Task to be Perform for Third week

This week our task is to study hands on work on lesser cutting and Vinyle cutting Machines

We need to perform Group Assignment as well as Individual Assignment also

Group Assignment:- In group Assignment we have to study about the lesser Cutter available at Vigyan Ashram Fab Lab-0.In that basssically focus on Power ,Speed ,kerf Calculation and joint clearance and Document this in group page.

Individual Assignment:In case of indiviual assignment we need to focus on design somthing on vinyle cutter and lesser cutter. Develop and design the parametric construction kit considering lesser cutter kerf which can be construct in multiple ways.

Learning outcomes

1) Demonstrate and describe parametric 2D modelling processes.

2) Identify and explain processes involved in using the laser cutter.

3) Develop, evaluate and construct the parametric construction kit

4) Identify and explain processes involved in using the vinyl cutter.

Computer Controlled Cutting

In second assignment we have tried to develope Some shapes on 2D and 3D designing software. In this Asiignment we have to cut the 2D Design on different cutting tools.The various cutting tools used like Knife, lesser cutter ,Plasma cutter ,Vinyle cutter for this week assigmnet.This cutting process we have to apply on material like Cardboard,Acralic,MDF,fome, Ply ,Paper.

The Computer Controlled Machine is used to computerized controlled and machines tools to cut the material from stock Pieces.

Group Assignment :-

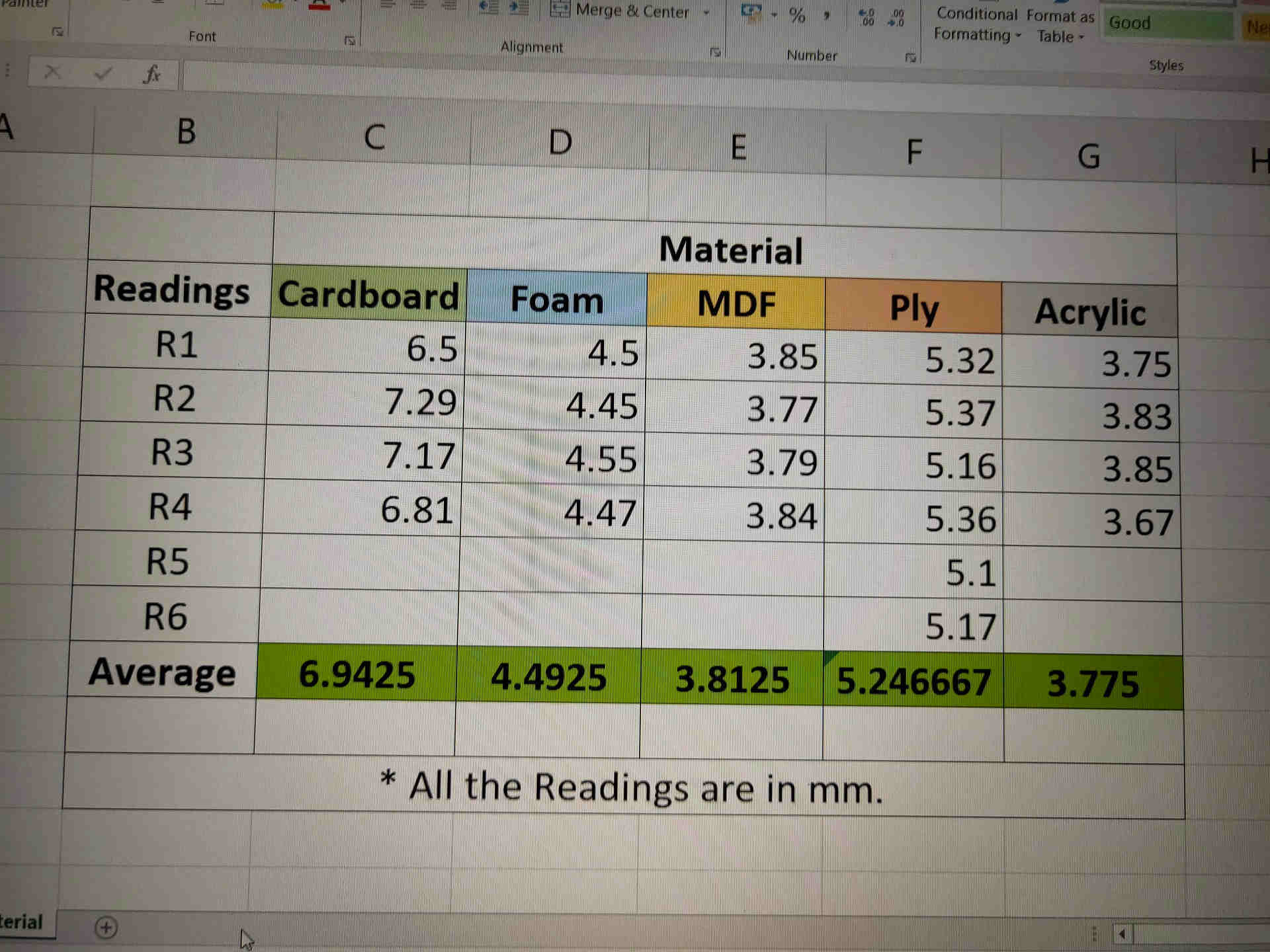

In group assignment, We have to study about characterize the lasercutters focus, power, speed, rate, kerf and joint clearance. We cut different pieces variousmaterial and cheaked it speed and power, then optimize the proper speed and power for the materials. Then by measuring the cutting dimension, compared it with design dimension, we calculte kerf and document your work (Individualy or in group).

For more detail about the group assignment CLICK HERE

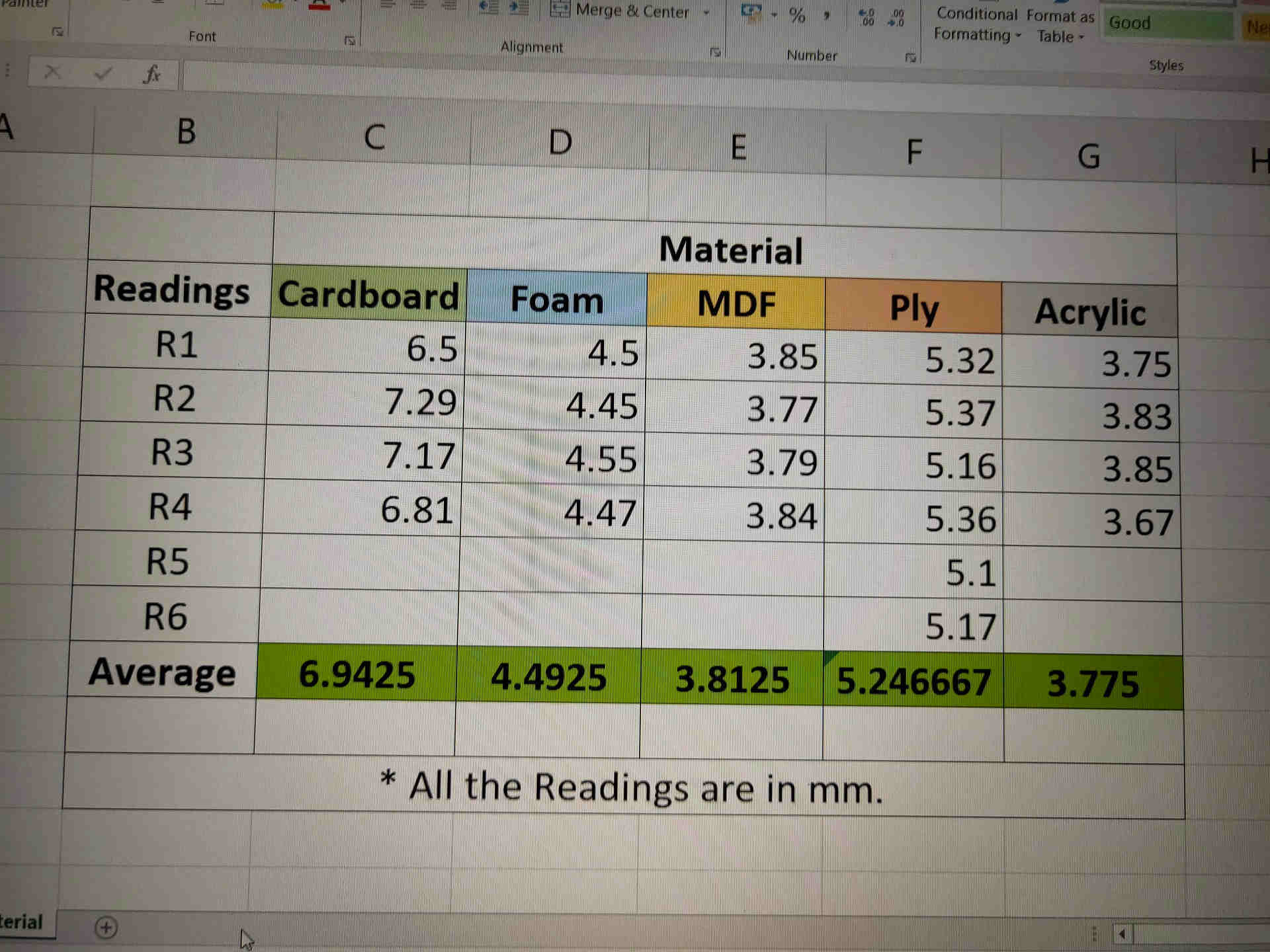

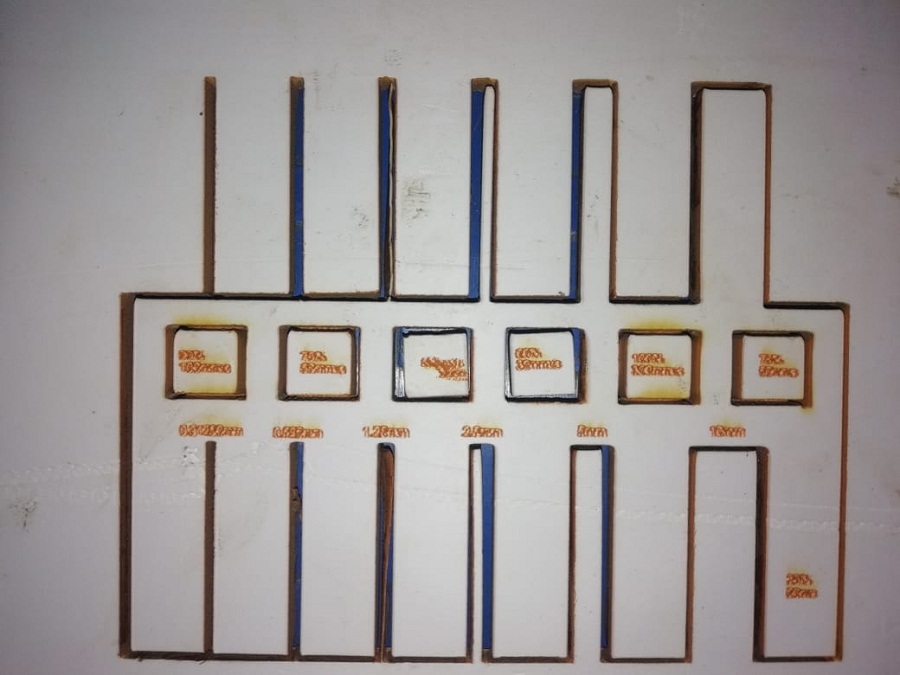

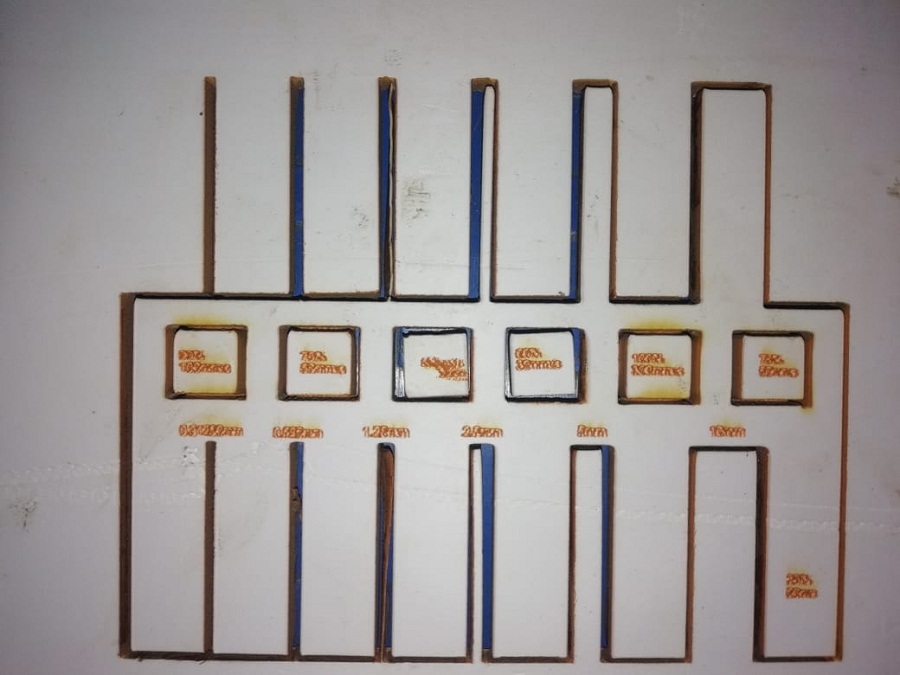

We have designed the comb like design having 6 square with different speed and power to calculte the kerf of the lesser cutter machine.

Then we have divide the availble material in our Fablab and for calculations of kerf of different material we have measure the dimmenssions of each material.

This is the result of Fome material after the different combinations of speed and power for fome i can conclude that the fome 4.49 mm thickness required to be cut the spped of 40 mm/sec and the power required is 50%.

Individual Assignment:-

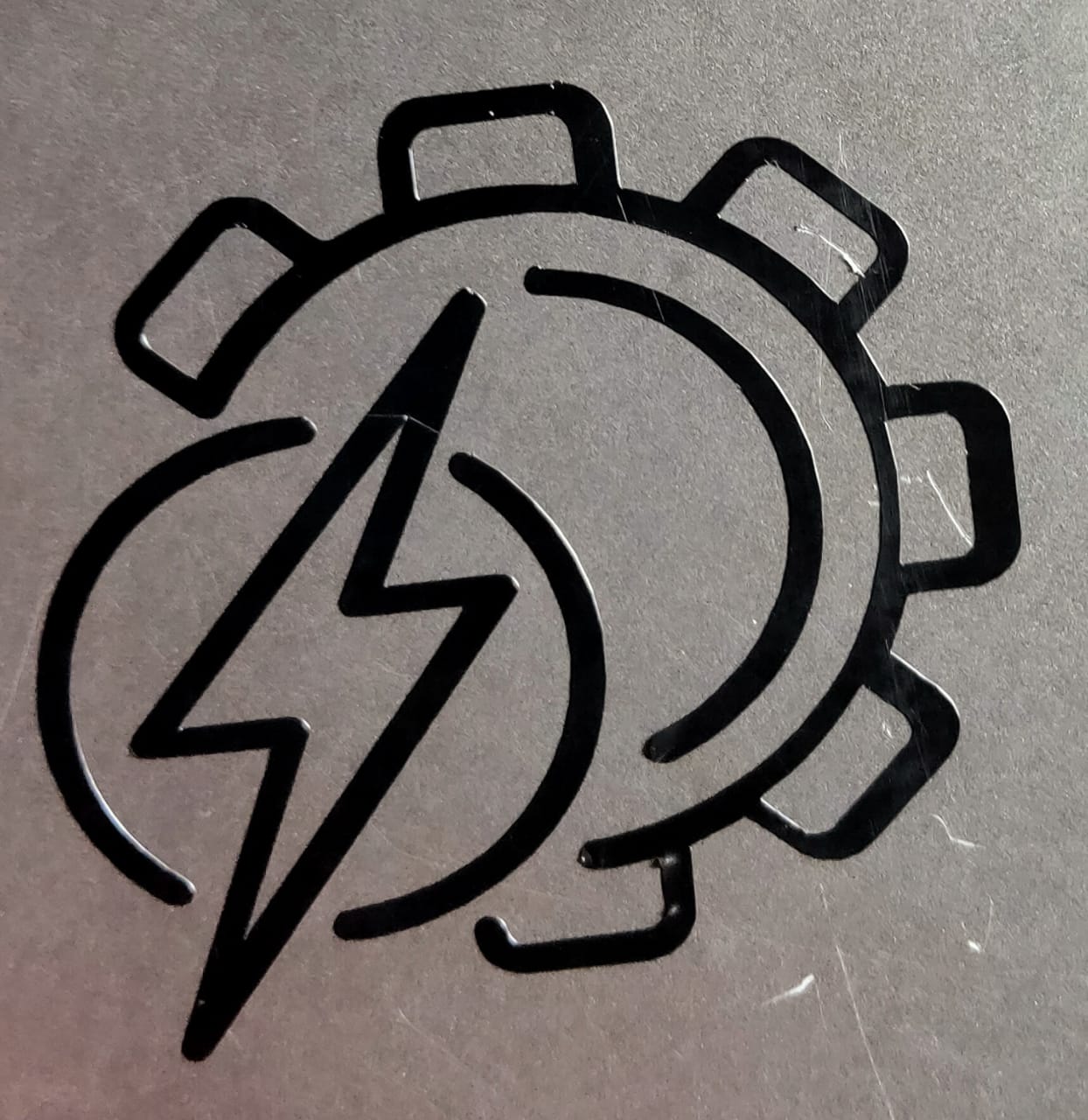

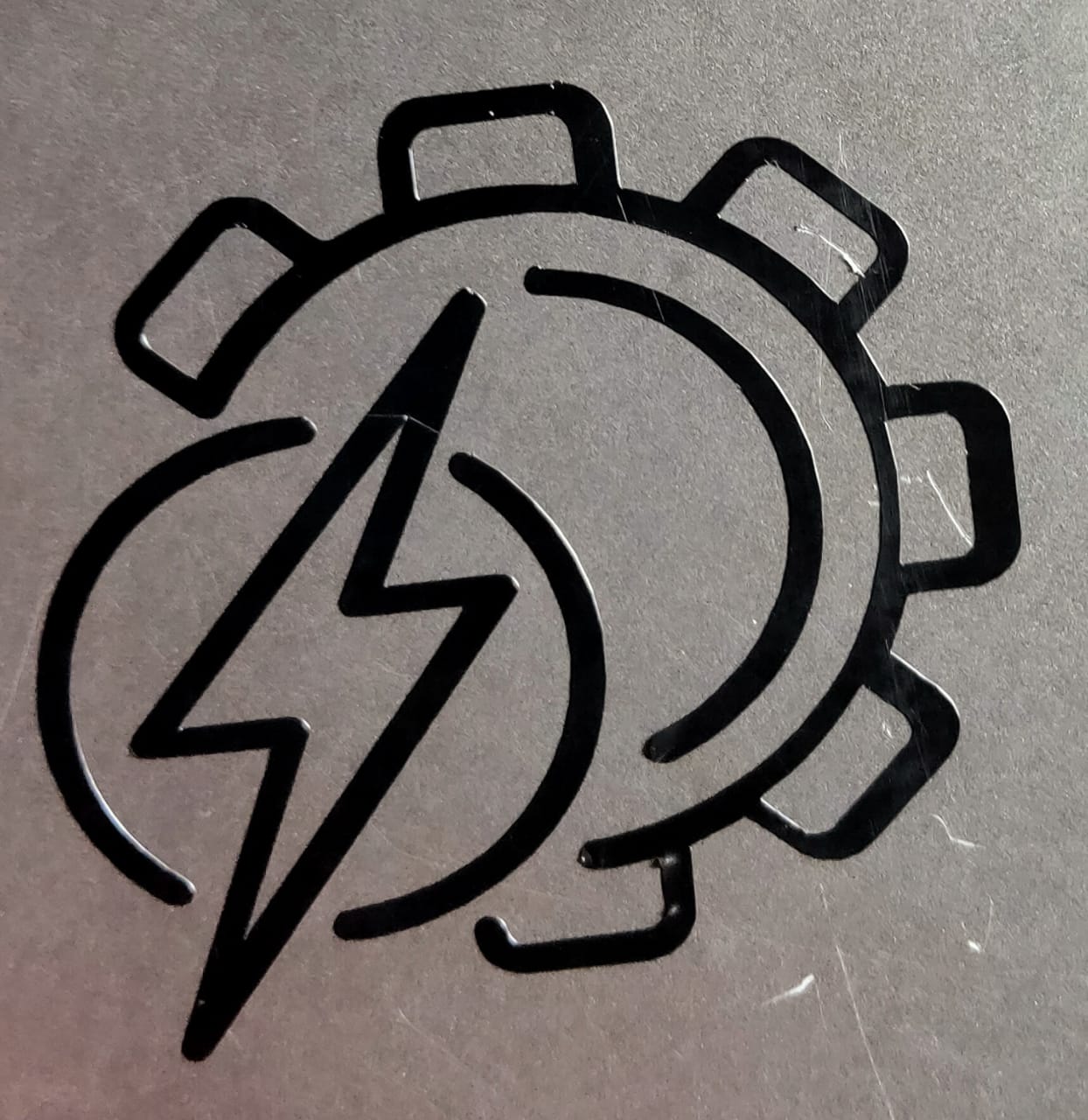

In Individual Assignment we have to make a parametric contruction kit using lesser cuter Machine and also by using vinyle cutter cut something and document it.

Leser Cutter:-

Stand for Light Amplification by stimulated Emmision of radiation. device that generates an intense beam of coherent monochromatic light (or other electromagnetic radiation) by stimulated emission of photons from excited atoms or molecules.

As the name Suggest this process of cutting material Using lesser beam.This can be done either trim down the material or to help cut it into complex shapes that more conventional drills would strugle with.

This process is similler to drilling and engraving processes.

The former involves the creation of thru-holes in a material or dents, like an engraving used in the later process.

These dents and holes are essentially cuts, and you will often see a laser machine also being used for drilling and engraving too. A vast range of materials and thickness sizes can be cut with lasers, making it a handy and adaptable process.

In FABLAB at Vigyan Ashram Leser cutter machine as Follow

• Name :SIL Laser Engraving - Cutting Machine

• Model No:1325 – 1318

• Laser Type:Co2 DC Glass laser Tube

• Laser Power:80 Watt

• Processing Area(Bed size):900 x 600 mm

• Working Speed :Adjustable

• Power Supply: Single Phasehase AC 230V, 50HZ

• Software: RDWorksV8

• File Format Supported: .dxf .obj .svg

Some factor realated to Leser Cutter

1) Kerf:- The thikness of laser is called as kerf. as per own thikness of leser beam it cuts the any material with change in dimenssions so that it may observe that its change the original dimessions we can calculate the kerf by original values assigned to the job and the actual job cuts by leser cuter {(X-axis kerf-Y-axis kerf)/2}

2) Speed :- Speed of leser beam is depending on material thikness.Means at which speed the head leser beam will cuts the material.

3) Power: Power is the importent factor while cutting and engraving the material in both the cases power is vary as per need and types of material

While operating the leser cutting machine we need to take some necessary precautions

1) While cutting any material on leser check exhaust should be on.

2) We should not looks directly to the leser beam because it may harm to eyes.

3) Do not leave the machine while performing any operation on it

4) Keep leser cutter machine off after the operation

Process to start the operation of leser Cutter

1) Turn on Mains(Power Supply)

2) Isolation transformer

3) Switch on the UPS

4) Switch on Air compresser

5) Switch on the cooler

6)Switch on the mains(laser)(Laser on)

7) Switch on the Exhaust

Parametric Design

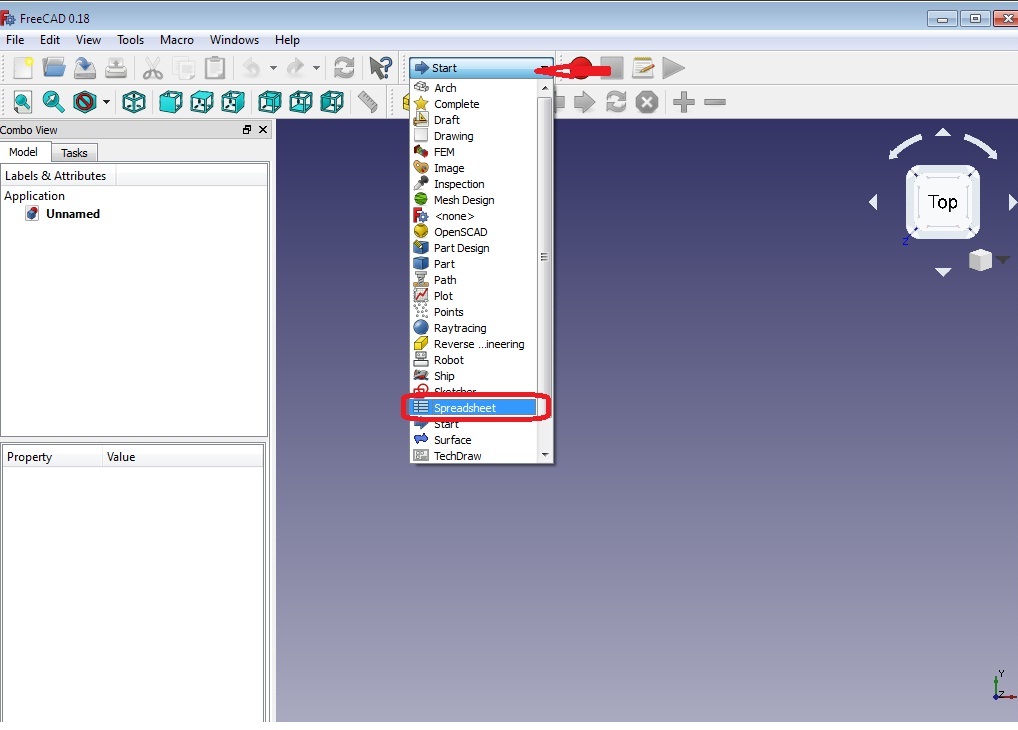

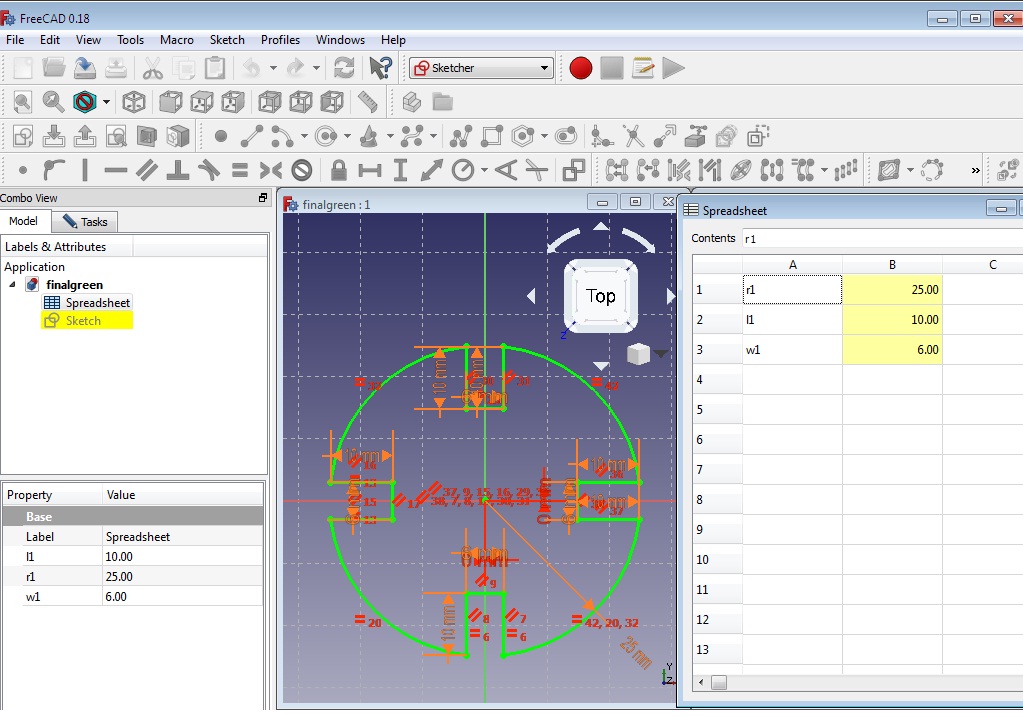

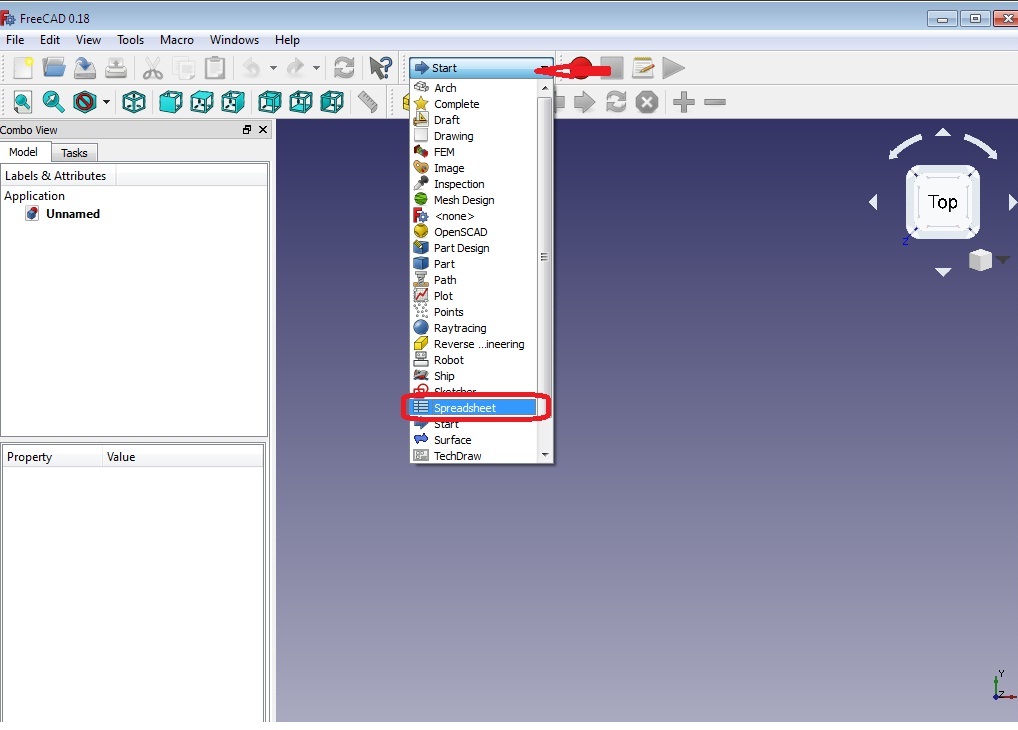

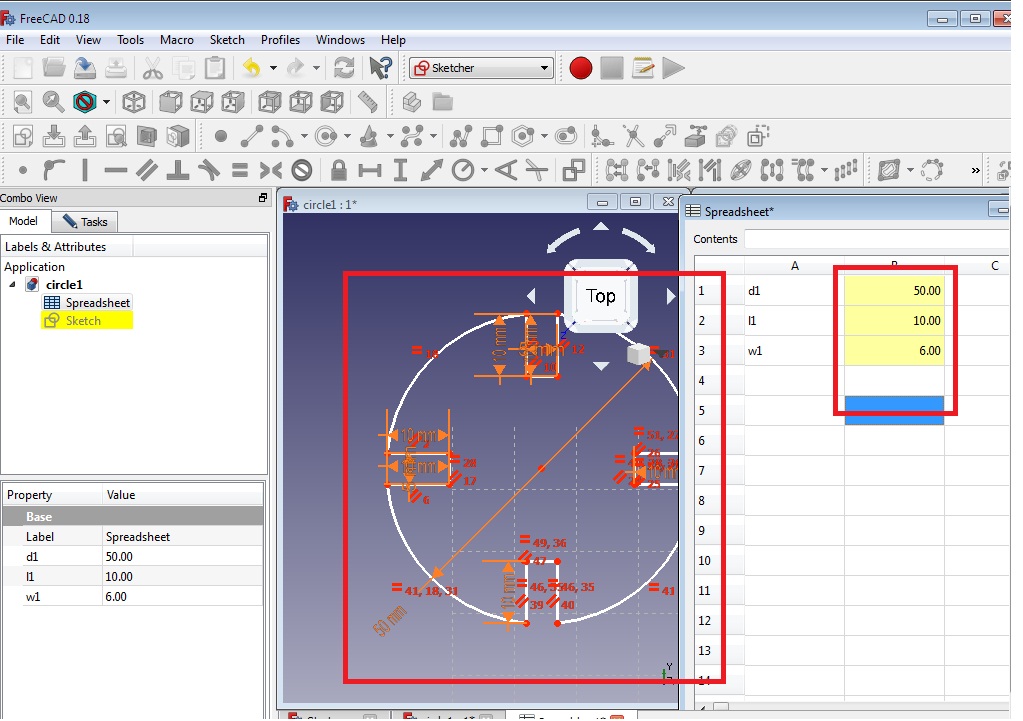

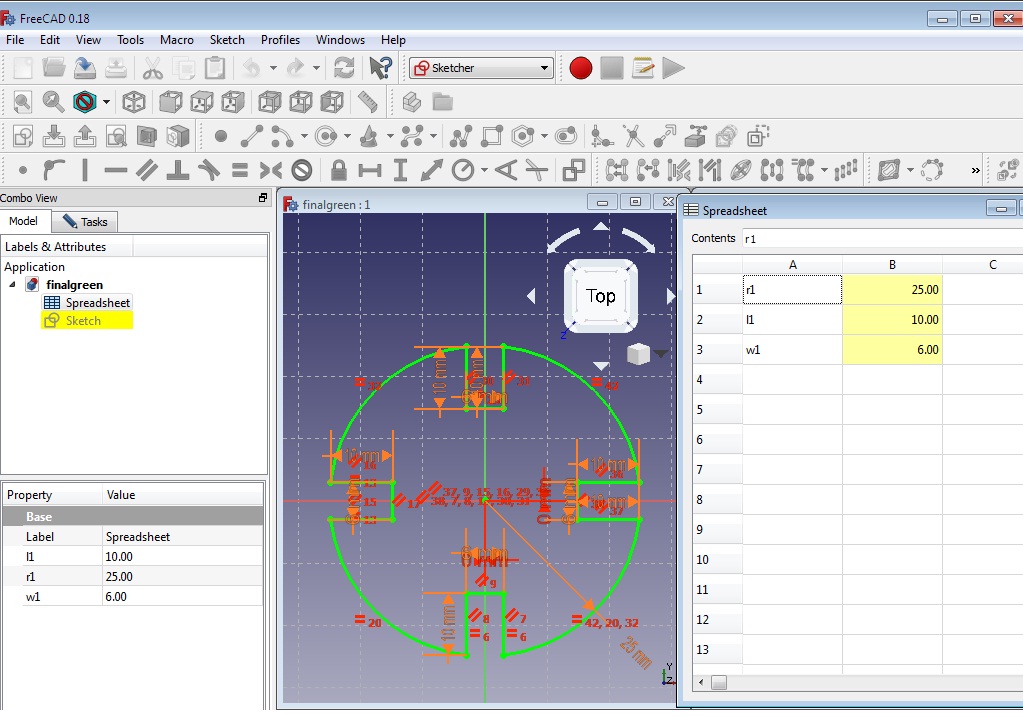

1) I have cretated the parametric desing in FreeCad and for dimession use spreadsheet.

2) Using the spreadsheet workbench we can create and edit the spreadsheet.

3) For Dimmension of shapes in sketcher we use the spreadsheet data.Use the data from spreadsheet for paramater model , perform calculations, and export the data to other spreadsheet applications such as LibreOffice or Microsoft Excel.

4) If you made any changes in spread sheet for any dimession it will automatically reflect on your design object.

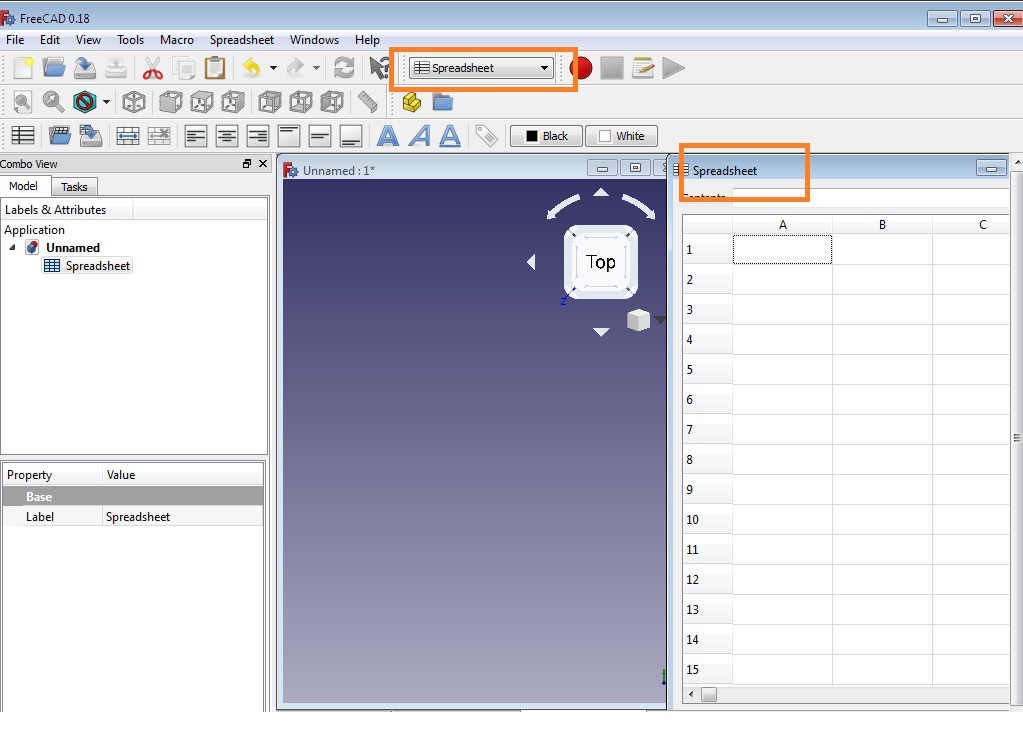

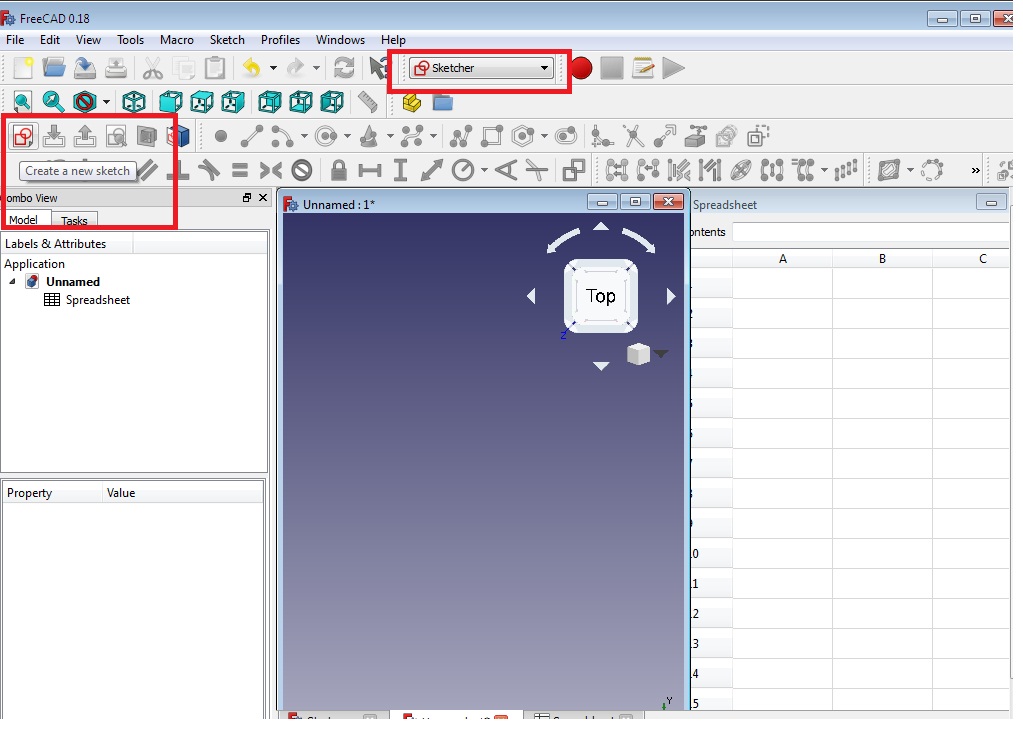

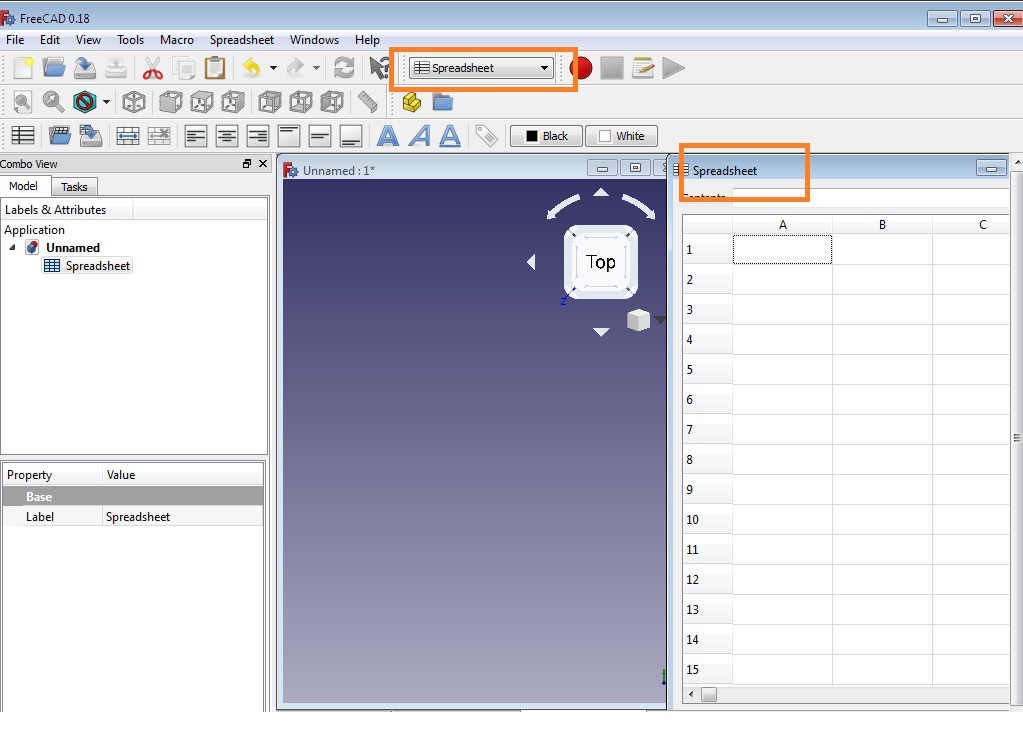

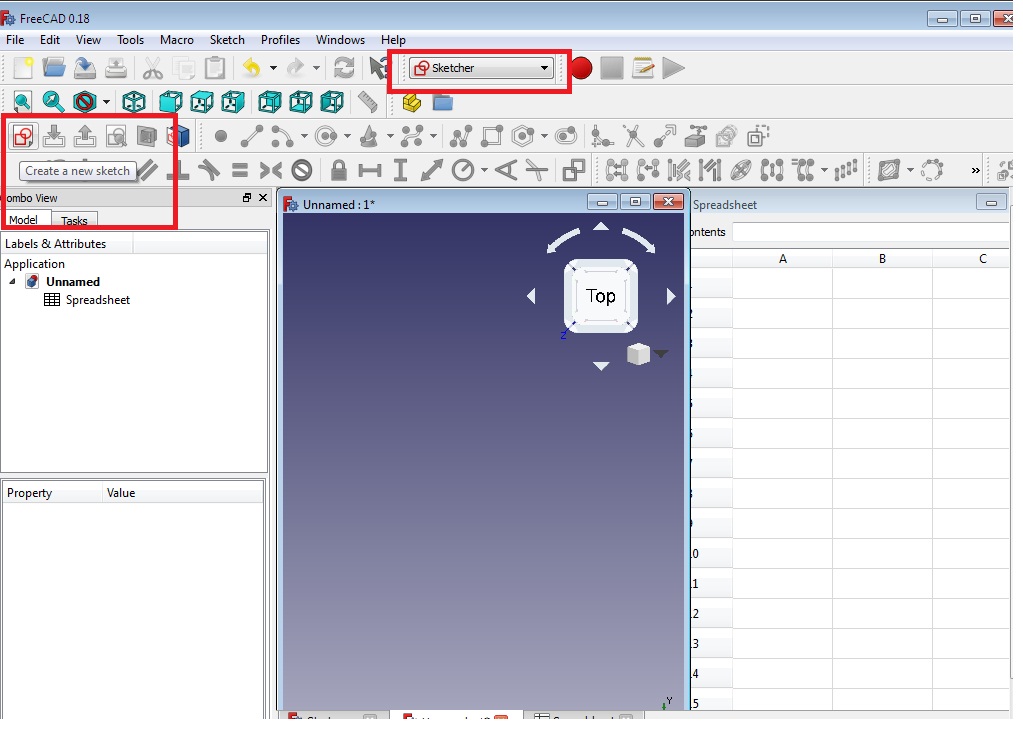

For parametric design first i need to open my FreeCad Software to get started, go to spreadsheetworkbench and click on create new spreadsheet and then select the skecher workbench create new sketch

Then go to window make it tile your screen looks like,you can make both the workbench on single screen that means you can use both at a time.

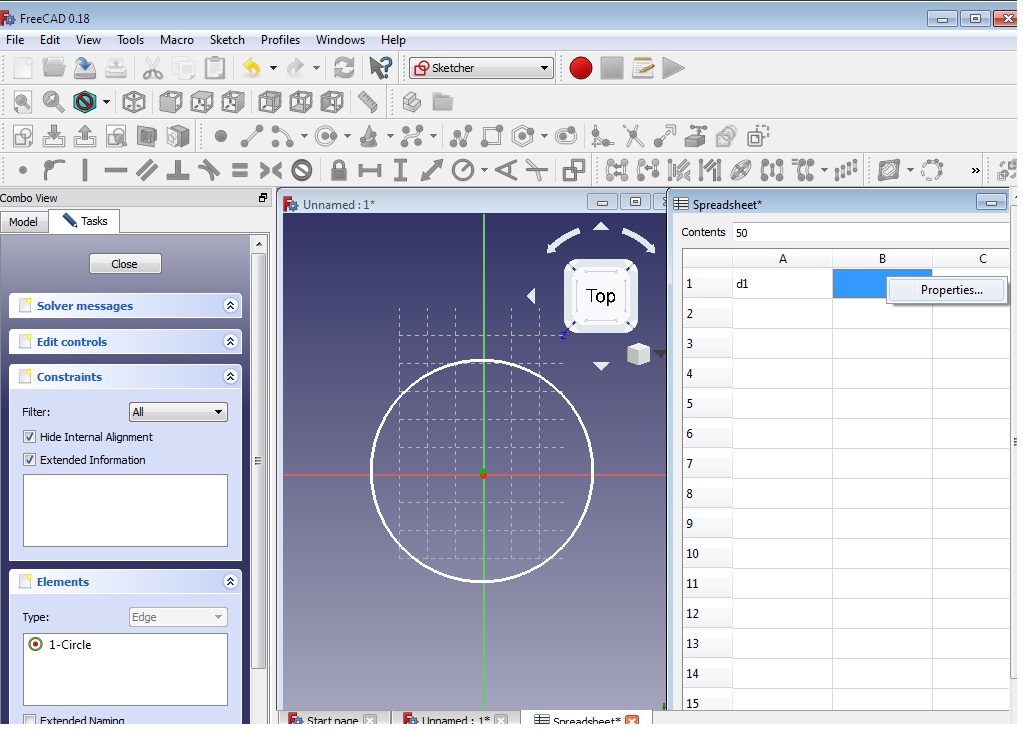

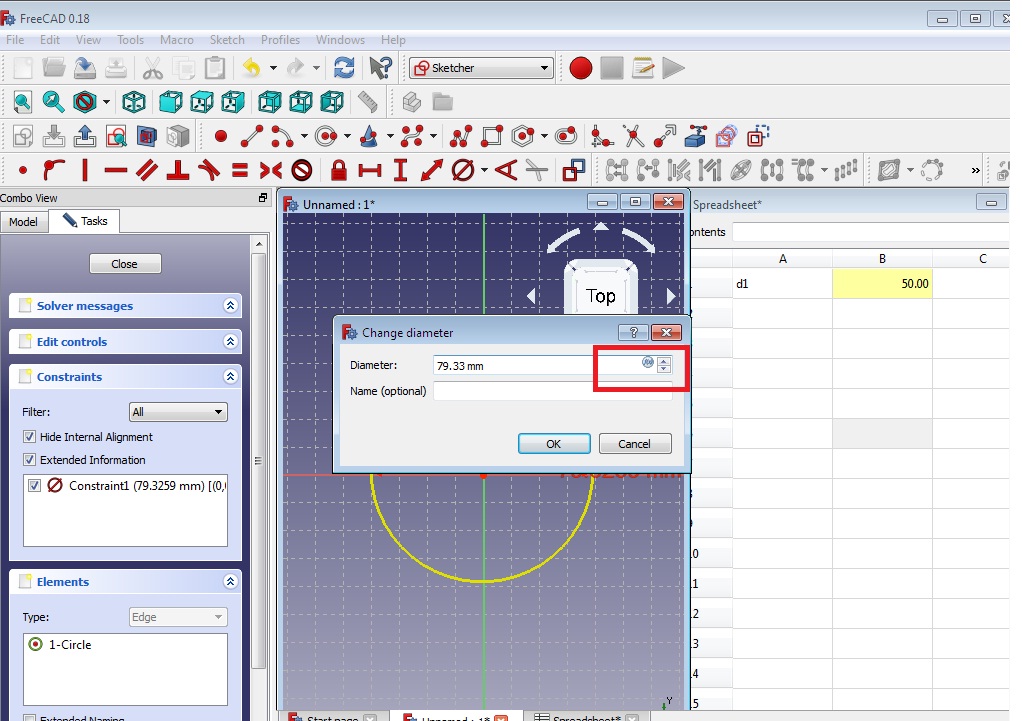

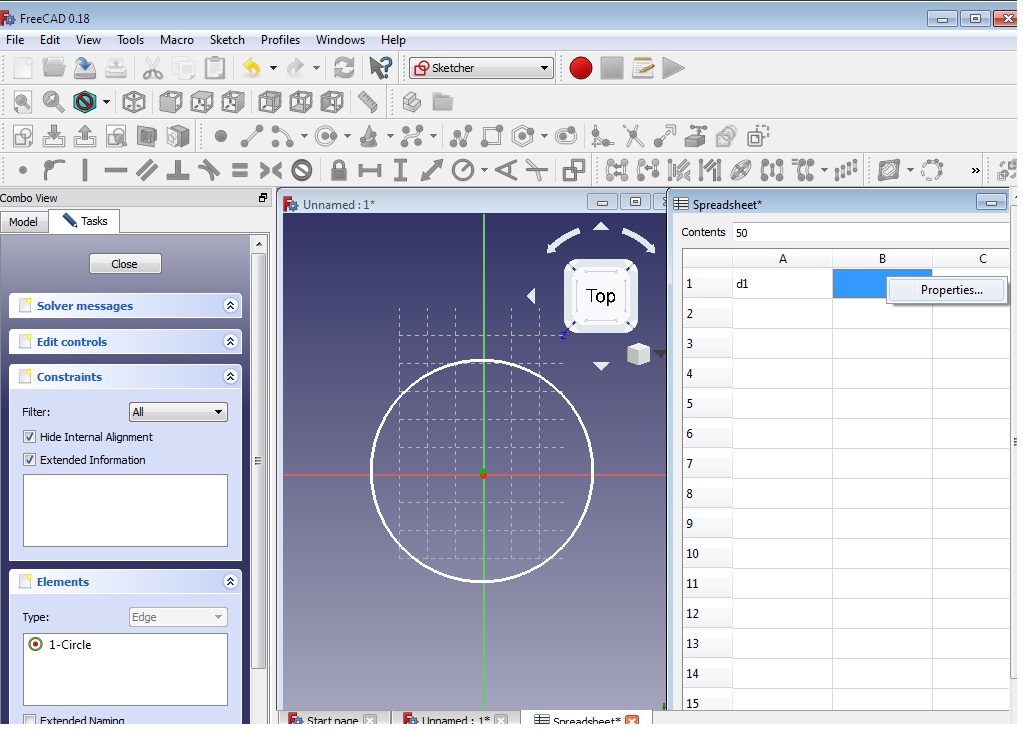

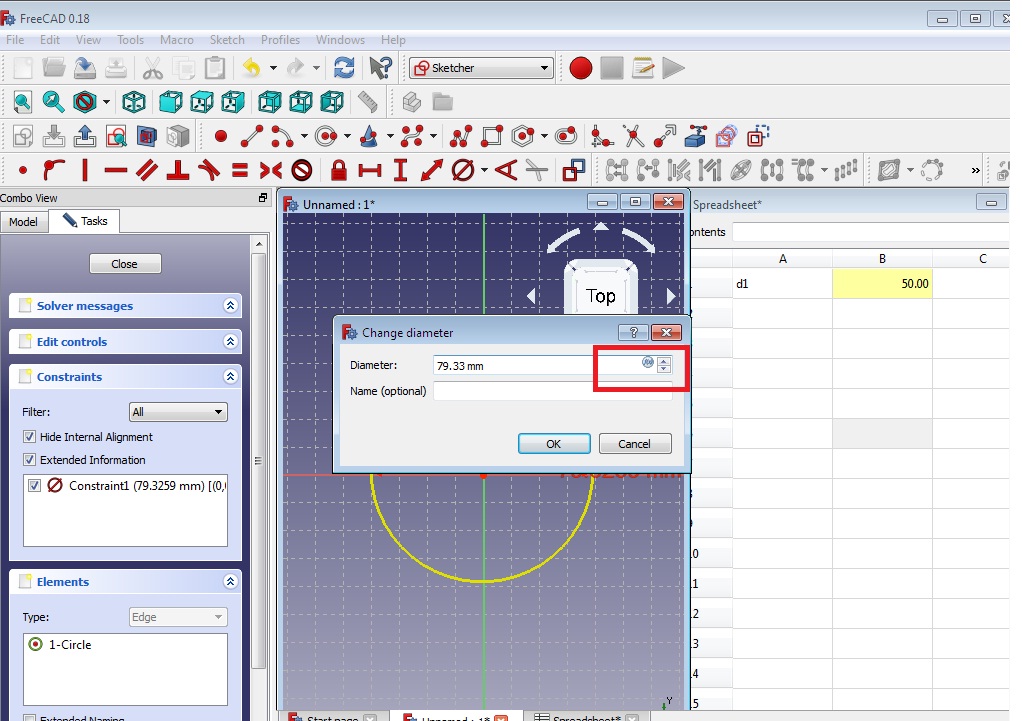

I have made one circle here and constrain it by the use of spreadsheet.

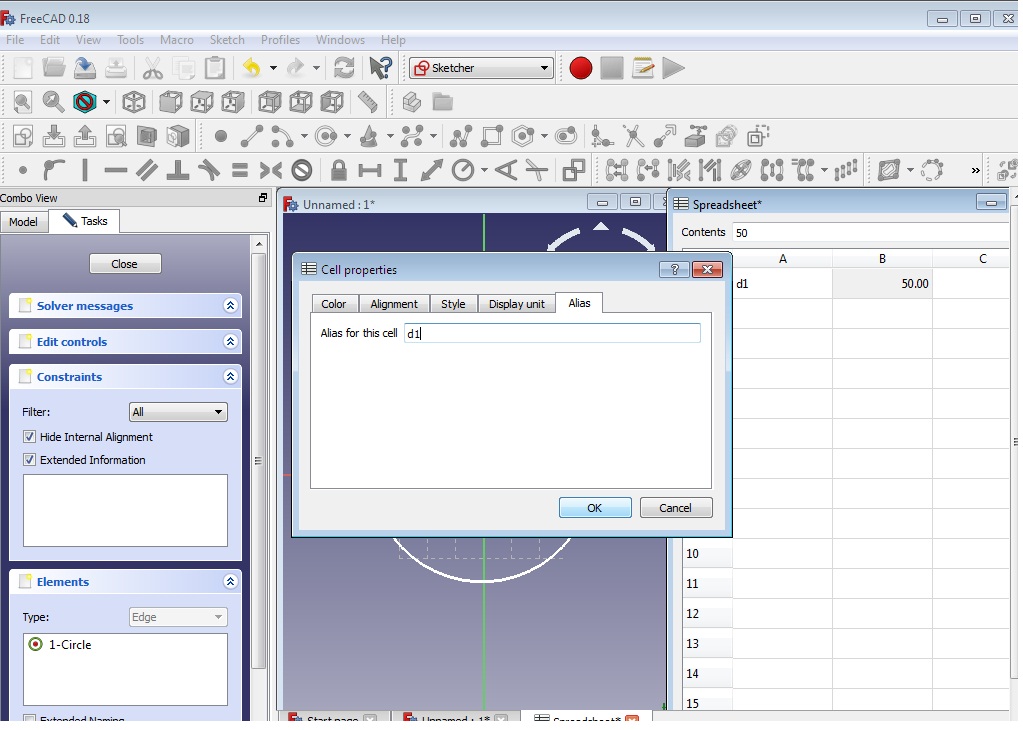

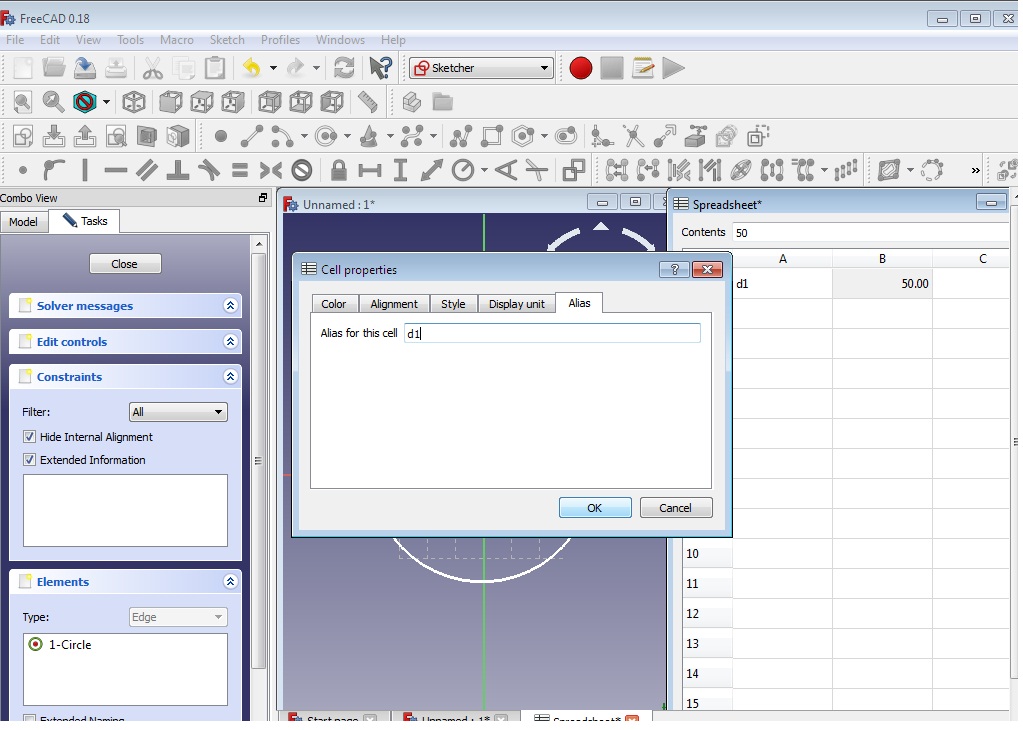

Then goto cell properties and press ok,and in alias give the same name for cell.

Click on skech workbench go to constrain as a dimeter as i have considered d1 is the dimeter of circle

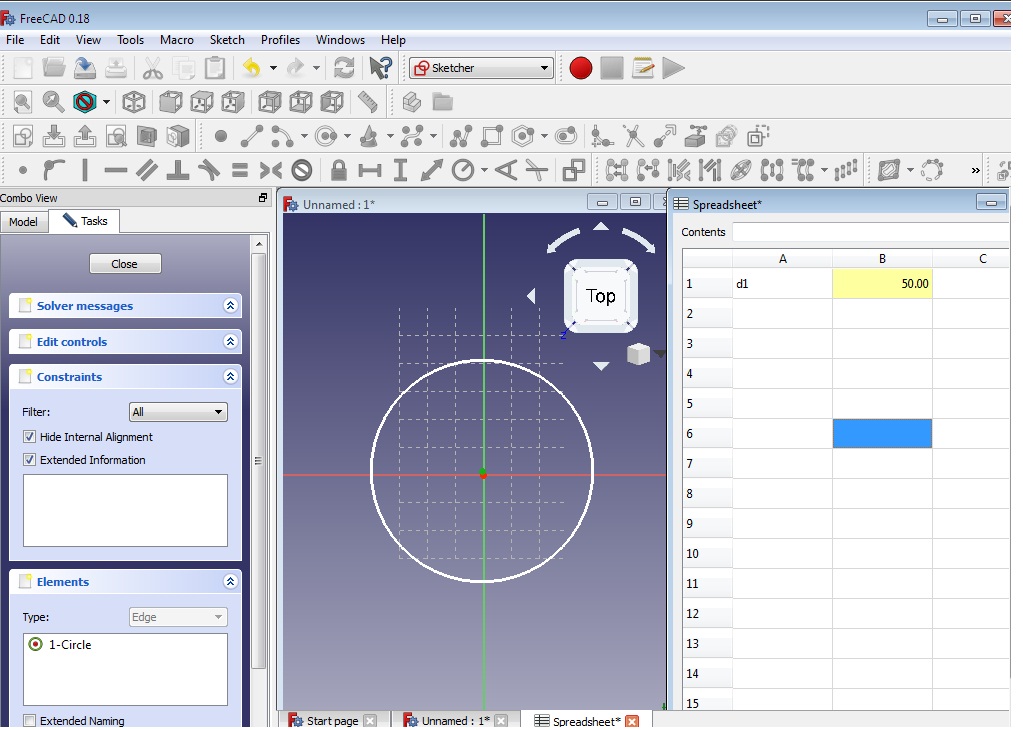

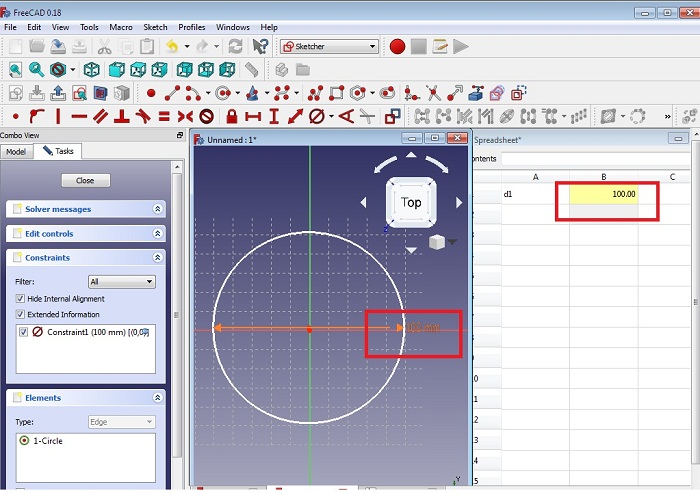

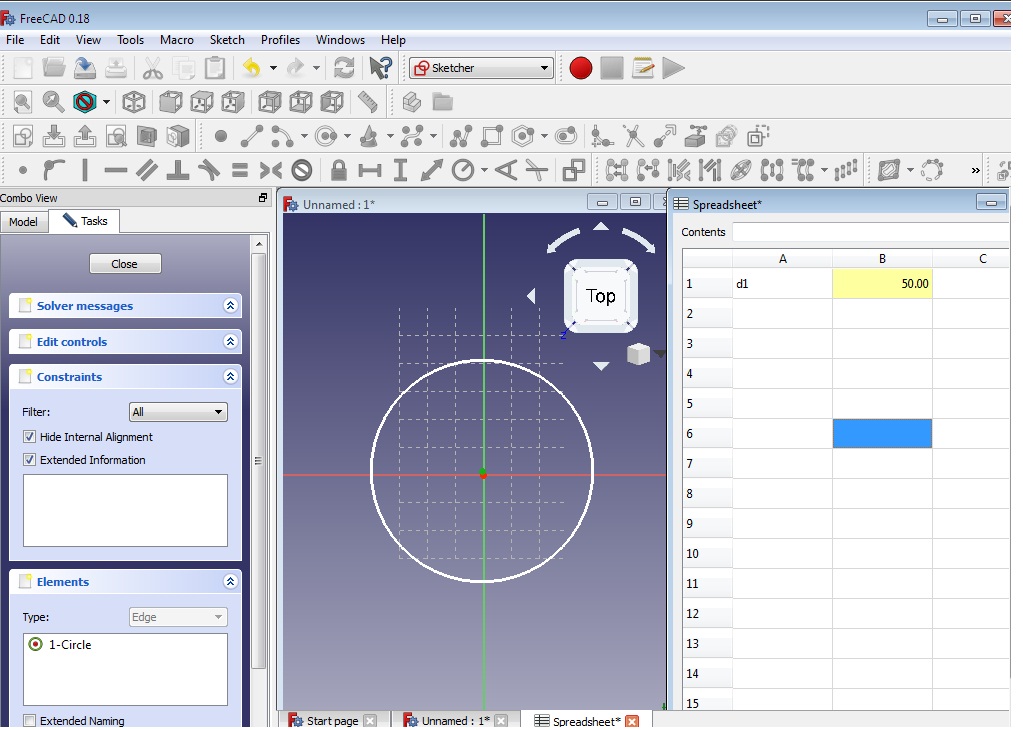

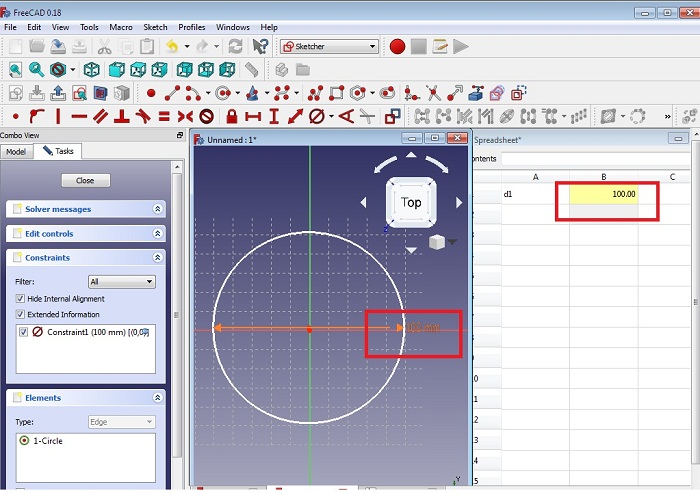

Then suppose if i want to change the dimenssion of circle only i have to chnge the value of d1 in spreadsheet.

it will be autometically reflect on the skecher workbench

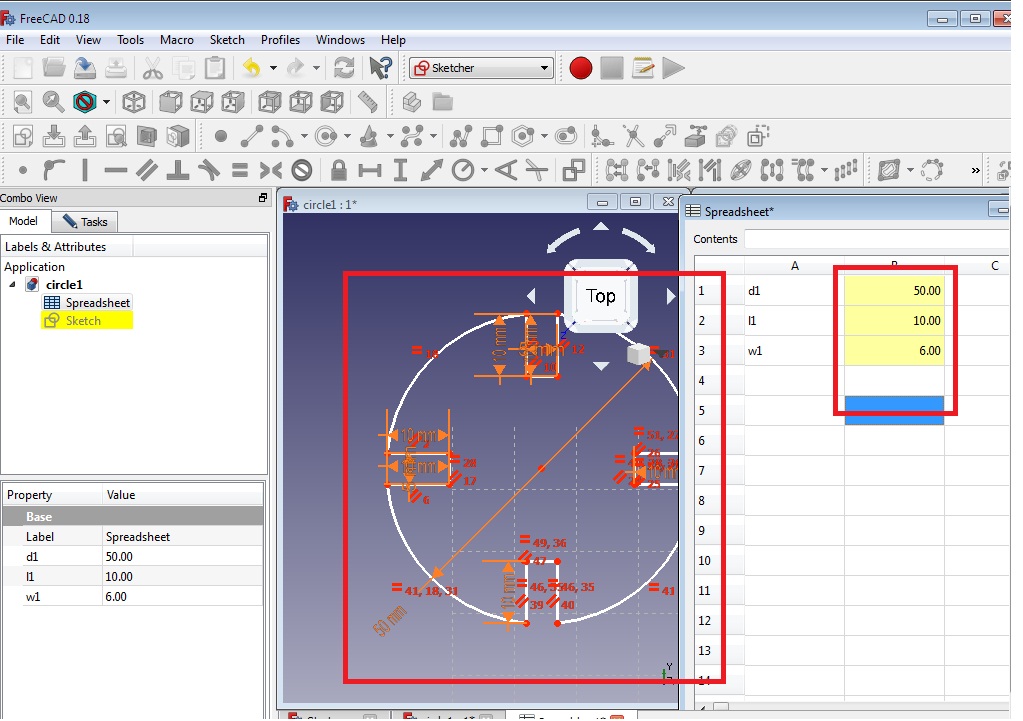

Then i have created some groove on the circle and put the dimession on spread sheet as i consider l1 and w1 is the lenght and width of groove.

The value of l1 and d1 which i given in spreadsheet apply to groove by using vertical and horizontal constrain

I have created the parametric design and give the dimession as per spread sheet

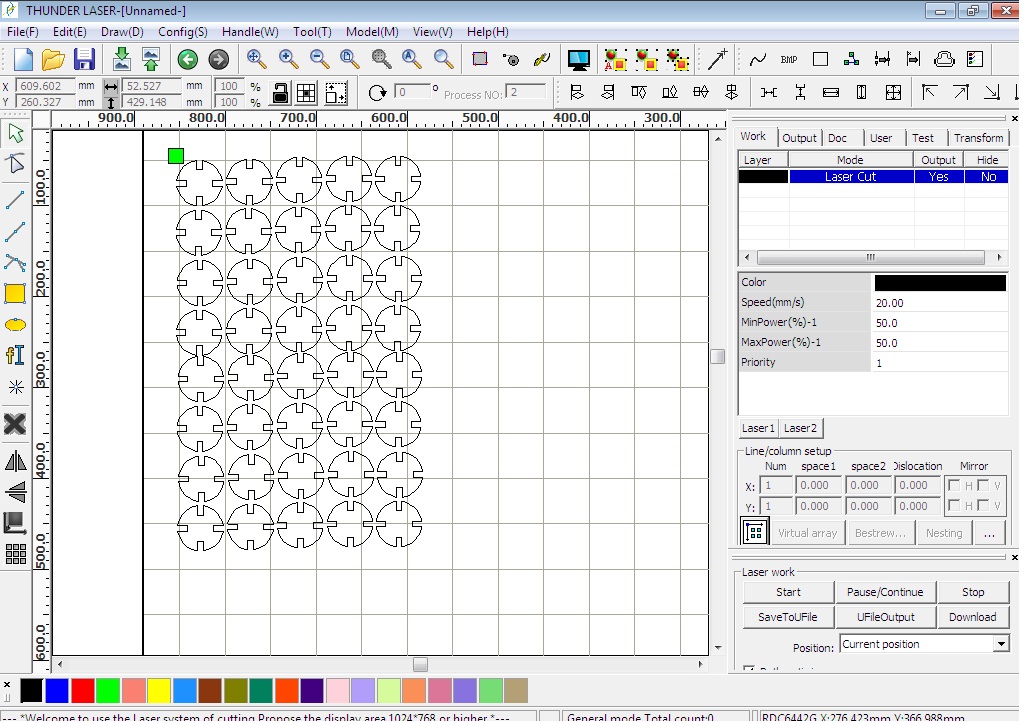

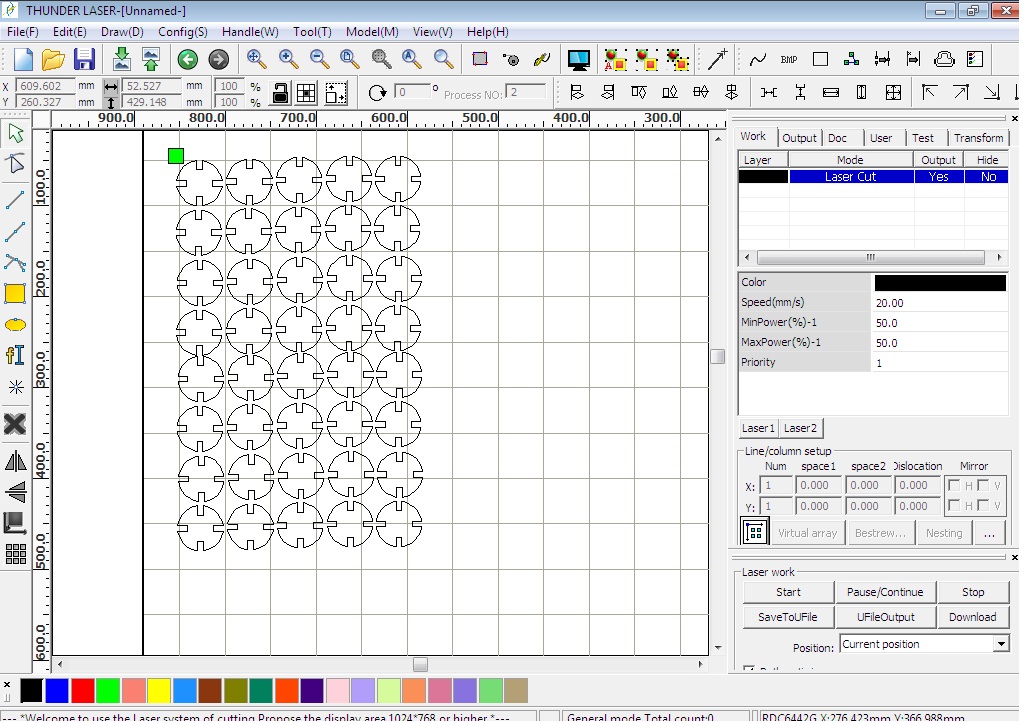

Now this design imported in lesser Machine software

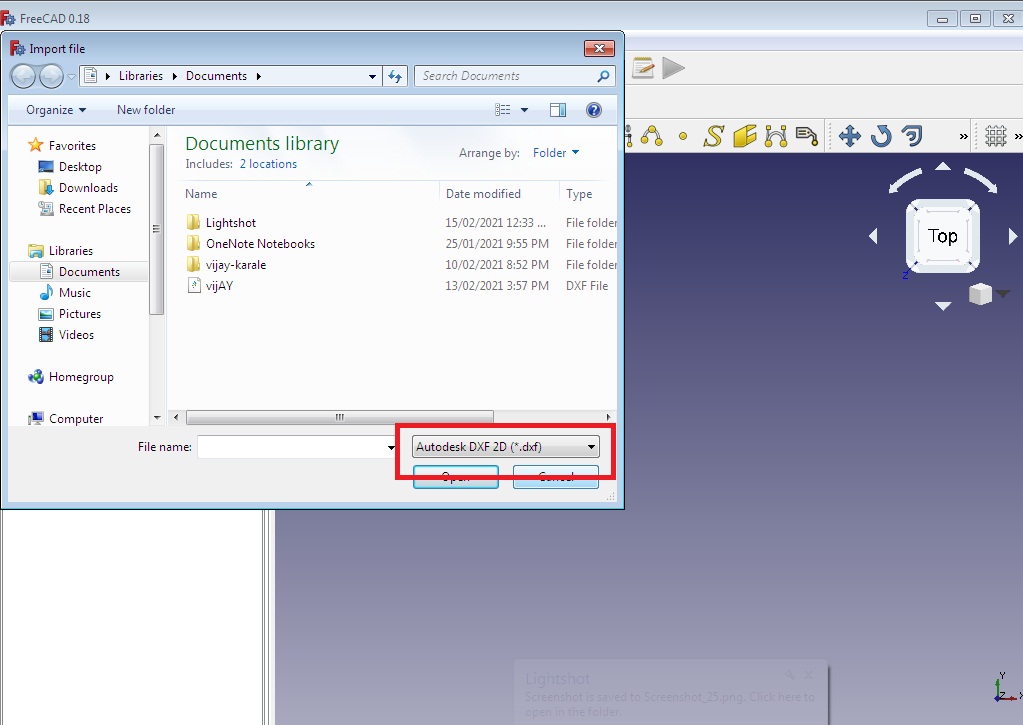

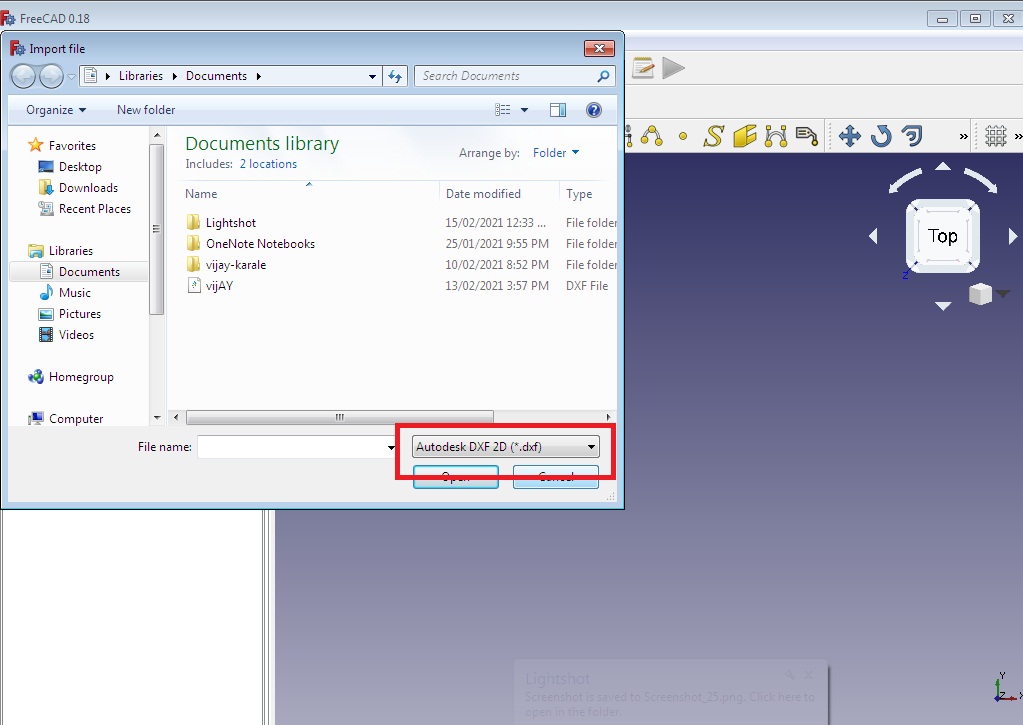

1) First close the skecher workbench

2) Go to Draft form menu

3) Go to File menu import the file save it as AutodextDXF 2D.dxf

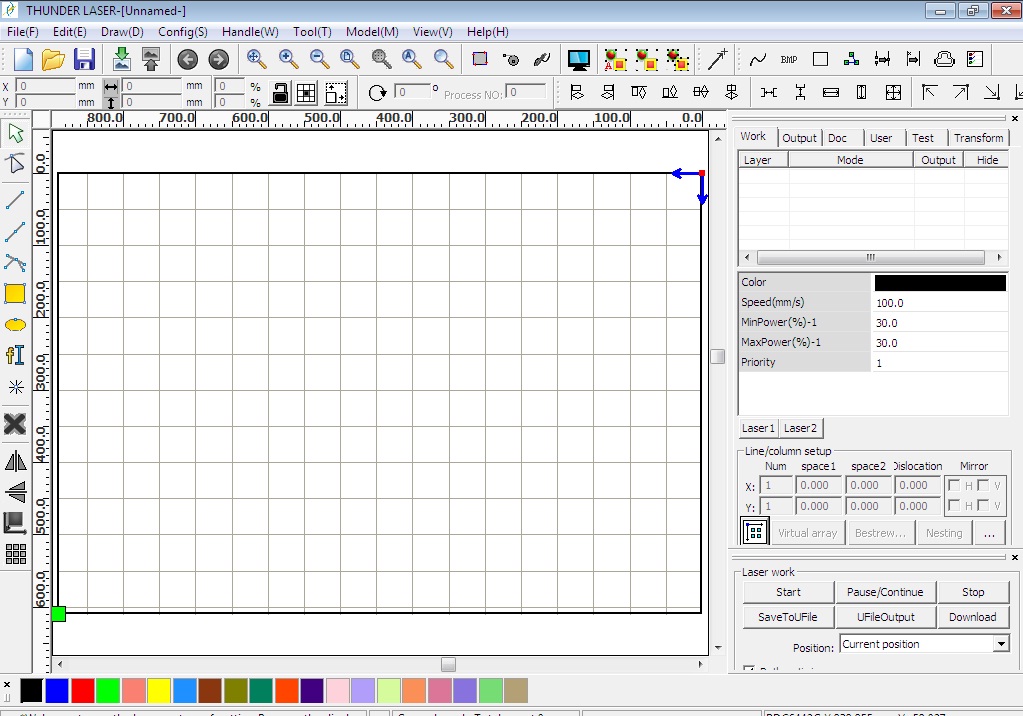

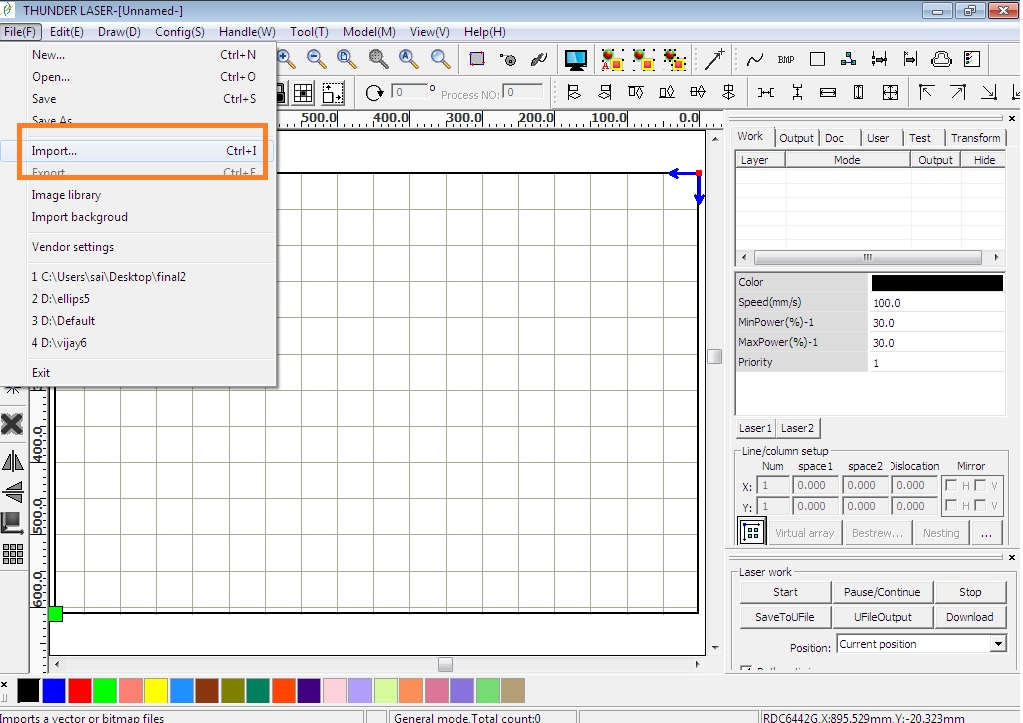

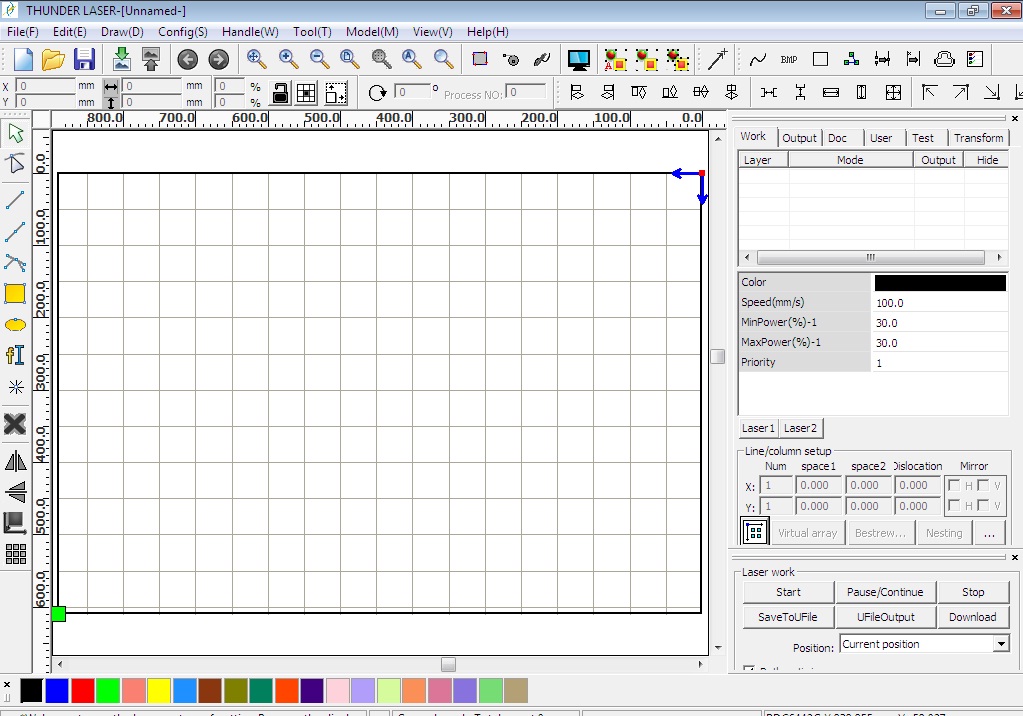

After saving the file we need to download and open RDWORKS Software.

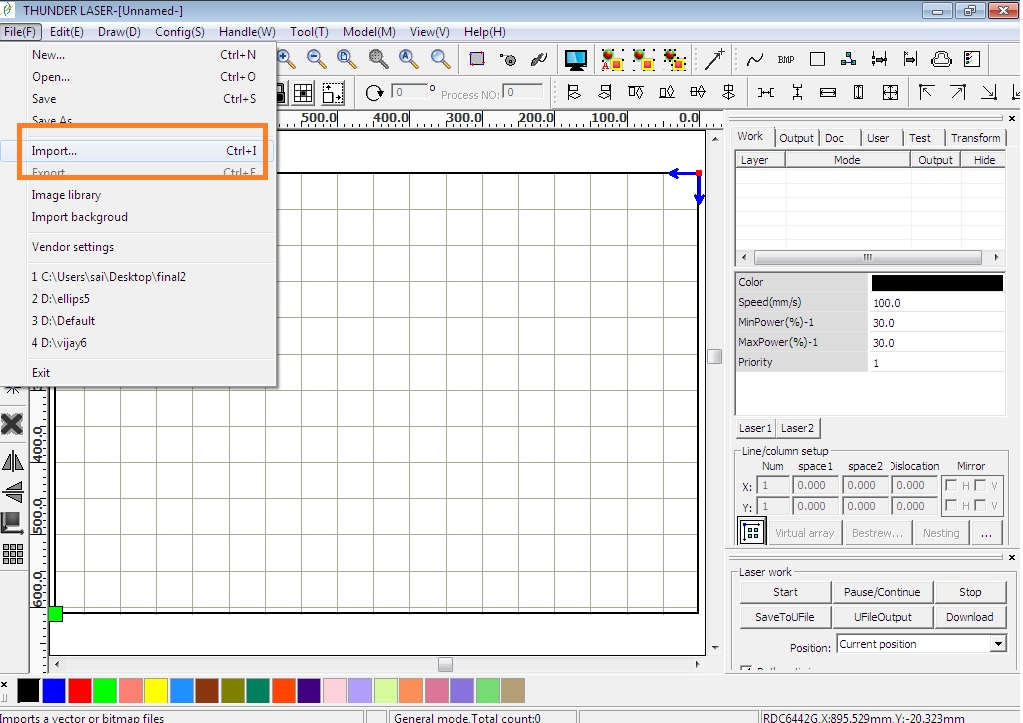

Then go to File menu select import files or you can select the .dxf image that you want to open in RD woks

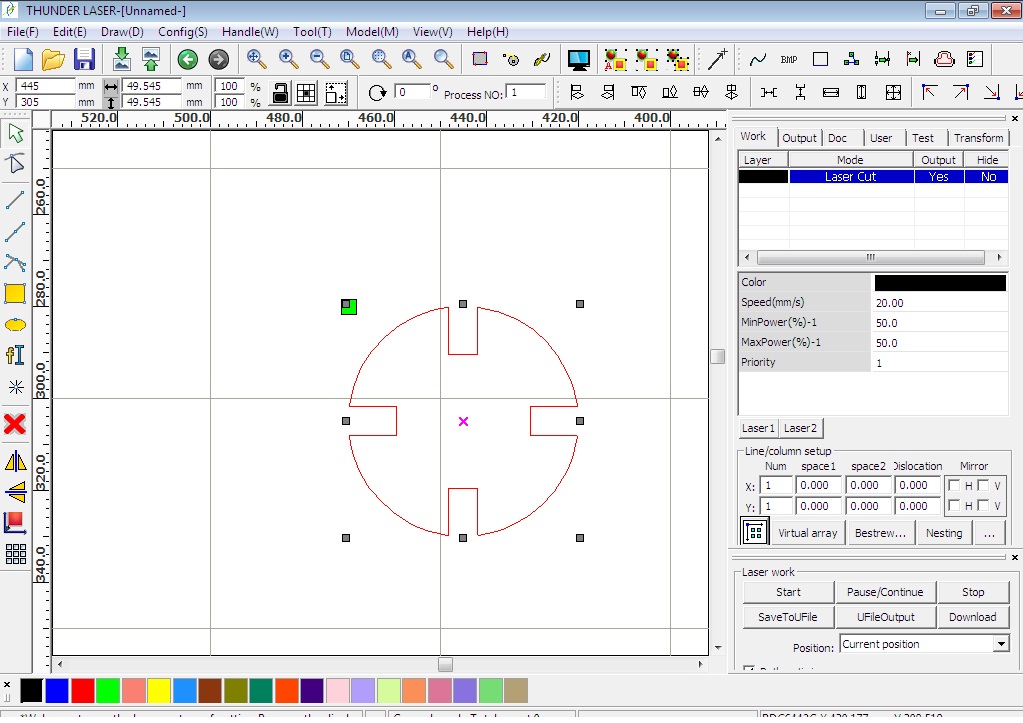

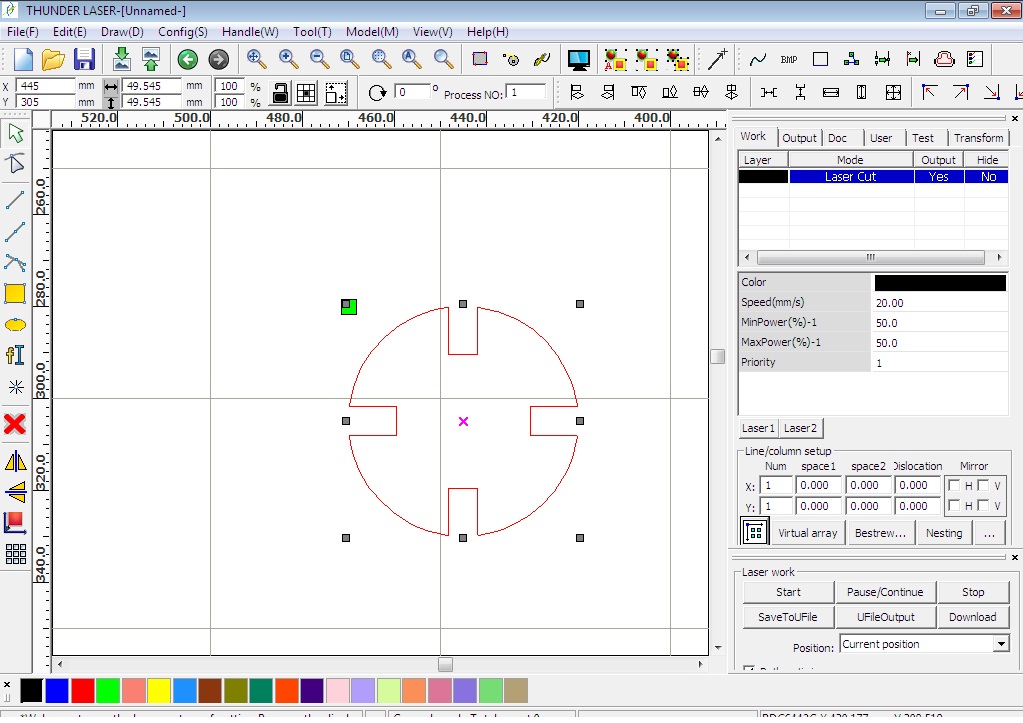

Once file open in RDworks

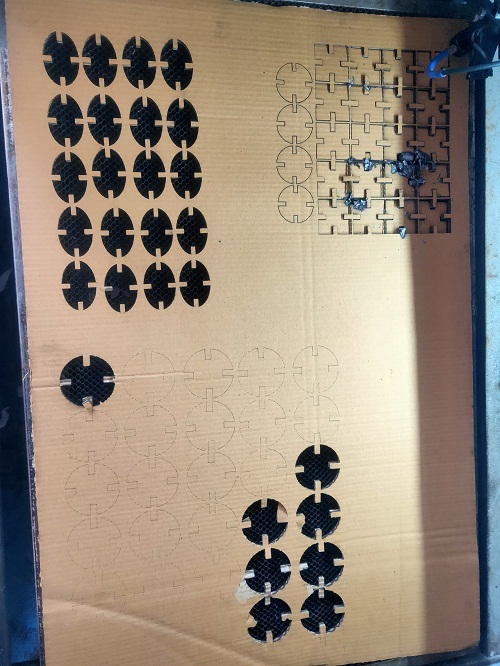

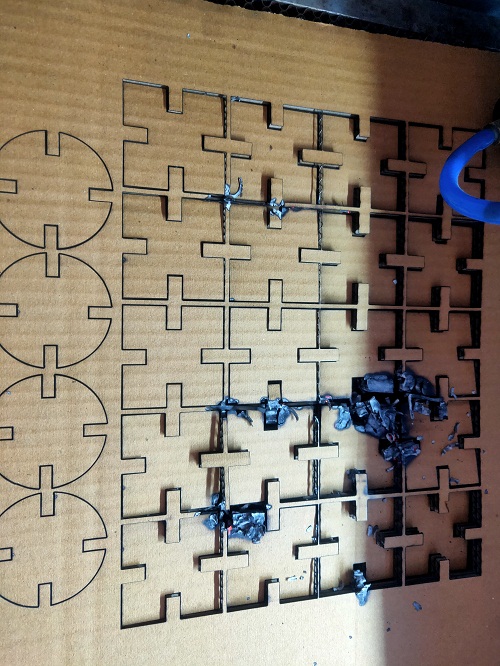

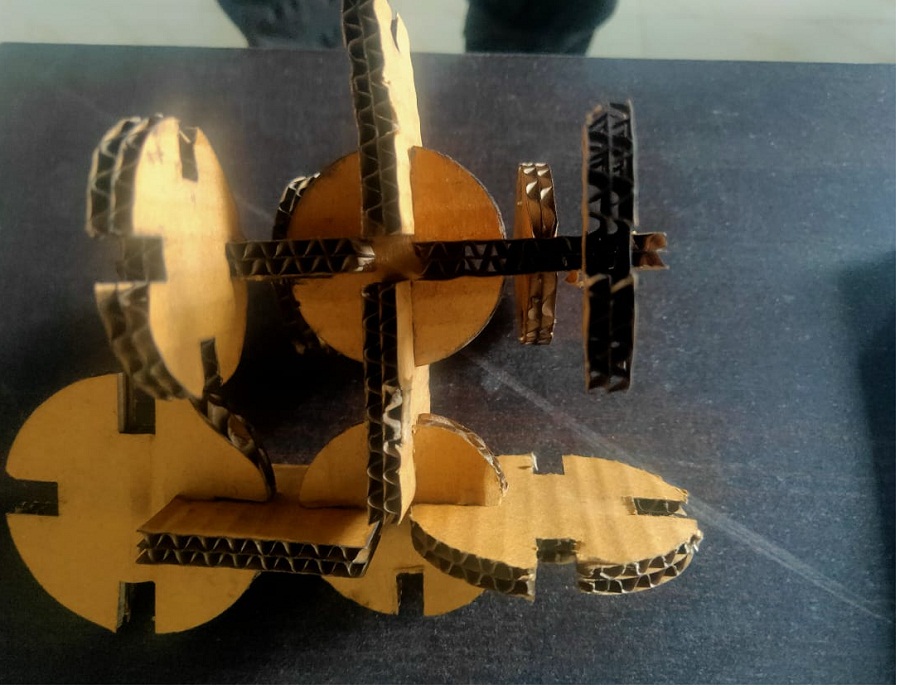

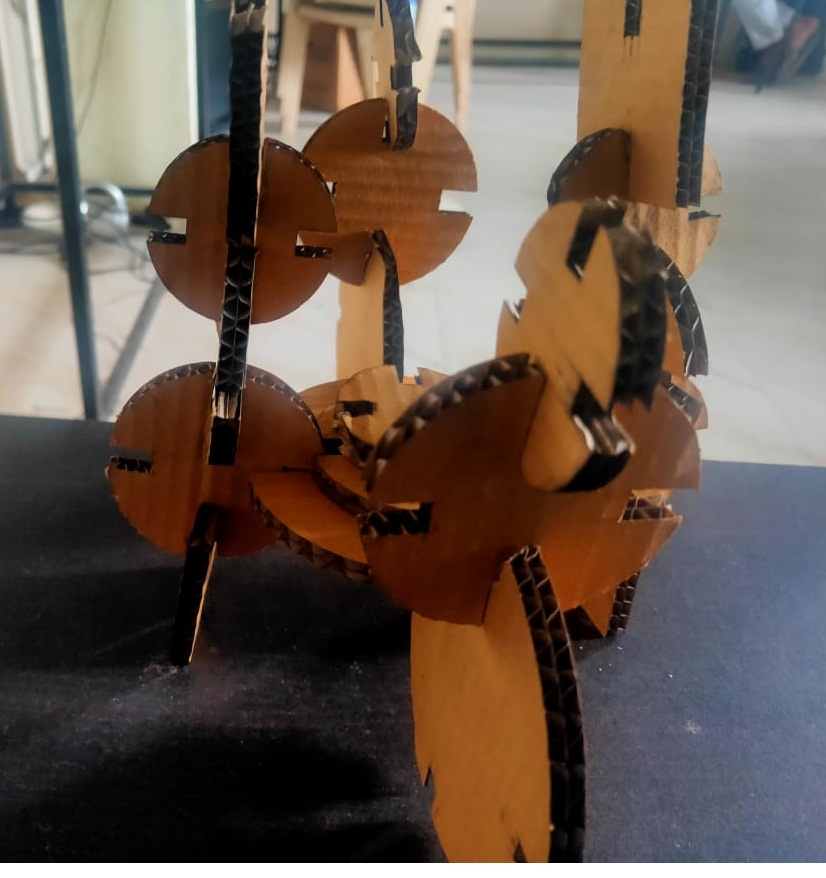

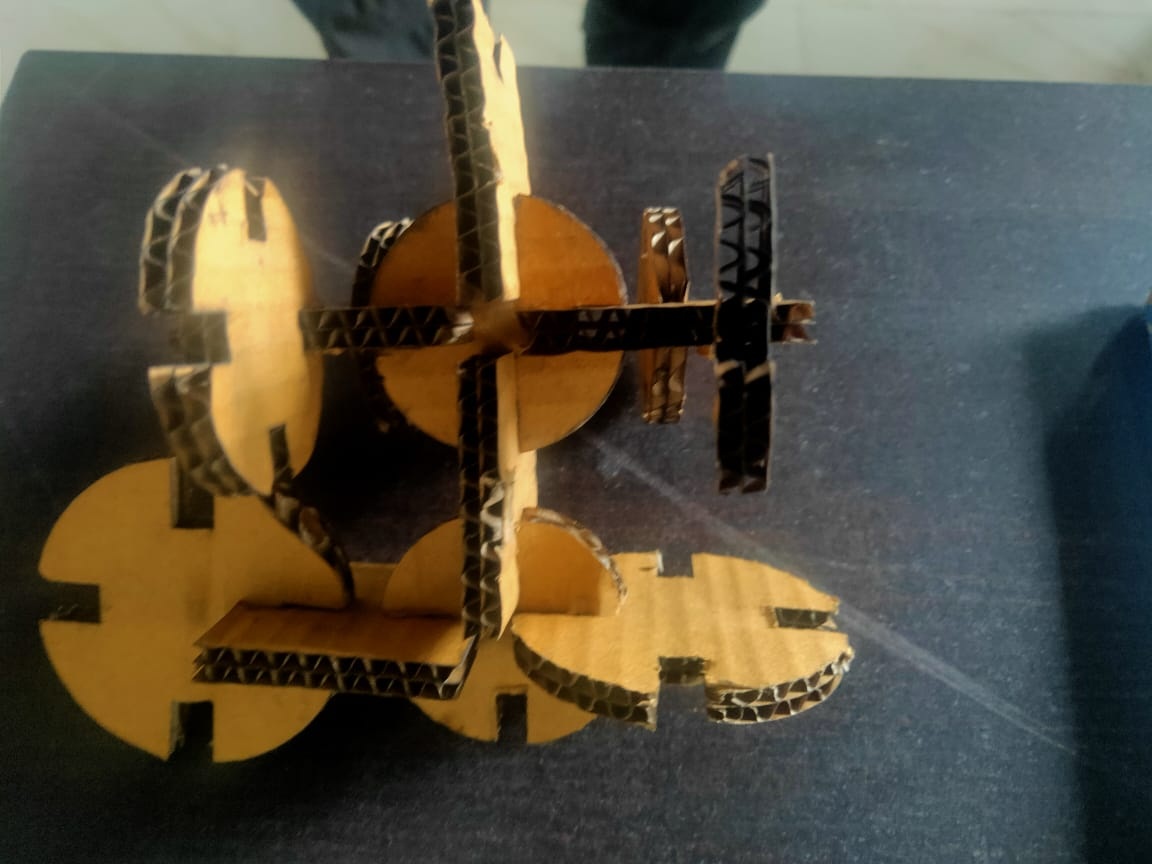

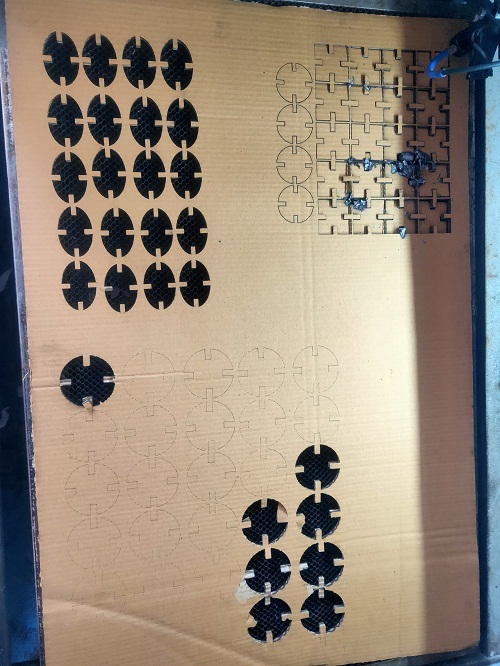

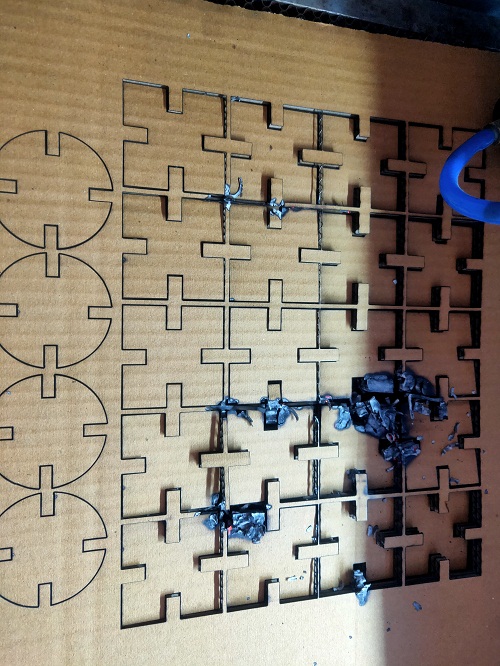

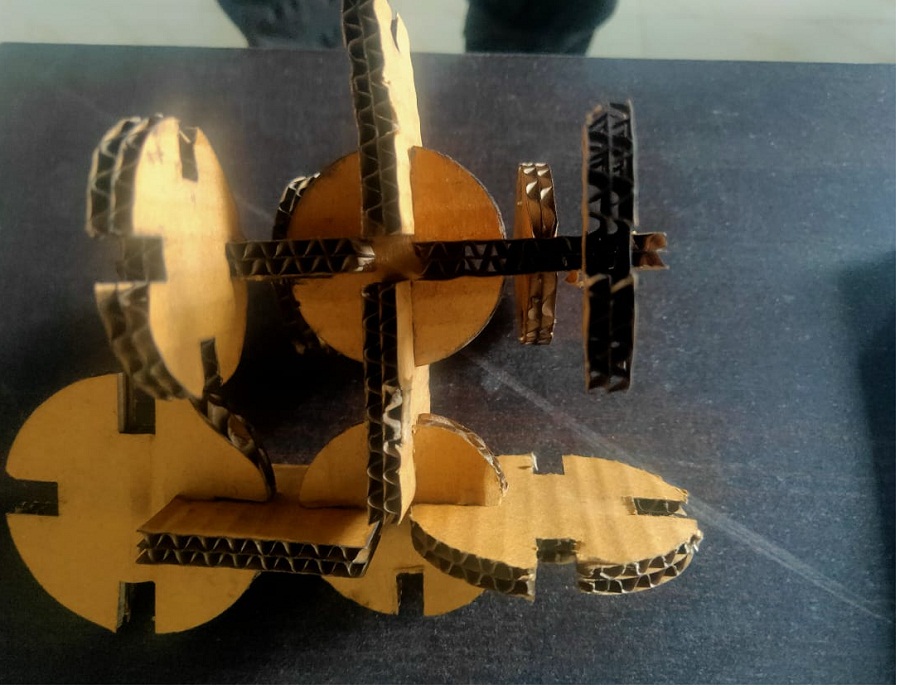

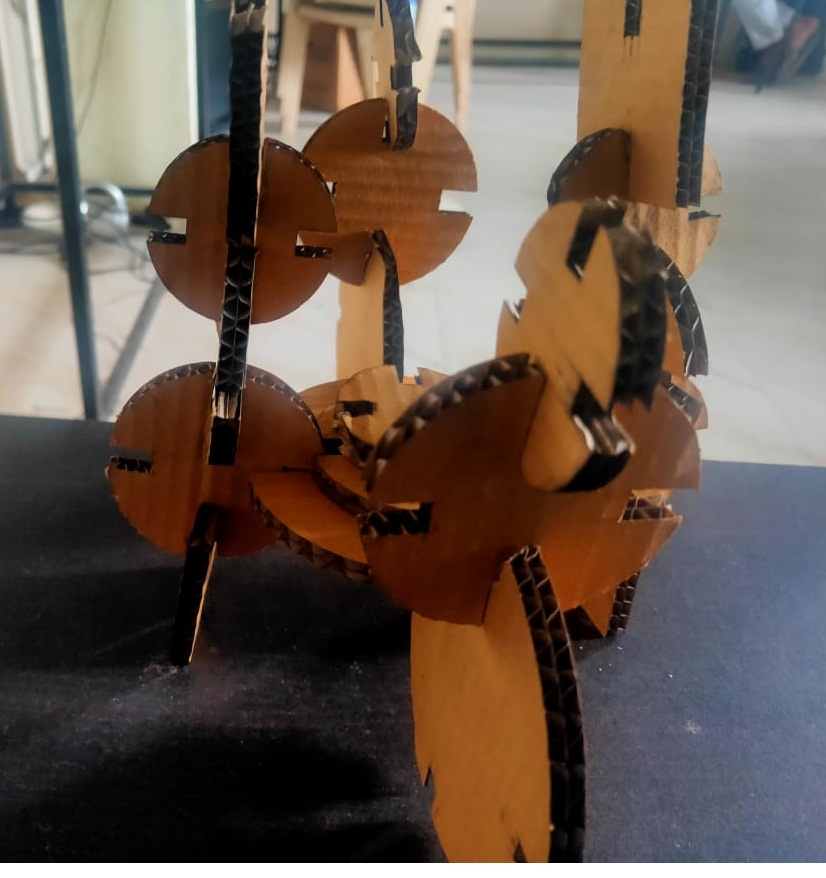

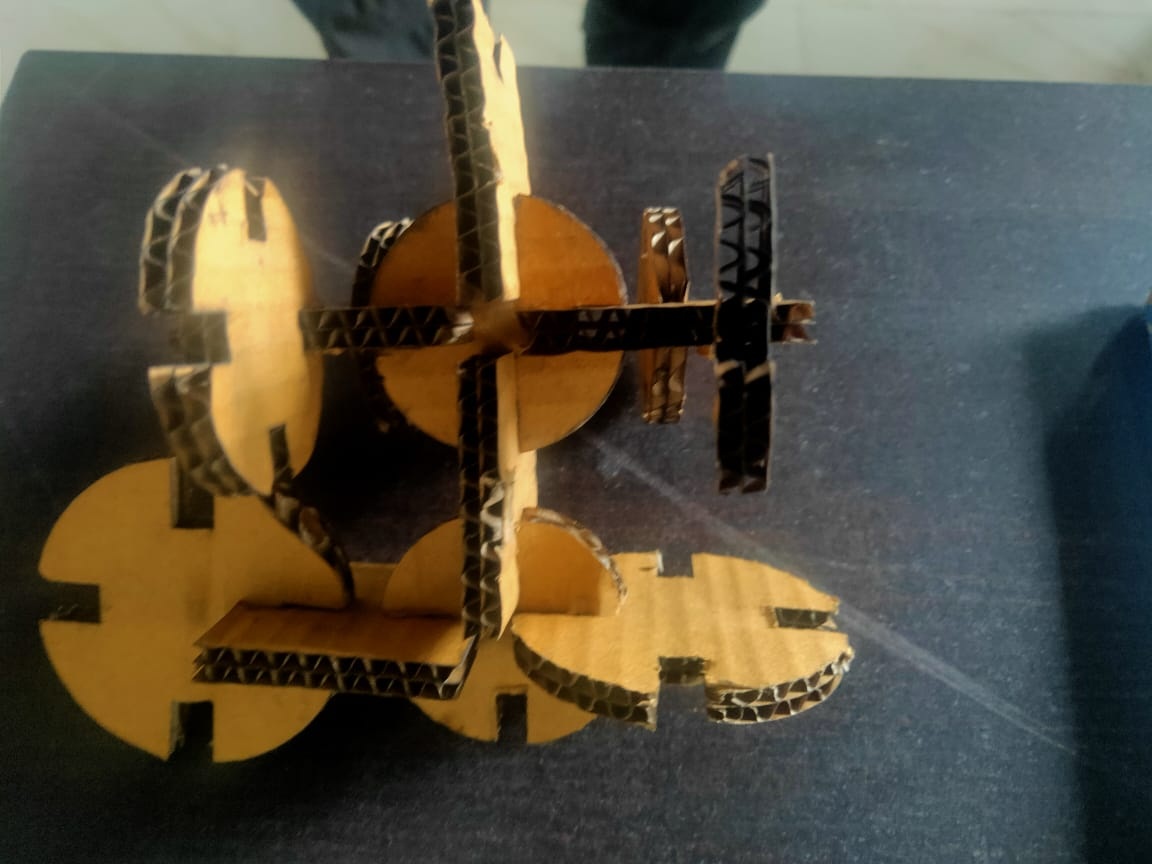

As have develope parametric design of circle with groove so single image into multiple so that i got number of pieces to contstuct the kit

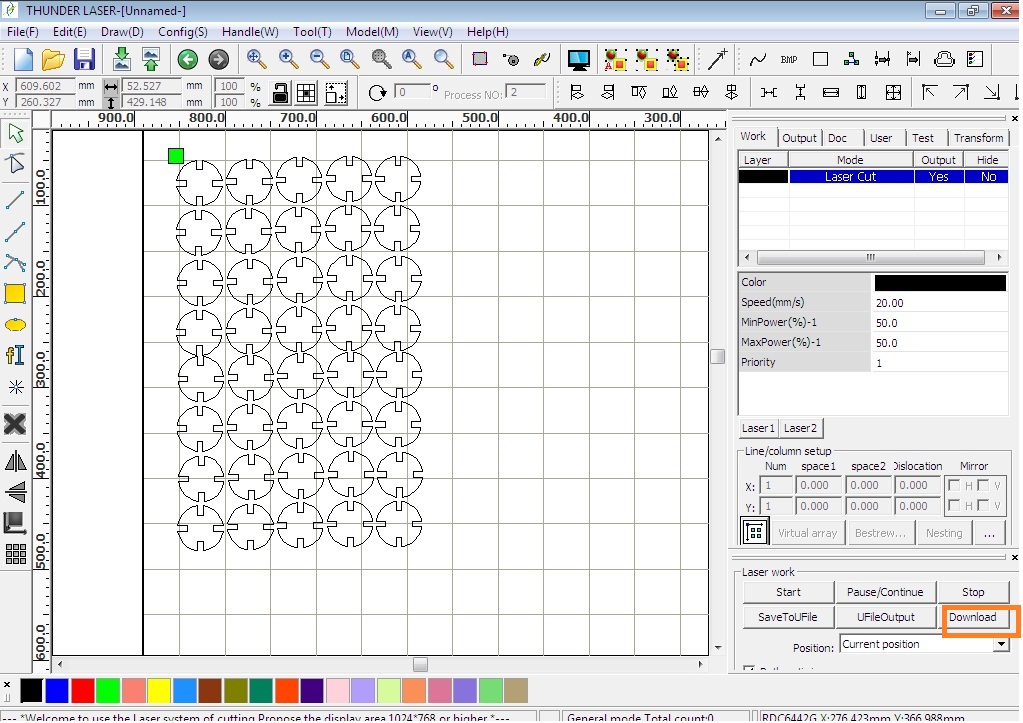

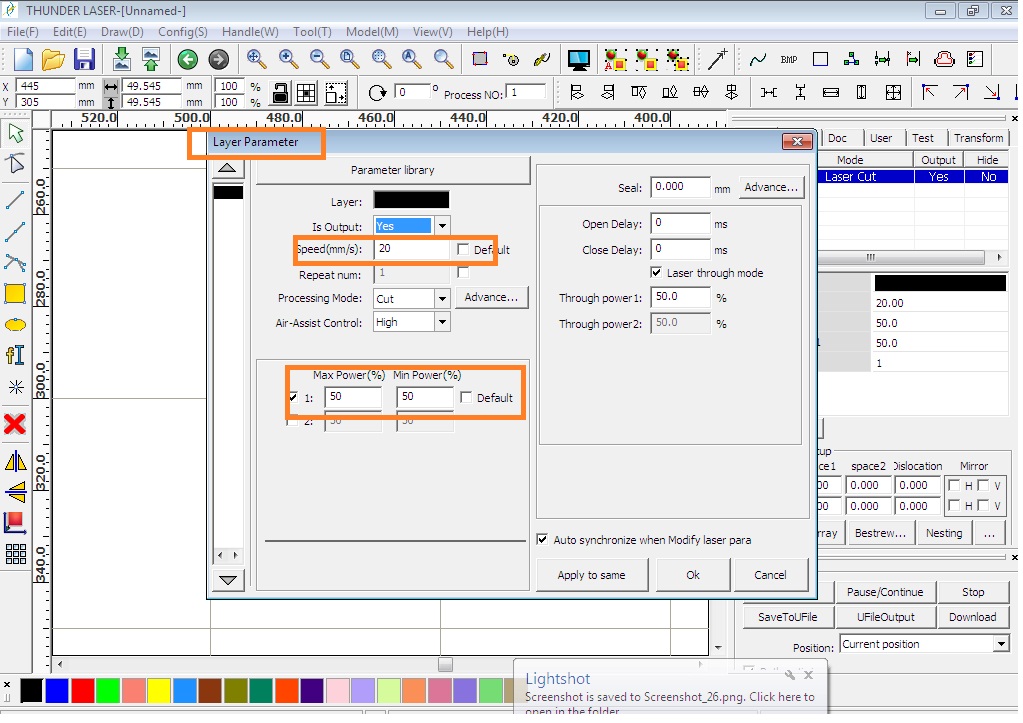

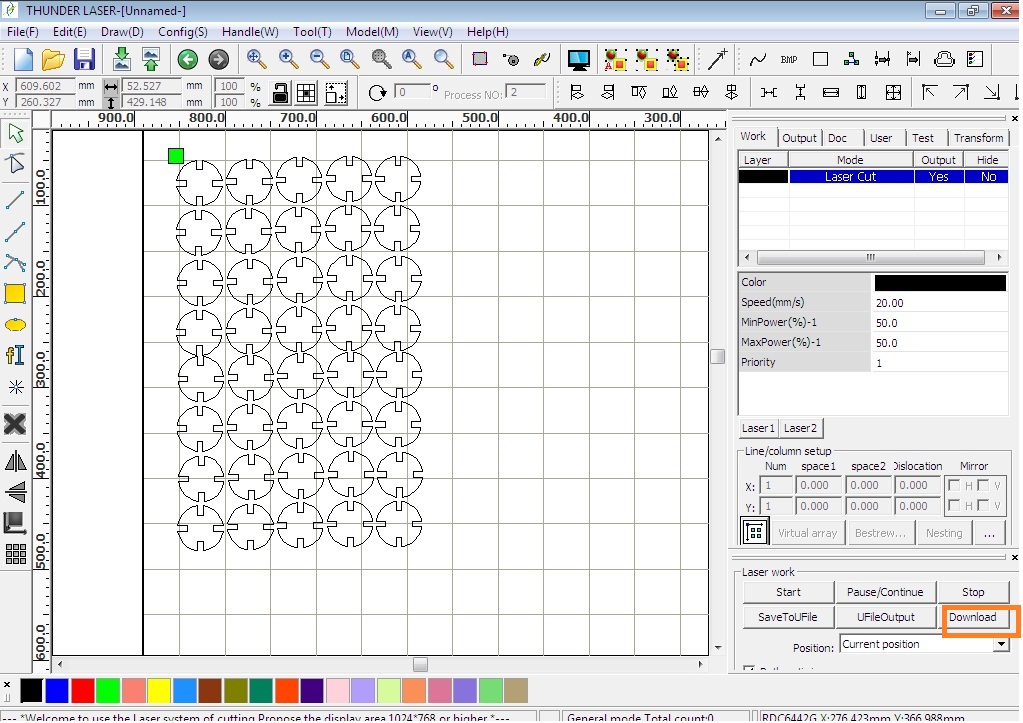

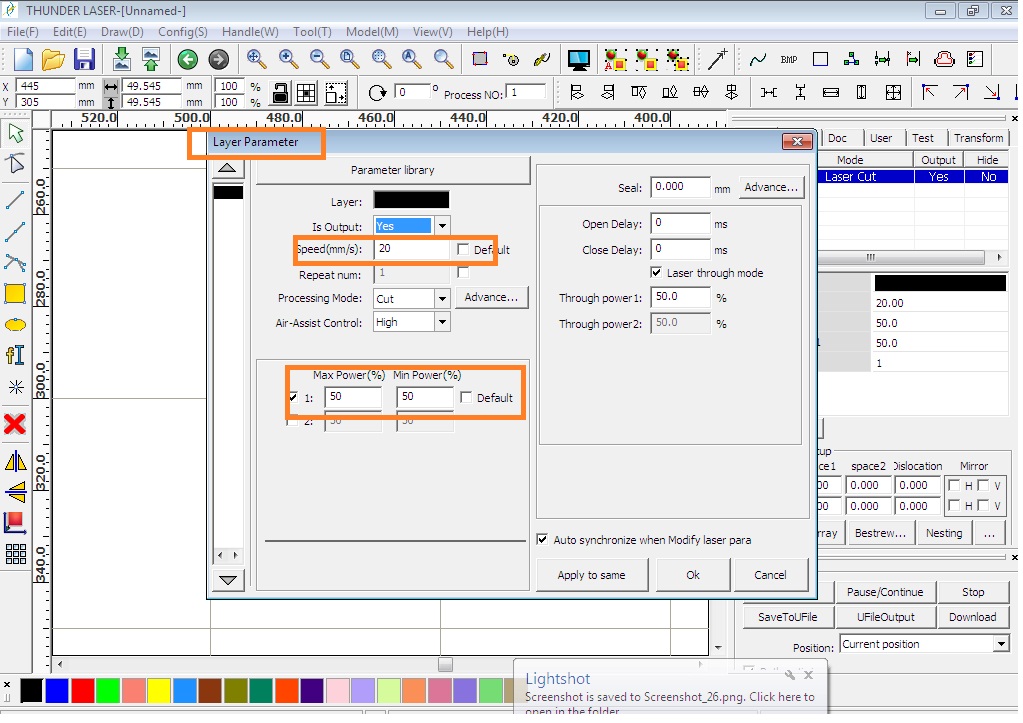

After that i have set the layer parameter like speed and power by double click on color.

Once file is in rdworks we need to upload the file on laser machine by click download option on left side

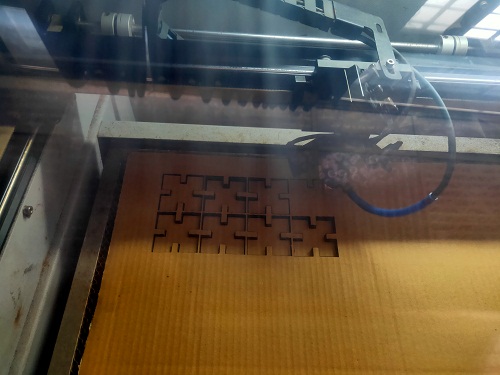

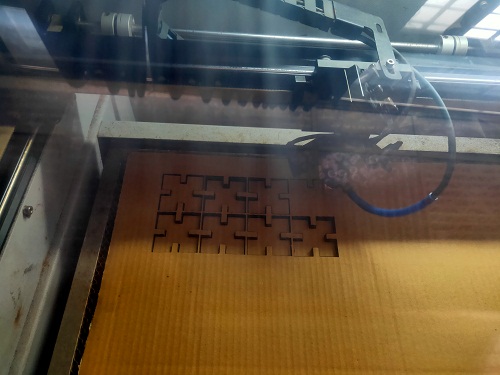

As i have use the cardboard of thikness 6.90mm so as per thikness of material the calculted speed and power 20mm/sec and 50% respectively

After that We get the message file downloaded successfuly

How to Use leser cutter machine

Start the Laser Cutting Machine by following this steps

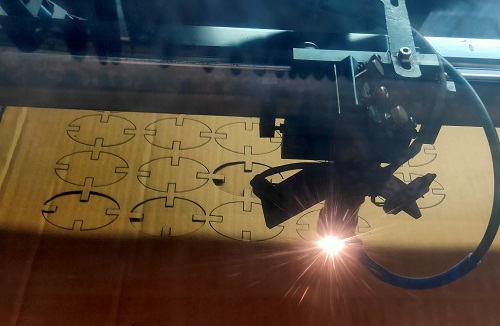

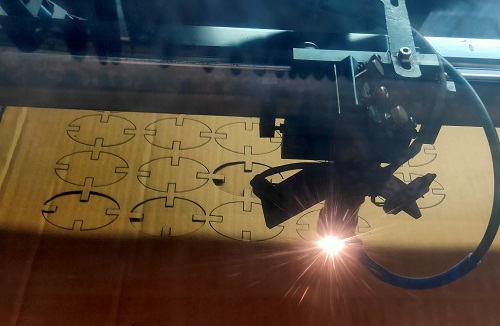

1) Place the material on bed of leser cutter machine

2) Set the X,Y,Z axis as per requirement

3) Set the head origine as per convinient level

4) Select your file and identify the cutting area

5) Click on start/ Pause button for cutting your job

Some part of the cardboard burn while operating the machine becasue of less speed or may be due to high power

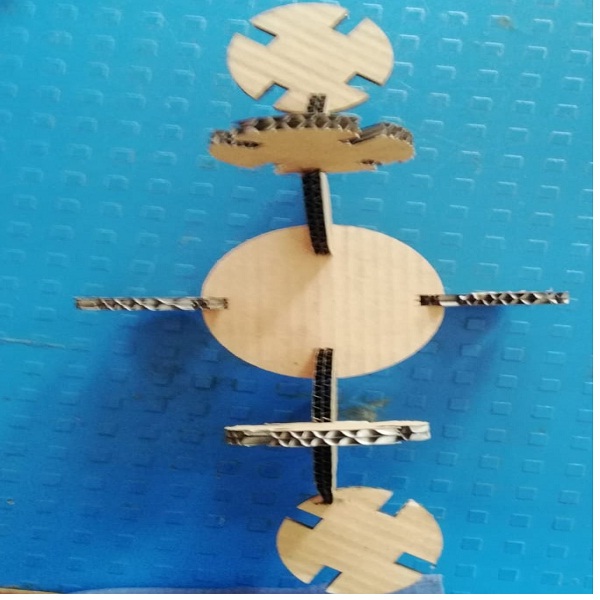

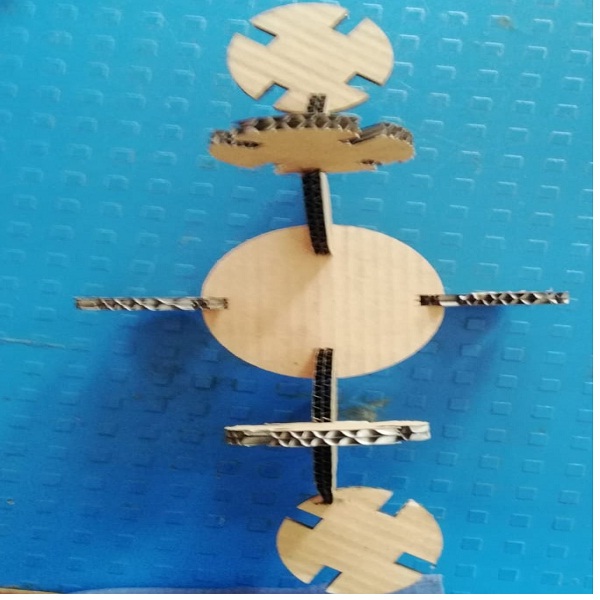

This is how I have press fit my designed by creating different kind of shapes

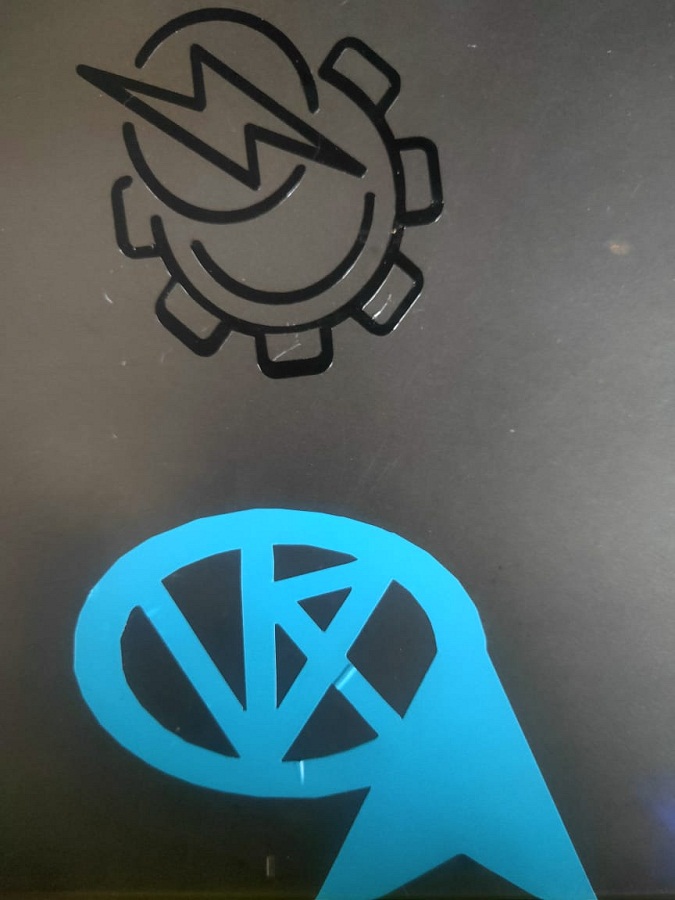

Vinyle Cutter

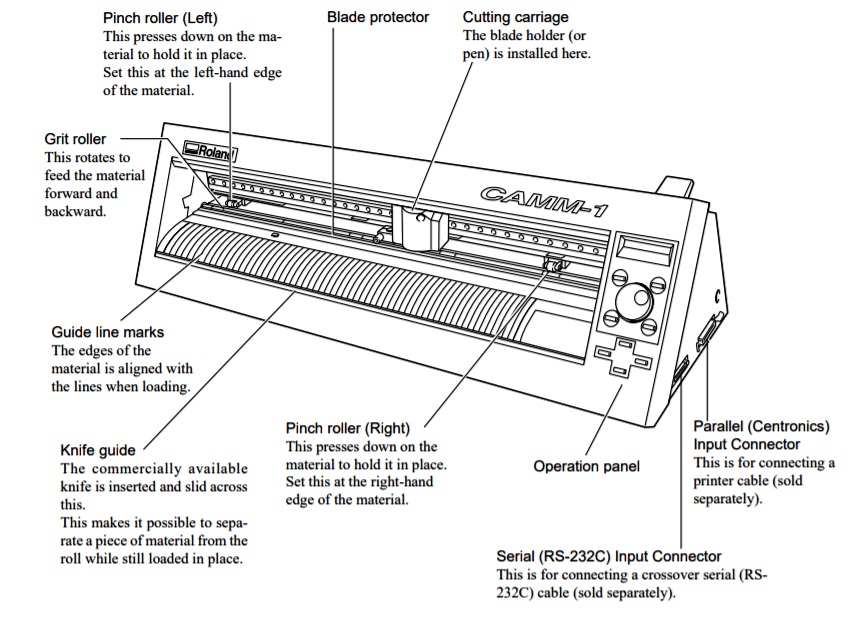

Vinyle Cutter is again the type of Computer Controlled cutting Machine

like a printer Nozzle,The computer controls the movement of a sharp blade over the surface of the material.

This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic (vinyl).

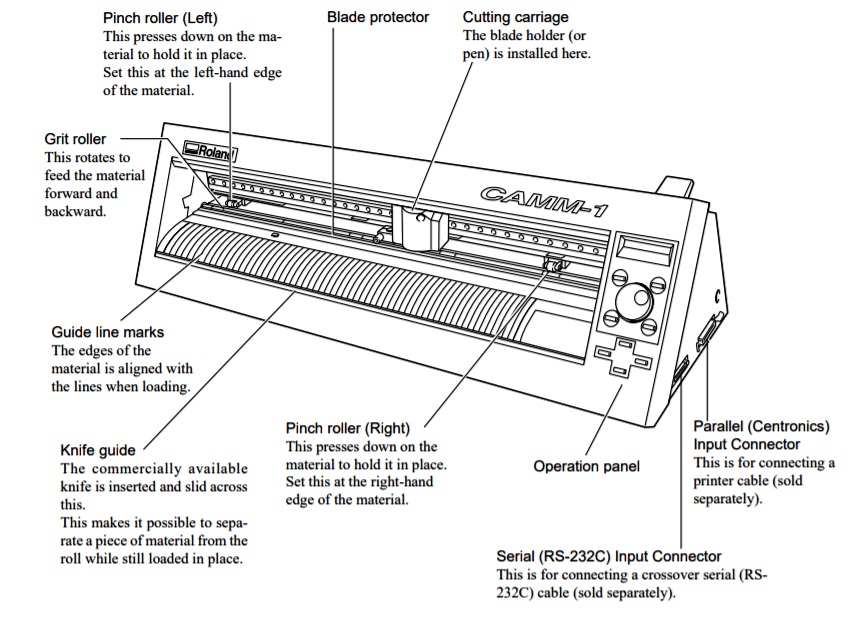

In our FabLab-0 at Vigyan Ashram, Pabal has Roland Camm-1000. It is used for cutting the vinyl, even plastic film, copper film for electronics PCB design.

We had to cut the logo or any design on this machine. This machine tempts you to be creative and adds aesthetics to the product.

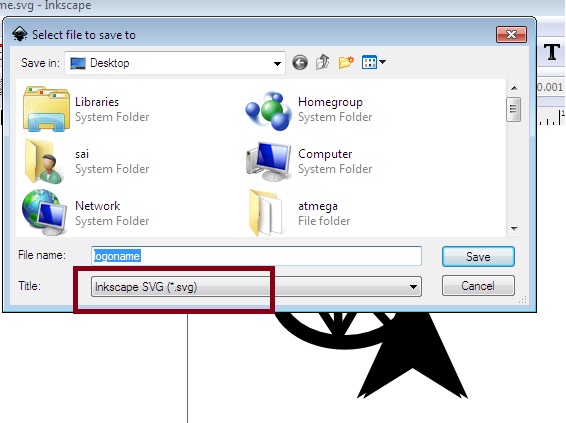

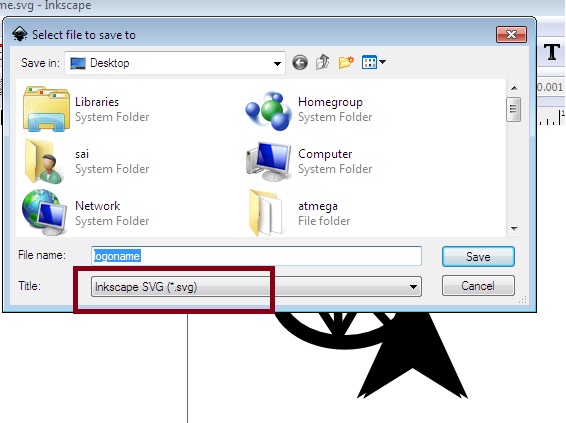

Creating logo In Inscape Software

In second assignment i have learned some what about how to bit map the image in Inkscape software so I have downloaded logo and bit map it and set the size of image as per need.

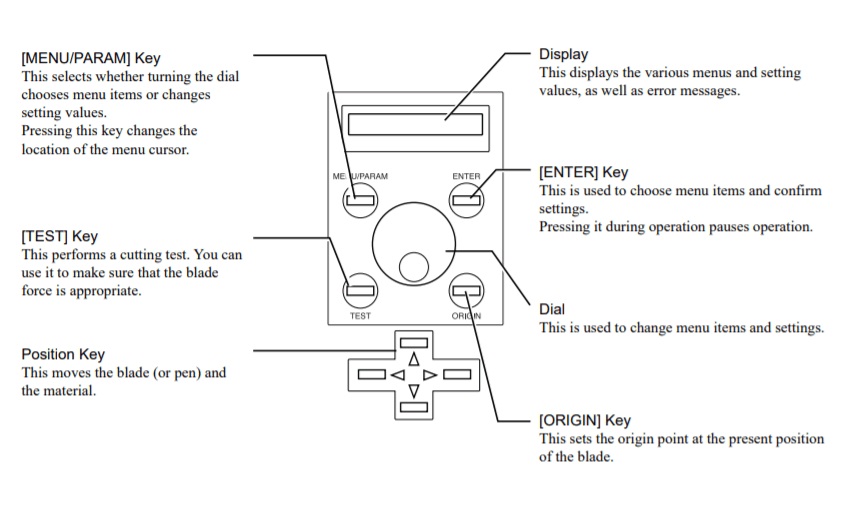

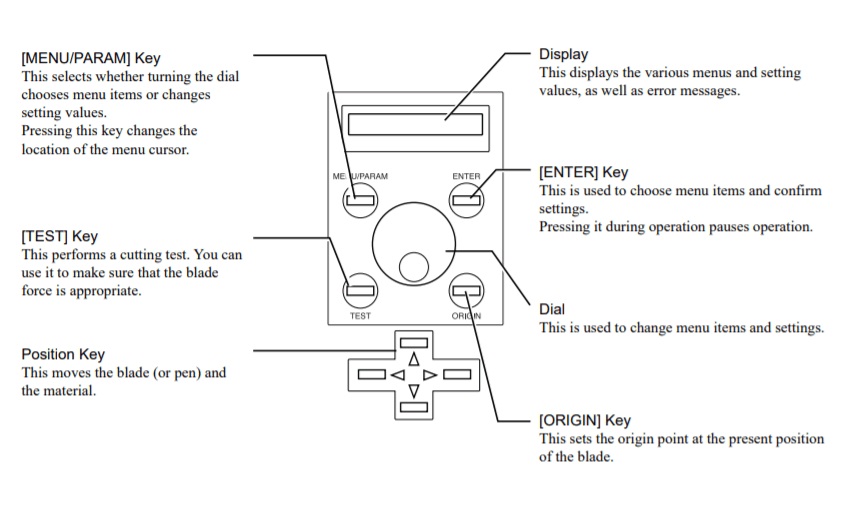

Process to use Vinyle cutter

1. Switch on the main power Supply

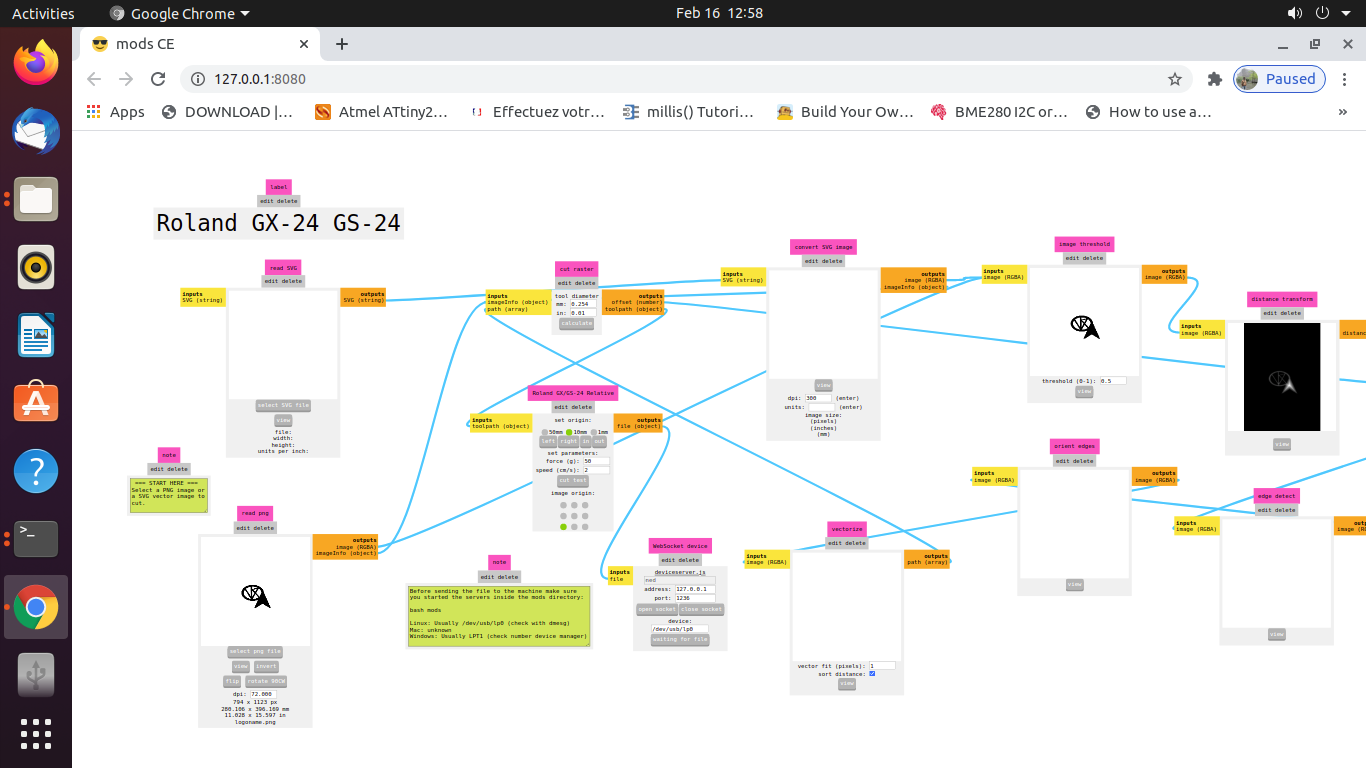

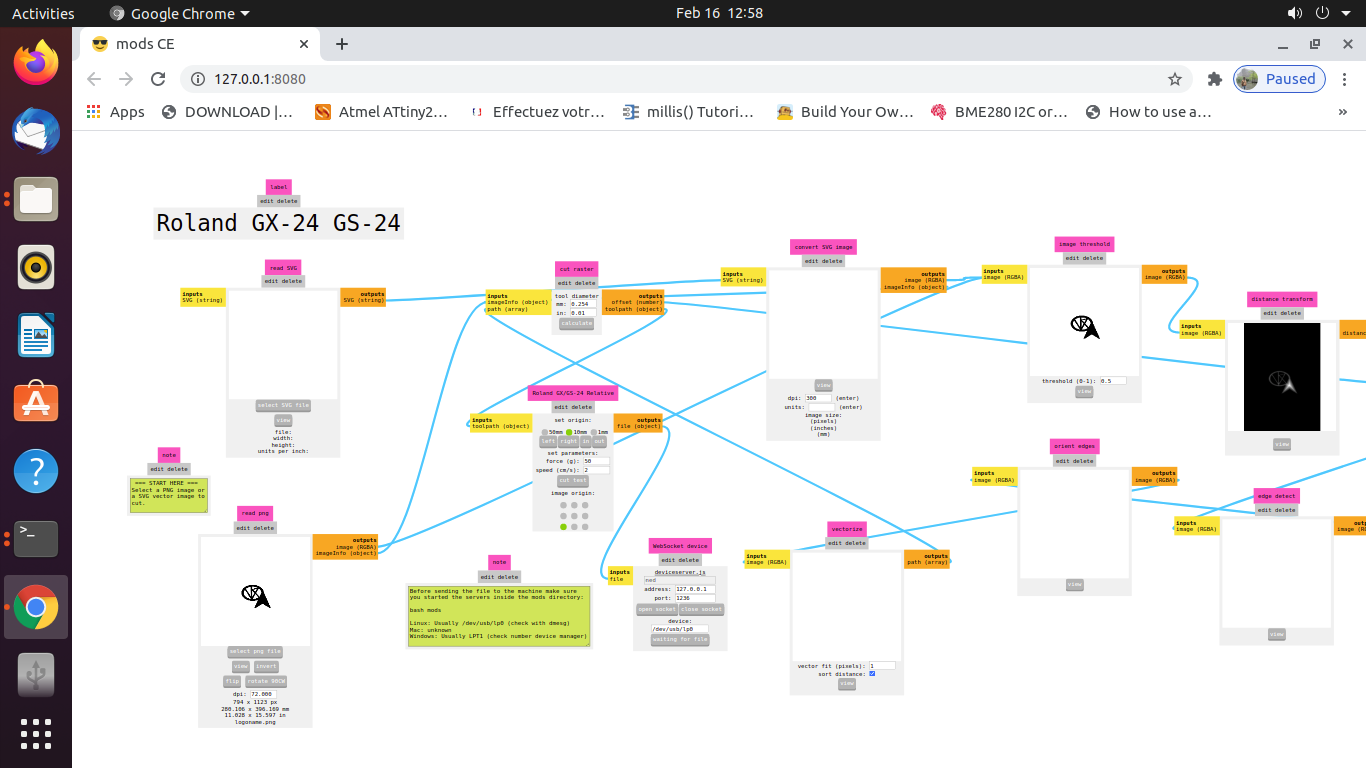

2. Set the parameter of image to be cut in Mods on desktop Pc

3.Set the rolls by placing them under the white markings. (There are 3 markings in the machine. This defines the cut area.)

4.To avoid Weeding (Picking/Cutting what is not needed and leaving that is needed), adjust the blade properly. Be cautious while dealing with the blade as it is very sharp and placed at 45-degree angle.

5.Load the Vinyl paper or copper film.

Lift the clamp situated at the back side of the machine. This clamp holds the material in its place and allows proper cutting.

Flow to cut the Image by vinyle Cutting

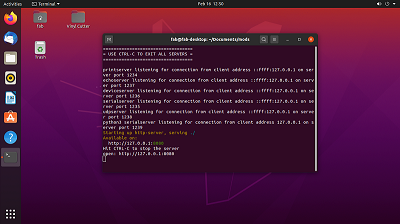

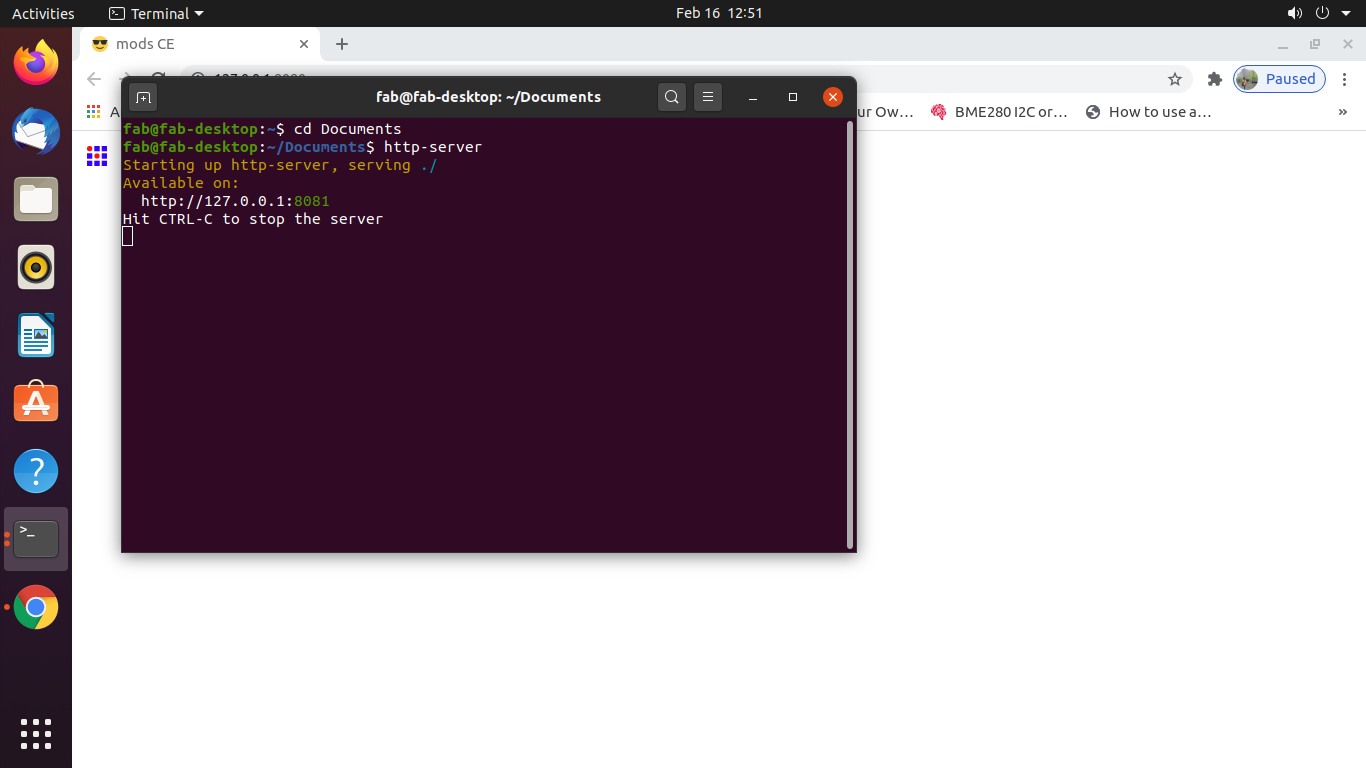

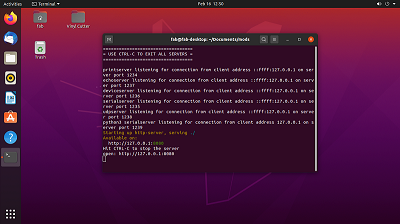

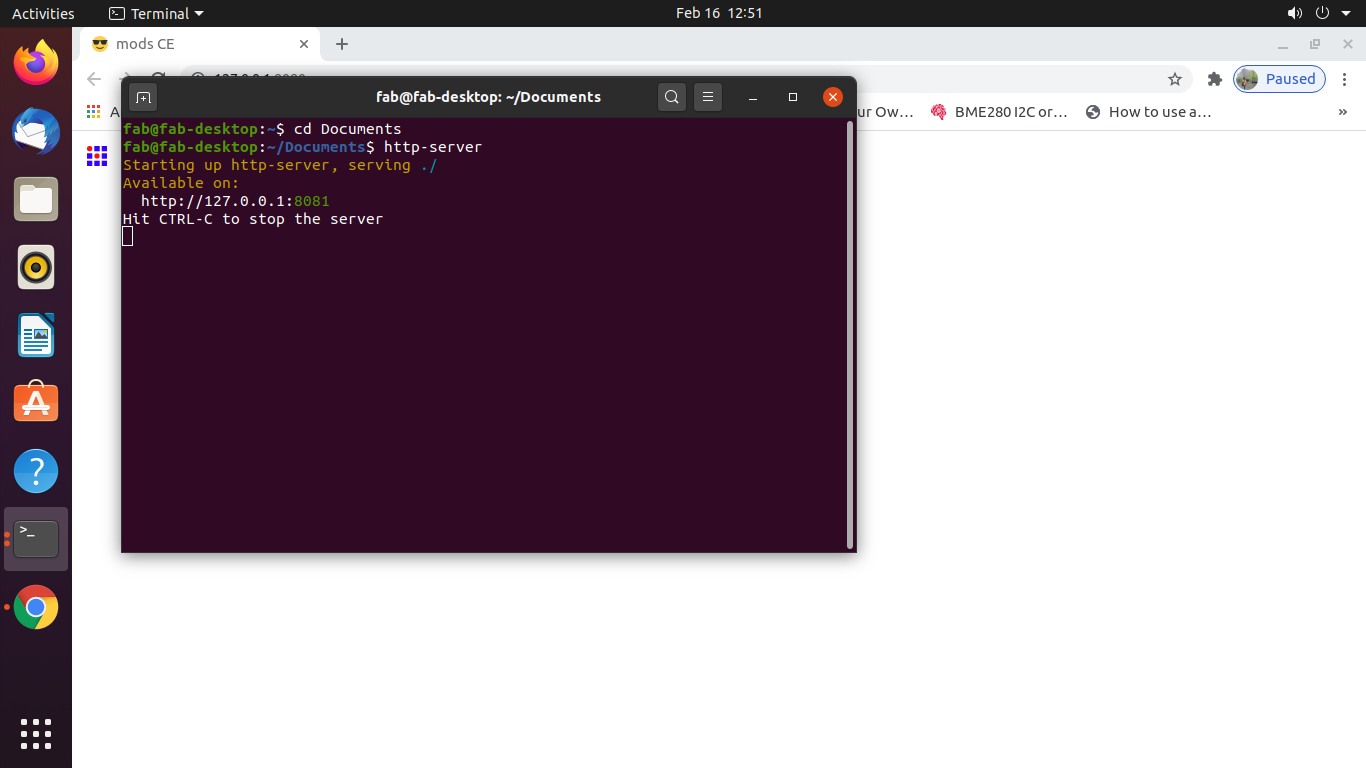

First Boot your system as a Ubuntu OS

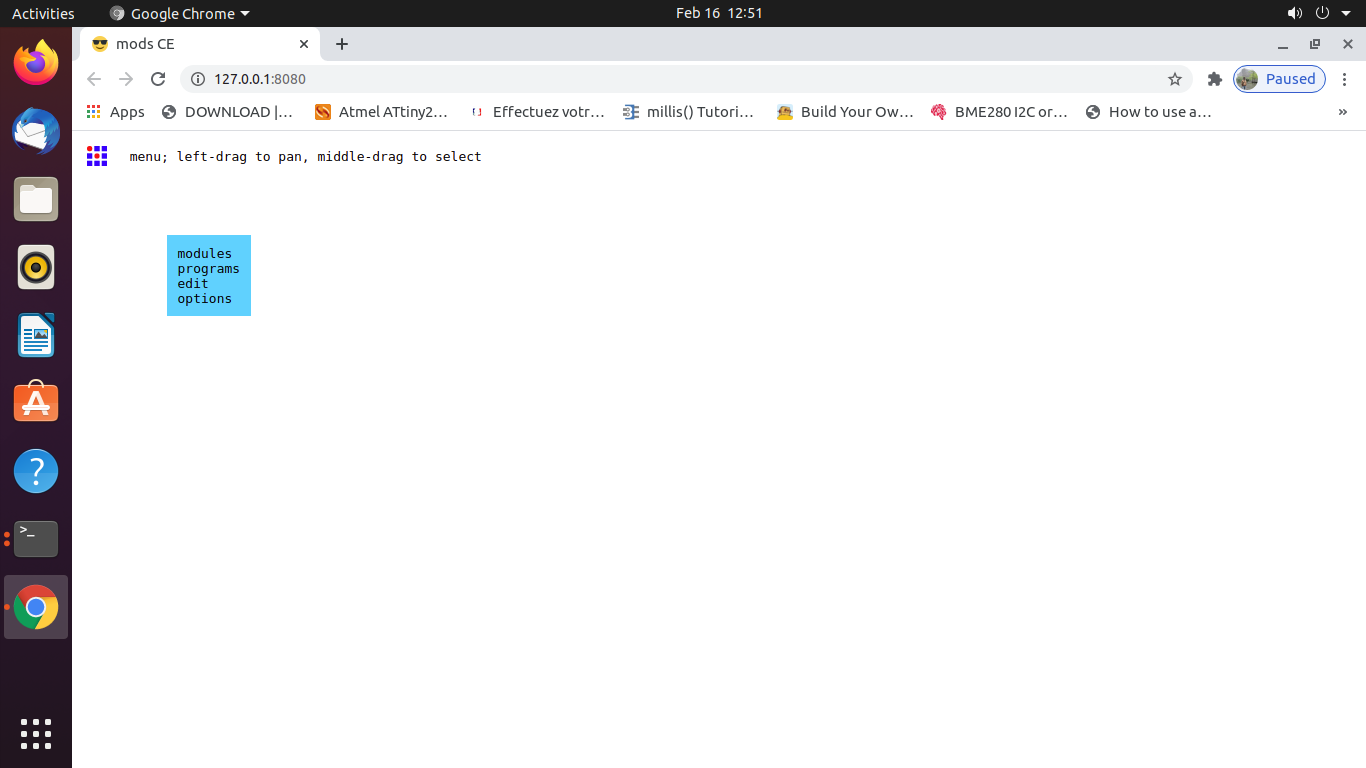

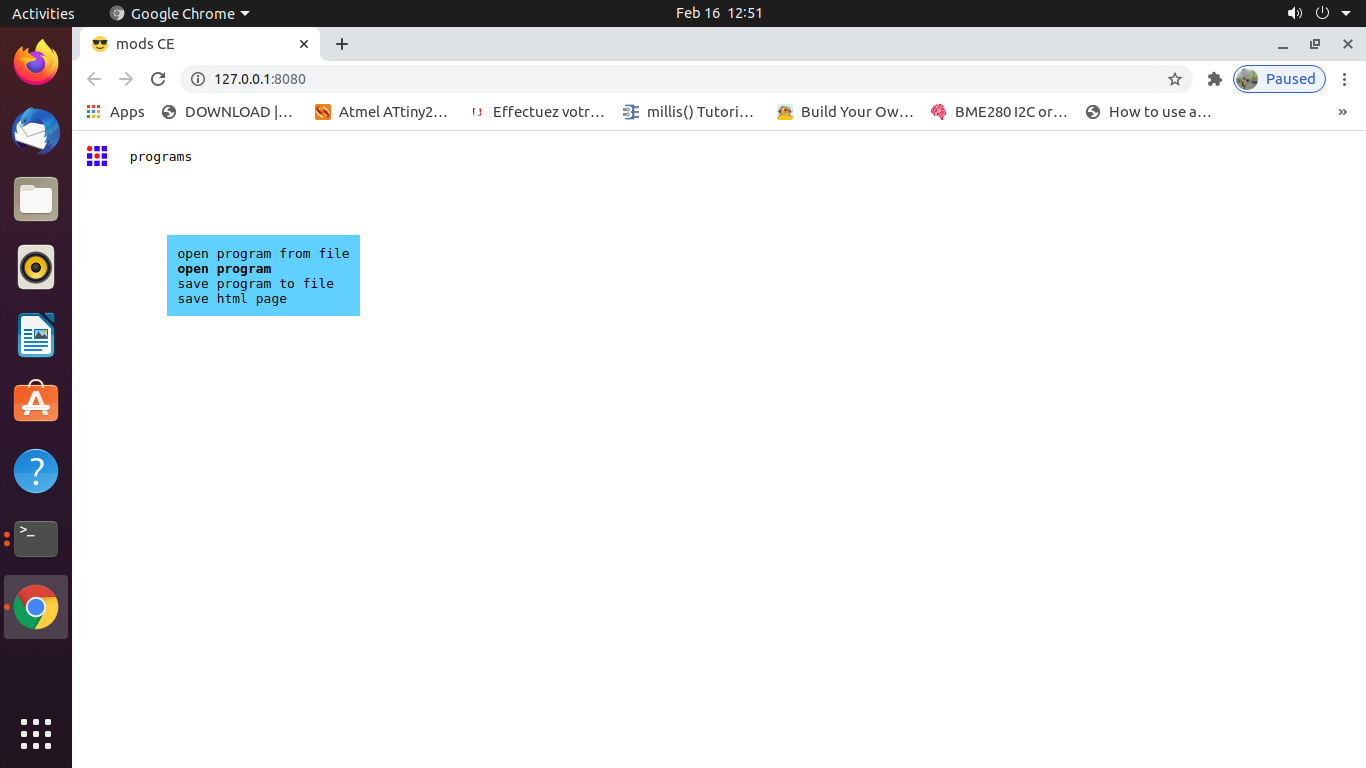

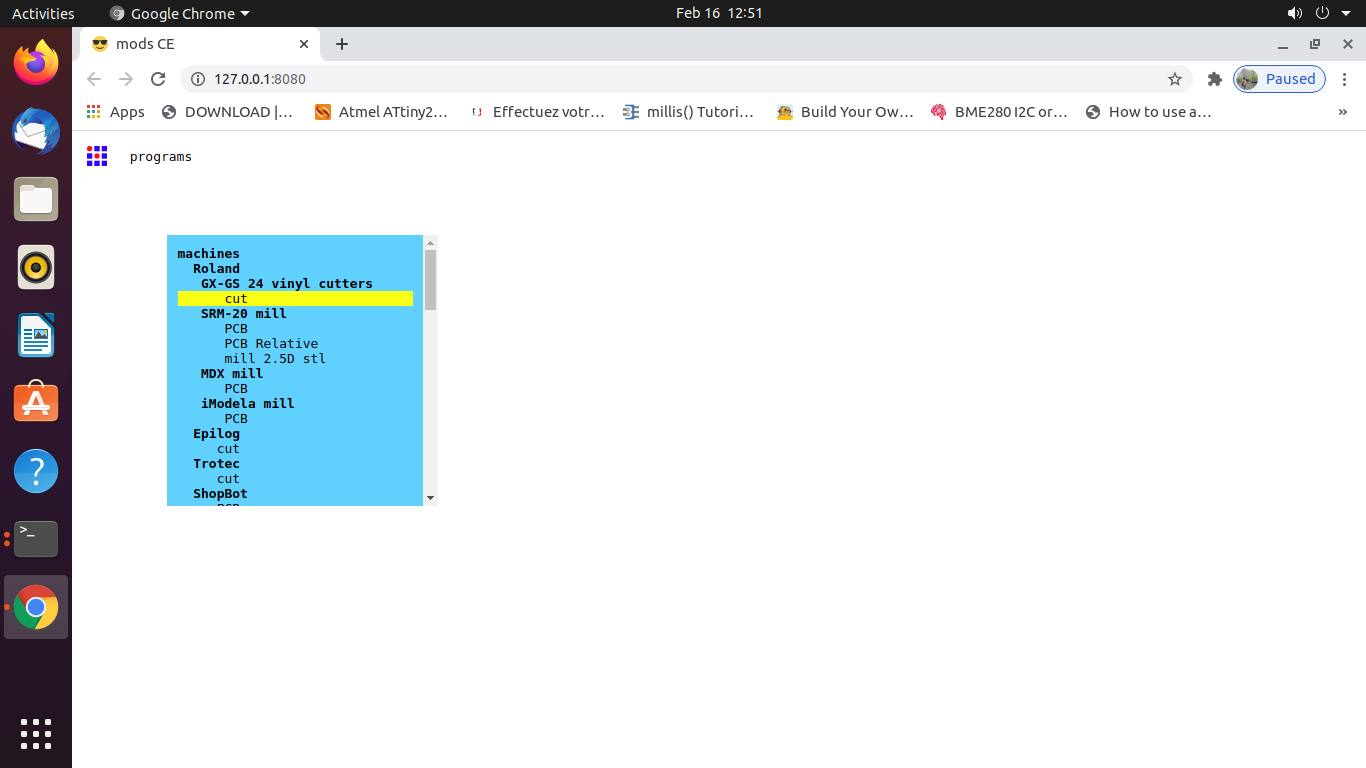

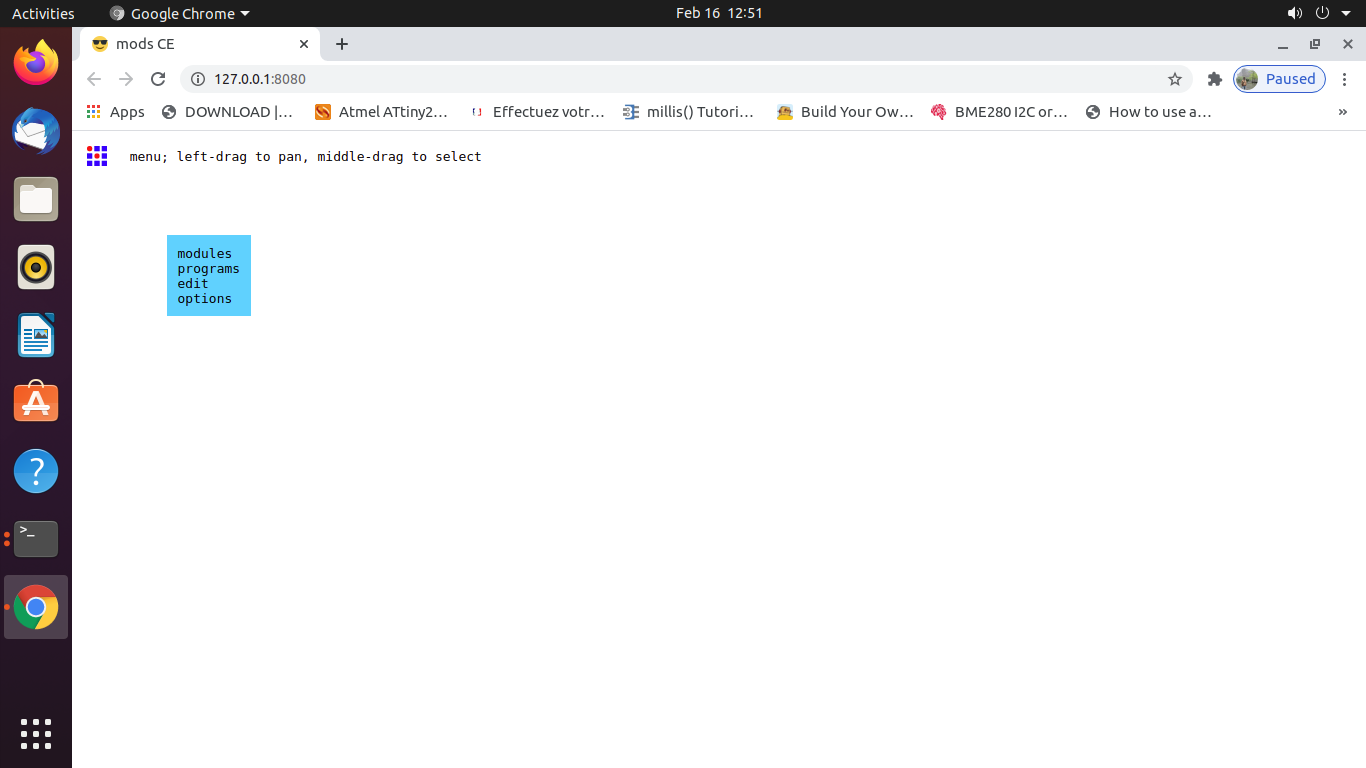

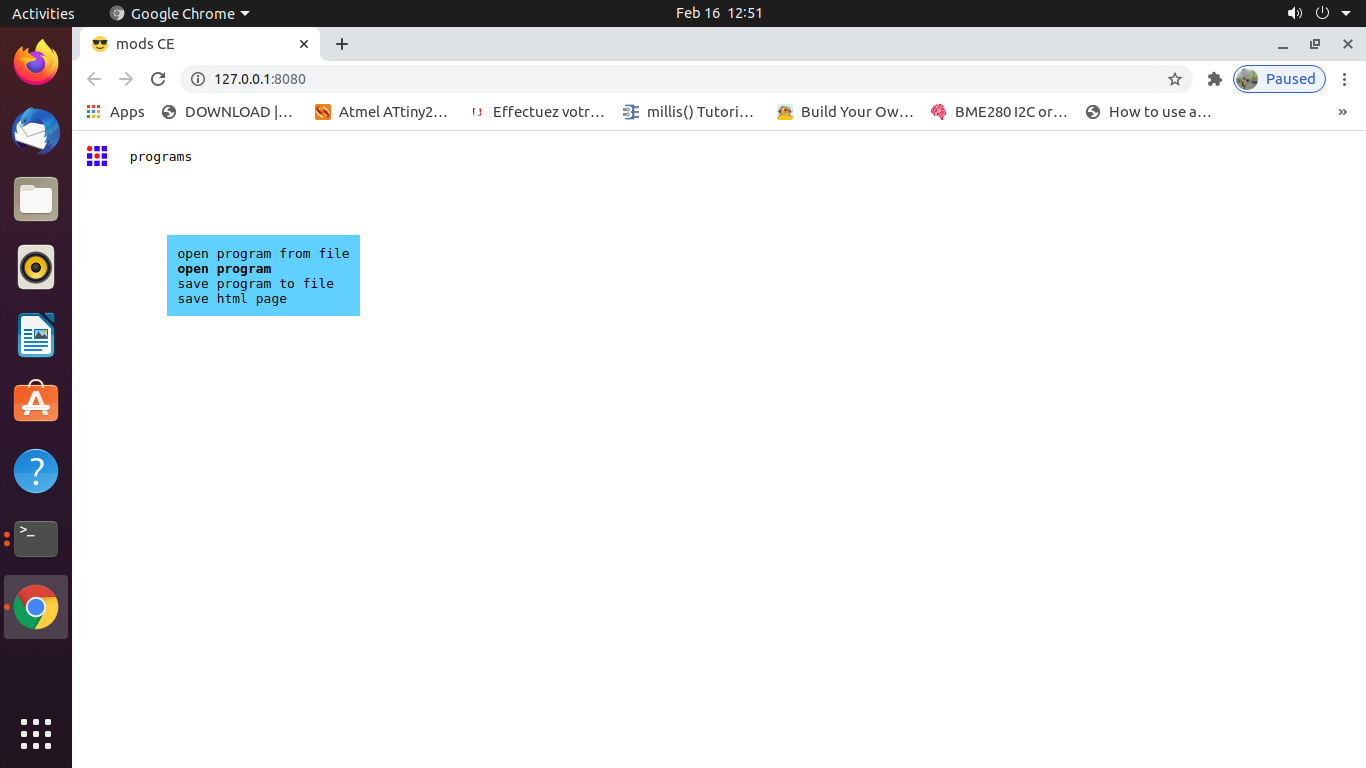

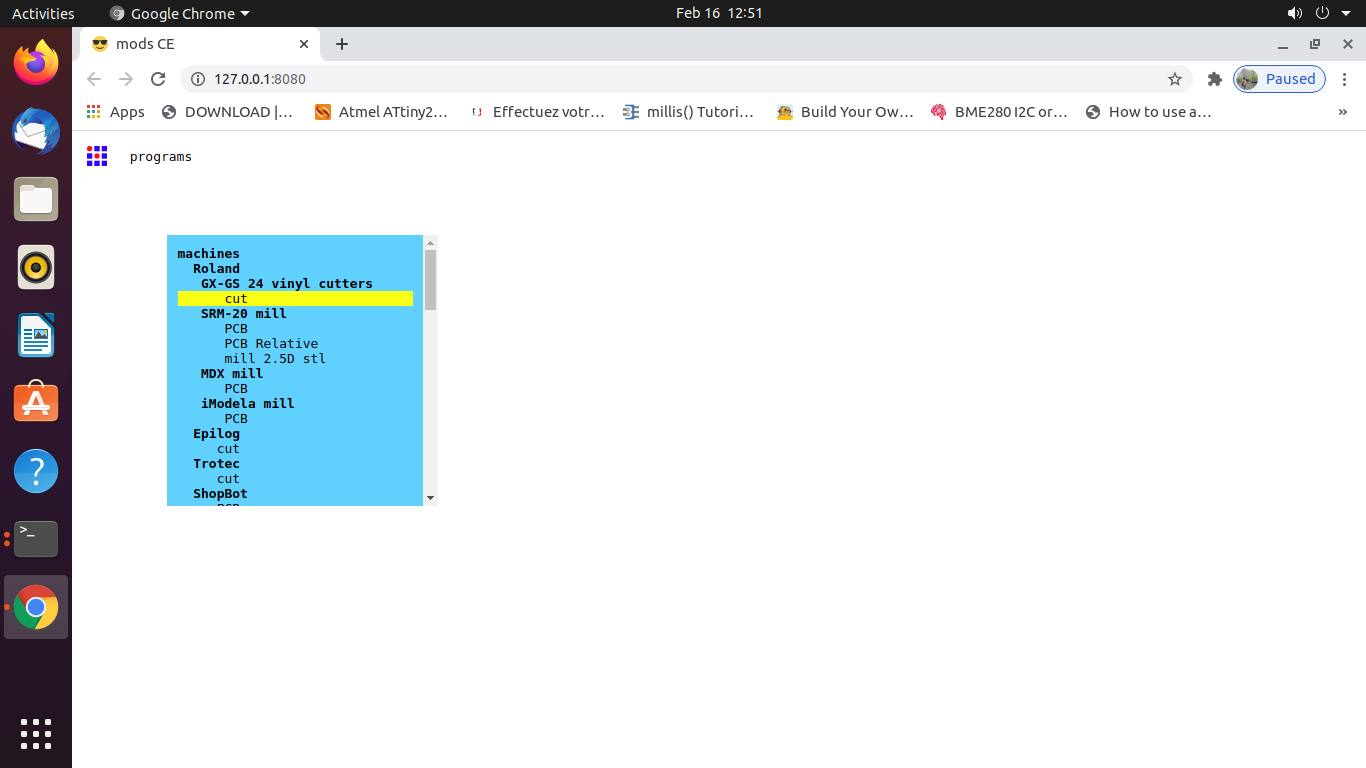

Open Terminal and use commands>cd Documents to change directory> mods >bash mods>Again Open New Terminal and use commands>Cd Documents> http – server>This will open a Window in Google Browser.>Right Click in the Window>Four options will be displayed like Modules, Programs, Edit, Options etc.>Select Program >Select cut>Select the Photo/Image to be used for vinyl cutting>Check the format of the image (.svg or .png)>Check the Tool Path>Open the Socket by inserting (ttyUSB0)>Calculate the path >Send the File for vinyl cutting.

After executing above command in mods the server get connected.

This type of server windows may open

Here we need to select the program and files .

Select the proper option that you want to perform.

Here, select the files that you want to cut by vinyle cutter machine

Specifications of Vinyle cutter available in our FABLAB is as follow:-

1) Driving Method: Media-movement method Stepping motor (Micro-step)

2)Maximum cutting area: Width:584 mm Length: 24998 mm

3) Tools:Cutters: Special cutter for CAMM-1 series

4) Pens: Water-based fiber-tipped pens

5)Max. cutting speed: During cutting: 400 mm/sec.

6)Blade force: 30 to 200 gf

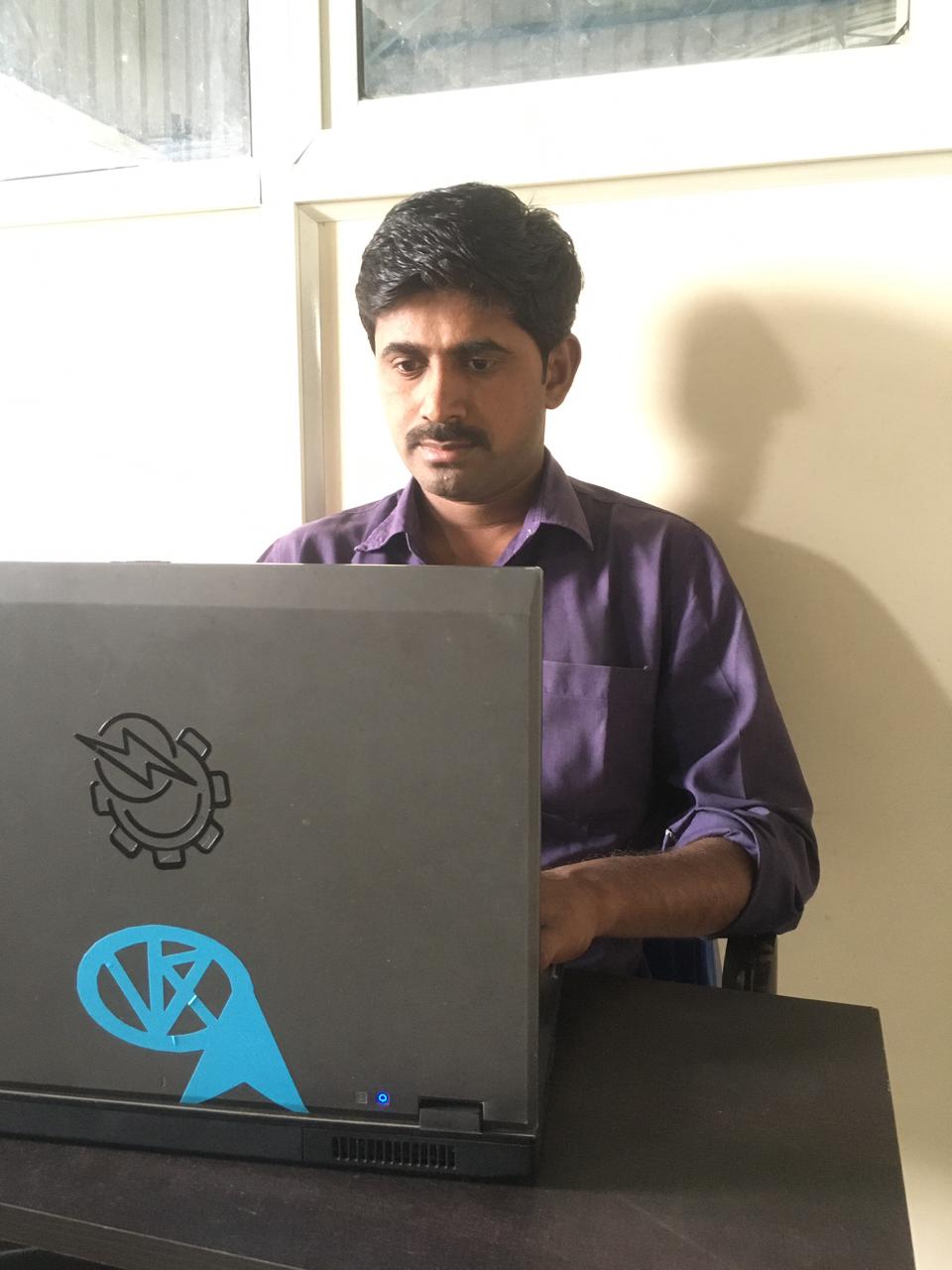

This is how i have design the logo in inkscape software and cut by vinyle cutter

Now, The designed file get conveted into .svg format by clicking save as into .svg

This is I have stick the logo on my laptop.

What i have learned ?

1) Laser cutter's focus, power, speed,rate,kerf and joint clearance.

2) Important of kerf for press fit.

3) Different processes involved in Laser Cutter Machine.

4) Development, evaluation and construction of parametric construction kit.

5) How to use the Fab Mode and other modes for Vinyl Cutter and other machine of Fab Lab.

6) Different process of Vinyl Cutters Machine.

Download my original file here