4. Computer controlled cutting¶

Assignment

group assignment : characterize your lasercutter’s focus, power, speed, rate, kerf, joint clearance and types

individual assignment : cut something on the vinylcutter design, lasercut, and document a parametric construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways, and for extra credit include elements that aren’t flat

Vinyl cutter¶

Machine and properties¶

Materials¶

Drawing tested¶

Cutting¶

Transferring¶

Laser cutting¶

Characteristics¶

type

focus

power and speed

rate

kerf

Parametric construction kit¶

By using FreeCAD¶

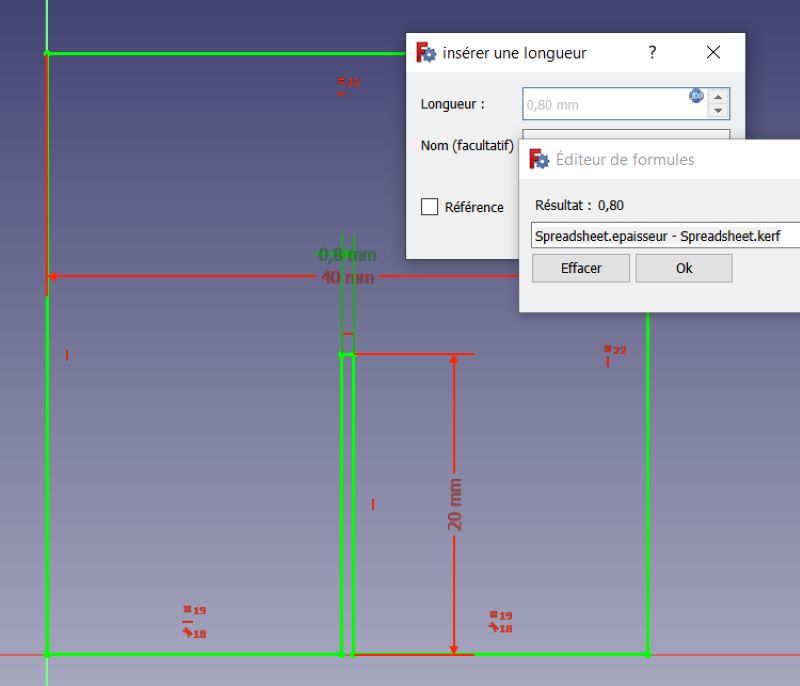

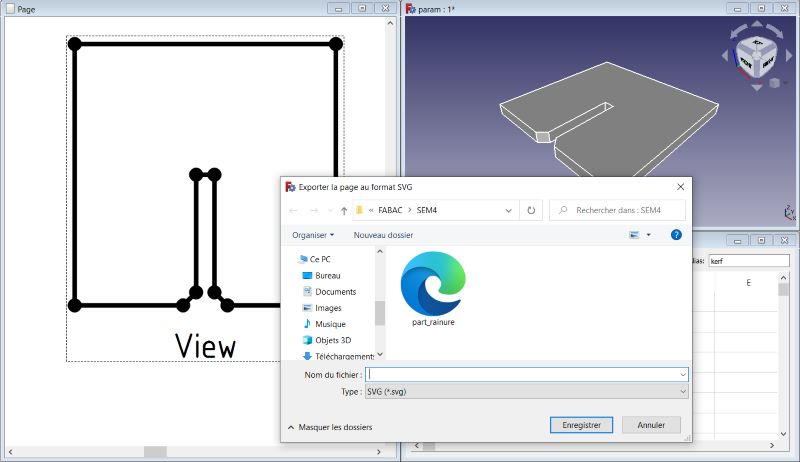

I use Feadi’s tutorial on zoom here and start to create a part with a groove which change with the thickness of the material.

|

|---|

| Length of the groove depending on thickness (“épaisseur”) and lasercutter kerf thanks to a mathematical formula. |

|

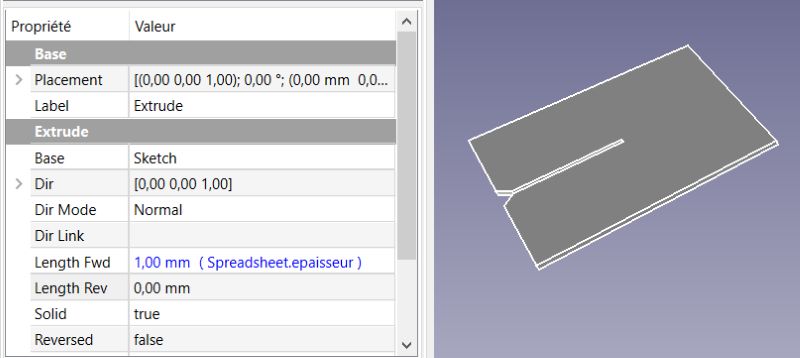

| Extrusion which is the thickness (“épaisseur”) = 1. |

|

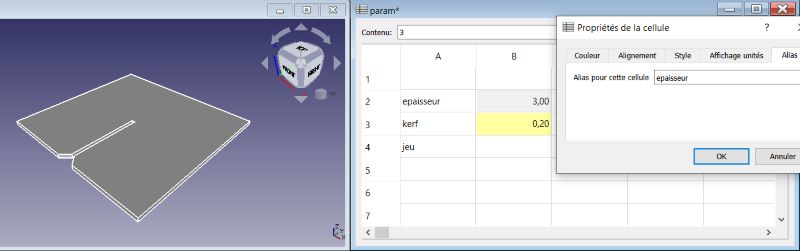

| Part with thickness = 3 and kerf = 0.2. |

|

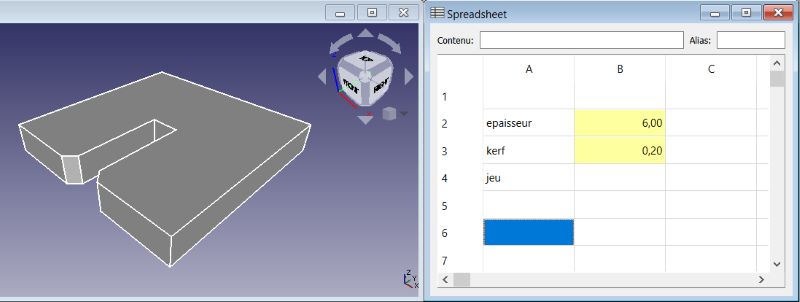

| Part with thickness = 6 and kerf = 0.2. |

|

| Plan and .svg export for cutting. |

By using Fusion 360 Slicer¶

By using Inkscape extension¶

Deepnest¶

Last update:

February 5, 2023