5. Electronics production

Group assignment

Characterize the design rules for your PCB production process: document feeds, speeds, plunge rate, depth of cut (traces and outline) and tooling.

For our lab, the 3D Milling Machine is Roland Modela Pro MDX-500.

Here is the manual of Roland Modela Pro MDX-500. Read before you operate.

USER'S MANUAL 1 - Setup & Maintenance (Read First)

USER'S MANUAL 2 - Cutting Using the Included Software

USER'S MANUAL 3 - Cutting Using NC Code

Programmer's Manual NC code

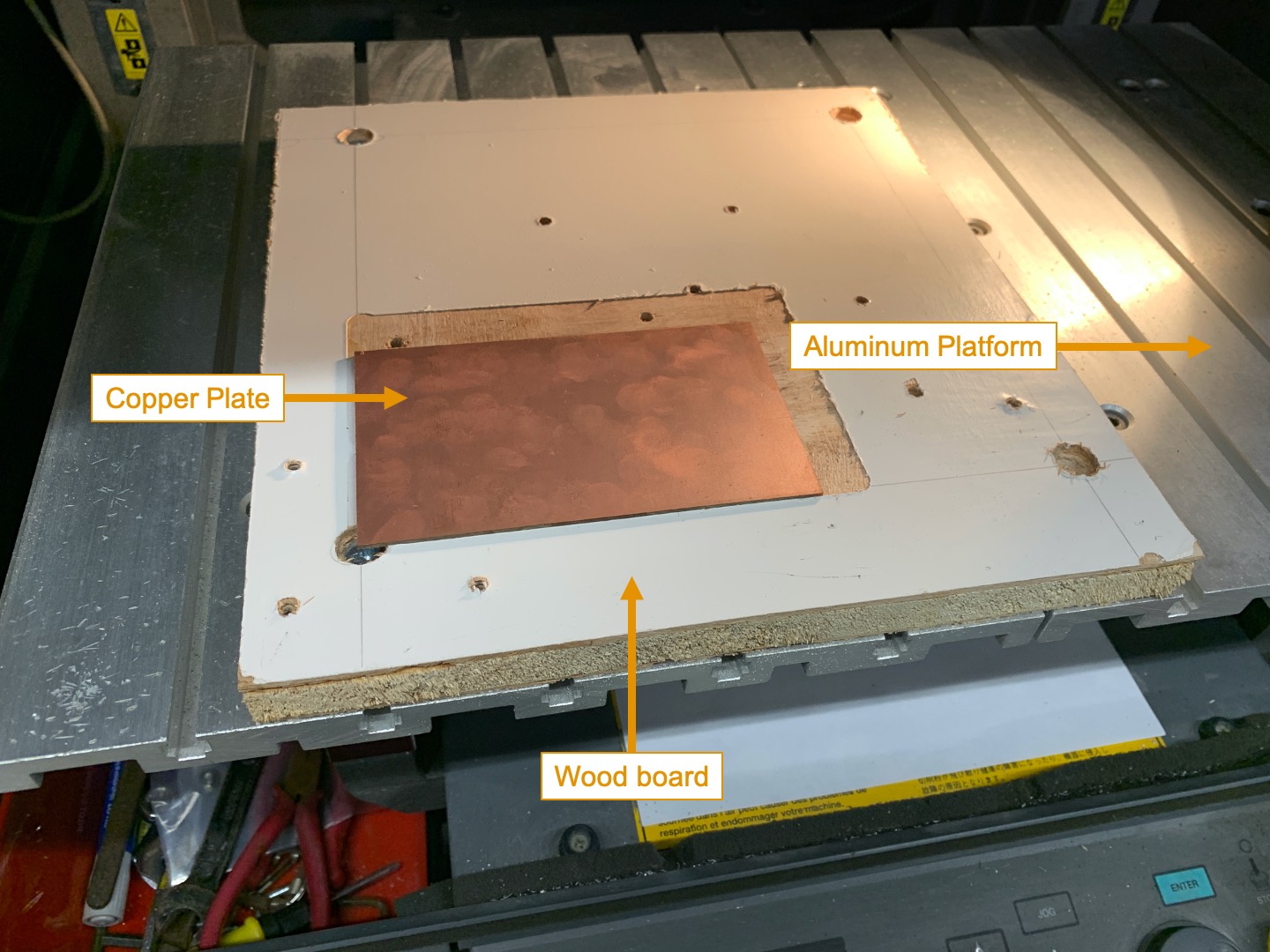

We decide to put a wood board on top of the aluminum platform. When using carving Mill Bits may increase the depreciation of aluminum platform. Changing aluminum platform is much more expensive and complicated. Therefore, putting a wood board (as a waste plate) on top of the aluminum platform help to keep aluminum platform condition. Also, wood board is cheaper and easier to get than aluminum platform.

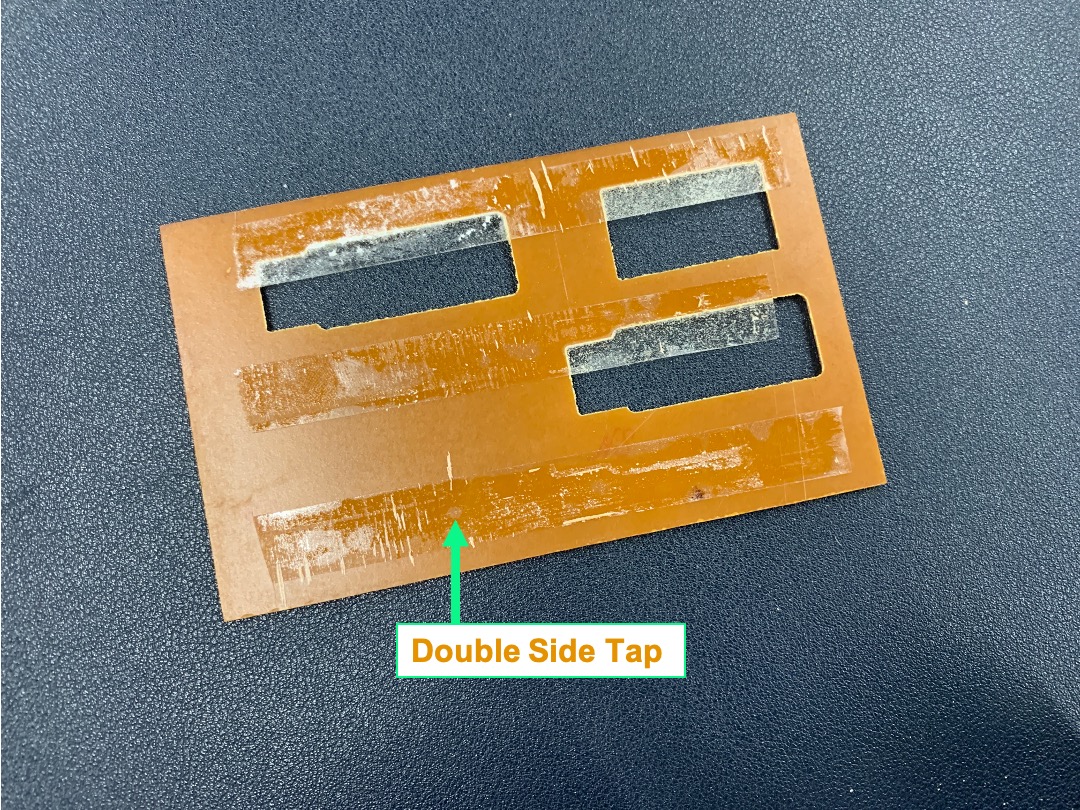

Before putting the Double Side Tap at the back of copper plate for stabilising in the wood board. During the operation, copper plate will not be moved.

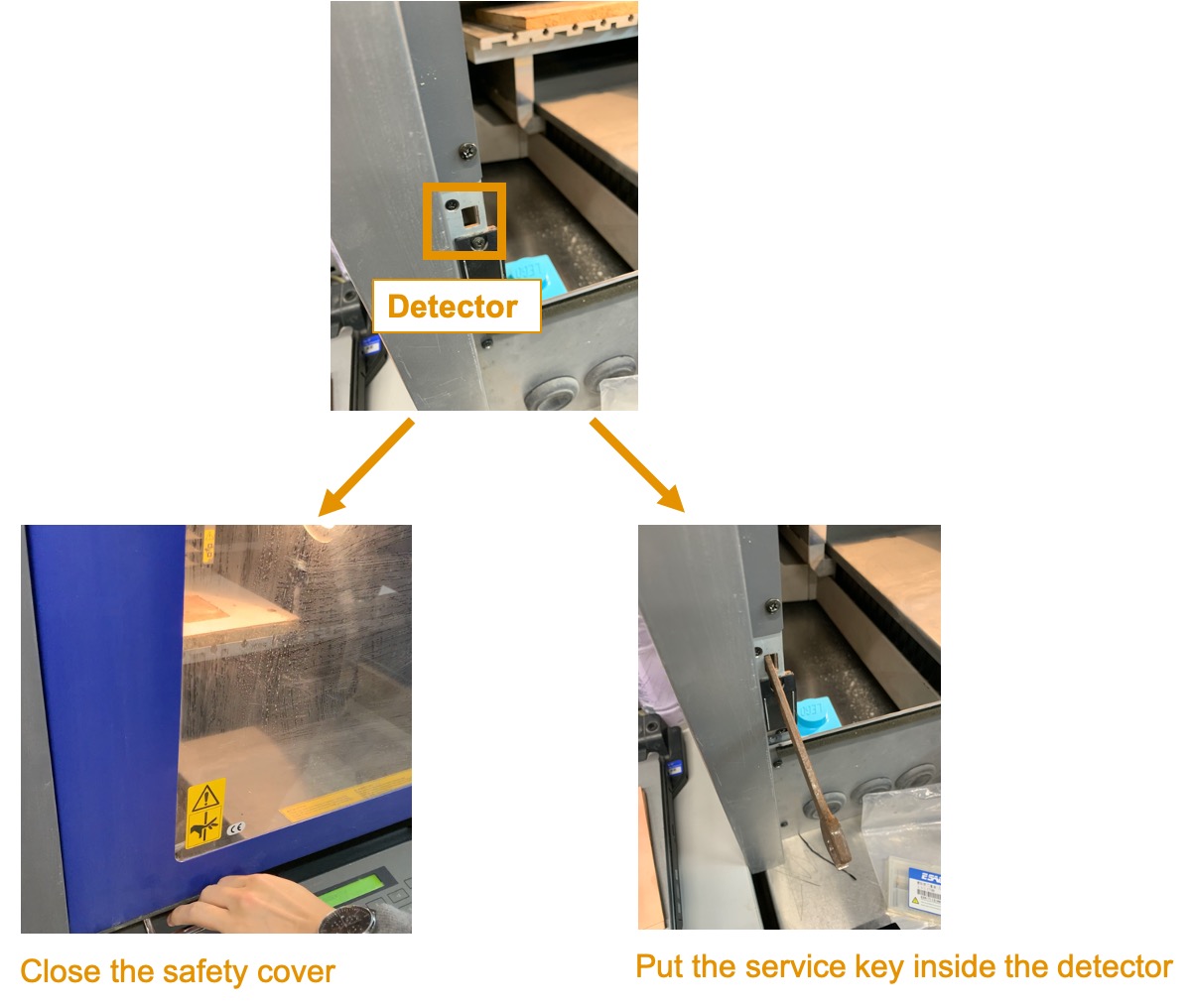

Before starting milling, you may see the monitor "PAUSE SFTY COVER OPEN".

It means you need to close the safety cover or put the service key into the detector. If you lose your service key, you CLICK HERE to download the file for further use.

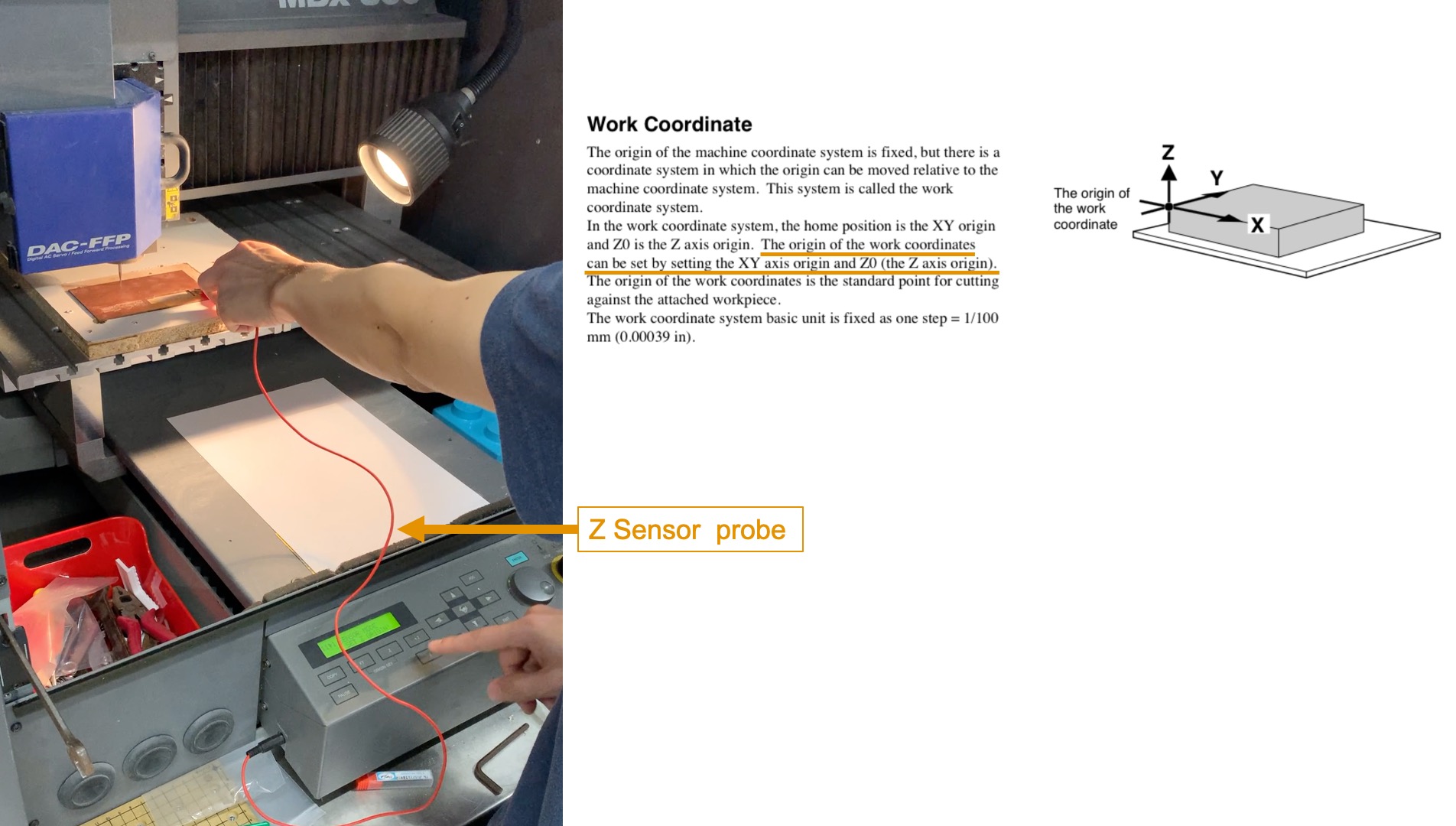

The red cable connect with CNC machine called Z Sensor Probe. CNC machine has a function called Work Coordinate. It helps for setting the Z origin by red cable touch with copper plate. Mill bit would not be broken when starting the operation.

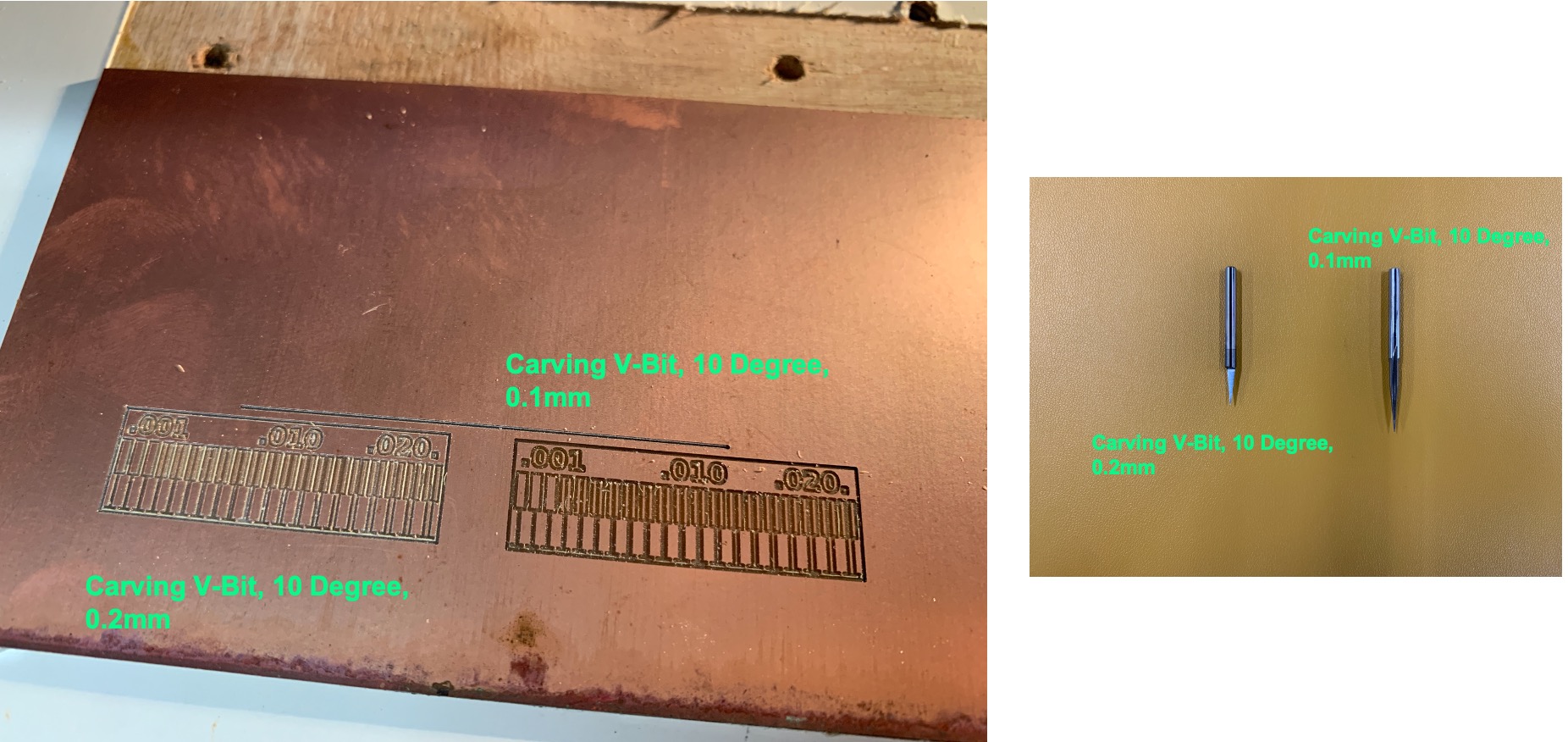

Here is the results of milling. We use 2 different mill bits.

1. Carving V-Bits, 10 degree, 0.2mm

2. Carving V-Bit, 10 degree, 0.1mm

As you can see, milling PCB requires tiny and accurate process. Carving V-Bit, 10 degree, 0.1mm seems able to milling more clear and able to mill as thin as for the circuit.

Video for different mill bit.

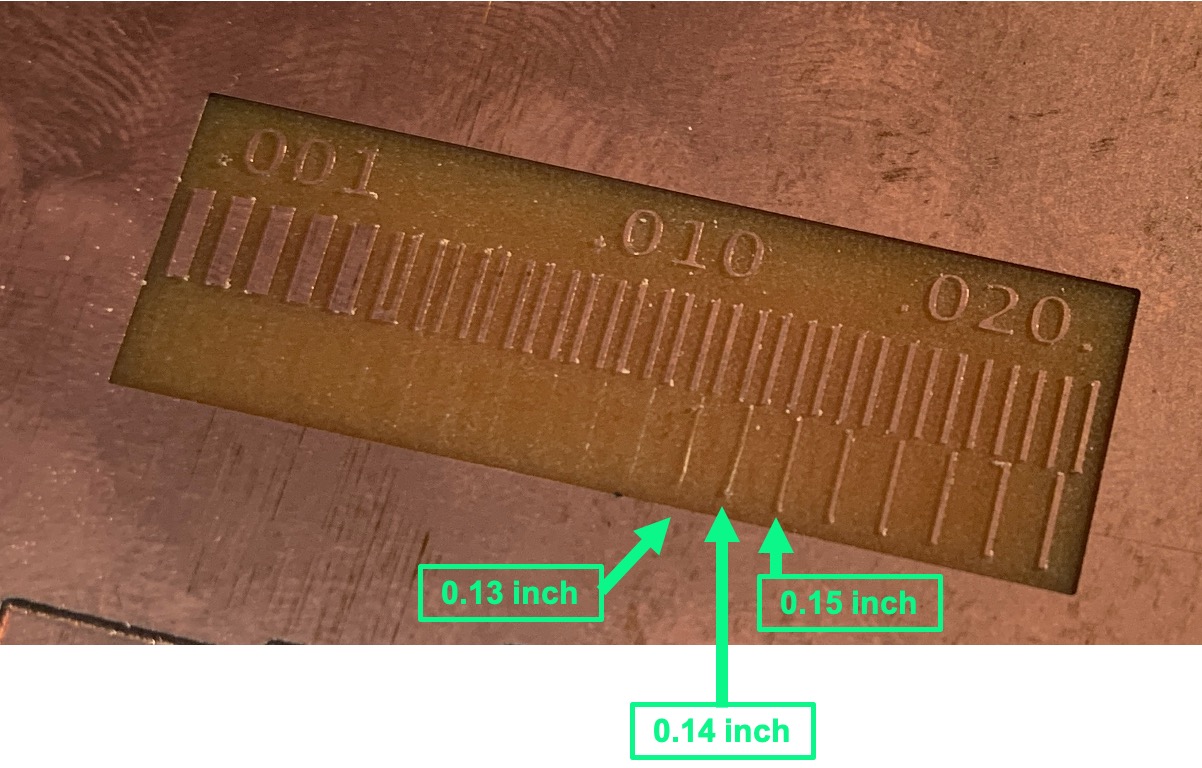

Since the copper plate condition is not good because those copper plates already purchased in 10 years ago. As you can see the bottom part of 0.13inch - 0.14inch easlier to be scrape. This is the result of scrape. For Carving V-Bit, 10 degree, 0.1mm is able to mill up 0.15inch lines. CLICK HERE for download the DATA SCRAPE.

Warning

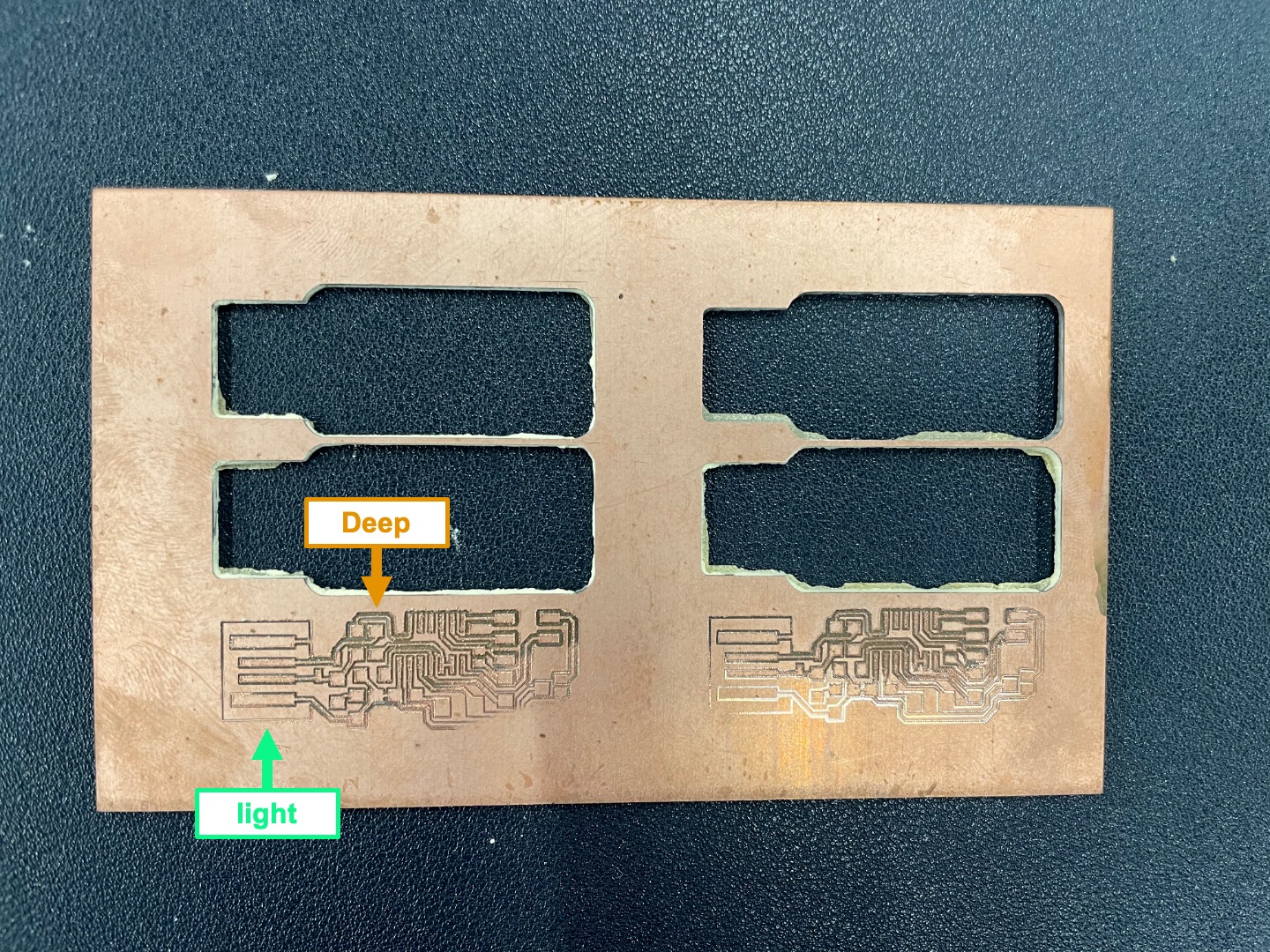

You can see the upper part of the PCB, line is more deeper. For the lower part, line is more lighter. It is because I didn't lock up the mill bit. Mill bit was loosen when it operated. Therefore, you need to remember to lock up the mill bit before operation.

The other problem is about putting the double side tap at the back of PCB is not flat enough. Therefore, when machine milling, the mill bit may not have a good touch with the copper plate. Please pay attention when you puuting the double side tap or glue at the back of PCB.

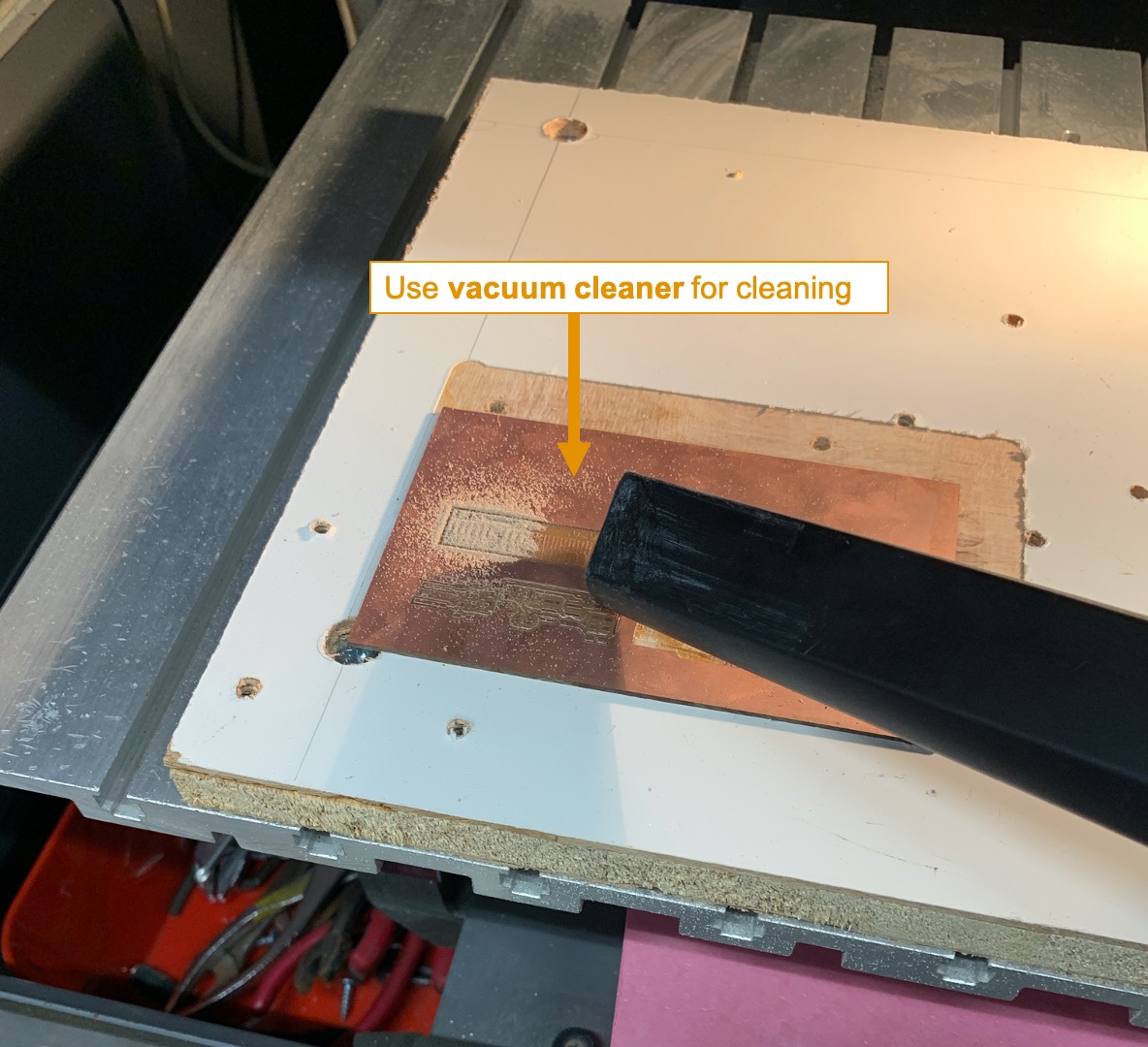

After finish the milling, I use vacuum cleaner for cleaning.