Implications and Applications:

In this Sixteenth week of Fab Academy, we had to explore Applications and Implications of our Final Project.

Objective:

Individual assignment:

- 2D and 3D design

- additive and subtractive fabrication processes

- electronics design and production

- microcontroller interfacing and programming

- system integration and packaging

Where possible, you should make rather than buy the parts of your project. Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable.

See Final Project Requirements for a complete list of requirements you must fulfil.

The answers to the questions below will allow you to create your BOM (Bill Of Materials).

Learning Outcomes:

Checklist:

Opening Quotes:

- "Stitch in Time saves Nine."

- "Well begun is Half done."

- "Sharpen your Axe before cutting down a Tree"

Individual assignment:

In this week, I have to answer various questions about my Final Project. These answers will direct me to prepare a plan for development of my Final project and clarify the doubts.

About My Final Project:

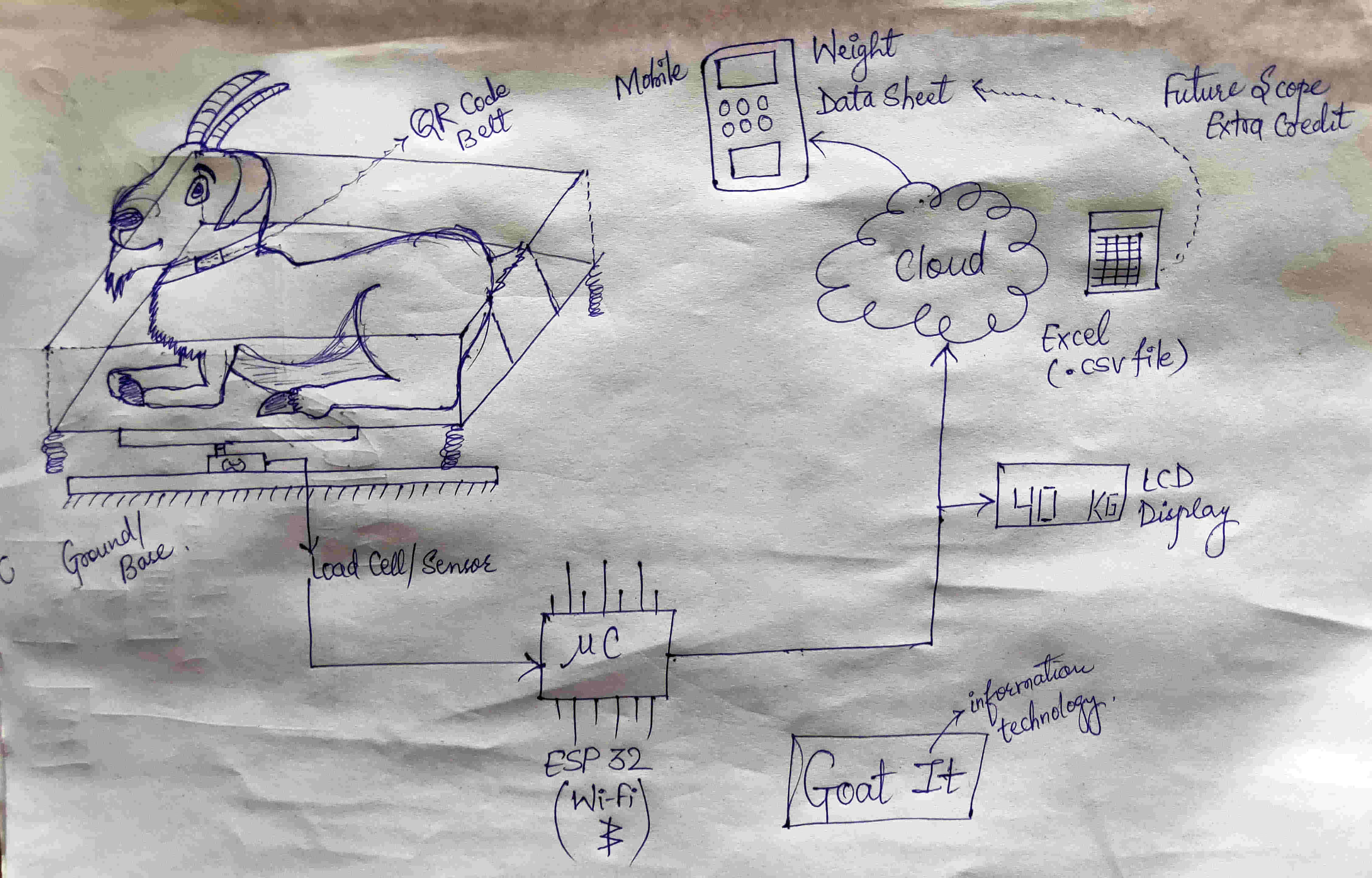

My Project is Smart Goat Weight Measurement and Management System. I prefer to call it "GoatIT" - Application of (IT) Information Technology to measure and monitor the Weights of Goats with respect to FCR (Feed Conversion Ratio) / Link2 to manage the Growth and Profitability.

Body weight information of livestock animals is significant for trade, routine animal health monitoring and dosage calculations for treatment of diseases.

The answers to the following questions will give an indepth overview about my final project.

I selected this project out of many Ideas that popped up due to certain reasons.

Vidarbha region of Maharashtra is known infamously for Farmer suicides due to scarce rains and inproductivity. An allied/supplementary business of Goat Farming could help them to sustain. Only thing is to do the Goat Farming scientifically.

The commercial weighing scales and machines available in the market are very costly. I wanted to bring the the price of these weighing balance in the grasp of the farmers.

Also, the data log on the server will notify the farmers about the options to sell or hold or pay attention to a particular goat (Doe or Buck).

What will my Final Project GoatIT Do?

My project will be able to help Farmers in multitude of ways. The Flow of the activities in my project is as follows:

- The goats will have RFID tags attached to their necks through a band and the goats will be differentiated based on their RFID numbers

- The goats will approach the Weighing Balance placed at the entrance of their cage.

- The RFID tag reader will read the tag and send the information to the Server

- Goat will stand on the Weighing Balance

- Weight of the Goat will be displayed on the LCD screen attached to the scale/machine.

- The same weight of the Goat will be sent to the Server and entry would be done in the respective RFID number of the Goat.

- Thus, a data log would be created on the server for the weights of the goats.

- This data could be accessed by the farmers anytime and anywhere and used to make decisions about paying attention or holding or selling a particular goat.

- Basis being the FCR i.e Feed Conversion Ratio - which calculates the Weight gain by the Goats in relation to the quantity of the Feed Input. The weight of the goats increases on daily basis approximately 60 grams and more.

- This weight change could be monitored with the help of my project.

The scope of the present project relates to the design of a Goat weighing system device used in the field

and the trading of livestock, namely GoatIT with automatic datalog on the server. The developed instrument is designed to complement and enhance the benefits of the existing livestock scales, so that the use of digital scales can be more extensive and effective. The scale is built for four legged animals weighing up to 150 Kgs. with a cage model. The scale is designed to be placed in the path of the animal crossing to ascertain the cattle move into the cage one by one, to be weighed. The opening and closing of the door should be done carefully where each animal must be ensured to be precisely inside the cage. Because once the door is closed and it hits the animal body, it will make the

cattle become traumatized.

Livestock scale that meets the market needs, including livestock, slaughterhouses, and livestock markets, must have a good quality and standard or reasonable price. In the present project, the developed digital weighing balance uses only one beam load cell that is placed at the center point of the platter, with a cage size adjusted to the size of the animal to be weighed. The size of the cage is adjusted to the size of the animal with the aim that the position is directly above the load cell, so that the weight of the animal can be measured with a high degree of accuracy. In addition, to ensure the animals enter the scale one by one, the scale is placed in the middle of the path of the livestock with a width of the scale adjusted to the width of the walking lane. This line system establishes a livestock queuing system, allowing only one animal to pass through and to be weighed. To avoid any potential trauma, the door is operated manually with a certain position to ensure that the animal has been on the scale and safe. The result of the animal weighing is displayed on the LCD screen and sent to the RFID-based database identification system. Reference / Link2

Who has done what beforehand?

I surfed a lot through google, YouTube, ResearchGate and other platforms to find about Smart Goat Weight Measurement Scale but couldnt find enough references.

Most of the research was on finding the weight of the goat by measuring the size of the girth, length of the goat etc.

Commercial weighing Machines have been made by many and suppliers could also be found on IndiaMart.

One of the Research Papers that I found was having the detailed documentation of Iot Weigh Scale machine for Cattles / Livestock. The Research Paper could be found here.

Few IoT projects done by the Makers Community are-

- Smart Weighing Machine for Remote Weight Measurement and Monitoring on IoT Design Pro Website

- Weight scale IoT by ESP32 on GitHub

- IoT Weight Logging Scale by SFUPTOWNMAKER on SparkFun

- Digital Scale With ESP32 by Fernando Koyanagi in CircuitsMicrocontrollers on Instructables

- IoT Cat Litter Box on Instructables by Igor Fonseca Albuquerque

One of the websites with intensive information about esp32 and IoT is The Internet of Things with esp32 Created by Espressif Systems. Many Projects, Tutorials, Introduction and exploring could be done by referring these resources.

What will you design?

We have already gone through the CAD design in the Second week of FAB Academy. I will be designing the below mentioned parts and components for my Final Project.

- Weighing Scale Structure using Autodesk Inventor: I will design the Base, Top, Cage like structure, Entrance and Exit gates used in my final project.

- Final Project PCB: The PC Board that I will be using for Final Project will be designed in Autodesk Eagle and used.

- Goat Head shaped Circuit Board Holder Box for Aesthetics and Safety of the Circuit will be designed which would be Pressfit.

- Handles for the Weigh Scale could also be designed and 3D printed or the Metal TMT Bar could be welded on the structure

- Goat Head shape for Plasma Cutting and welding it on the Cage / WeighScale structure for branding the "GoatIT"

- Dr. Neil Gershenfield also suggested me to make the Load Cell as one of his students had done it at MIT. I have designed it in Inventor. But I would restrict myself to buying it from the market.

What materials and components will be used?

My final project needs a lot of hardware to be used for fabrication, assembly and structure. The various materials and components that I will be using are-

- Metal: I will be using TMT Bars for Handles, Square Hollow Tube for making the frame of the structure, Sheet for placing on the base/floor, Nuts, Bolts, Screws for tightening the structure.

- Plasma Cutter for cutting the Metal Sheet

- Welding Station for fabricating the Structure of Weighing Scale

- Polymer: I will be using the mesh/gauge for attaching to the side walls of the structure instead of the metal gauge/mesh or sheet to prevent Goats from going out of the Balance.

- Electronics Components:

- PCB: FR-1 type PCB for milling the Final Traces and Cut out over it.

- ESP32: The core of the project is the MicroController. I will be using the ESP32 Wroom D for sending the data over cloud through WiFi.

- Input Sensors: Load Cell of 150 Kg Capacity and RFID Tag Reader (MFRC522)

- Output Device: 16*2 LCD

- Amplifiers: HX711 module for the Load Cell

- Electronic Components like Connector pins - Male and Female, Resistors (Ohms), Capacitors (MicroFarads), Switches, Voltage Regulators, Power Jacks, Buttons, LED's, Bus Ribbon Cable etc.

- Soldering Station and required material like Soldering Gun, Metal, Flux etc.

Where will they come from?

Most of the Materials and Components could be used from the FAB Lab Inventory and certain others could be used from the Inventory of the DBRT (Diploma in Basic Rural Technology) Section of Vigyan Ashram. We also a Workshop where most of the Fabrication work could be done.

The source of the Material and Components is as given below:

| Material / Component | Source: |

|---|---|

| Metal: | Workshop Inventory, Vigyan Ashram or Local Metal Supplier |

| Plasma Cutter for cutting the Metal Sheet | Workshop Inventory, Vigyan Ashram |

| Welding Station for fabricating the Structure of Weighing Scale | Workshop Inventory, Vigyan Ashram |

| Polymer: | Workshop Inventory, Vigyan Ashram |

| Electronics Components: | |

| PCB: FR-1 type PCB for milling the Final Traces and Cut | FABLab Inventory |

| Output Device: 16*2 LCD | FABLab Inventory |

| Electronic Components like Connector pins - Male and Female, Resistors (Ohms), Capacitors (MicroFarads), Switches, Voltage Regulators, Power Jacks, Buttons, LED's, Bus Ribbon Cable etc. | FABLab Inventory |

| Soldering Station and required material like Soldering Gun, Metal, Flux etc. | FABLab Inventory |

| ESP32 Wroom d MicroController: | FABLab Inventory |

| RFID Tag Reader (MFRC522) Module and RFID Tags | FABLab Inventory |

| Input Sensors: Load Cell of 150 Kg Capacity | Online through Amazon.in |

| Amplifiers: HX711 module for the Load Cell | Online through Amazon.in |

How much will they cost?

The Bill of Material (BOM) for the Material and the Components will be as given below:

| Material / Component | Quantity | Rate/Price in INR | Approx. Price |

|---|---|---|---|

| Metal: | 75 Feet 3*3 feet 27 feet 10 | Rs.75/Kg Rs. 65/Kg Rs. 50/Kg Rs. 100/- | Rs. 2000/- Rs. 1200/- Rs. 300/- Rs. 200/- |

| Primer Red Oxide, Oil Paint, Thinner, Brush | 1 Liter | Rs. 200 rs | Rs. 400/- |

| Load Cell 150 Kg | 01 | Rs. 600/- | Rs. 650/- (GST + Delivery Charges) |

| ESP32 Wroom D uC | 01 | Rs. 350/- | Rs. 350/- |

| HX711 Module | 01 | Rs. 75/- | Rs. 75/- |

| RFID Tag Reader and Tags | 01 | Rs. 250/- | Rs. 250/- |

| 16*2 LCD | 01 | Rs. 200/- | Rs. 200/- |

| Miscellaneous Electronic Components | As prescribed | Rs. 200/- | Rs. 200/- |

Total Cost of the Project would be around Rs. 5825/-

What parts and systems will be made?

FAB Academy is about trying various things. You may make as many mistakes as you want. But dont repeat the same mistake. Also, Make the Mistakes - Fast, Learn from them and move on.

Dr. Neil even suggested me to make Load cell in the Lab as one of his students has done it in MIT. But, I will restrict myself in purchasing one online considering my skills, competence and expertise in this domain.

I will be making the following Parts and Systems in the FAB Lab.

- Designing the Structure of the Weighing Scale

- Plasma Cutting the GI Metal Sheet for Bed/Base.

- Cutting the Square Metal Hollow Pipes

- Welding, Grinding, Painting them for Fabricating the Weigh Scale structure

- Attaching the Load Cell, RFID Reader Tag, HX711 Module and LCD with the Final Project Board and assembling properly

- Configuring over ThingsSpeak for sending the Data collected over WiFi on Cloud.

- Designing, Milling and Stuffing, Soldering the PCB.

- Acrylic Casing Box for protecting and keeping the Circuit safe.

What processes will be used?

I will be using the Processes mentioned below for my Final Project:

- CAD:Computer Aided Designing will be used for the design of various Components used in the Final Project. It includes the PCB board, Structure, Logo etc. I will be designing the Final Project Board in the Autodesk Eagle software. Also, the Structure of the Weighing Scale will be designed in the Autodesk Inventor. I designed the Logo of Goat for Branding and named it "GoatIT" which means use of Information Technology in the Smart Goat Farming and an Aid in decision making for maintaing the track record and decision making.

- CAM: Plasma Cutting - I will be using the PLasma Cutter to cut the Metal GI SHeet for laying it on the Bed/ Base of the Weigh Scale. Also, I will be cutting the GI Sheet for making the Logo of GoatIT.

- 3D Printing: I will be 3D printing the Handles to be used for holding the various sides of the Weigh Scale and attach it to the Body by using Screws.

I am also thinking of 3D printing the Wheels that could be attached to the base for easy movement of Scale from one place to another. - Soldering:I will be making the PCB using esp32 MicroController and other electronic components for my Final Project. I will be soldering these components oin my Final Board.

- Welding:My final project involves the use of Metal GI Sheet for fabricating the structure of the Load Cell. I will be Welding the Square Metal Pipes with each other using the Welding.

- Grinding:To give clean finish to the Welding and removal of the grains and extra material, I will use grinding.

- Painting: To give a bit of Aestheitc touch, I will paint the WeighingScale with Oil paint. First of all, I will grind, apply the Primer paint (Red Oxide - Non Rusting) and then apply Oil paint of suitable color available in the Workshop Inventory.

- Programming: I will be using the Arduino IDE for programming the Final Project board and combining various codes. I will have to intergrate the codes of Load cell, RFID Tag Reader, LCD, WiFi, ThingsSpeak.

What questions need to be answered?

Commercial Weighing Scales are already available in the market at prices ranging from 12 thousand INR to even 50K INR. Questions that may arise could be-

- IoT in Weights of Goats

- 5V of LCD attached to the esp32 uC could run properly or it may harm the circuit board which runs on the 3.3V

- Whether the correct flow of activities be maintained like scanning the RFid Tag, weighing, displaying Weight on LCD and sending the data on ThingsSpeak cloud over WiFi.

- Little ones (Baby Goat/Kid) would not stay at one place. How to measure their weight. Also, they tend to get nervous due to the Cage like structure.

- The Goats eat or scratch the belts attached to their Neck. This may spoil the RFID Tags and ould not be read by the Tag Reader. Which material should be used and where to attach the Rfid Tags to the Goats?

How will it be evaluated?

Success of any Project lies in its Utility for the Masses and not restricted to certain Classes. The Load Scale that I will design and make should first of all solve the problem of Vigyan Ashram of

1. Weighing the Goats

2. Identifying them properly

3. Displaying the Weight on the LCD display

4. Connecting to the WiFi

5. Sending the data of RFID Tags to the ThingsSpeak Server

6. Sending the Weights of the Goats in their respective fields.

In the Spiral, the data that is collected could be exported to the Mobile Phones of the Owners and then the informed decisions could be made based on this information which is processed and made available to the Goat Farmers. These decisions would include -

1. paying attention to the daily gain the weights of the Goats with respect to the FCR i.e Feed Conversion Ratio

2. Option to Hold or Sell the goats or even pay attention to their health.

Summary:

In this week,

- I learned about the Progress of my Final Project.

- This week has set the wheel in motion by trigerring me and I will have to push myself to meet the deadlines.

- The documentation of the Final Project and answers to these questions have even given me more insights about my final project.

- The Literature Review has clarified my certain doubts.

- I came to know whether I am going to meet my Objectives of making a Smart Weighing Scale for Goats in Time and in less resources or not.