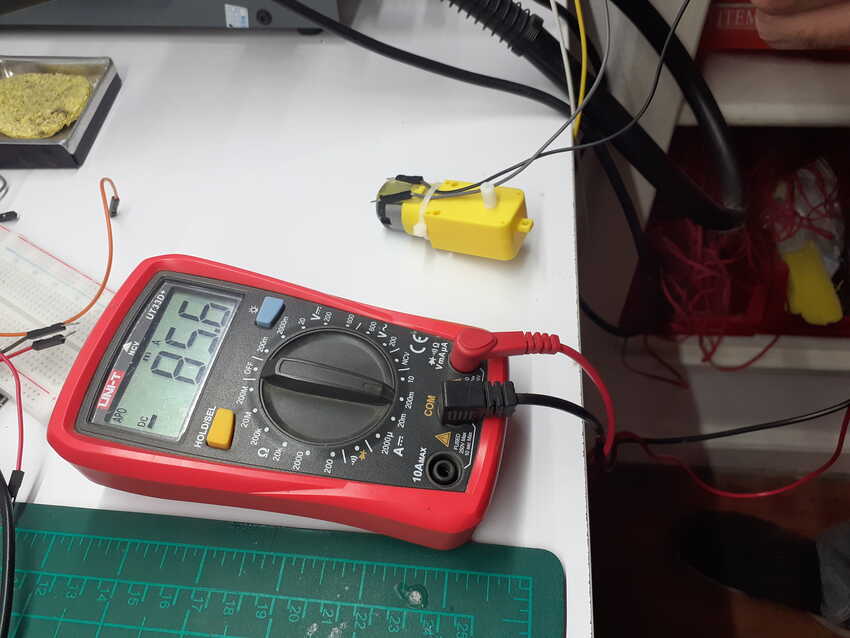

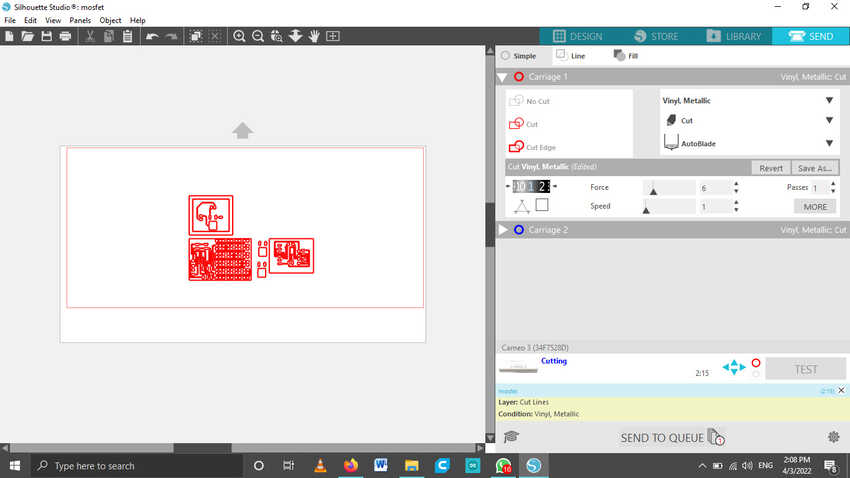

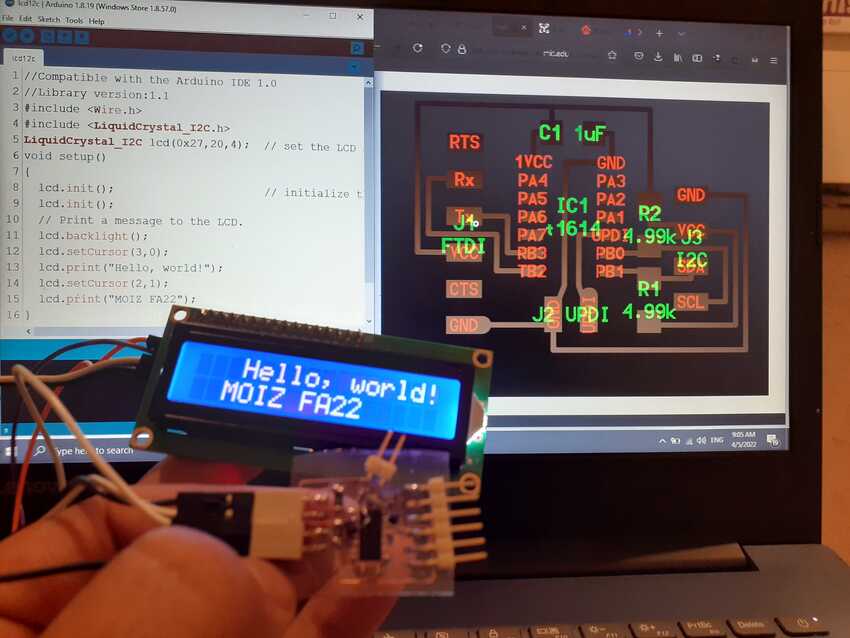

Example of display:

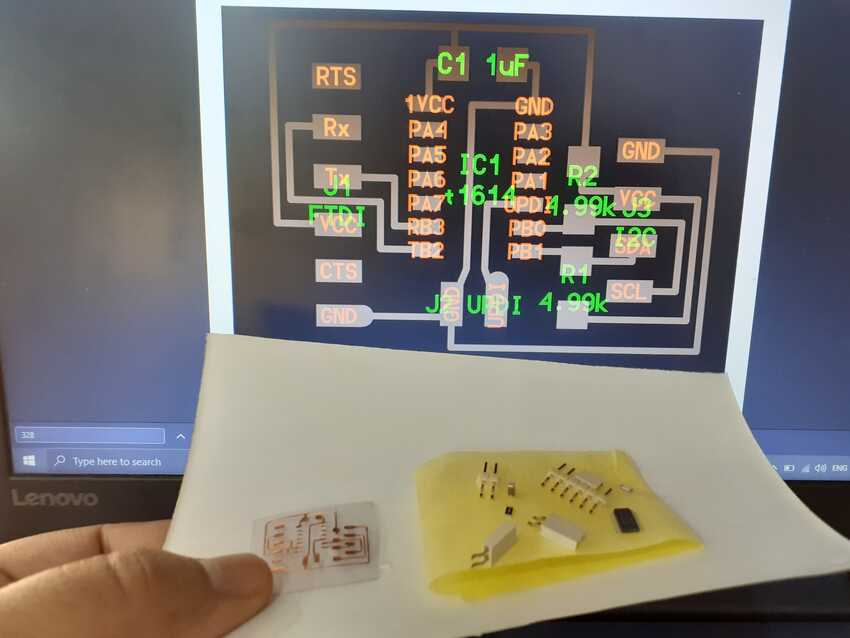

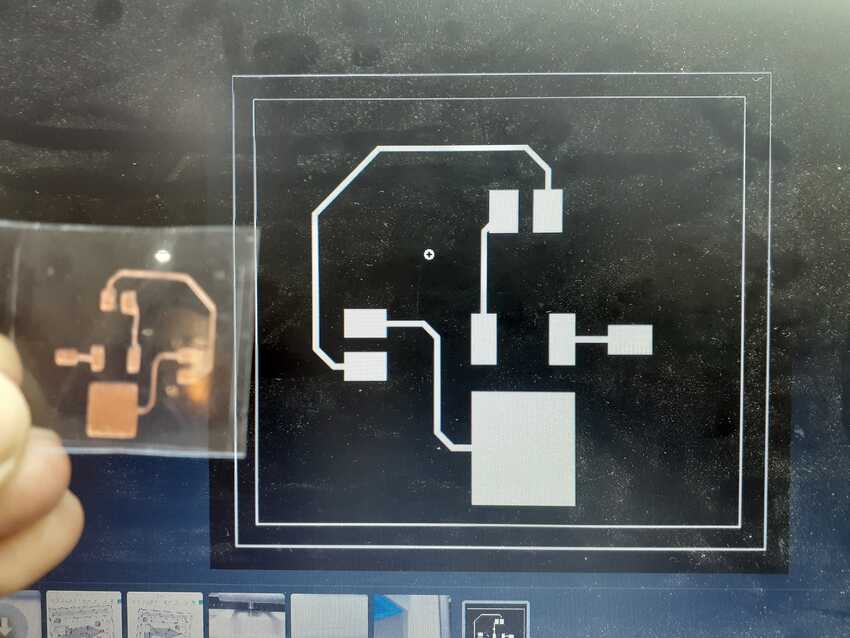

I then practiced on a small LCD 16 x 2 with a 12c module , at first I couldn't find a complete code with a liquid crystal library. Special thanks to amany ayman who gave me the code needed.

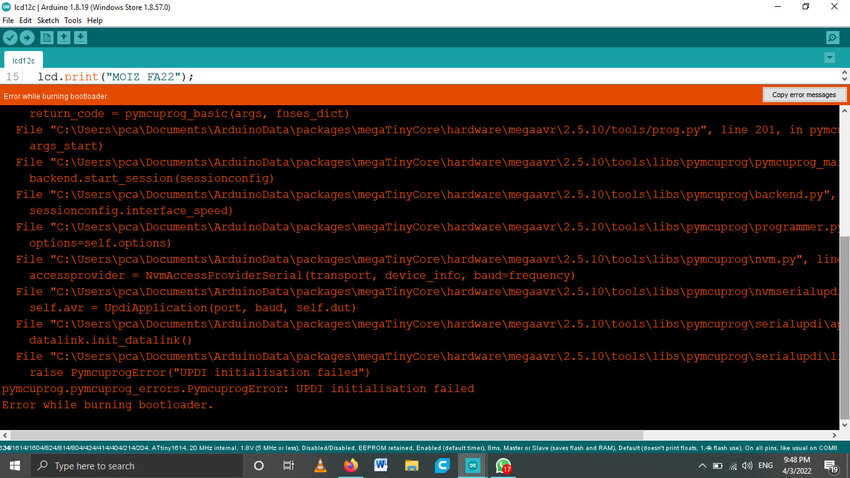

This is the new code

//Compatible with the Arduino IDE 1.0

//Library version:1.1

#include

#include

LiquidCrystal_I2C lcd(0x27,20,4); // set the LCD address to 0x27 for a 16 chars and 2 line display

void setup()

{

lcd.init(); // initialize the lcd

lcd.init();

// Print a message to the LCD.

lcd.backlight();

lcd.setCursor(3,0);

lcd.print("Hello, world!");

lcd.setCursor(2,1);

lcd.print("Ywrobot Arduino!");

lcd.setCursor(0,2);

lcd.print("Arduino LCM IIC 2004");

lcd.setCursor(2,3);

lcd.print("Power By Ec-yuan!");

}

void loop()

{

}