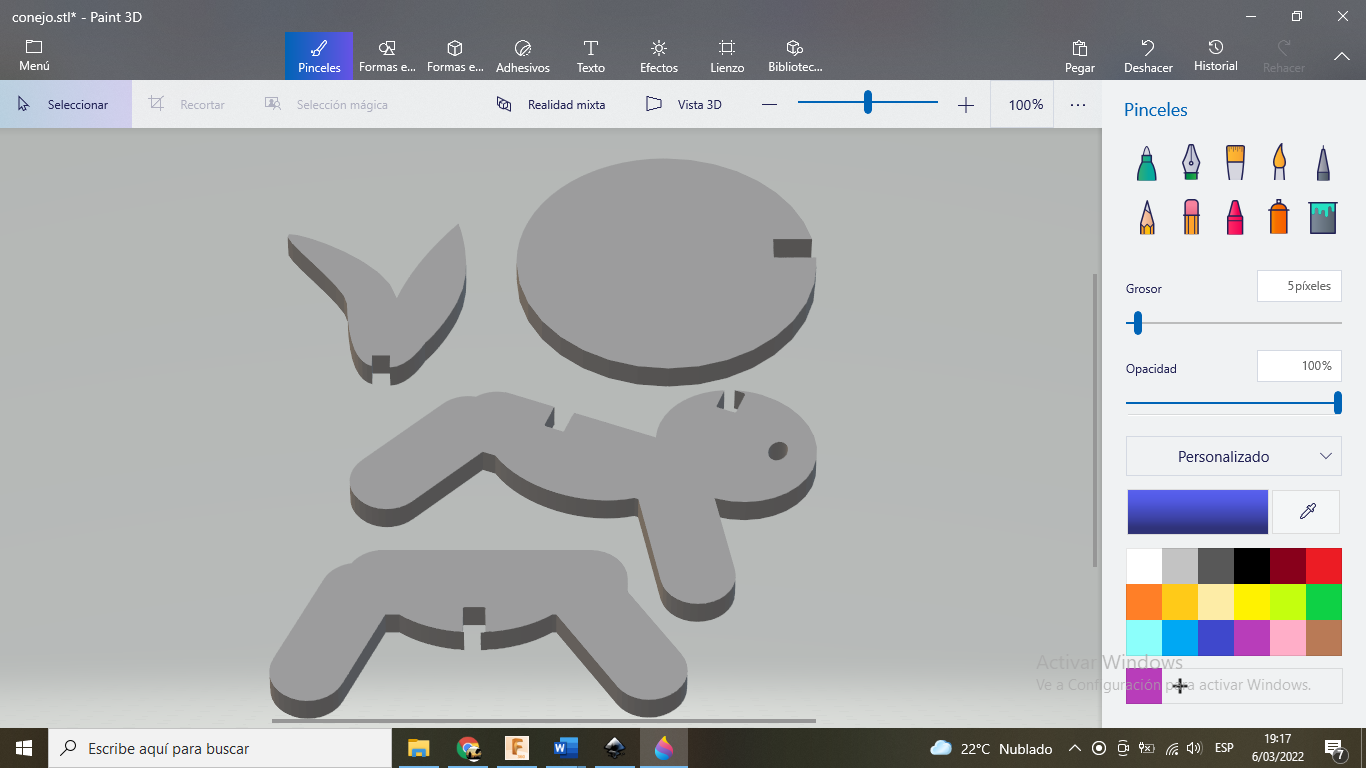

In this design, we worked with MDF material, to make designs, like this table for a girl in the shape of a bunny, very didactic for our little ones. The idea is to draw a snap-fit base so it can stand up, each joint is snap-fit. The leaves would be squares adapted to join each other and the sides of the table and will have the shape of a little animal. This task began by designing the base. The base must be solid and stable.

Download files

-

some files to download from my work done:

- .

- Cut something on the vinylcutter