Molding & Casting

Unitedwe stand!

This week the #academychallenge is to design a mold in 3d and reproduce it in a block of wax using the technique of 3d machining with a CNC milling. The second step, is to cast it on a soft material like silicone. The idea is that you can cast your pieces in the final material, such as chocolate, soap, plaster, water and a wide variety of materials.

At our location, we have certain limitations and complications to get materials for this assingment, but together with Mayra Ascencio, we are determined to explore this week as deeply as we can, and with what we have available.

I must greatly thank Fab Lab Esan and its instructors Victor Pimentel and Jorge Valerio, also Josep Martí, from Fab Lab Barcelona, for the support provided to complete this task successfully.✨Although everything seems more difficult due to the global health crisis, you always find the Fab support to give you a hand, so, let's get to work. Attention to the following!

Ice Cream Mold

Week 11 Assignment

📆 April

GroupTask

Like the past weeks, we must review the data sheet and safety of the materials that we will use, and make test models with these materials to become familiar with them. In this case, we will test silicone for molds and for casting material we will test plaster. It is important to test the proportions of the mixtures and the appropriate times in the work processes with these materials.

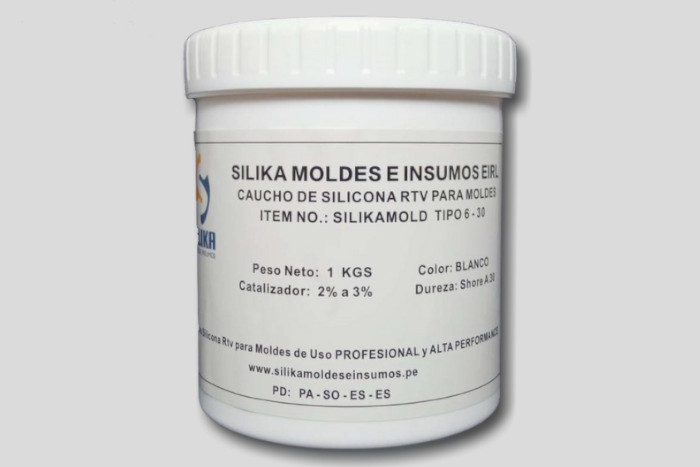

Looking for materials

Our laboratory has been closed for many months due to the pandemic, therefore, we didn't have materials for this task, so we had to do an arduous search for casting materials and machinable wax. We were able to find a supplier in our country, called "Silika moldes e insumos". They have silicones, resins and plaster.

Also, we were able to get some small blocks of jewelers wax, and luckily Mayra received a block of wax from Fab Lab Barcelona, which has been used very wisely and we greatly appreciate it. 🤜🤛(thanks!)

Focusing on testing the most "rubbery" materials, we acquired one kilogram of RTV type 6 silicone rubber and its catalyst and one kilogram of ceramic plaster.

- Silicone Rubber Rtv TYPE 6 1Kg + Catalyst S /.54.00

- Ceramic Plaster 1 Kg S /. 4.00

RTV SILIKAMOLD TYPE 6 Silicone Rubber

Ceramic Plaster 1 Kg

Handling and Safety

For safety, this type of process where we use silicone, resins and similar materials must be carried out in places with good natural ventilation, or with assisted extraction. It's important to wear gloves, glasses and protect our airways. Ideally, wear respirators that filter chemicals and gases. It's also important to have good lighting and to have a water source to be able to act quickly, in the event of any contamination on the skin, face or eyes. In my recommendations, lines below, I will explain a little more in detail my experiences in this fun process.

Technical data of materials

Silicone RTV TYPE 6

These are the technical data that are available from the provider (Source: clicking on the title)

RTV SILIKAMOLD TYPE 6 Silicone Rubber + Catalyst

The Ideal and Economic Silicone, for Super Resistant and Very Durable Molds.

Good medium / low viscosity, will allow you to apply it by brush and / or by casting.

Excellent Flexibility and Hardnes (30-A) for Easy-to-Use and Unmold Molds.

Extra Resistance to Tear and Tension, ideal for resistant and long-lasting molds.

Easy to Use, just add to the Silicone, 2% of Silicone Catalyst, (Included in the Price and available in Blue and colorless)

Stir until homogeneous, approximately 2 to 3 minutes and pour over the piece to be replicated.

- Medium / Low Viscosity

- White color

- Working time 10 to 20 minutes.

- Curing Time 4 - 8 hours in Summer, 8 - 12 hours in Winter

- Hardness / shore 30-A

- Presentation Plastic Bottle Net Weight 1 kg + Catalyst 30 ml Dropper Bottle

- Storage Life 1 Year

- Store covered, in a cool and dry place.

- Exclusive and Imported Product by SILIKA MOLDES E INSUMOS EIRL.

Ceramic Plaster

These are the technical data that are available from the provider (Source: clicking on the title)

- Ceramic Plaster 1 Kg

- The Ideal Plaster for making Molds, Artistic Figures and Reproductions in General.

- Homogeneous White, Clean, Free of black spots and impurities.

- Sealed container prolongs the shelf life of the product, protecting it from absorbing moisture.

- Recommended mixing ratio: 2 parts of plaster for 1 part of Water.

- Exclusive Product of Silika Molds and Supplies

Machinable Wax Block

Here in the Lab, we have available small blocks of machinable wax, which we get; the blue block is 1cm high by 10cm by 3.5cm. The "L" shaped block measures less than 10cm x 10cm by 4cm high. The yellow depilatory wax does not appear to be hard enough. Anyway, later we could try these waxes.

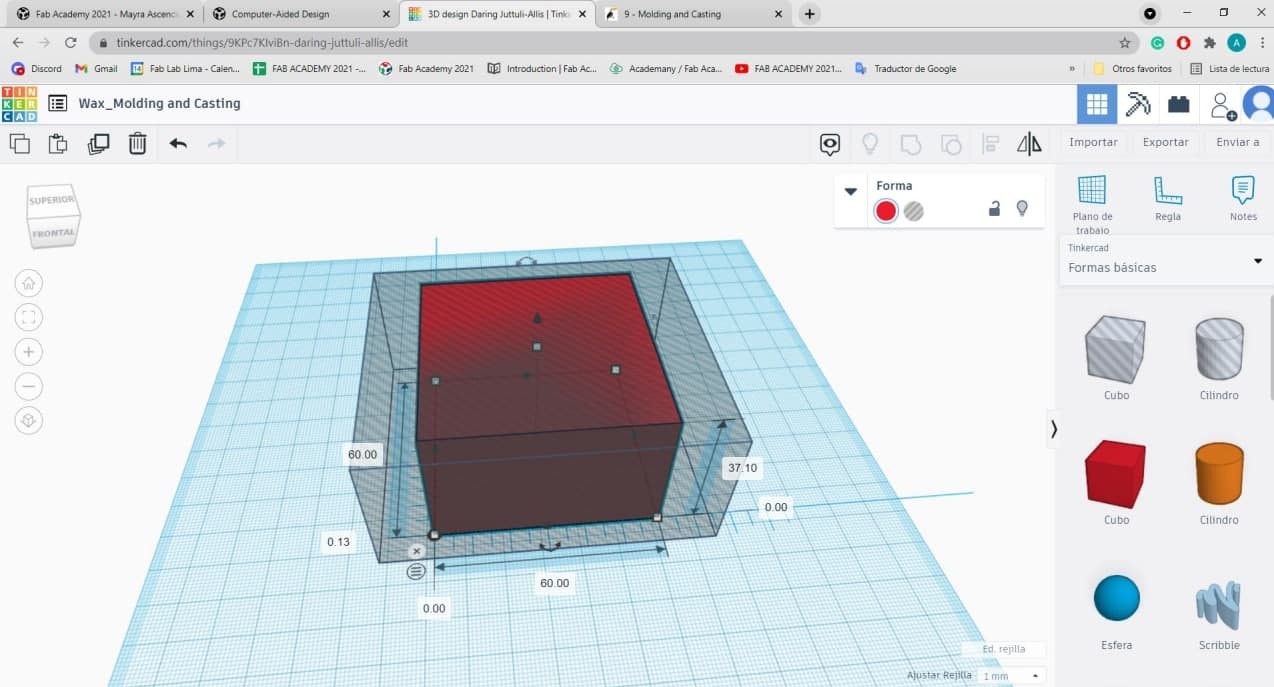

As I mentioned before, Mayra has a Ferris brand blue machinable wax block and it weighs 453,592 grams (1 pound).

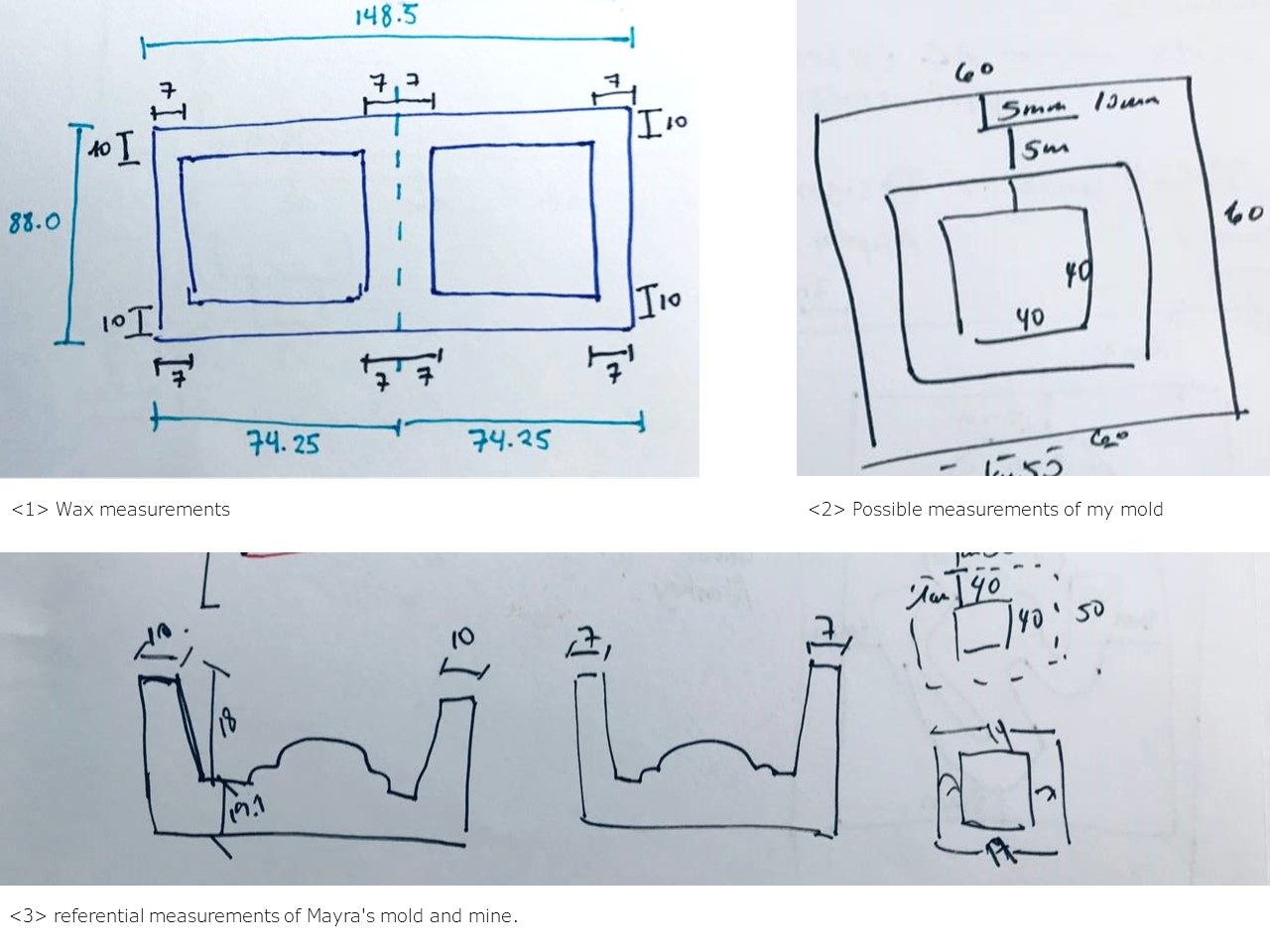

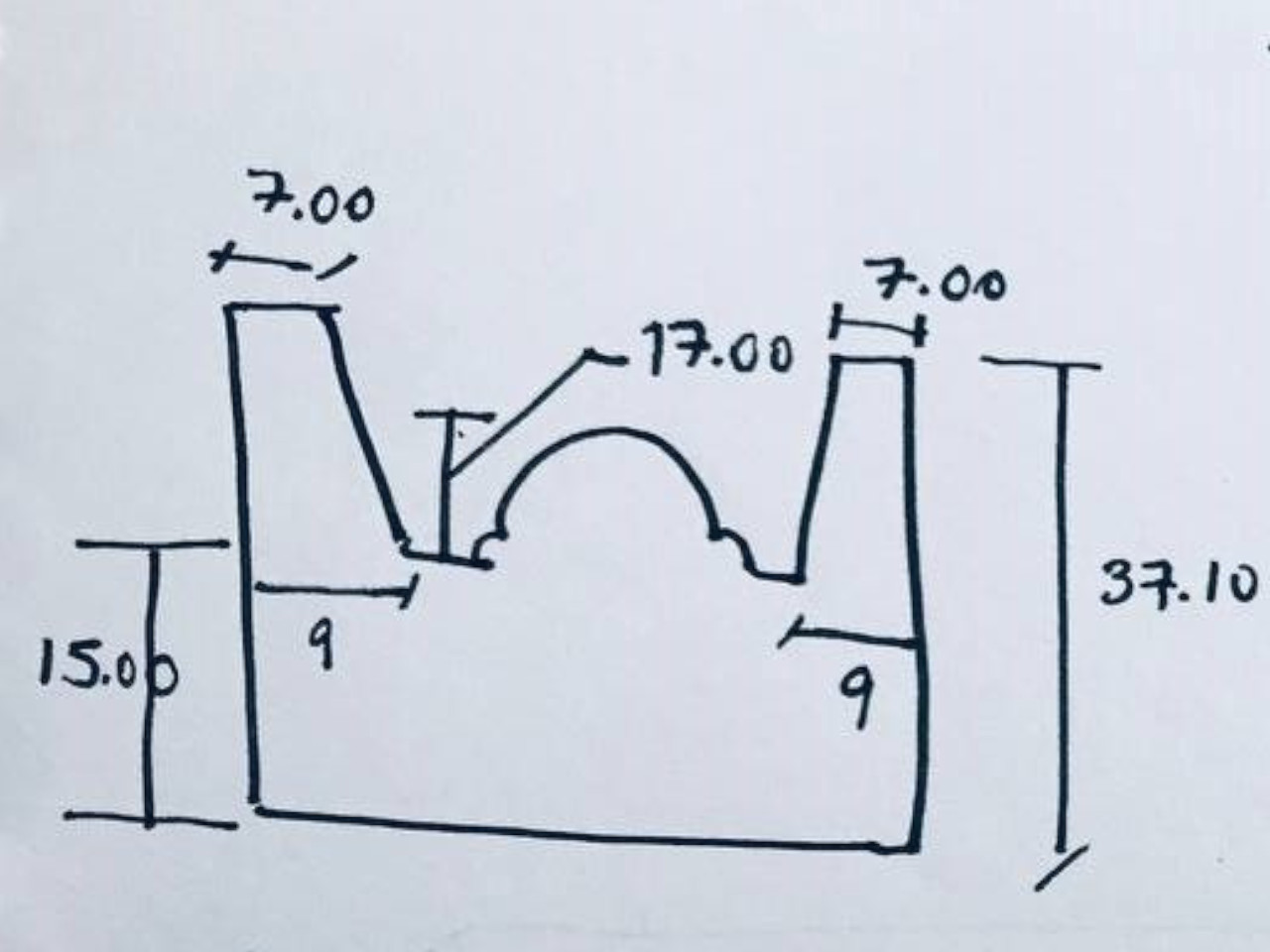

Measures: 148.5mm L x 88.0mm W x 37.1mm H (6 "L x 3-1 / 2" W x 1-1 / 2 "H).👉Here is the SDS.

The blocks are available in four colors and each wax color implies a differentiated characteristic, it is color-coded hardness.The blue wax turns out to be the most suitable for the type of mold that I am going to design. Since it is more flexible, and this is suitable for the milling process in small CNC machines such as the model and suitable for rounded edges. On the supplier's page we can see this description and the table below (Source: clicking on the title):

- Green: A very hard wax, it can’t be flexed. Ideal for sharp edges and for intricate carvings and delicate engraving.

- Purple: General purpose, hard with some flexibility.

- Blue: Less hard and more flexible than green or purple. Good for rounded surfaces and less intricate designs.

- Turquoise: Displays exceptional surface finish, especially in recessed areas. Maintains superior strength, toughness and extreme flexibility. Not brittle and thus making it very forgiving when milling prongs. When roughing out models, it does not clog the tools such as hand files.

| Color: | Blue | Purple | Turquoise | Green |

|---|---|---|---|---|

| Melting Point (°F): | 240 | 240 | 242 | 243 |

| Ash Content: | 0.003% | 0.003% | 0.003% | 0.003% |

| Flash Point (°F): | 585 | 585 | 465 | 585 |

| Flexibility: | Excellent | Good | Fair | Fair |

| Hand Carvability: | Good | Excellent | Excellent | Fair |

| High-Speed CNC: | Poor | Fair | Excellent | Good |

Different Wax

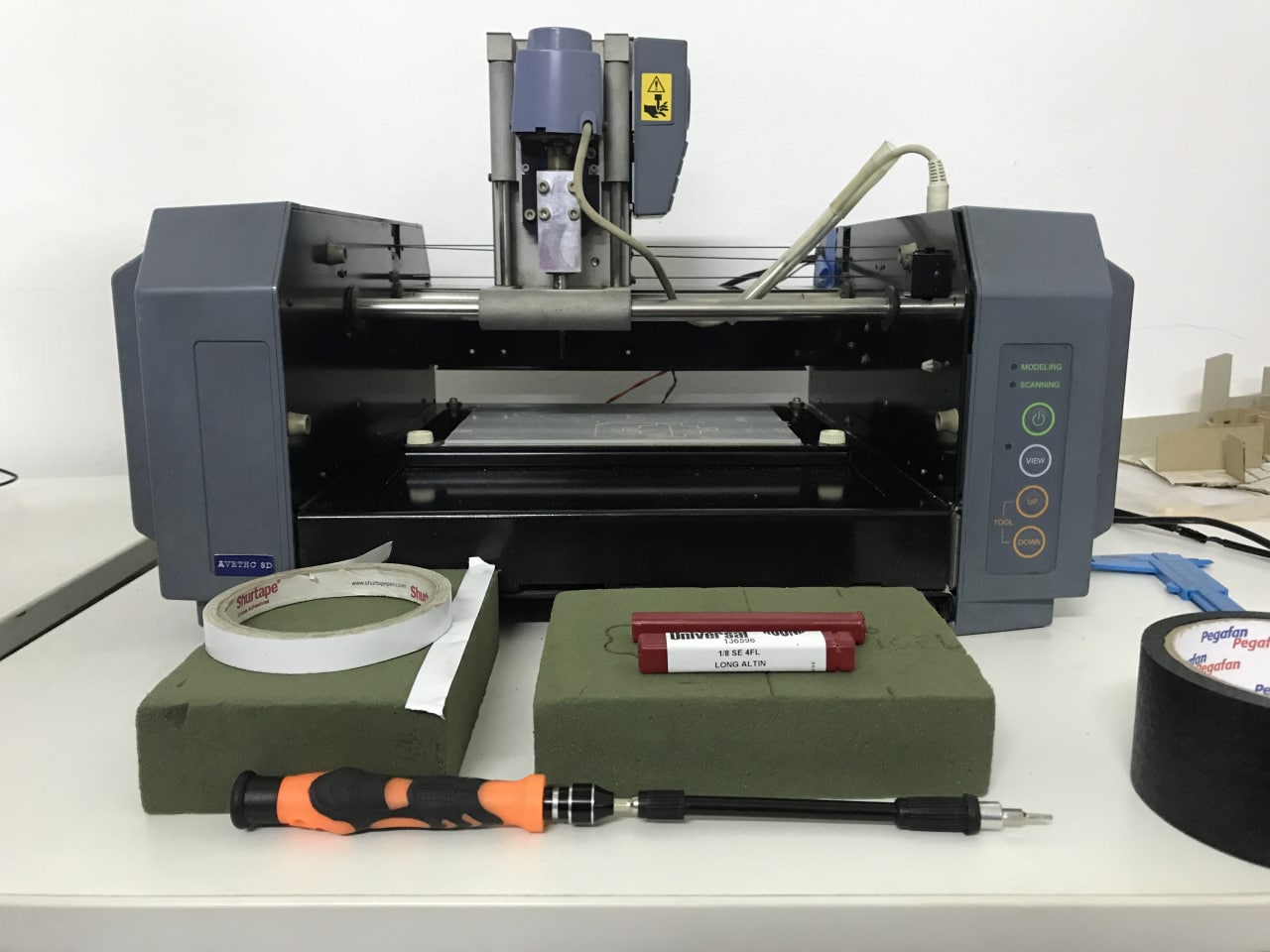

MoldMachining Test

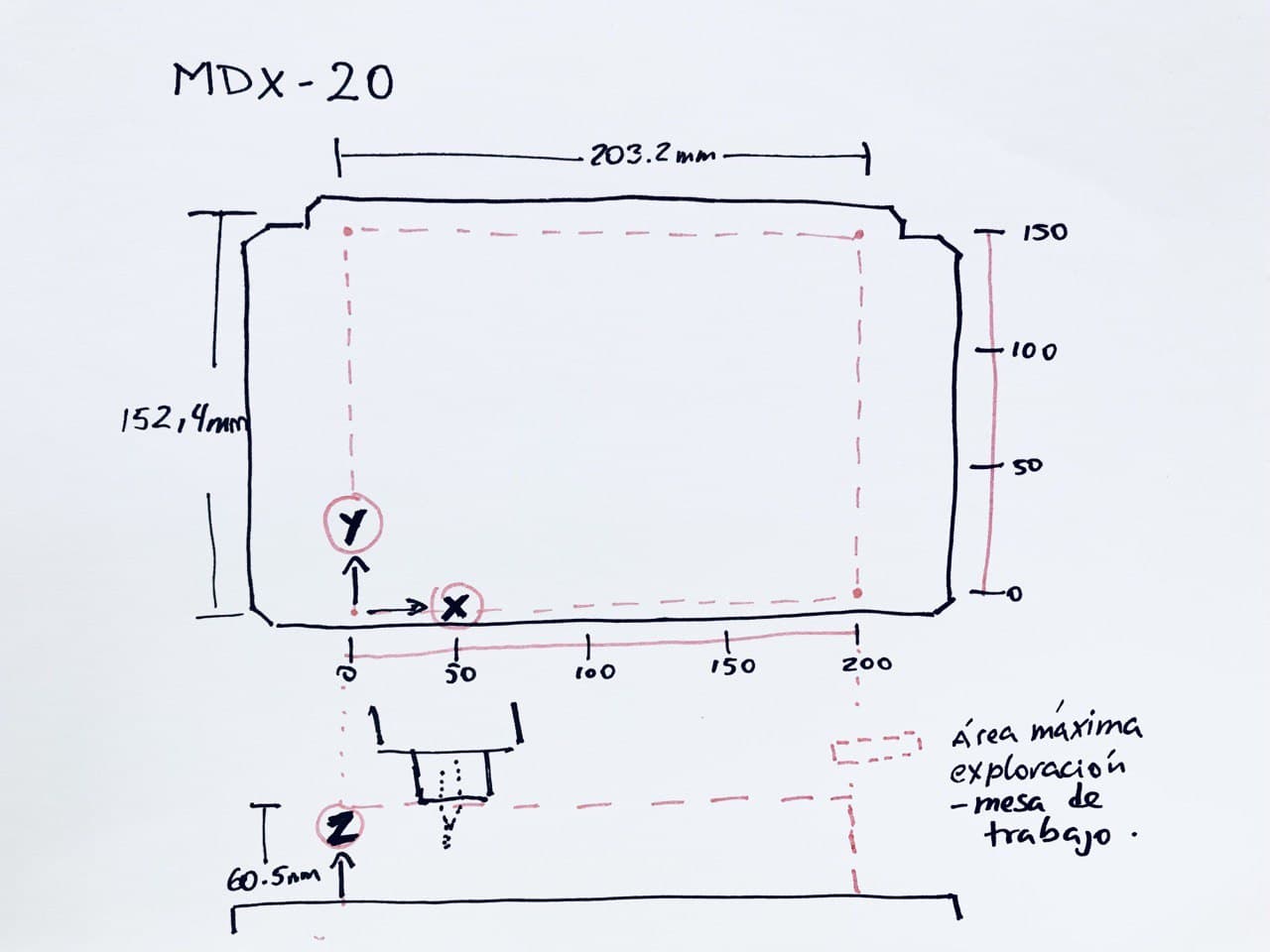

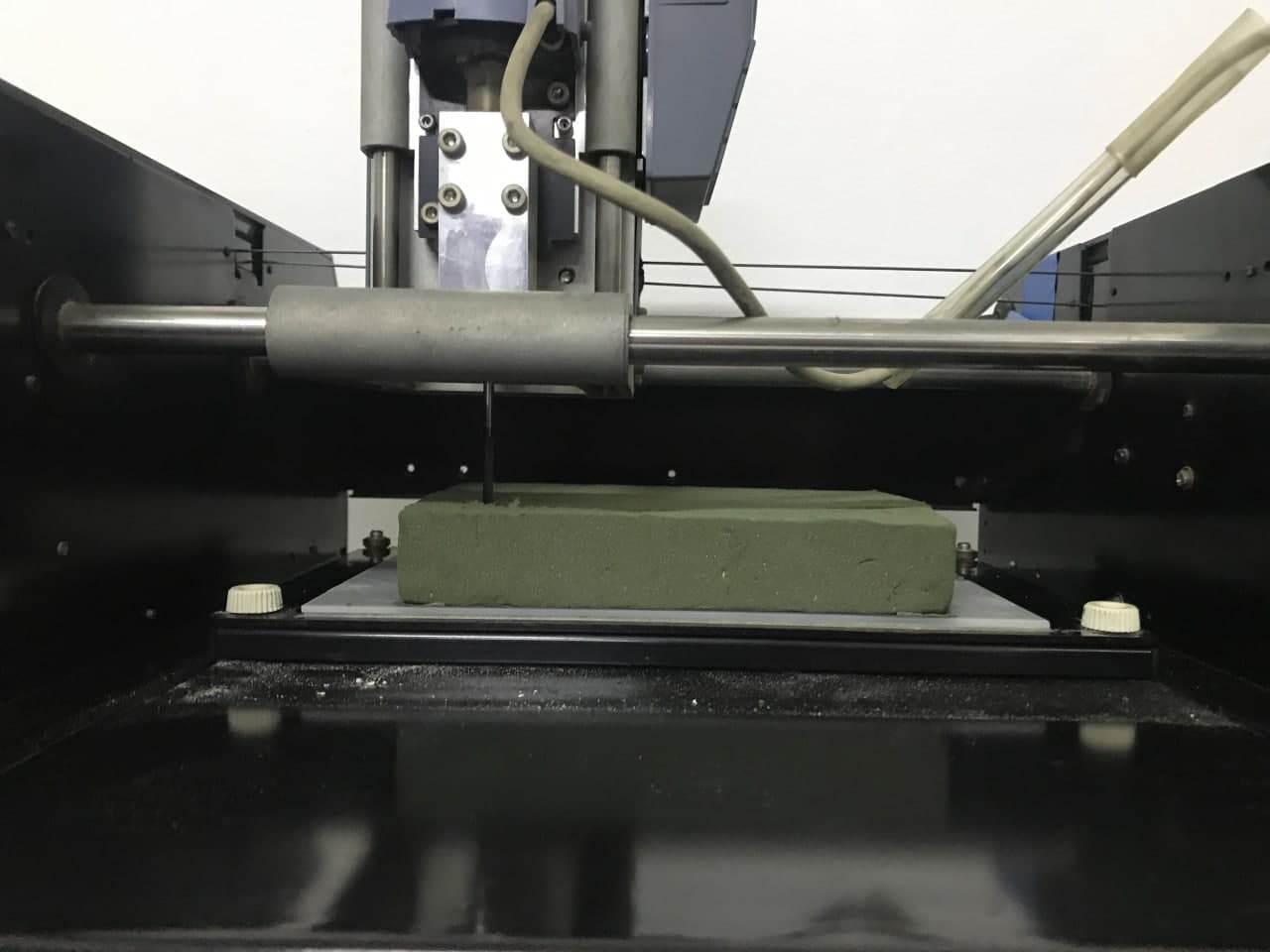

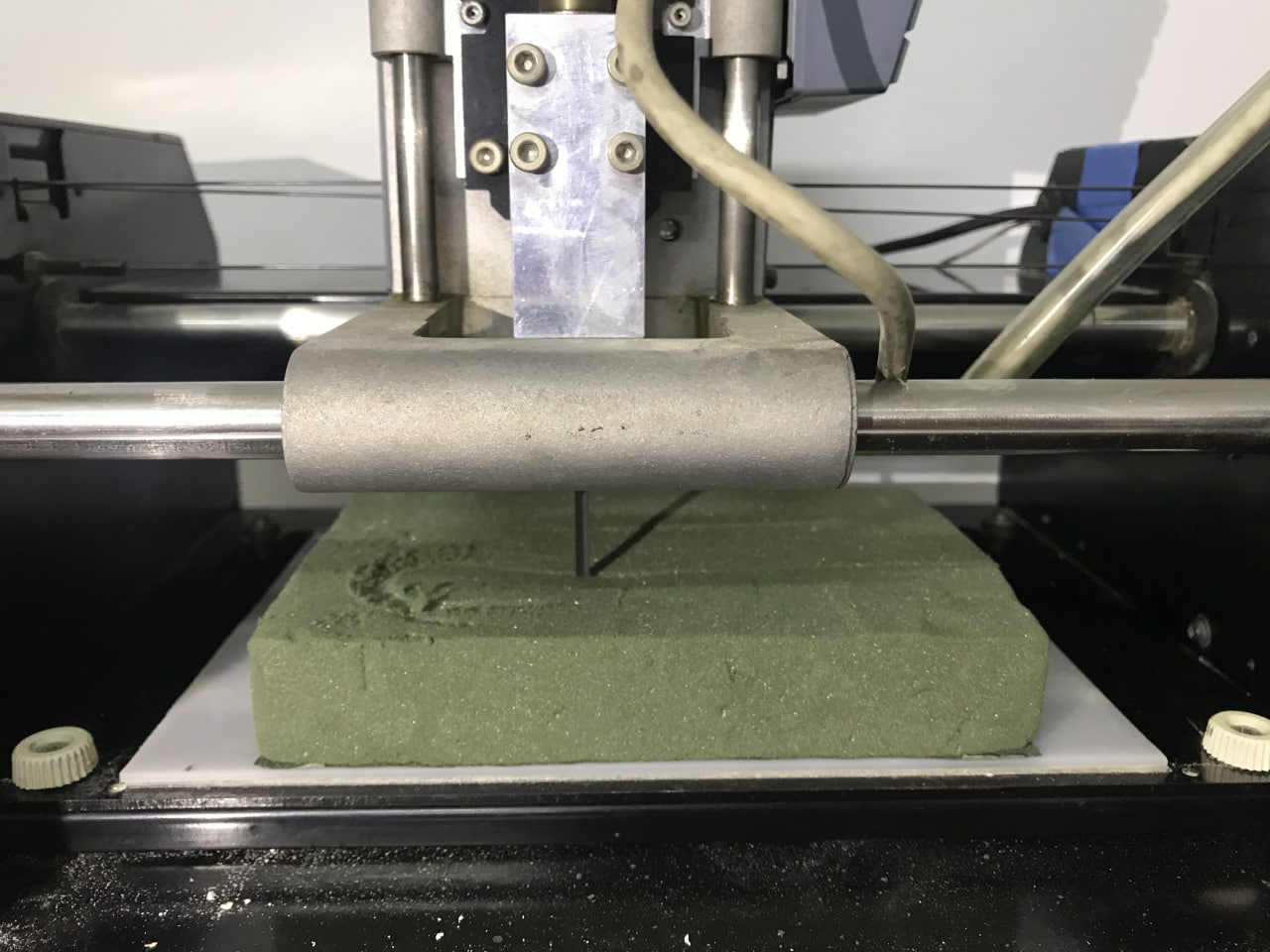

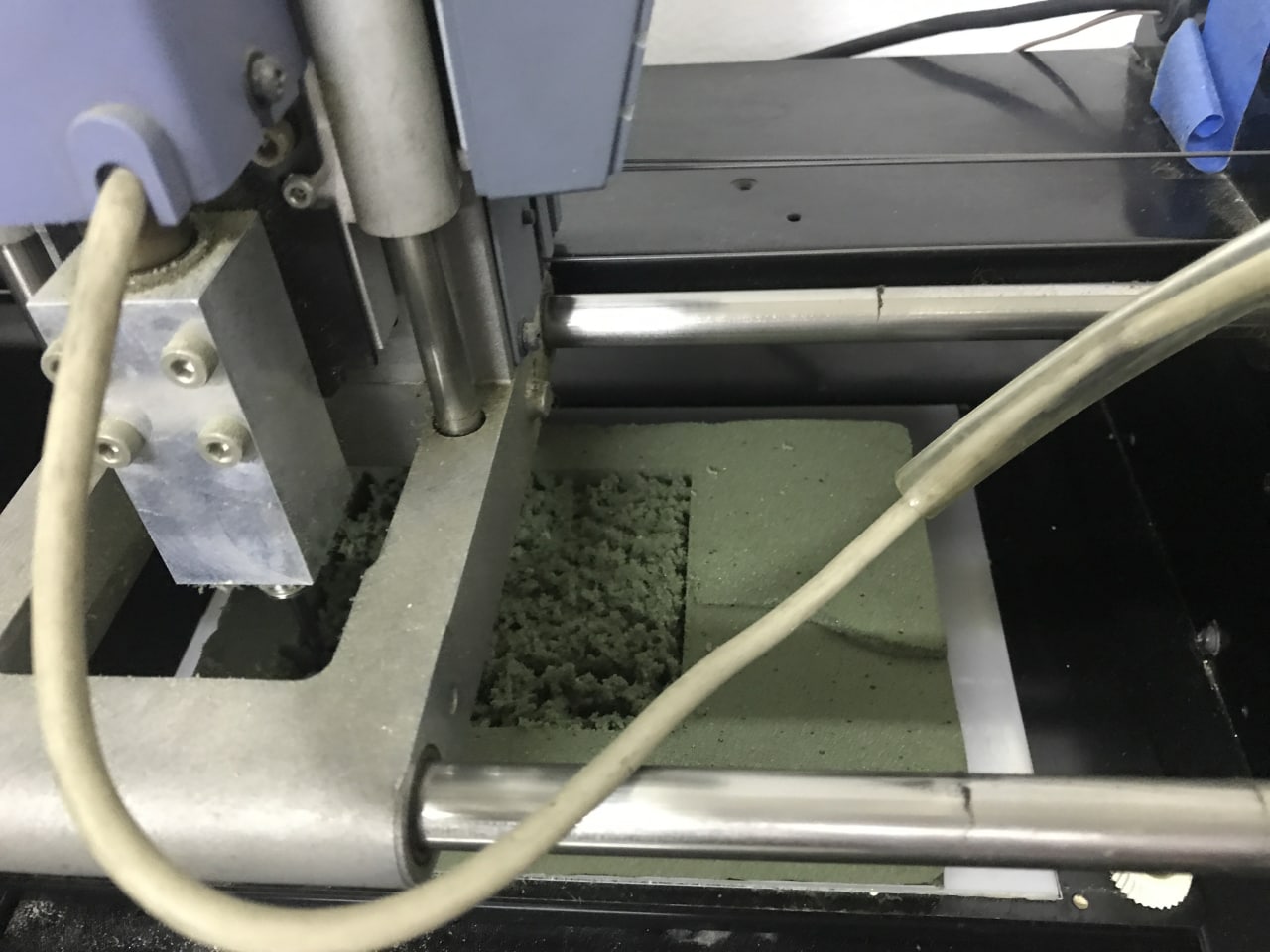

Before using the only wax block available, we decided with "Samurai (侍)" that we would look for an alternative material to test the 3d machining process with our Modela MDX-20 3D Milling Machine "Hacked", remember that it was revived in week 4 and now it works with Arduino and with other softwares that are not the original ones.

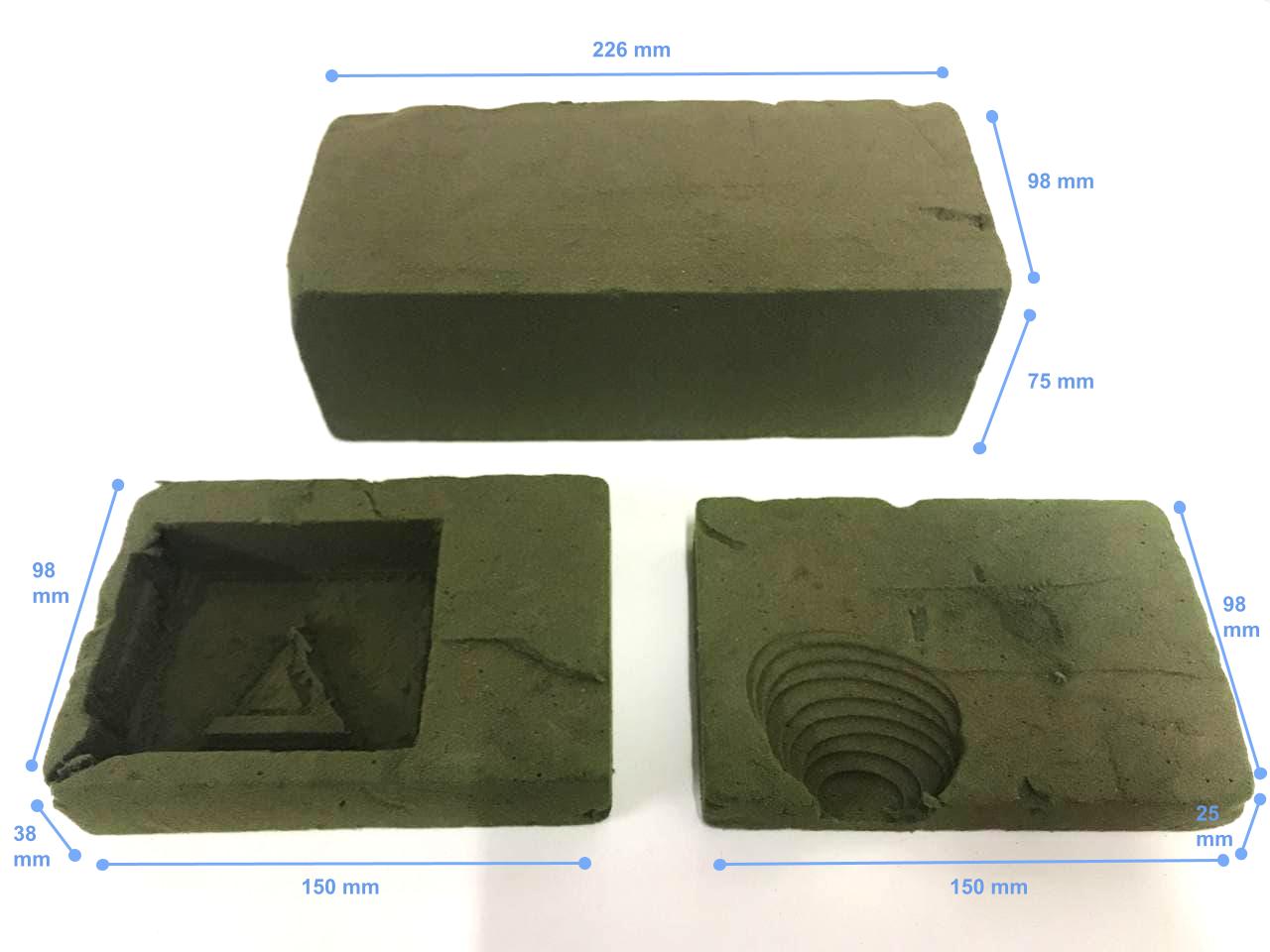

The material we find is a block of floral foam, the typical green foam in which flower arrangements usually come. In addition, we used a Carbi-Universal brand 1/8" cutter. The foam had to be cut in two halves lengthwise, because the available working height of the Modela is less than the height of the material. And the cutter didn't have free space for make quick and confident movements when moving.

Modela MDX-20 & floral foam

Carbi-Universal 1/8" SE 4FL cutter

Maximum working area Modela MDX-20

Foams cut to size

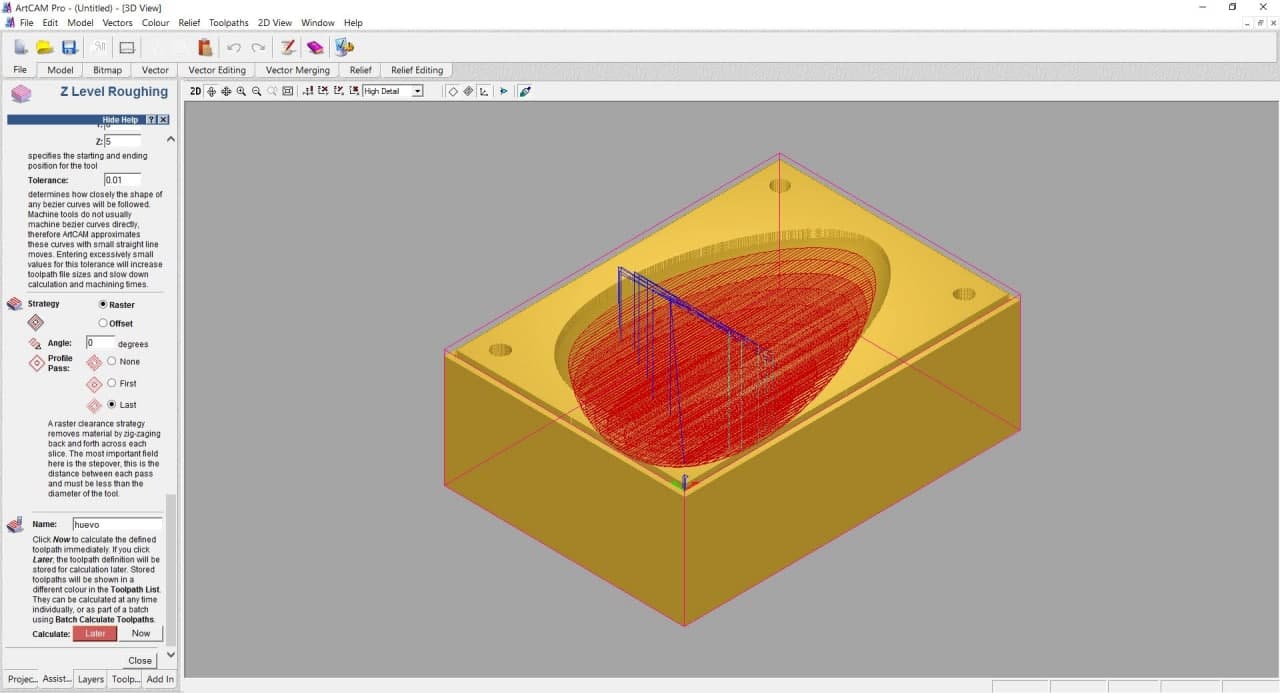

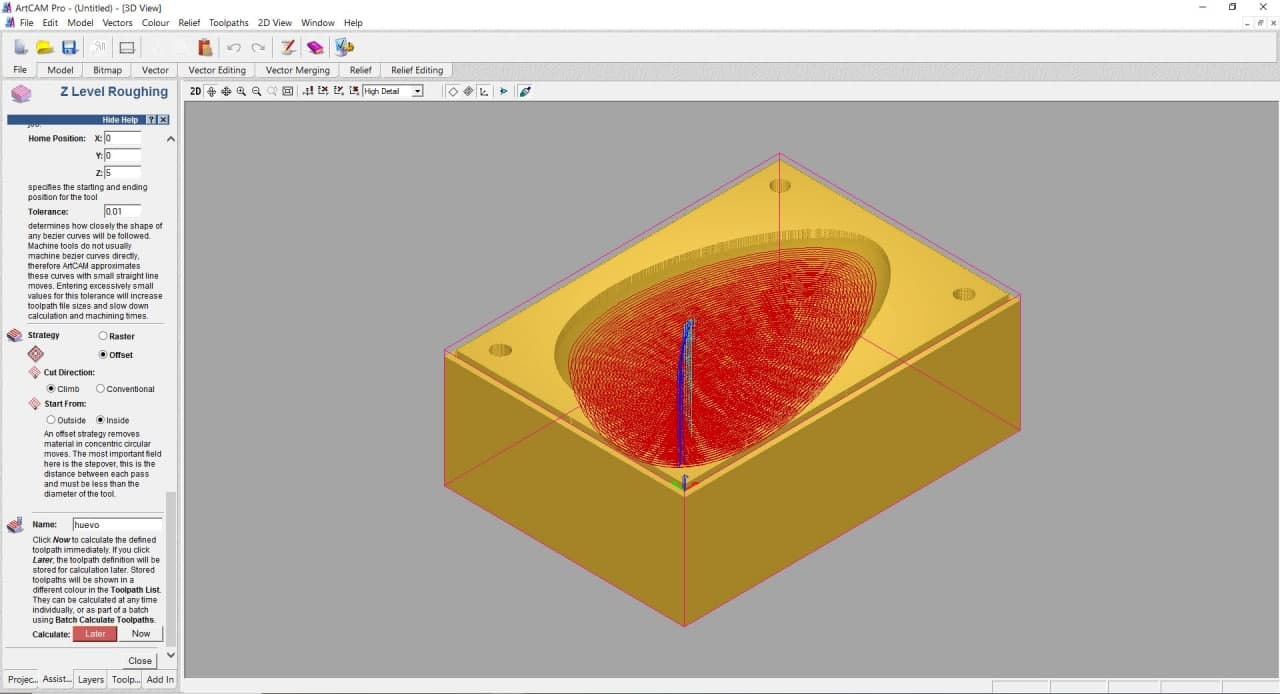

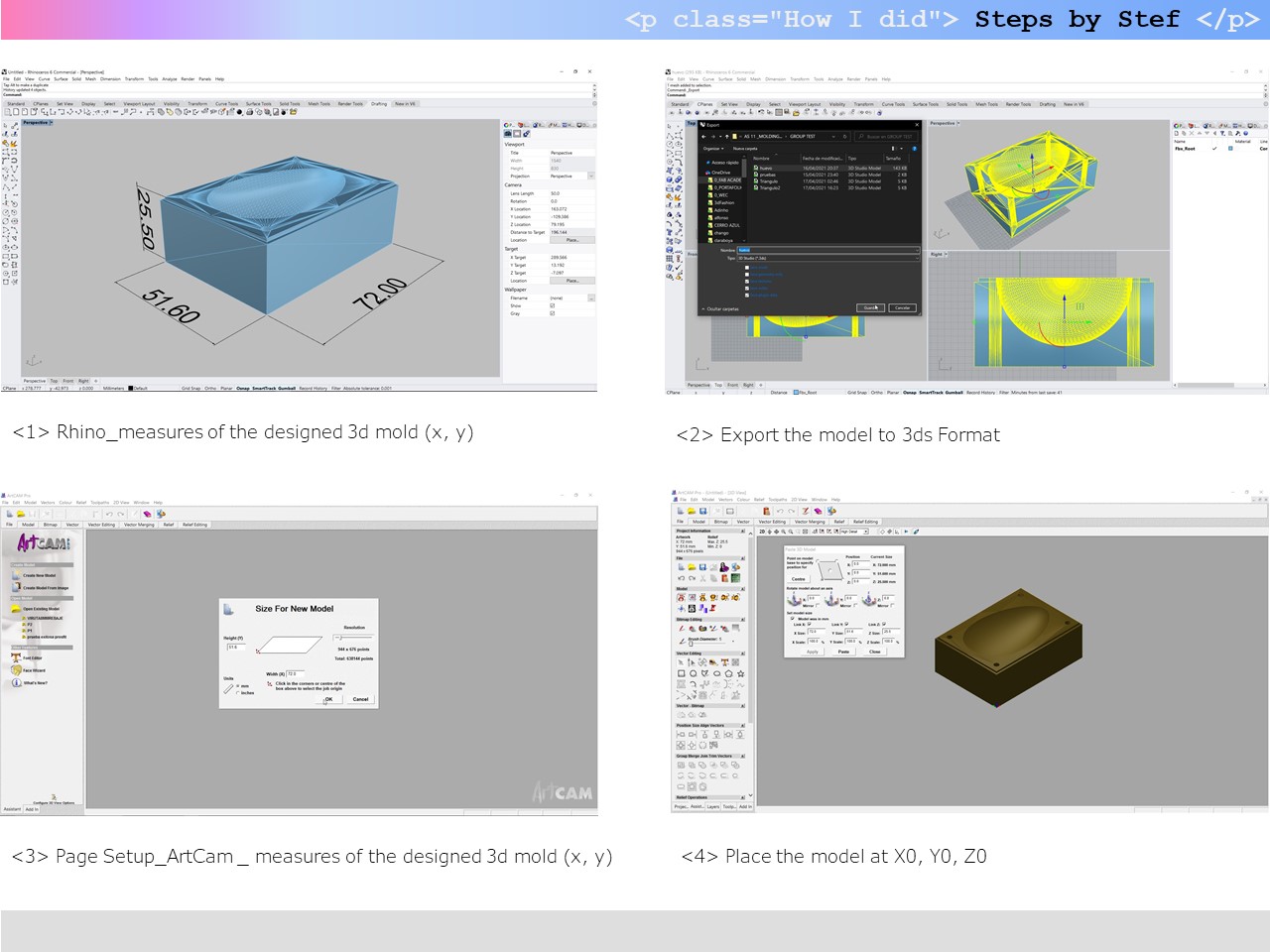

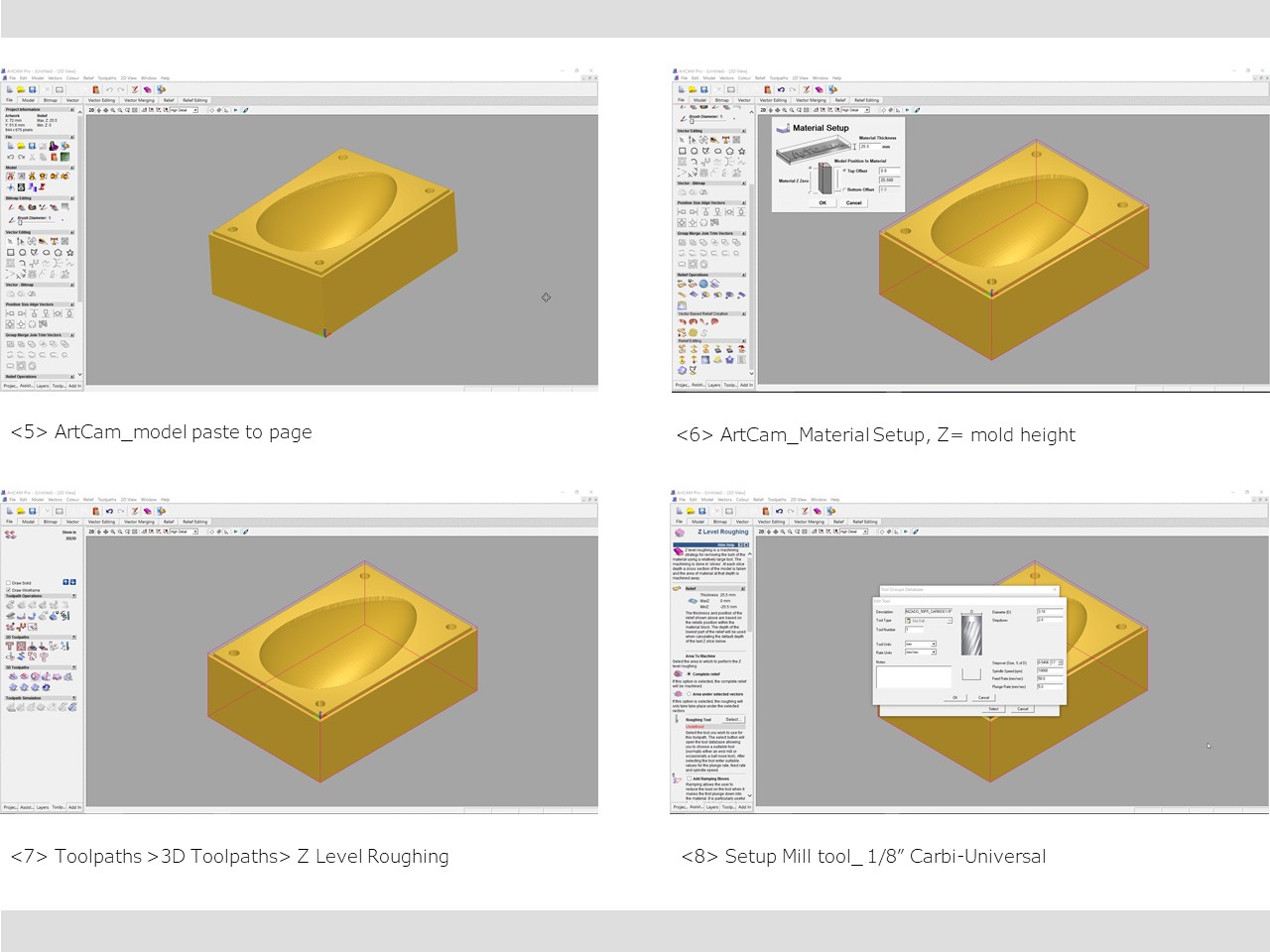

To do the cutting test, we downloaded a file of an egg mold (👉here) to test on the foam. We have already used the ArtCam program in week 7, when we cut with the CNC "something big". We explored this a little more and saw that there were functionalities to do 3d machining.

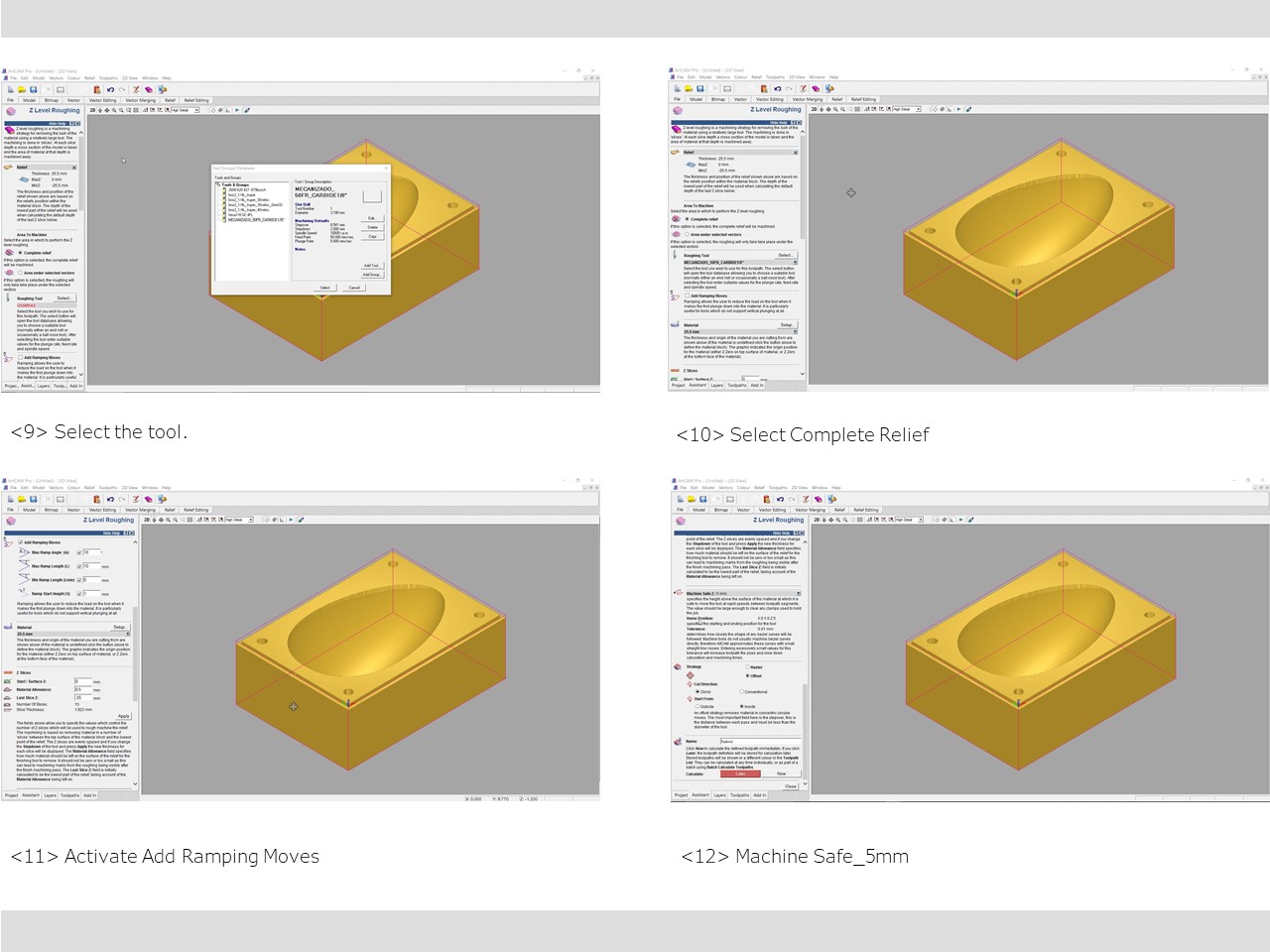

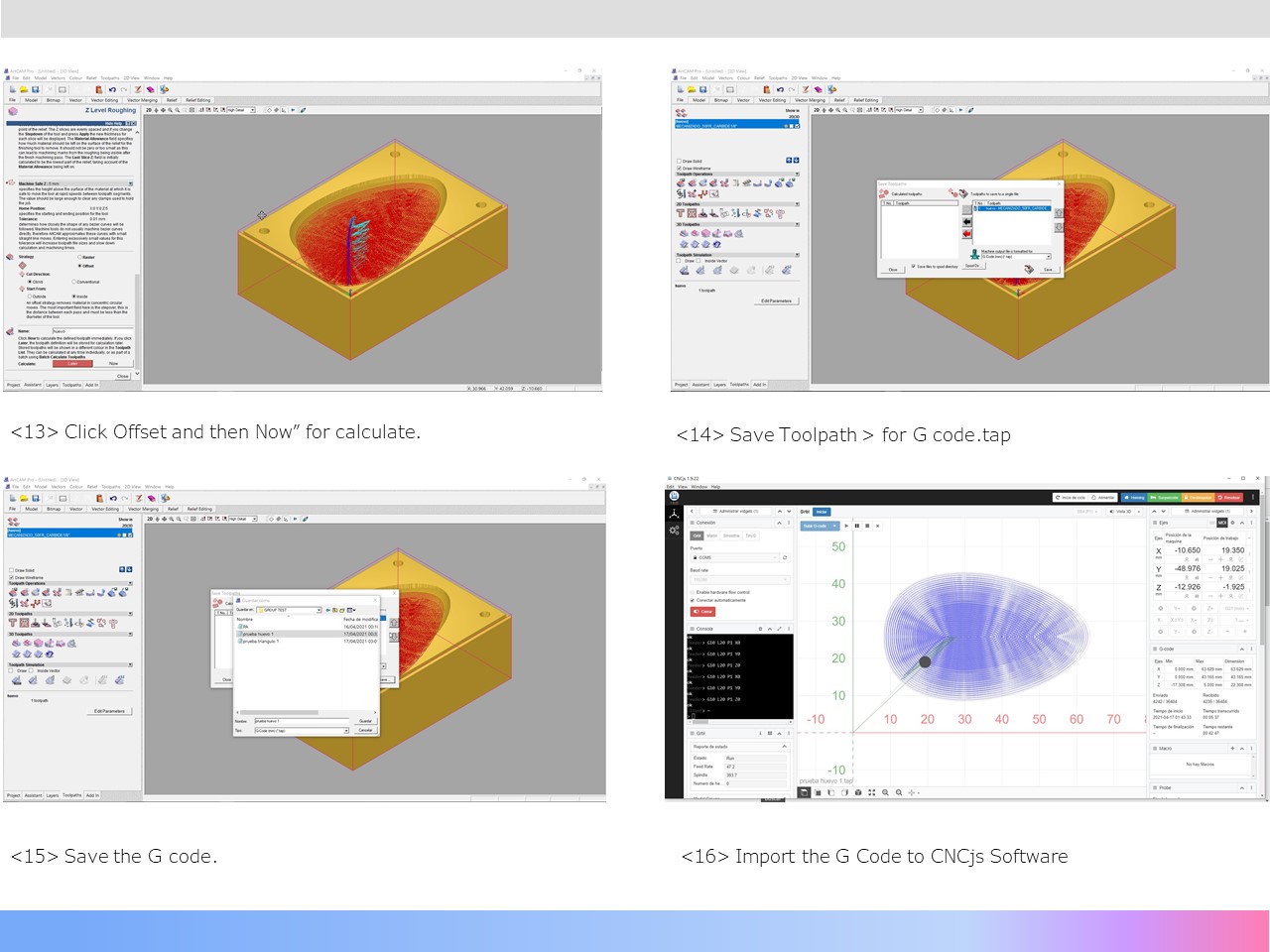

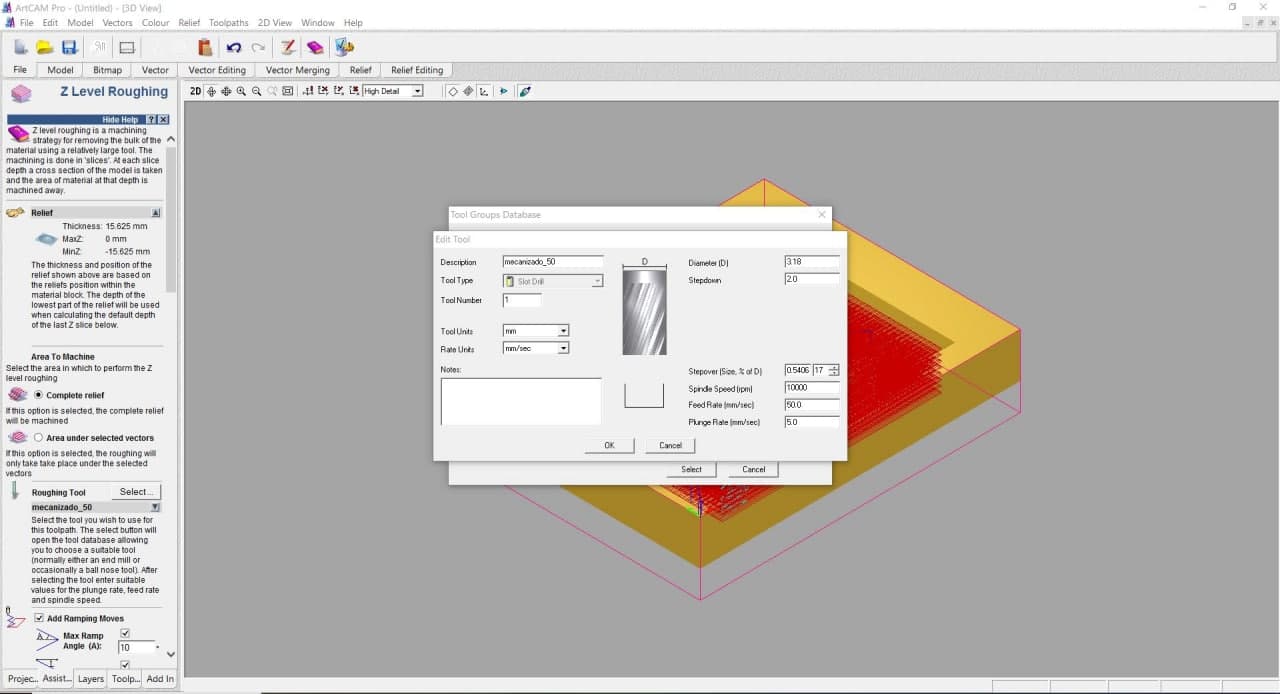

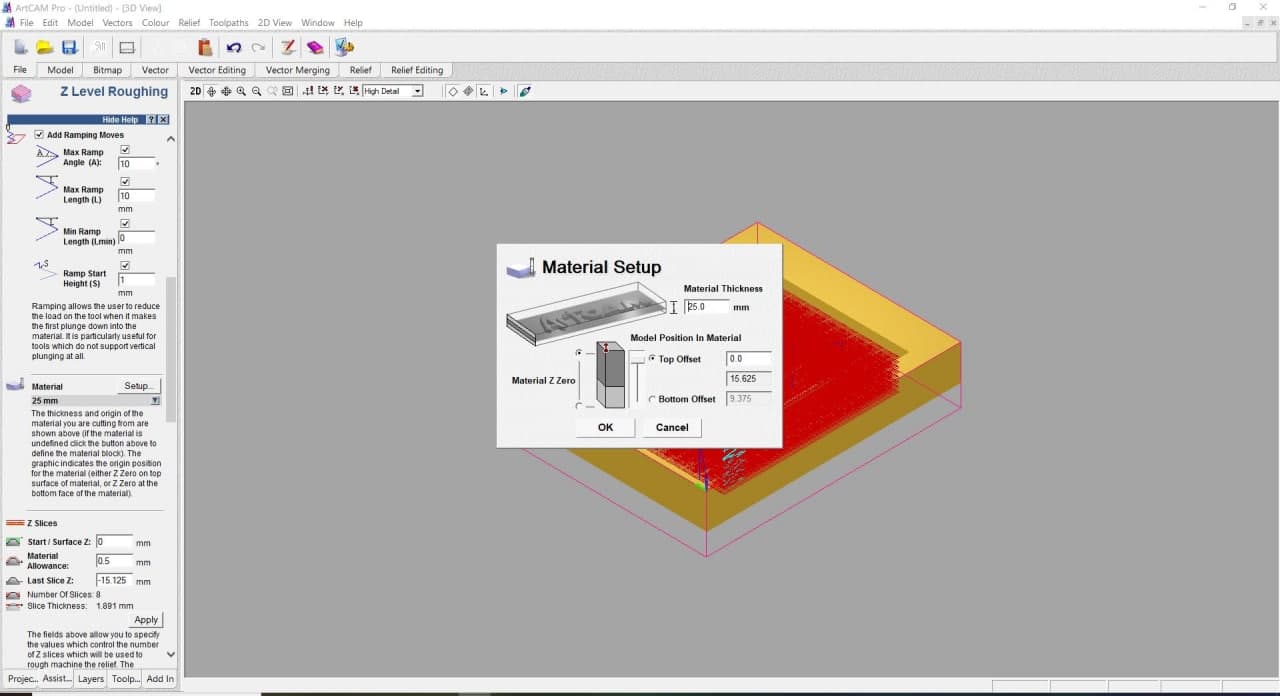

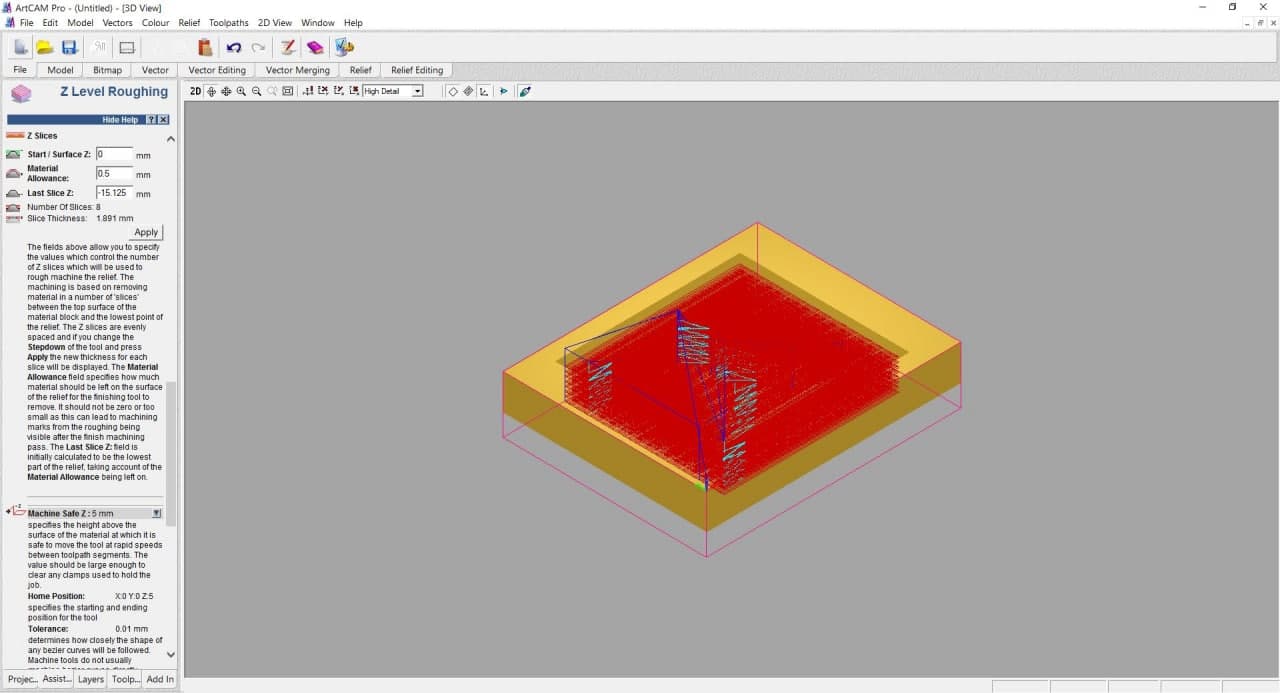

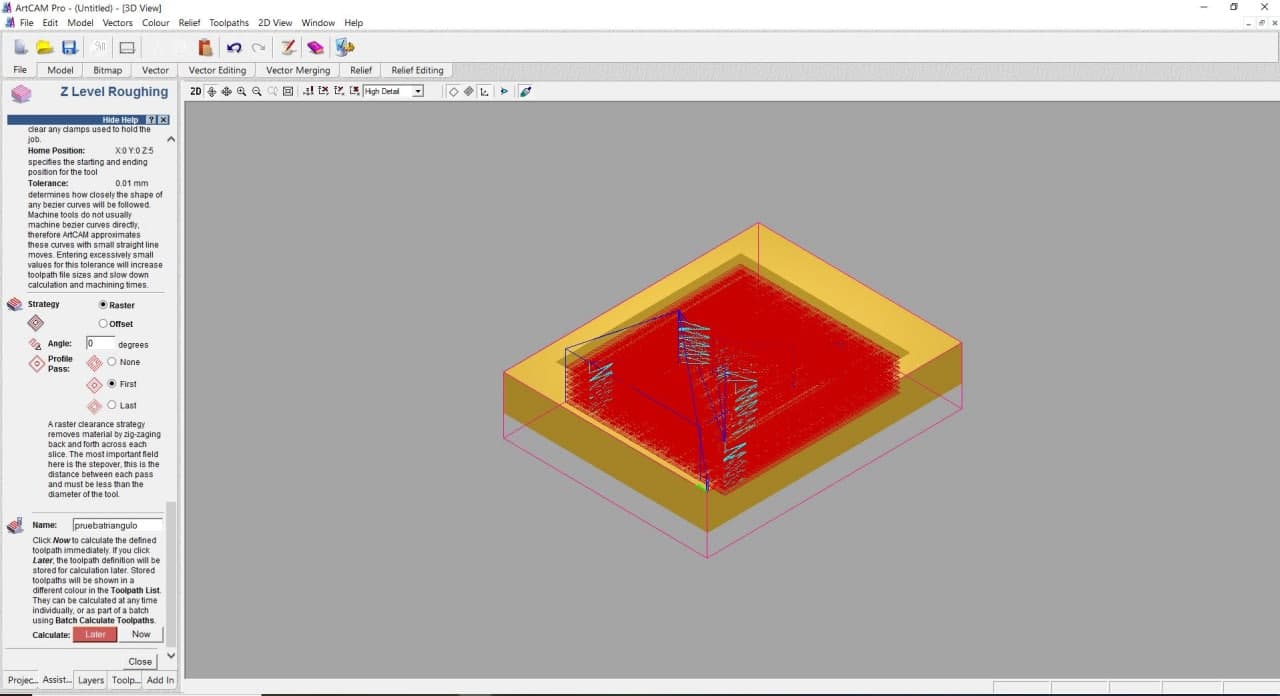

The process I did is as follows: first, check that the geometry of the 3d model is correct and fully closed. Then I imported the file to ArtCam in 3ds format and there I filled in all the machining parameters. For example, if we want the cut to be raster or offset, the Z measurement of the foam block and other factors. Also, I uploaded all the features of the mill tool. We tell the program that the CNC spindle make ramping movements when it descends from one level to another on the Z axis. This helps us to take care of our part, the machine and the milling cutter. The "ramping" movement is very convenient so that the cutter doesn´t hit at a perpendicular angle directly with the hard material and starts cutting laterally. In week 7 you can see about it.

Raster milling Egg Model in ArtCam

Offset milling Egg Model in ArtCam

Z Level Roughing_ArtCam

Z Level Roughing_ArtCam

Z Level Roughing_ArtCam

Z Level Roughing_ArtCam

We chose the egg mold because it is a curved and organic shaped that would allow us to test the quality and cutting precision of our machine. While I was solving this part, Mayra investigated in tutorials and designed how to solve the design of a mold with a triangular design in the FreeCad program, which would help us to visualize and explore how the machine would behave when machining right angles, direction changes and different depths. To share the information learned and send each one a test model to be machined. Finally, we sent the EGG mold test to be machined with the CNCjs program applying the Offset option and we waited for the result.

Z height_Egg mold machining process

Egg mold machining process

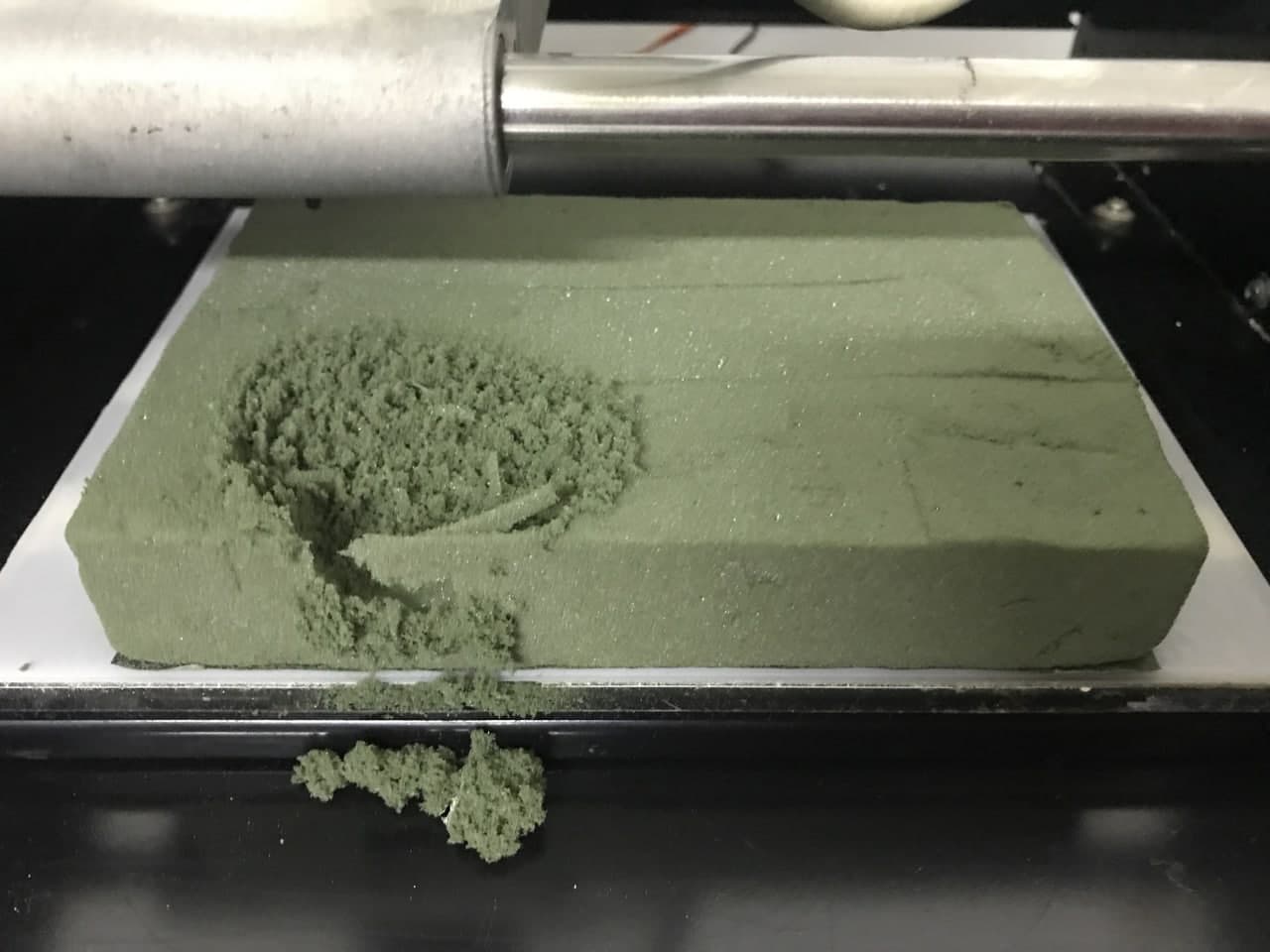

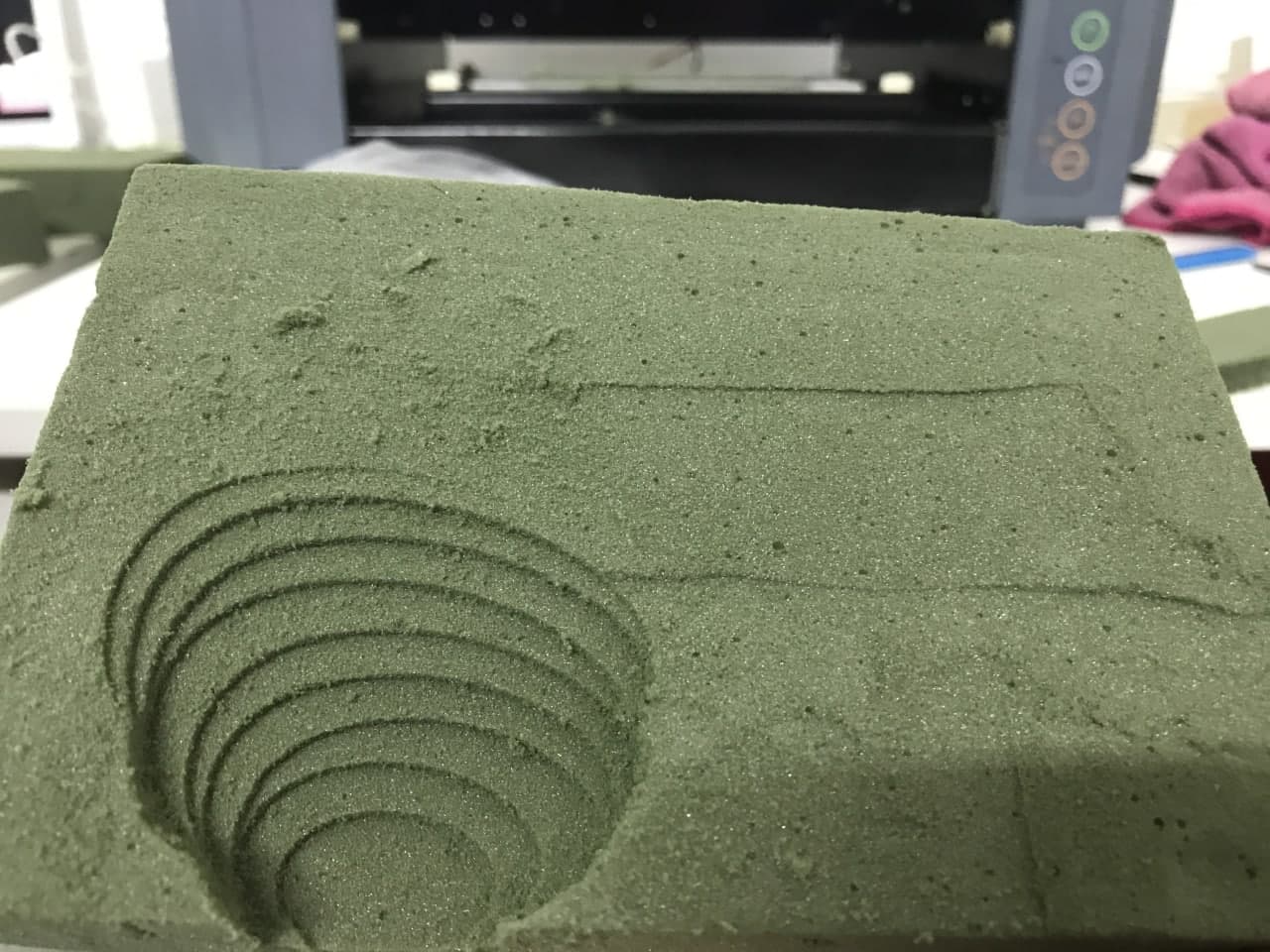

Egg mold machining finish

Egg mold machining finish

ConclusionScrambled egg, not cooked!

The G code generated by the ArtCam was correct, however, the final result was not what was expected. The mold was not exactly half an egg. They looked like more Inca platforms. 🌄 We detected that every time the Z-axis dropped in level, the tool was out of phase on the -Y axis and on the +X axis, which is clearly noticeable in the foam mold.

We tried to solve the problem from all the software we use, but we realized that the main problem laid in the Modela MDX-20 machine, which was not calibrated, much less accurate, after having been revived after ten years of being turned off. Also now it works with free software and Arduino, but not the original.

In any case, we reviewed, cleaned, and refined it, with the support of Eduardo Chamorro (Fab Lab BCN), to make a second attempt with the Triangular design.

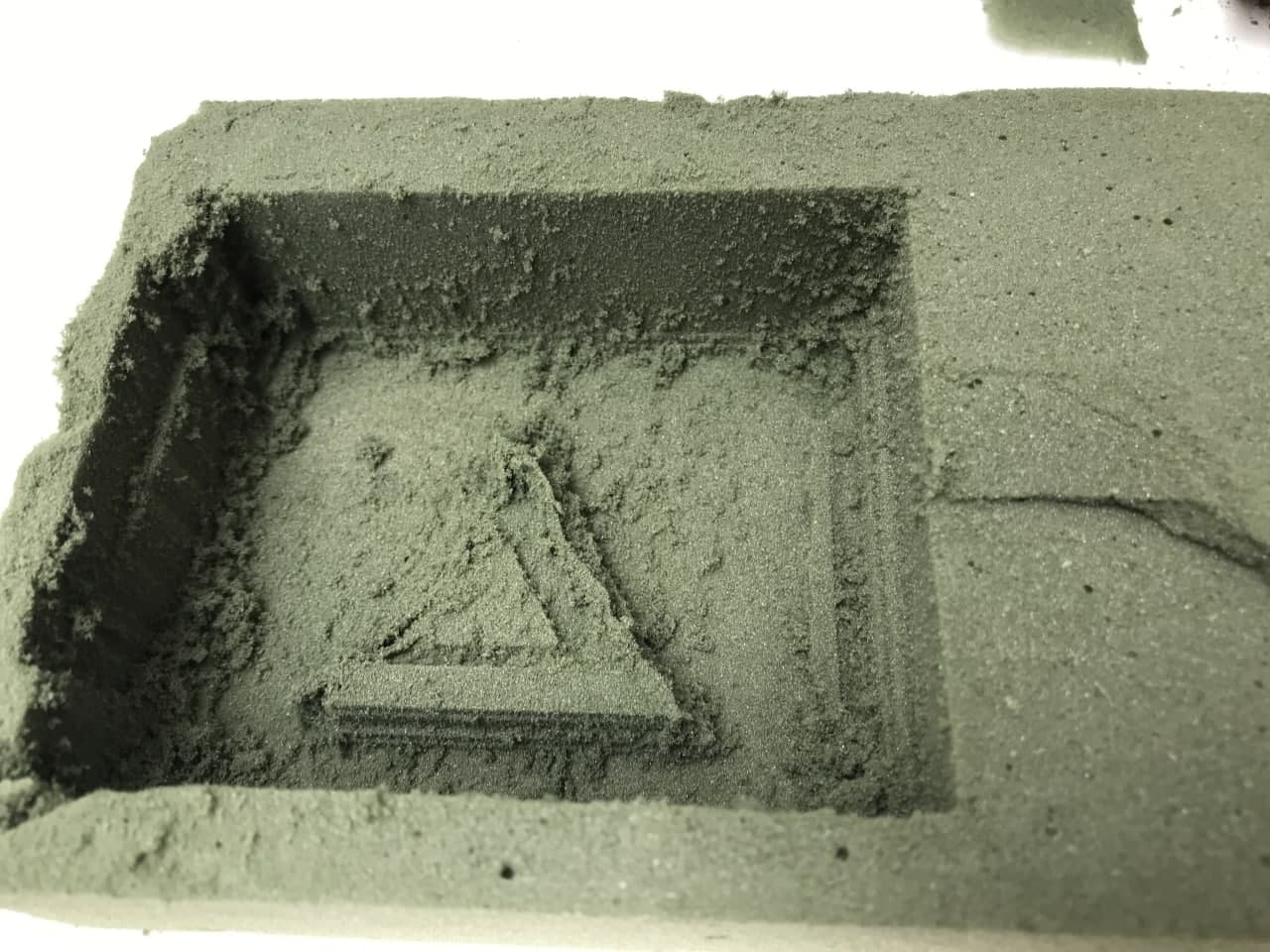

We configure the Triangular model in ArtCam, and we send the machining work but this time we choose the Raster option.

Tool Setting ArtCam

Material Setup ArtCam

Parameters Machine Safe

Raster milling & Now Calculate

The result of this test mold was not what was expected either. The model was also out of phase on the X / Y axis. We saw how the machine works at different depths, and we noted the following: We must leave at least 1cm of edge for our wax molds. A centimeter thick at the bottom would be ideal.

Triangle mold machining process

Triangle mold machining finish

MaterialsTesting

As we had two materials available, RTV SILIKAMOLD TYPE 6 + Catalyst Silicone rubber and ceramic plaster, we tested only these two.

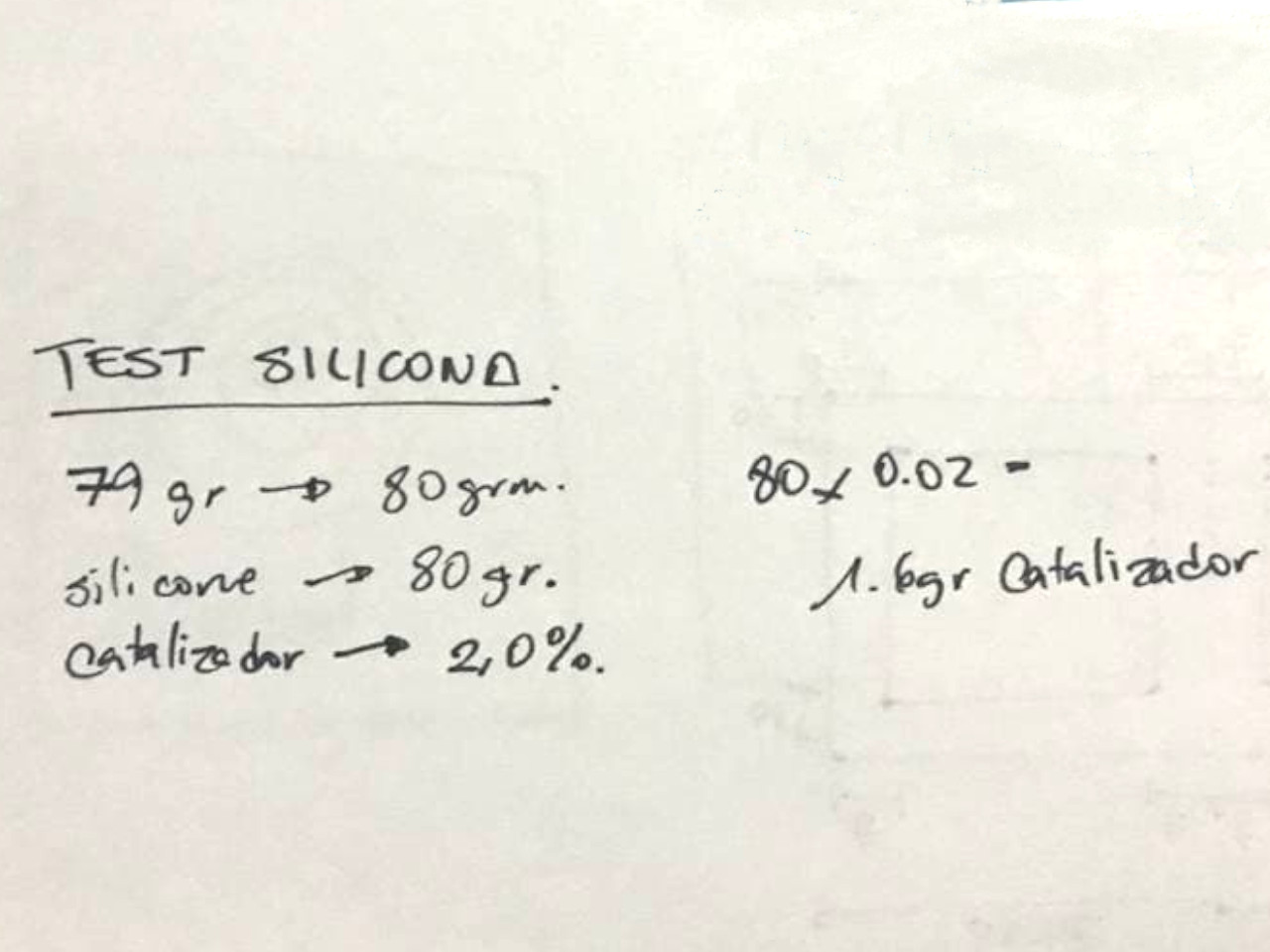

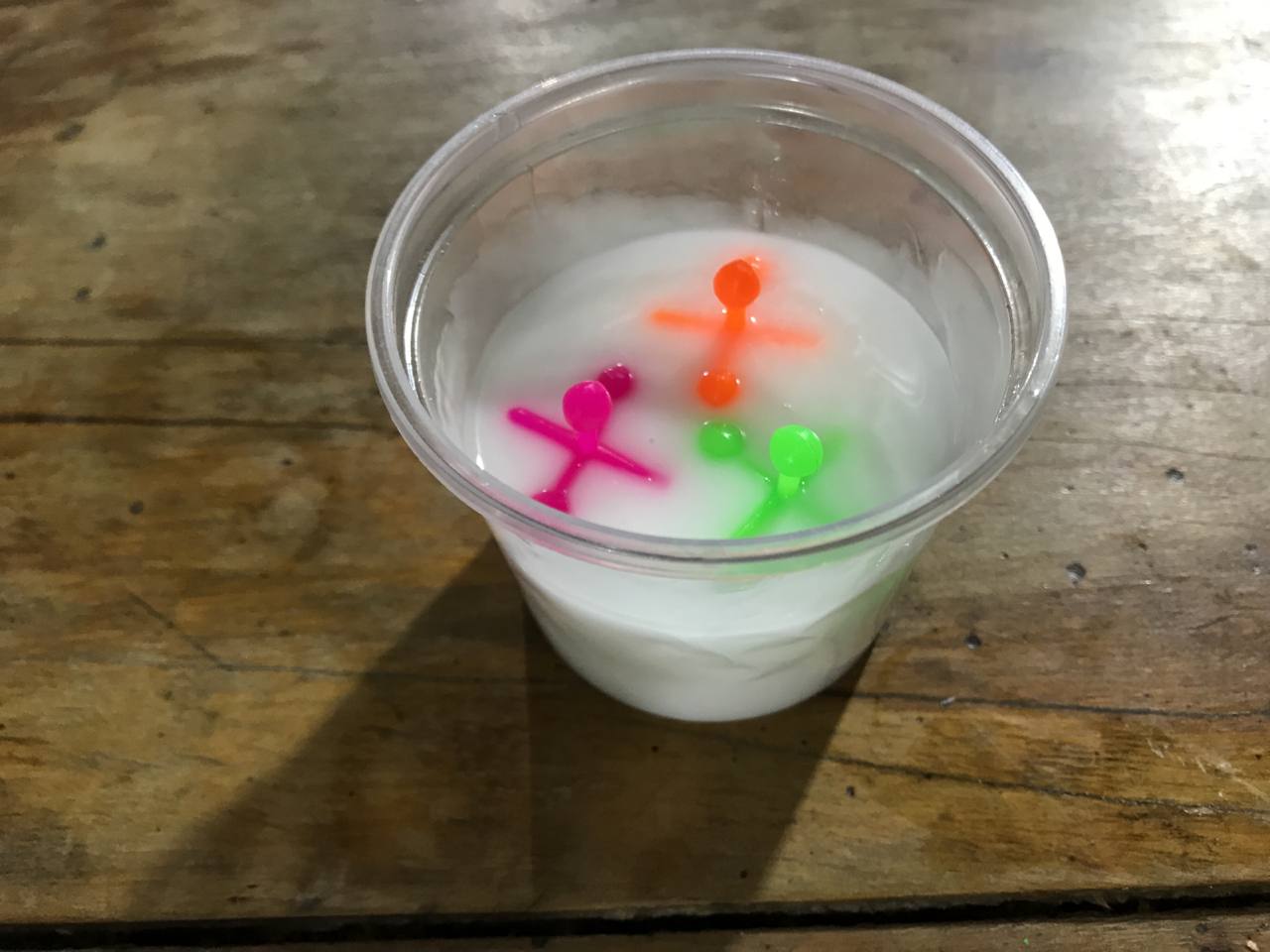

We use 80gr of silicone and 2.0% of catalyst with respect to the amount of silicone. We waited 24 hours to unmold, and we had no bubbles. What didn't turn out very well were the "yases" that we put on. They were difficult to remove and it is highly unlikely that we will be able to reproduce such pieces.

Mixing proportions

Silicone test with yases

Silicone test with yases

Unmold Silicone

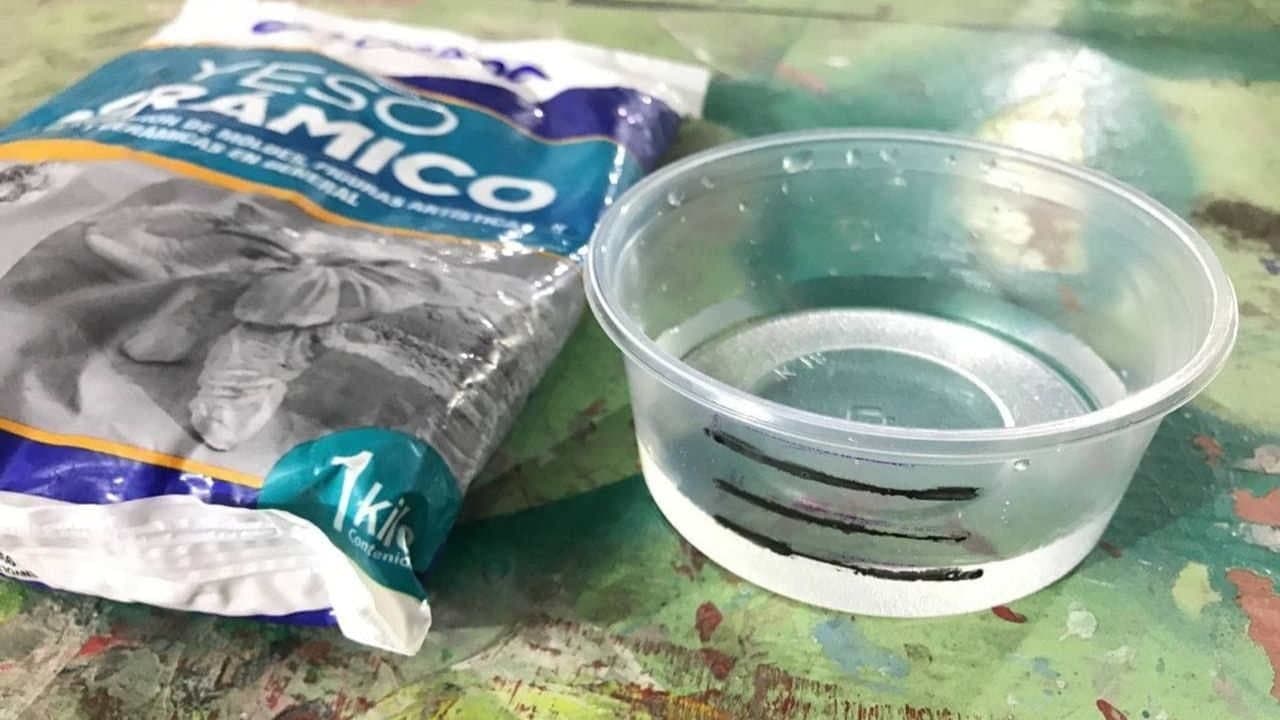

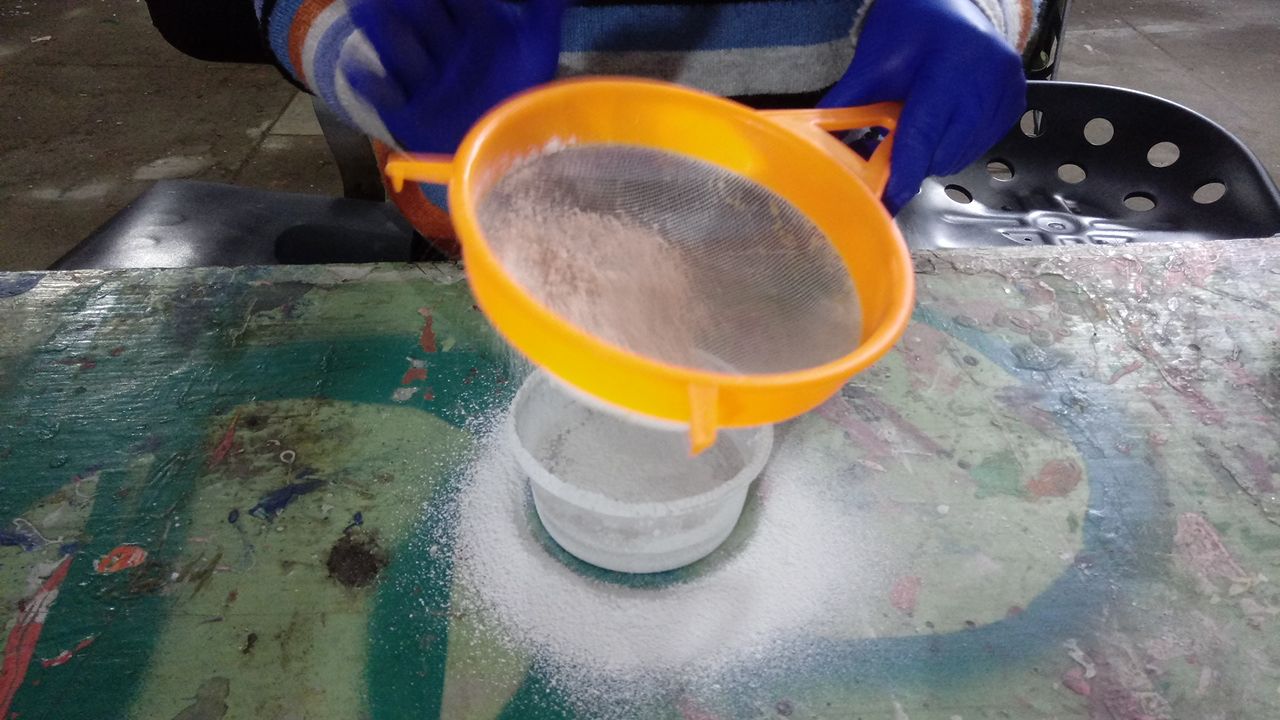

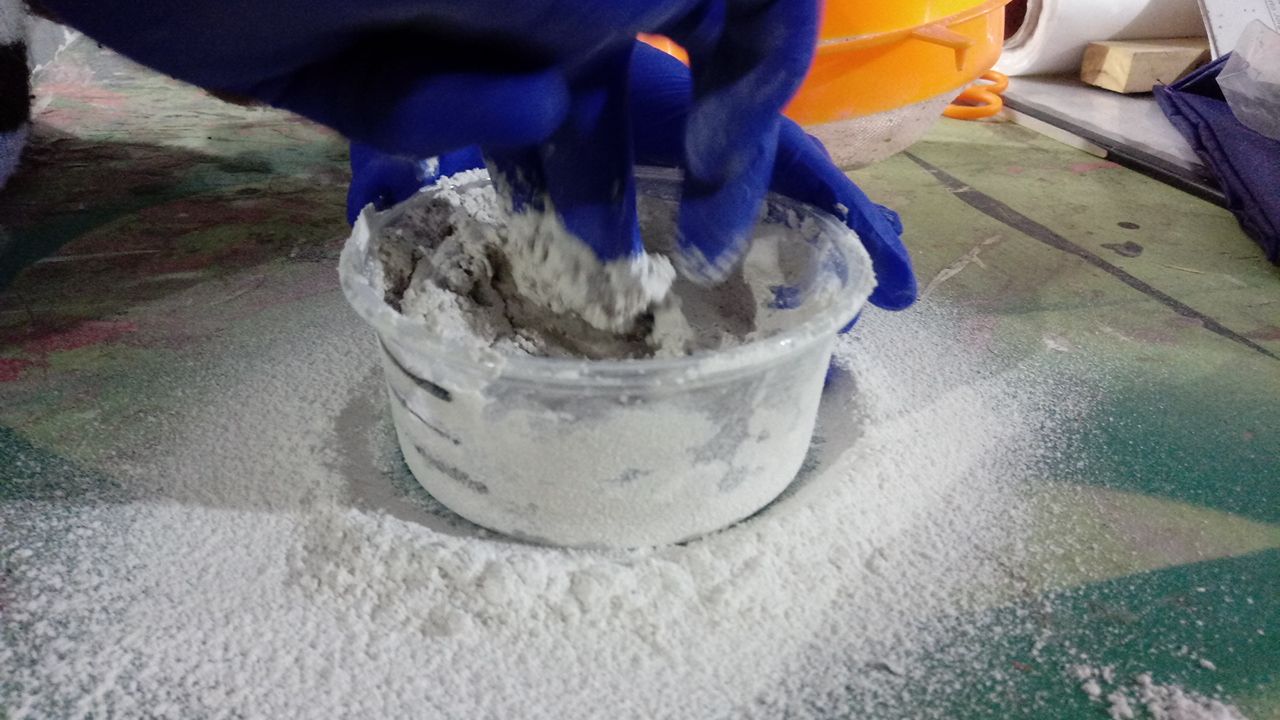

The recommended mixing ratio for ceramic plaster is 2 parts plaster to 1 part Water. We try to mix the plaster evenly with our hands to avoid lumps, but we do not pay attention to how quickly the plaster hardens. It is very important to put enough water in and always add the water first. Gradually add the plaster with a sieve and mix. Our mistake was trying to increase water while kneading. A disastrous result as you can see.🙄

Ceramic Plaster Test Proportions

Ceramic Plaster Test

Ceramic Plaster Test

Ceramic plaster test failed

IndividualTask

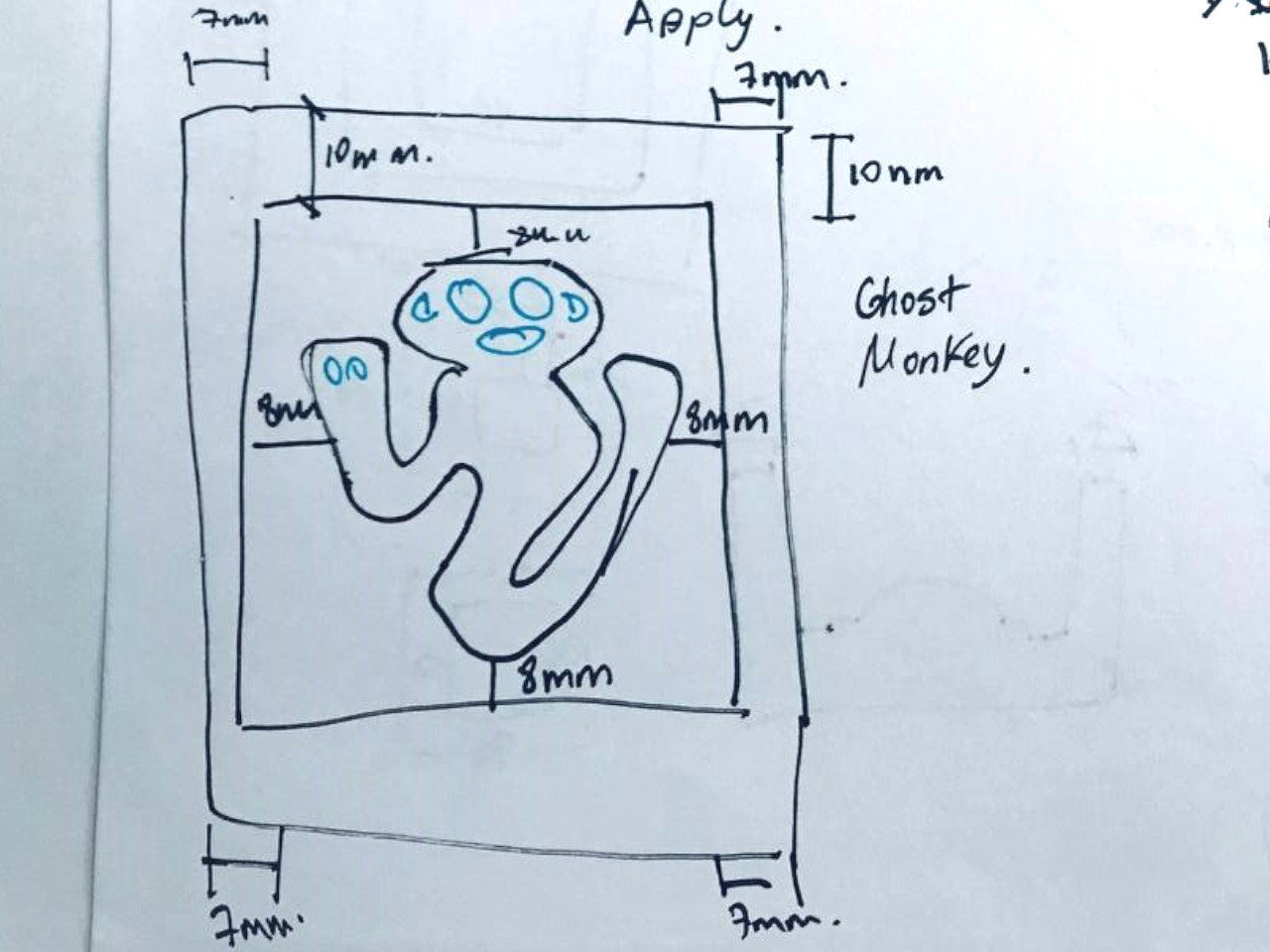

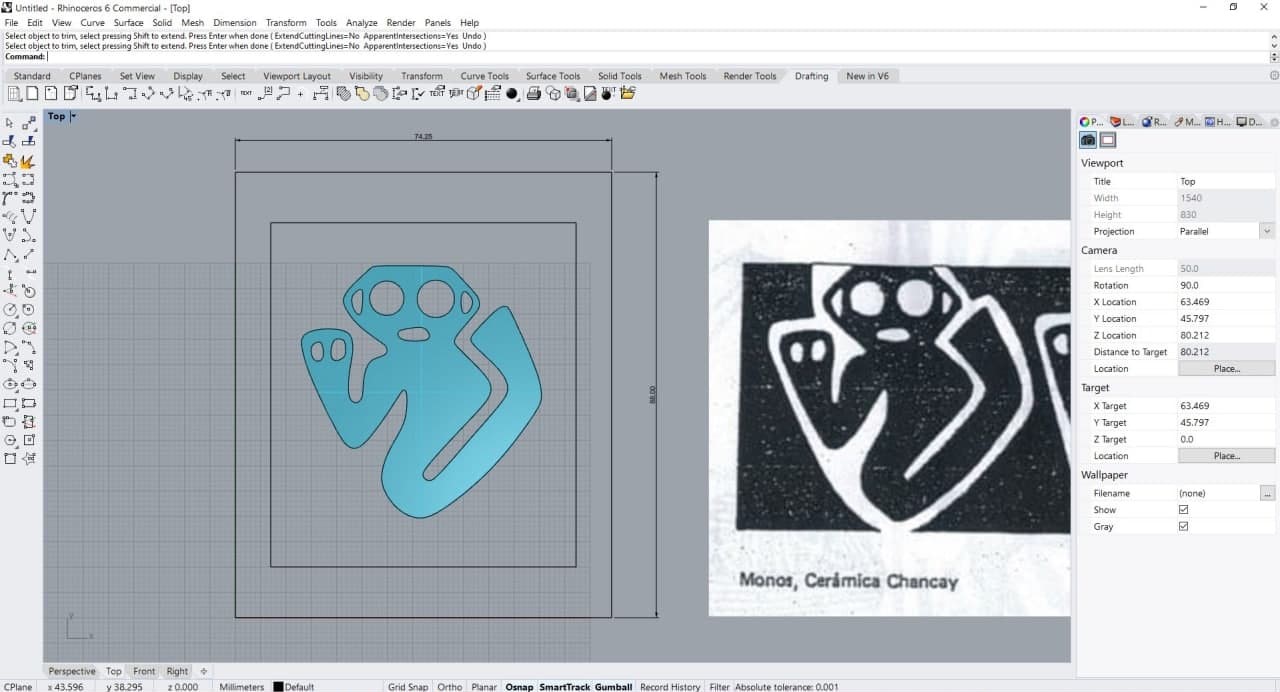

After all the preliminary exploration, it's time to do the design. Inspired by Peruvian pre-Columbian designs, I decided to make the "Ghost Monkey" 🐒, a very old drawing of the Chancay culture. I love this design and I think I can make resin necklaces with this mold. But, this exercise required more complexity. It had to be a 3d mold and have rounded surfaces. For this reason, I designed a second mold: "The Ice Cream mold"🍧. I also fell in love with this one. An excellent exploration together with "Analuisa" in the lab that we have been implementing at the same time!

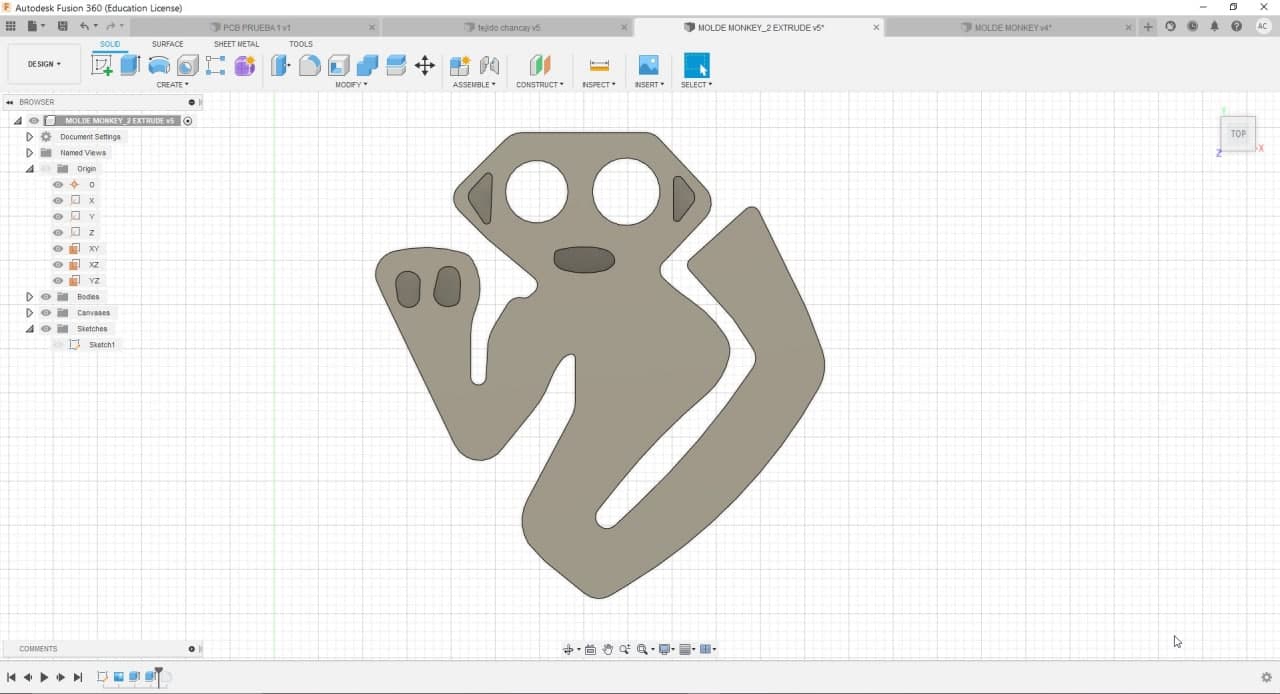

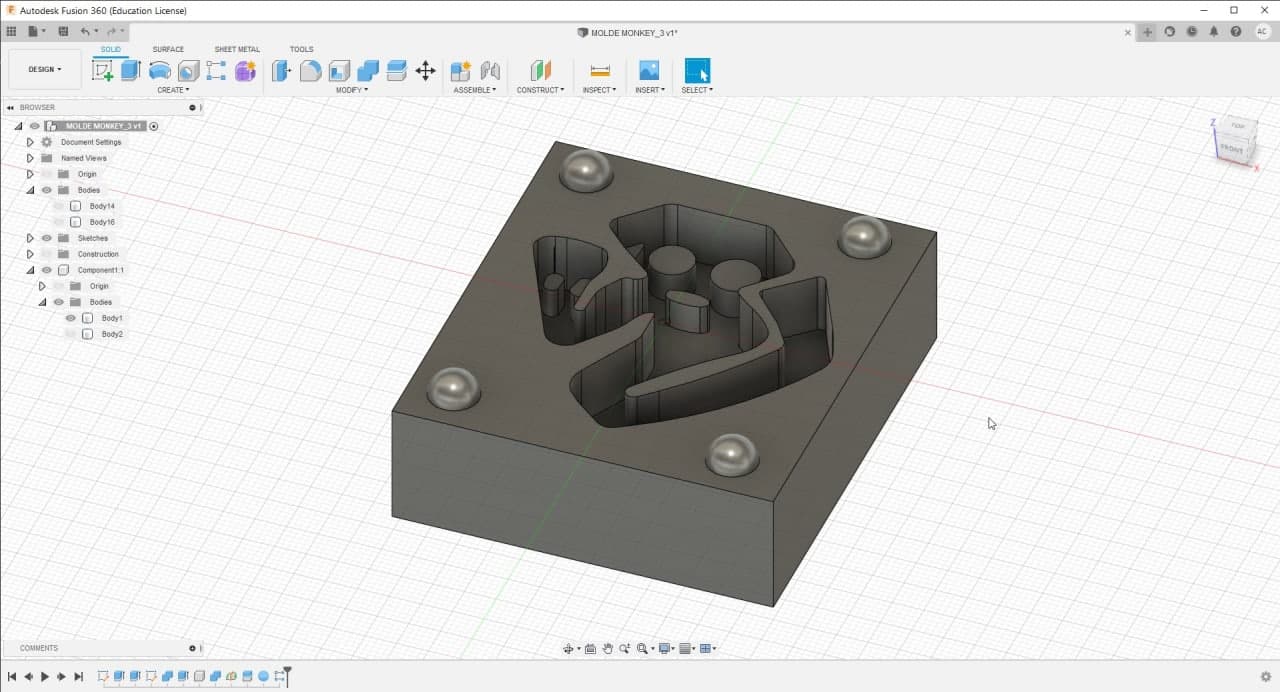

The first try:Ghost Monkey design

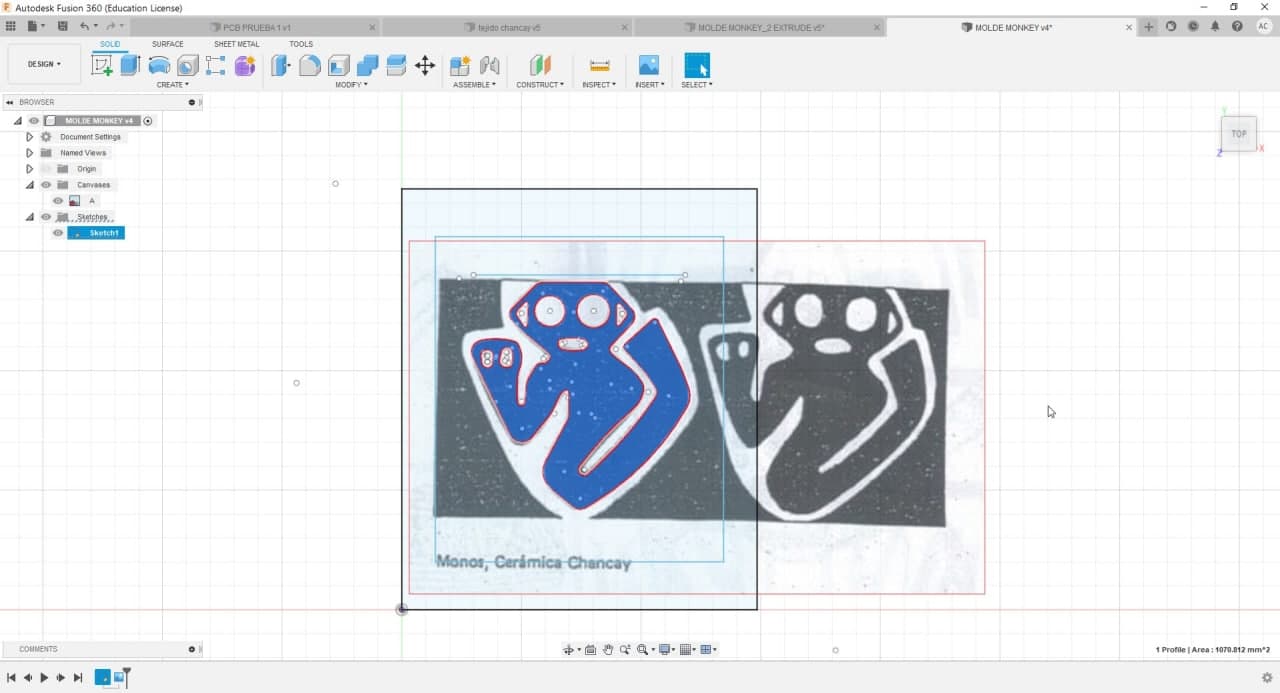

Guided by some tutorials that "GMH 000" shared with me, I made my design in the Fusion360 program. I was inspired by a monkey drawn on a ceramic from the Chancay culture, a pre-Inca culture, settled on the central coast of Peru. It is a very ancient civilization, between the years 1200 to 1470 AD. C.

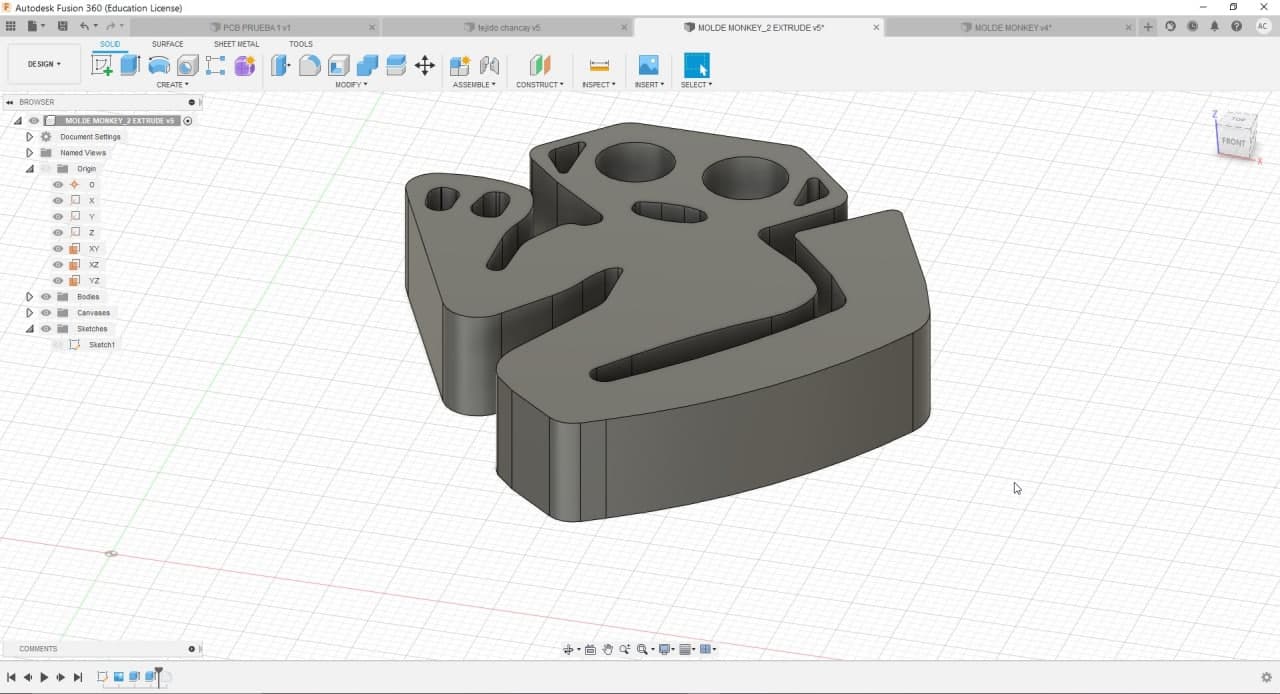

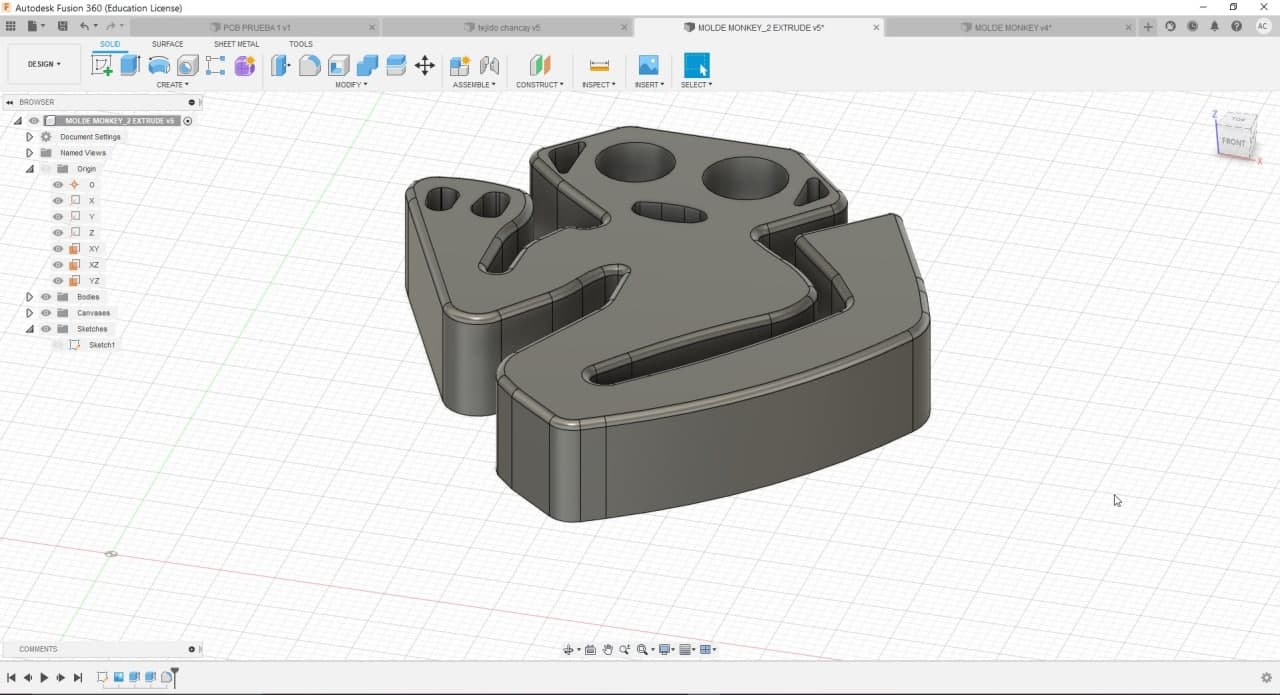

The abstraction of animals and shapes that they managed to capture in ceramics or textiles is very interesting. I was able to import the image into Fusion and then trace the shape, extrude it, and give it volume.

When rounding the edges, due to the proximity of some vectors to each other in the design, I could only make an edge fillet of 1 millimeter radius; therefore, the rounded part was very small. Probably if I had machined this mold, it would be all flat. On the real scale, it would only be perceived as an extruded shape, without any major complexity. I tried to round the same shape in Rhinoceros, but got the same response. So, use the "Ghost Monkey" to practice.

Design and measurements

Design and measurements Ghost Monkey

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

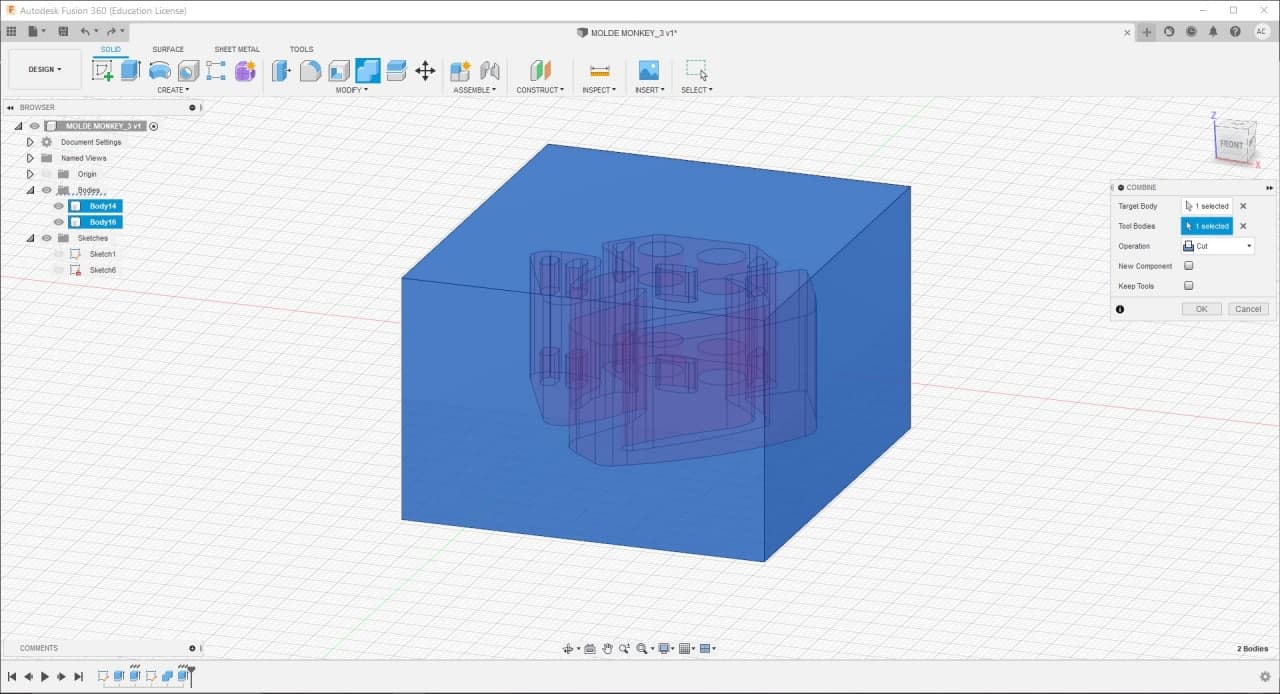

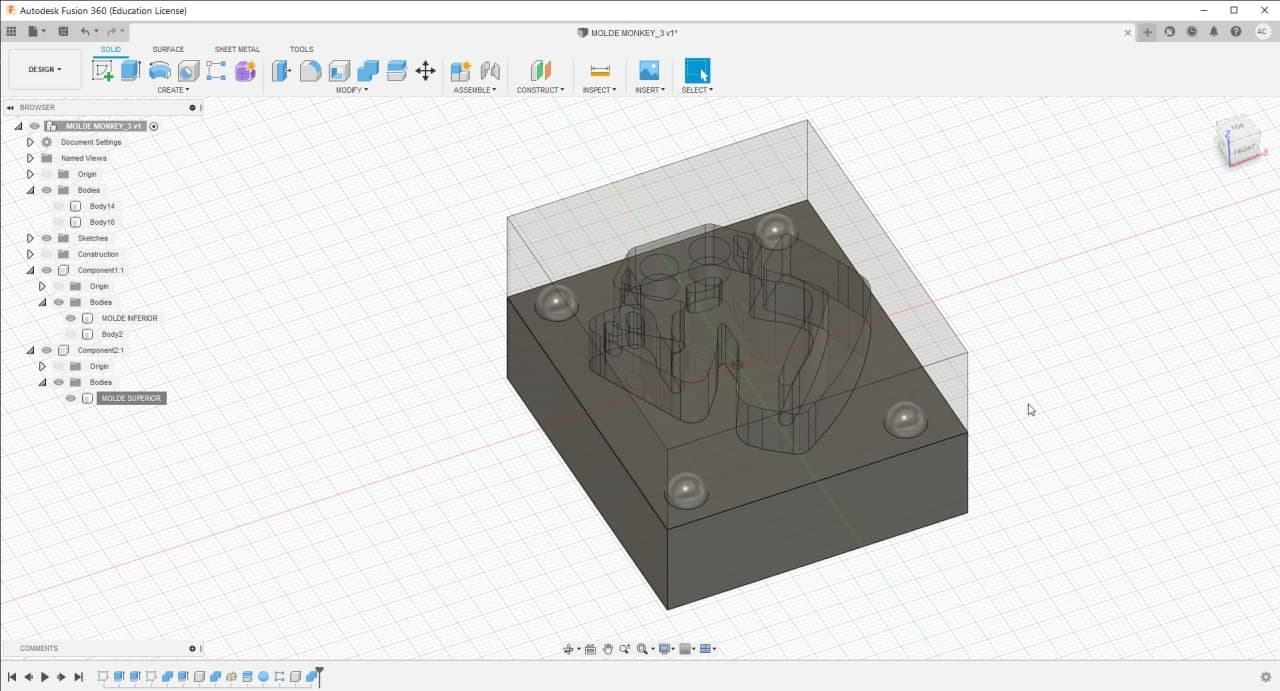

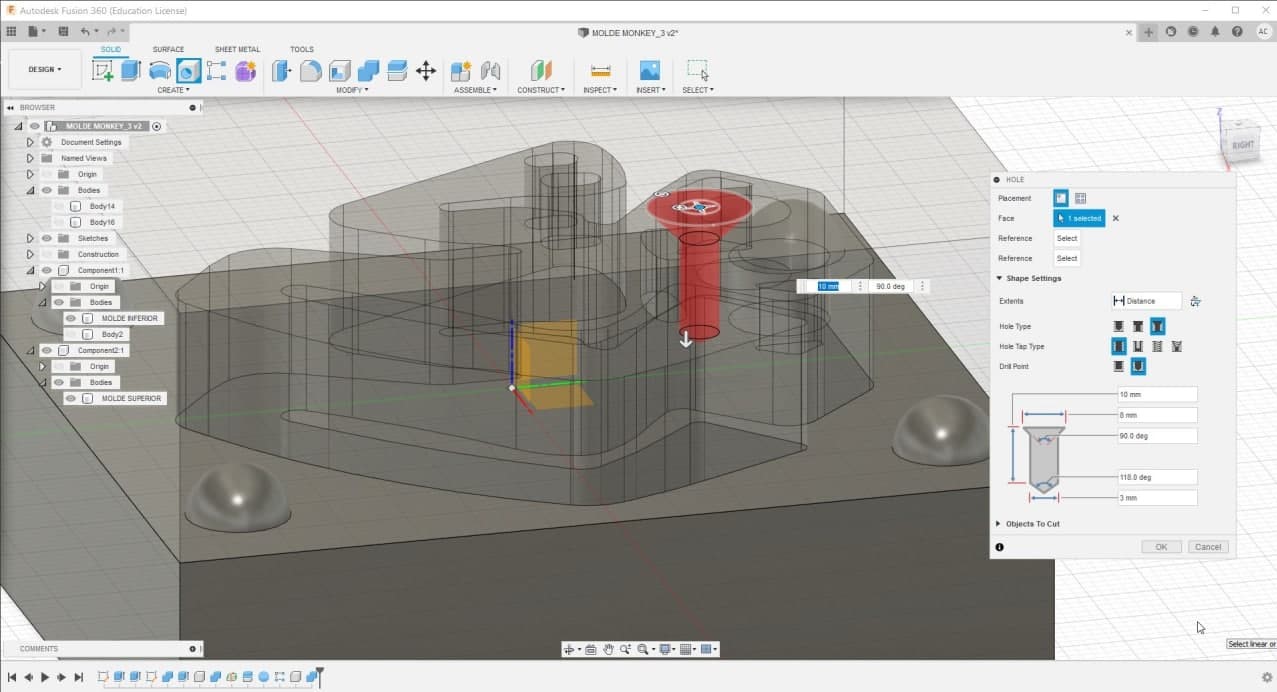

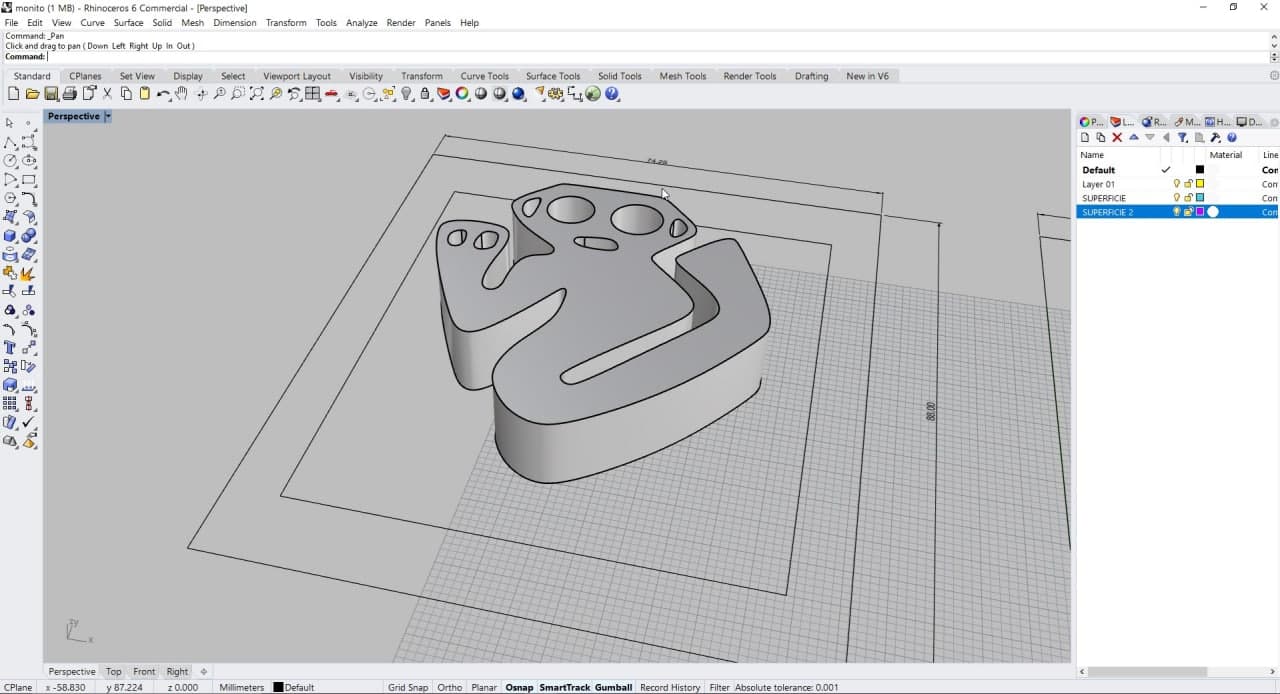

To continue the exercise, I made a top and a bottom part of the monkey mold. I added half spheres and holes to align the two parts. In addition, the holes where the silicone will be poured must be considered.

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

Ghost Monkey Mold in Fusion360

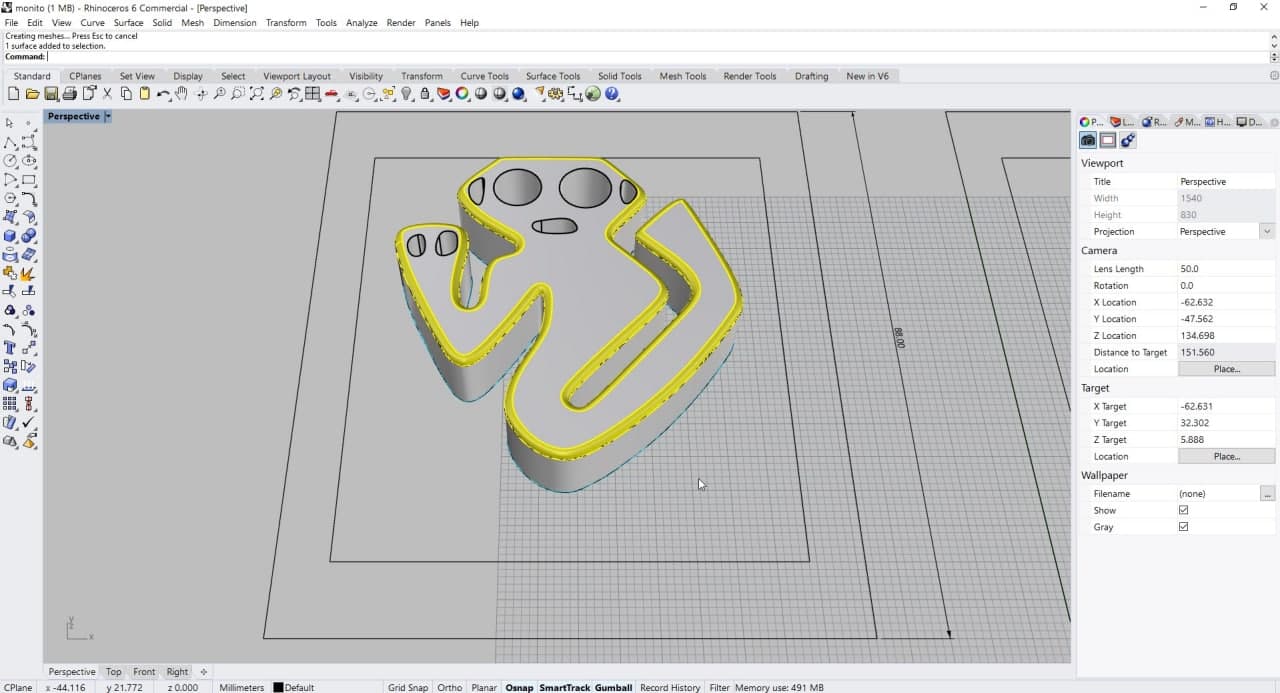

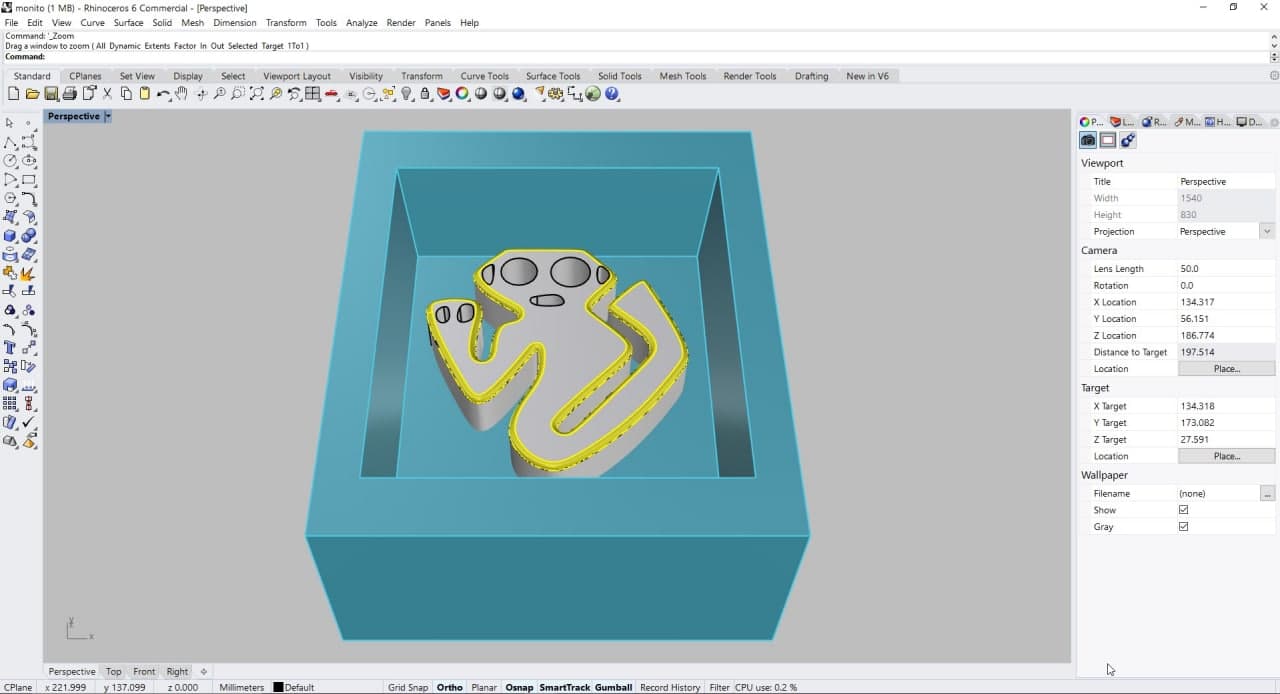

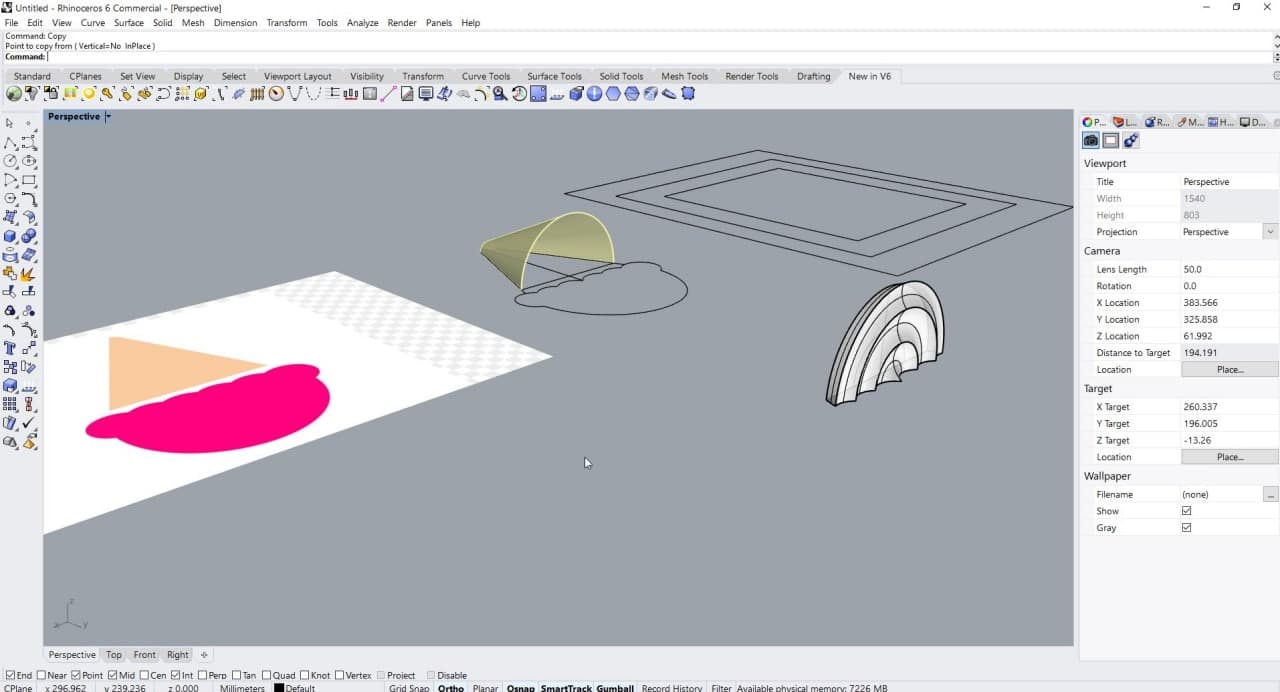

I also tried to make the monkey design in Rhinoceros, I used Fillet Surface, but I could only make 1mm radius of curvature. This is why I decided to change the design to an Ice cream.

Ghost Monkey Mold in Rhinoceros

Ghost Monkey Mold in Rhinoceros

Ghost Monkey Mold in Rhinoceros

Ghost Monkey Mold in Rhinoceros

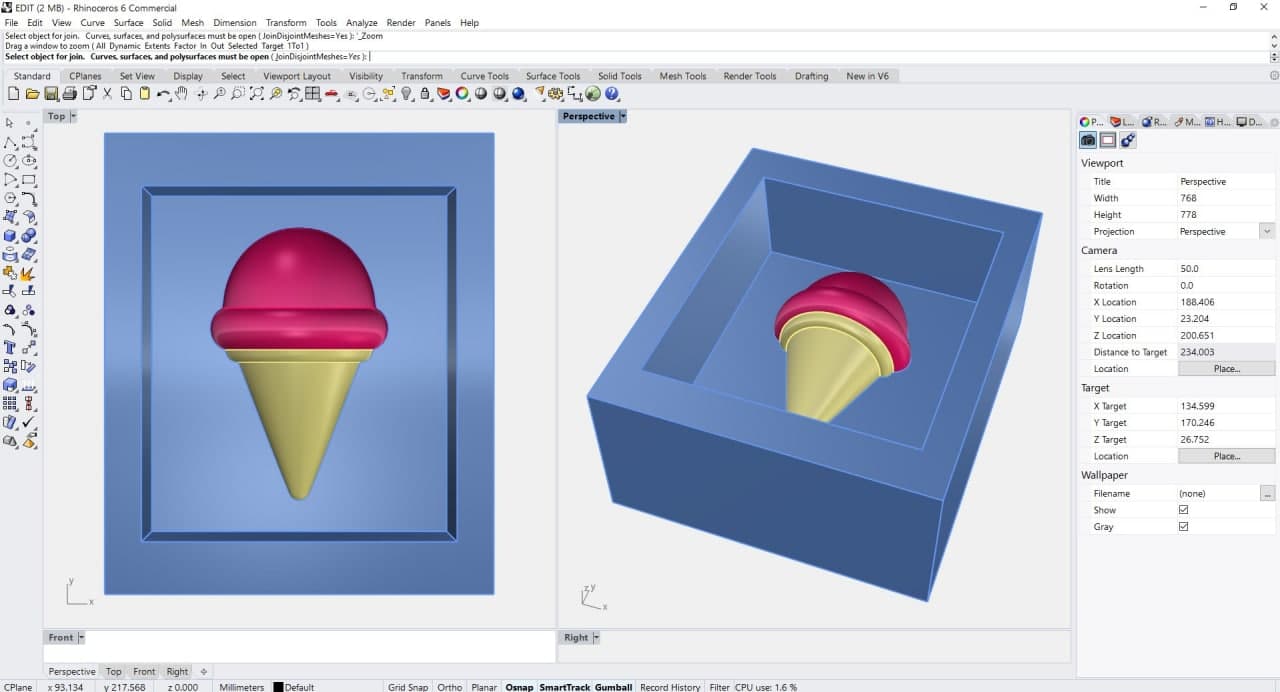

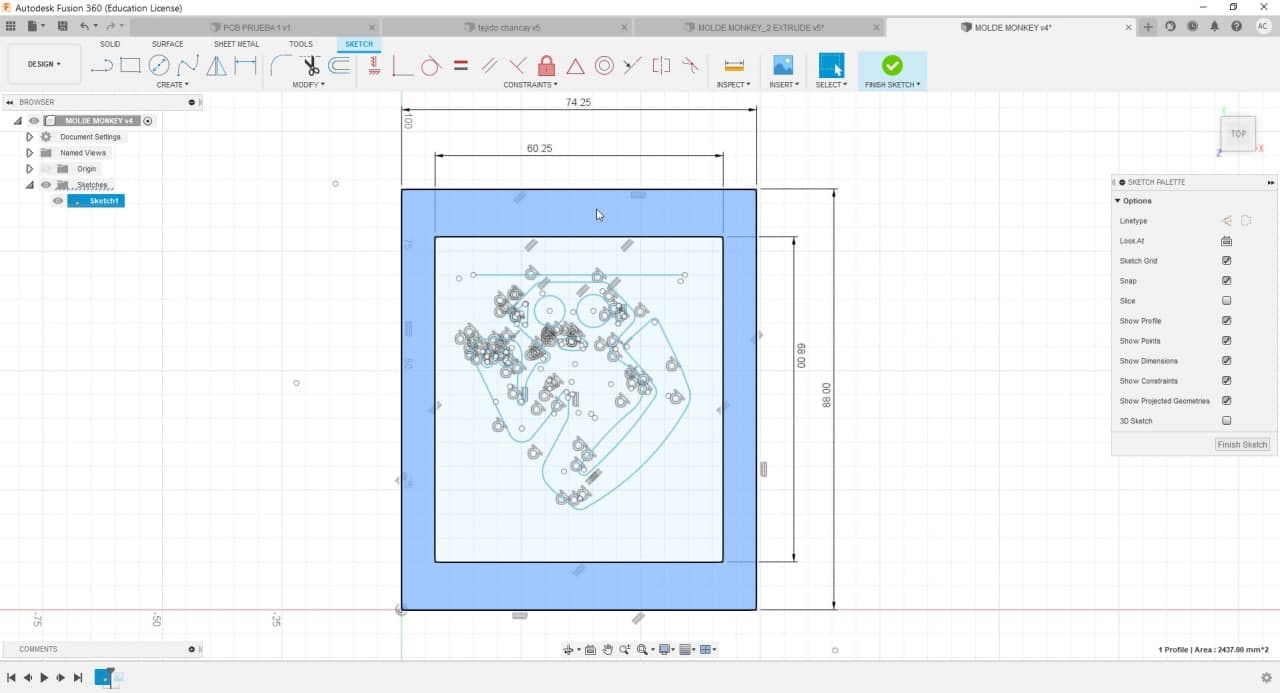

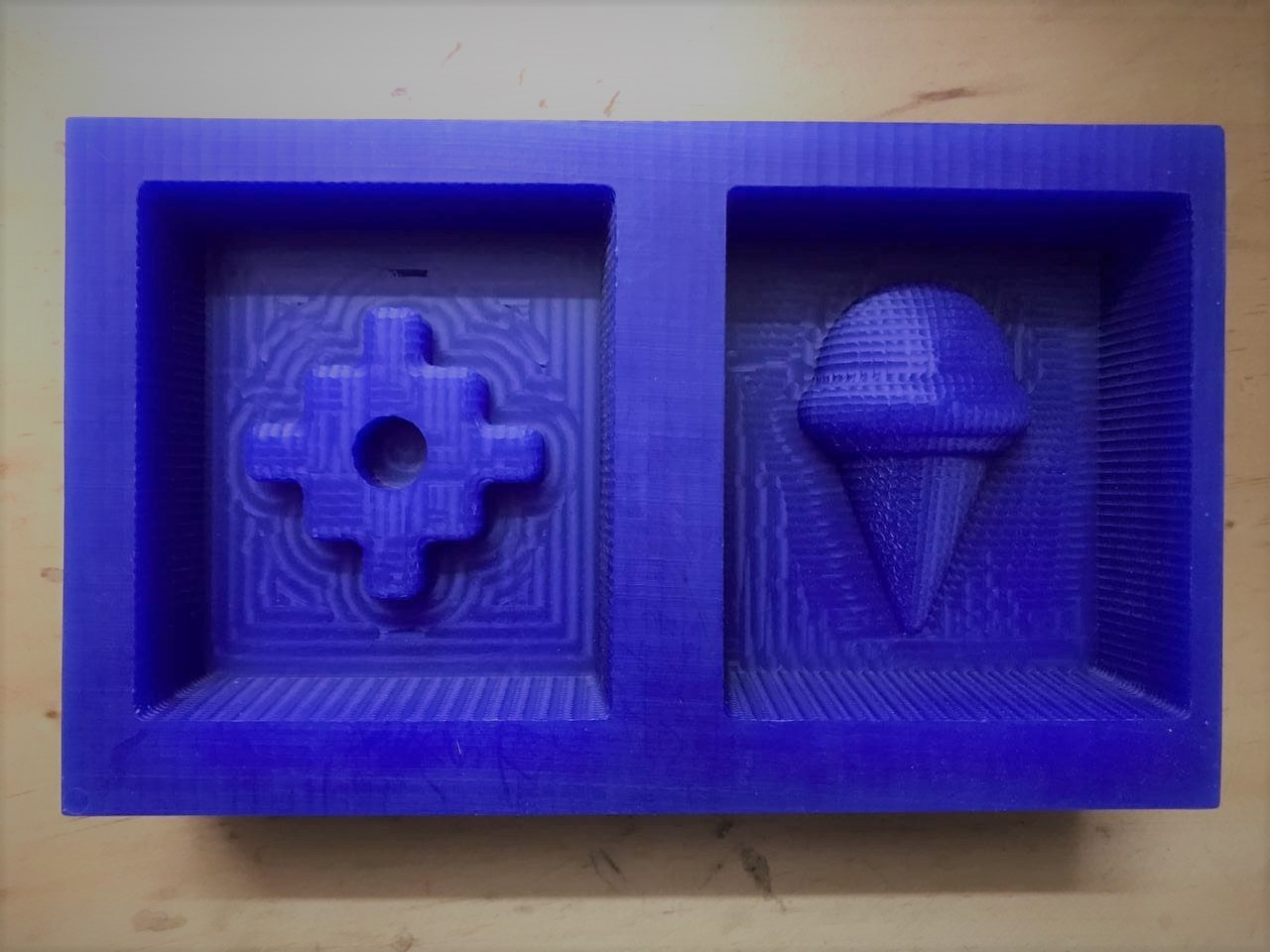

The finalDesign

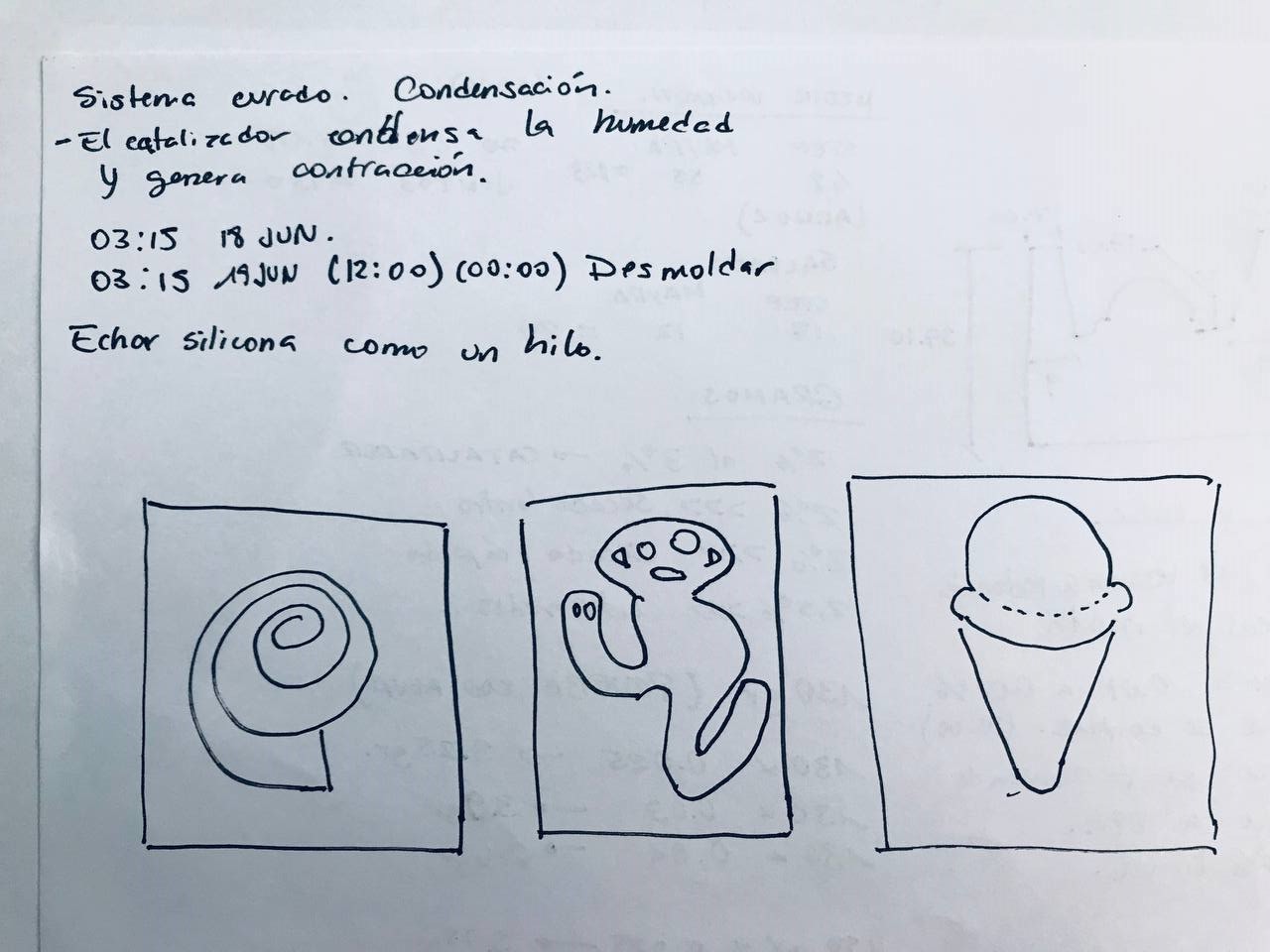

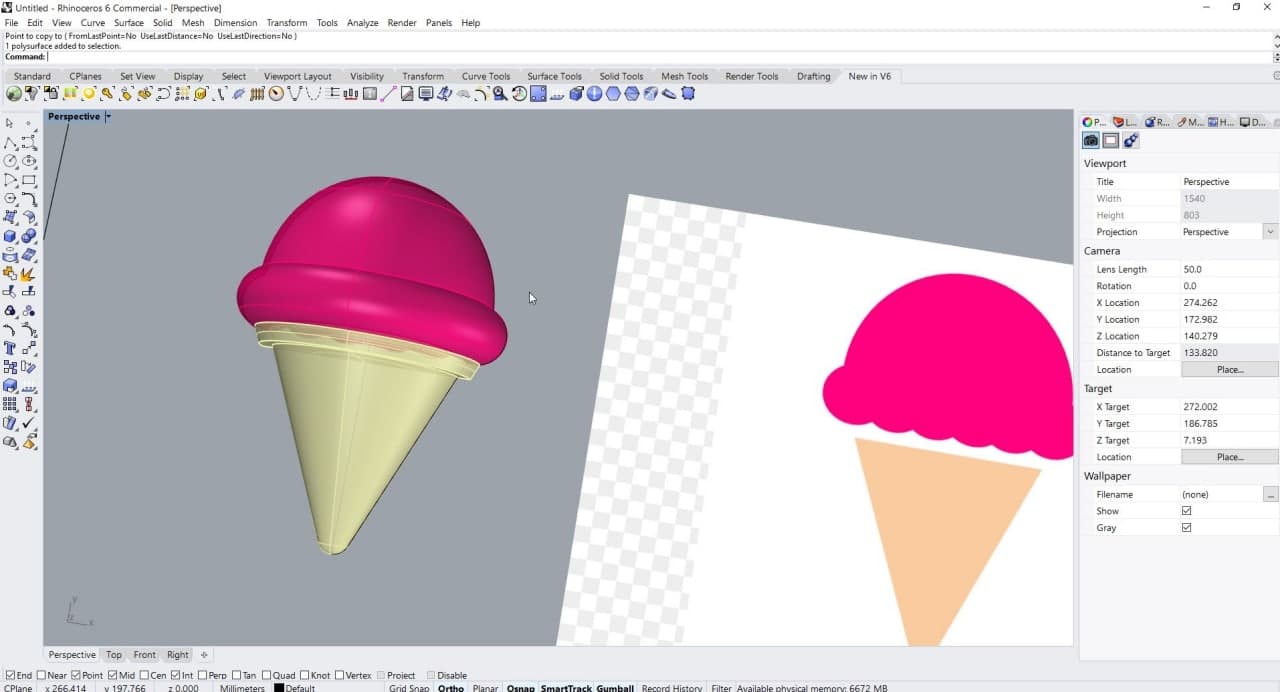

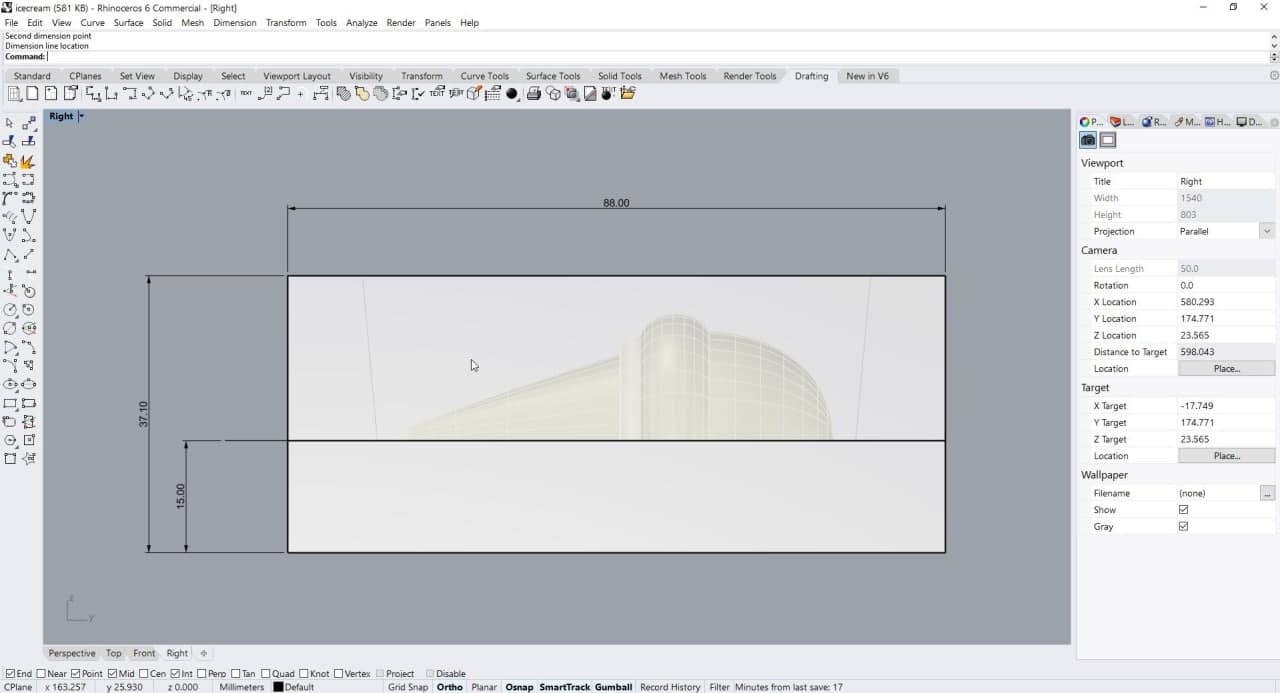

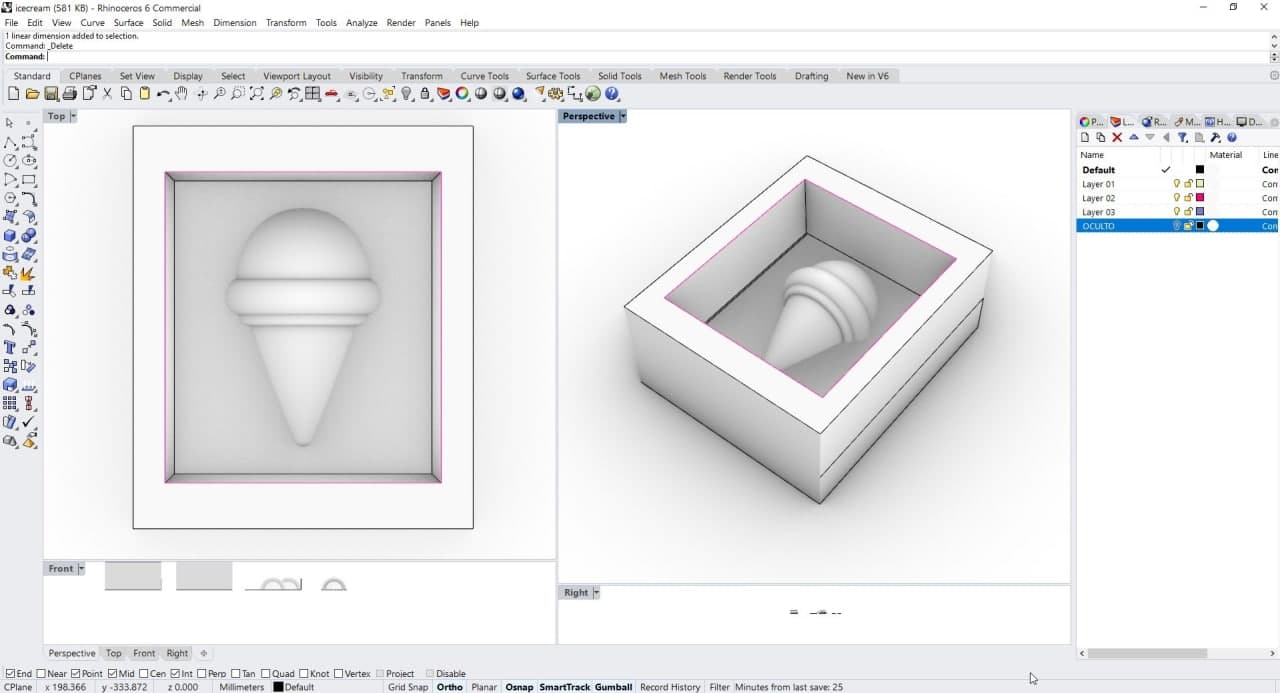

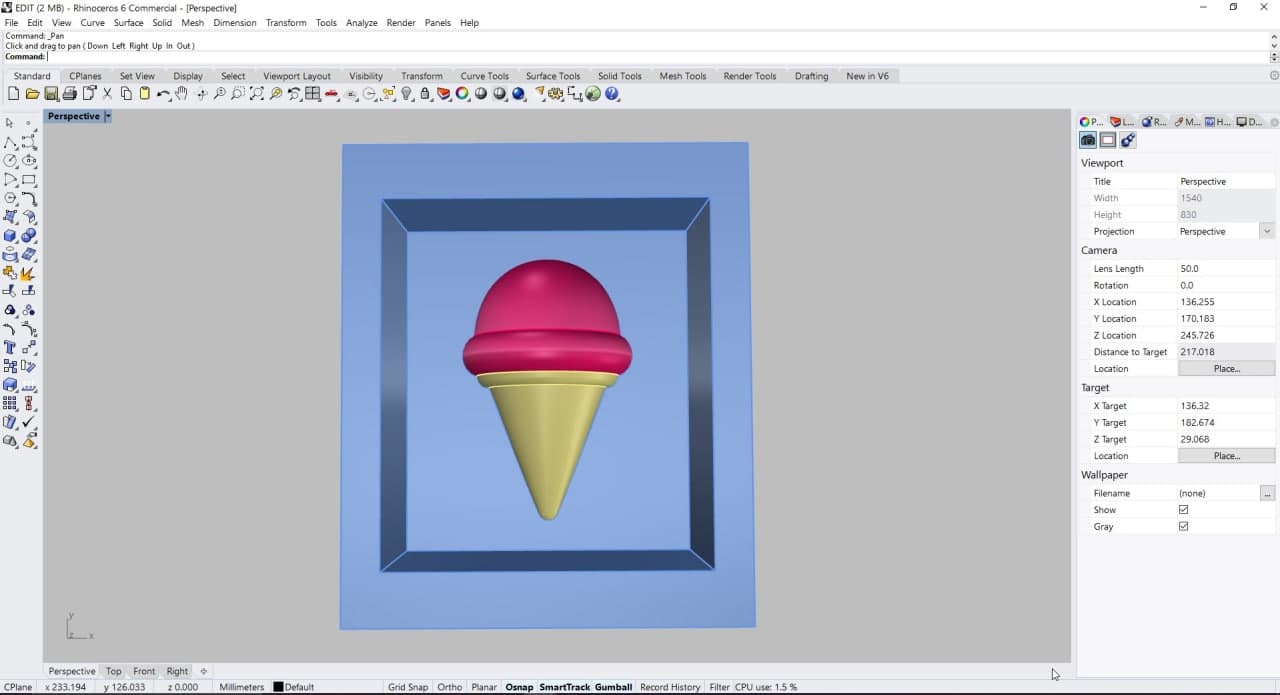

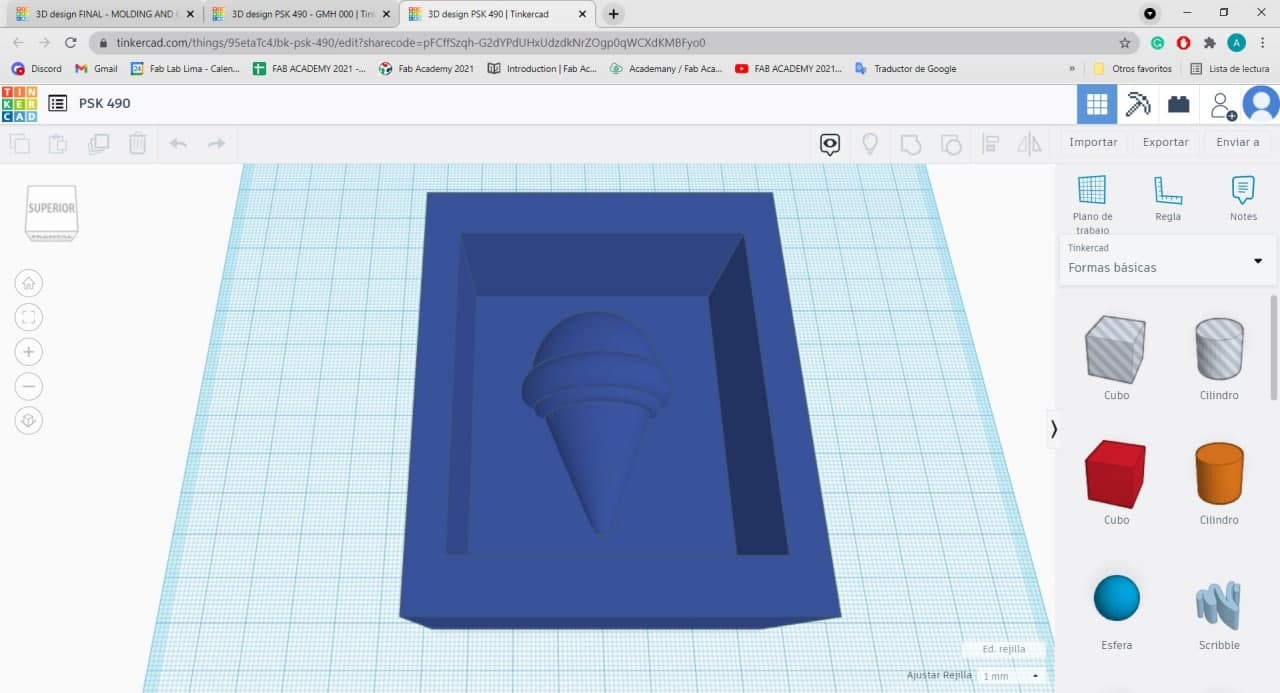

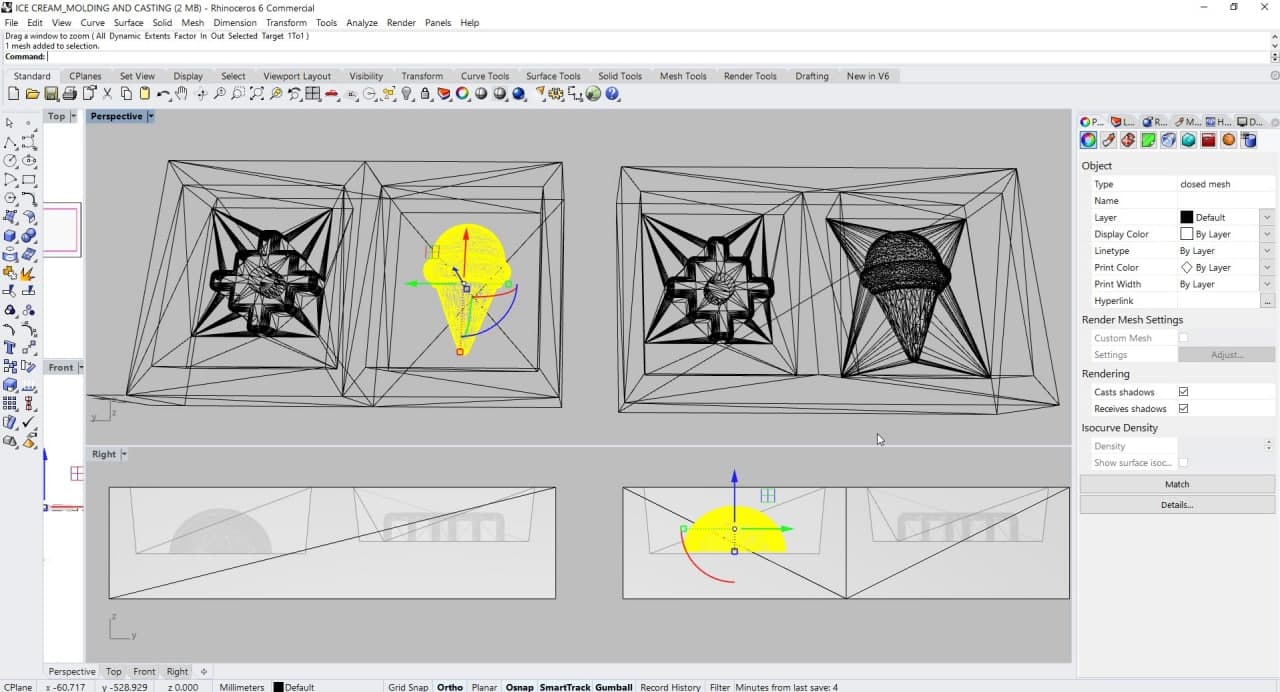

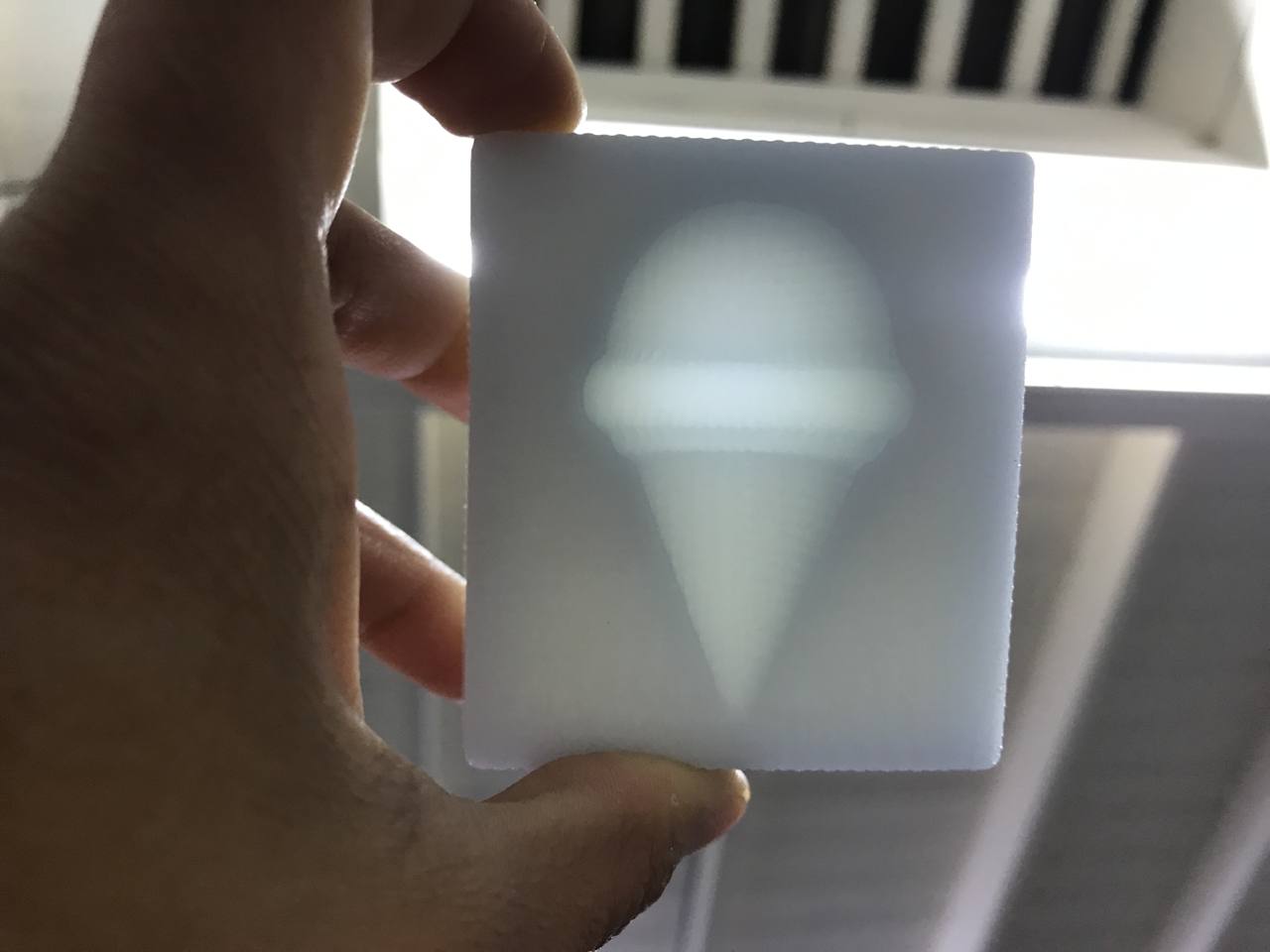

I chose an ice cream because of the complexity of its shape, I wanted to explore how the Modela worked with these types of surfaces. I made the design in Rhinoceros, traced an image and used the Revolve Curve command to get the half of the ice cream. The result was very good. Considering all the measurements previously explored, I designed the entire mold. I included the sloped interior walls. This helps to unmold the silicone much easier. It’s important to be aware that the mold to reproduce your shape is the silicone mold. The wax is a pre mold.

Notes to design

Notes to design

Ice Cream Mold in Rhinoceros

Ice Cream Mold in Rhinoceros

Ice Cream Mold in Rhinoceros

Ice Cream Mold in Rhinoceros

Ice Cream 3D Mold

Ice Cream 3D Mold

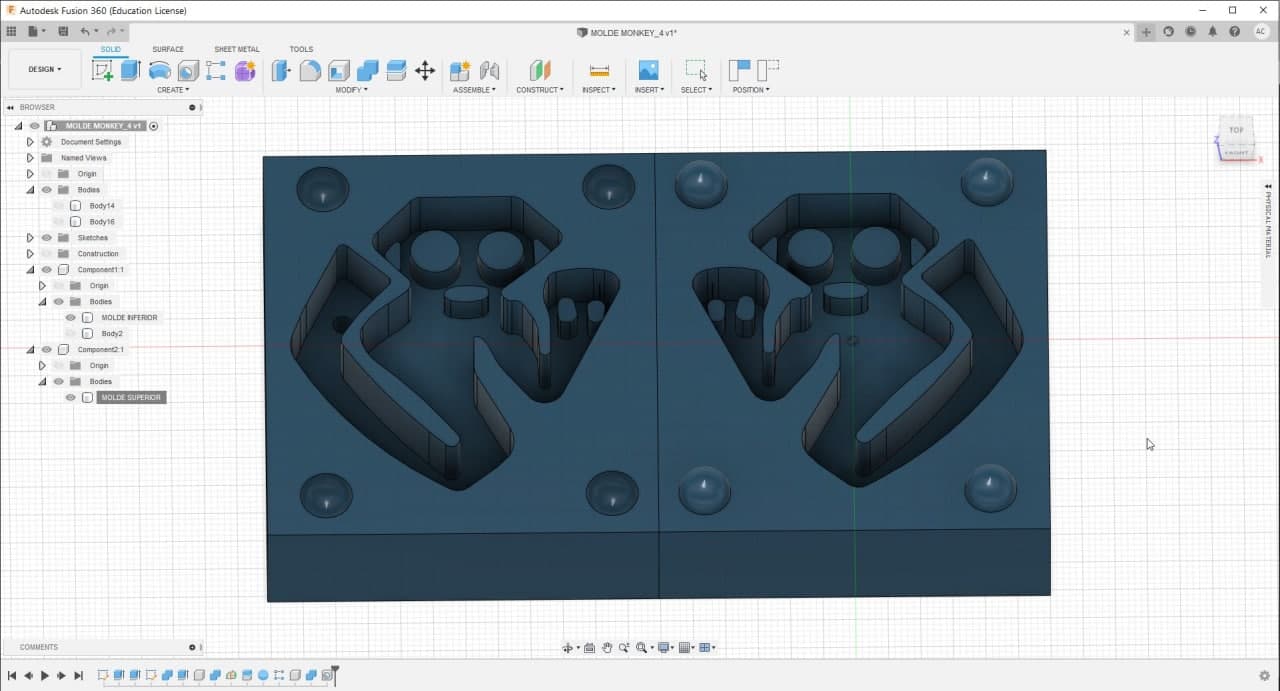

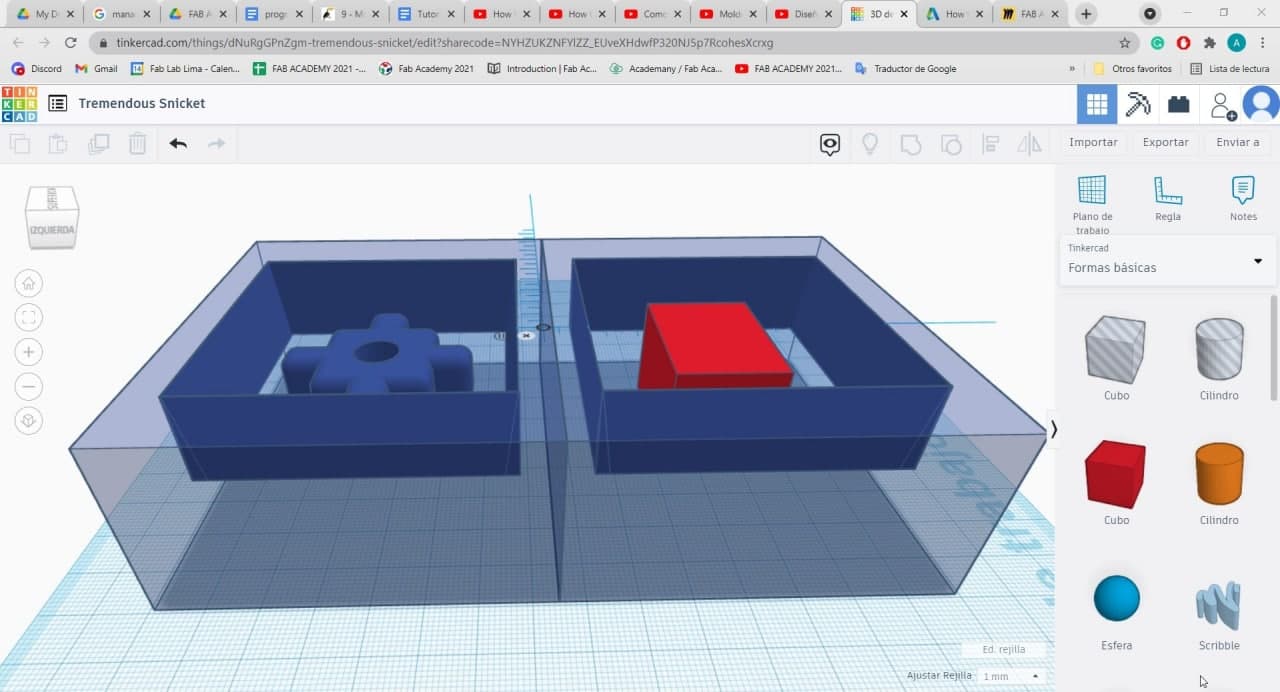

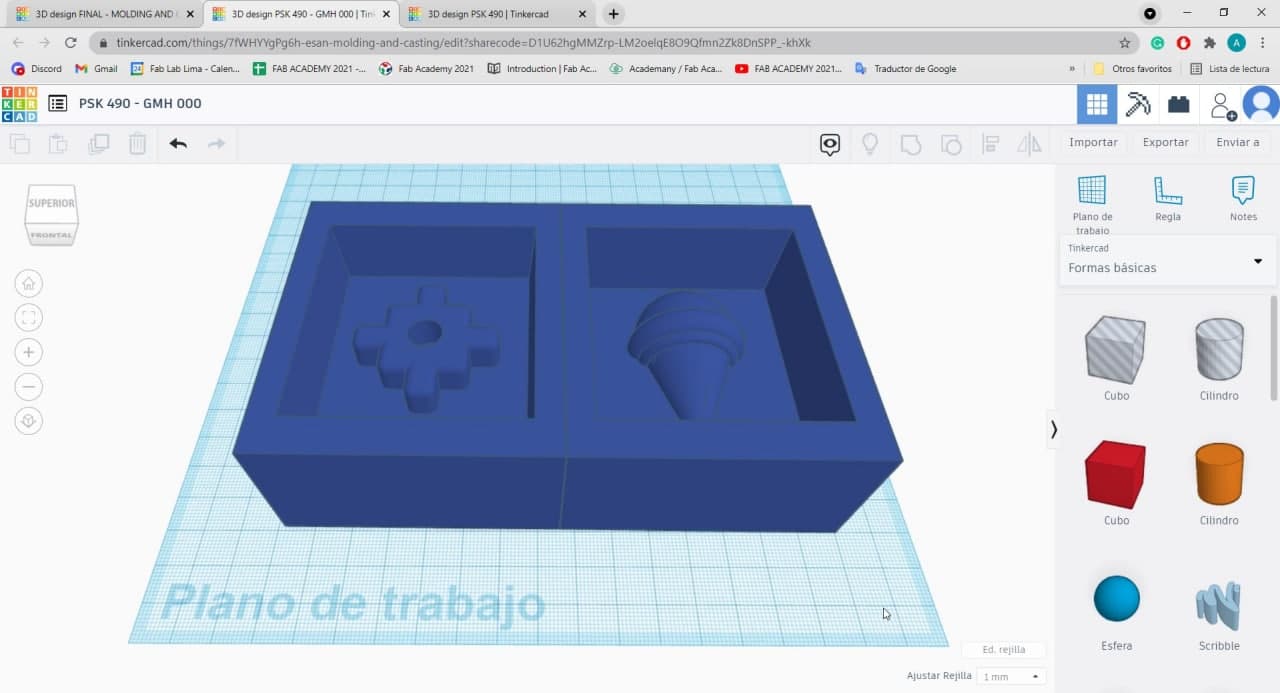

Joining the designs

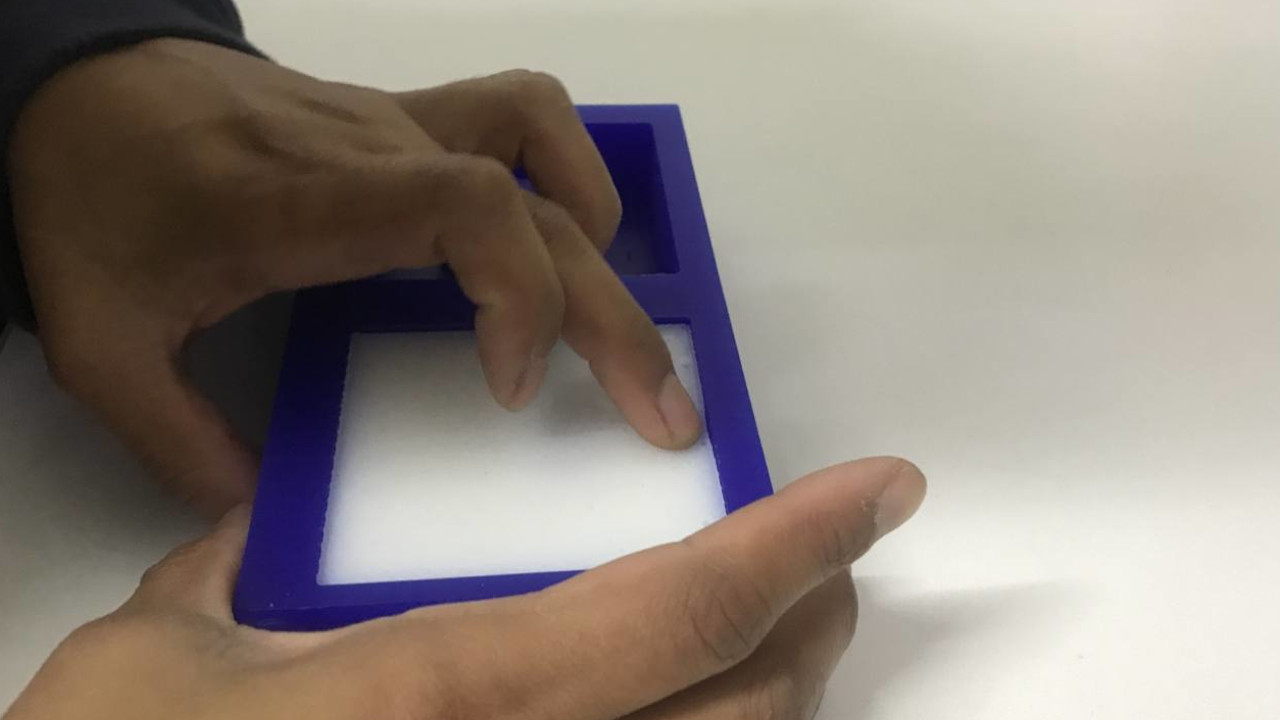

Optimizing the only wax block that "Rebecca" has and that she will kindly share with me. We decided to join our designs into a simple software: Tinkercad. The plan was that each one would make a one-sided mold. Then we import the designs in .STL format and put them together in an online file. It was quite simple, I recommend this method. Finally, we export the file in .stl format. We have a single block ready for machining!

Measurements in Tinkercad

Tinkercad - Joining our molds

Tinkercad - My mold

Tinkercad - Mold together

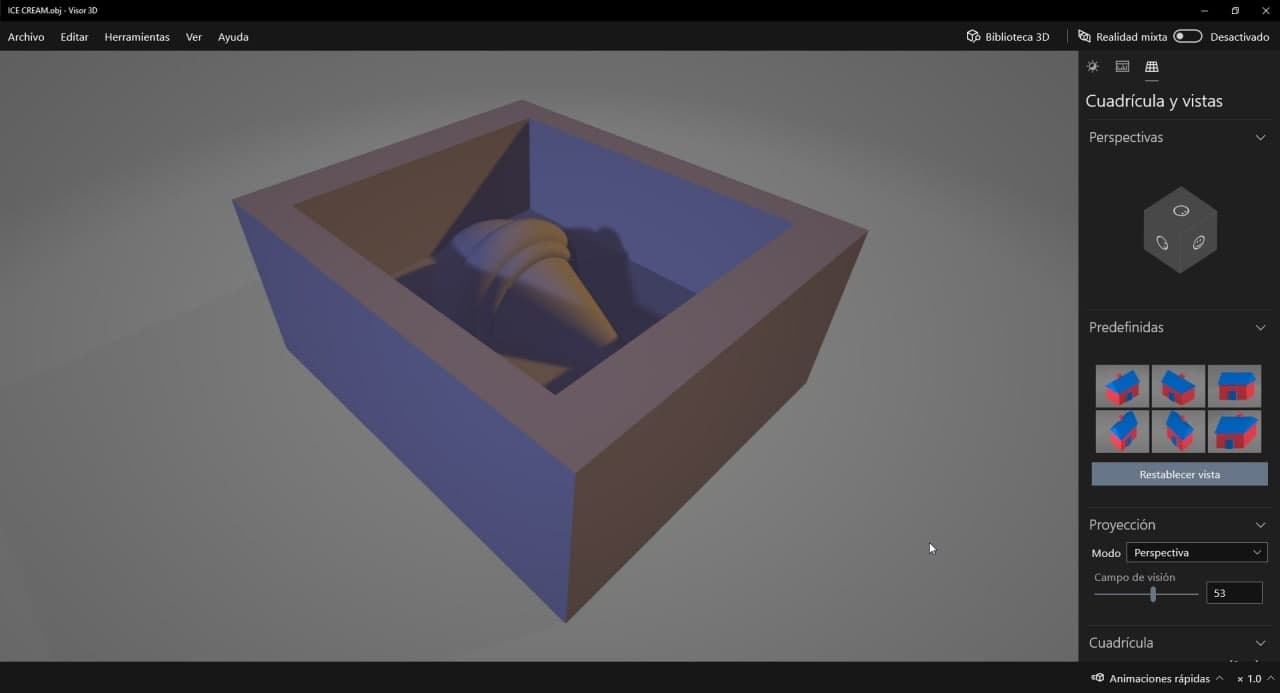

It's necessary to check your file in a program to see if everything is working correctly. When we opened the whole mold file in Rhinoceros after importing from Tinkercad, we discovered that the ice cream was flying. And it hadn't really merged, so we corrected it.

Checking the mold

Millingthe Wax

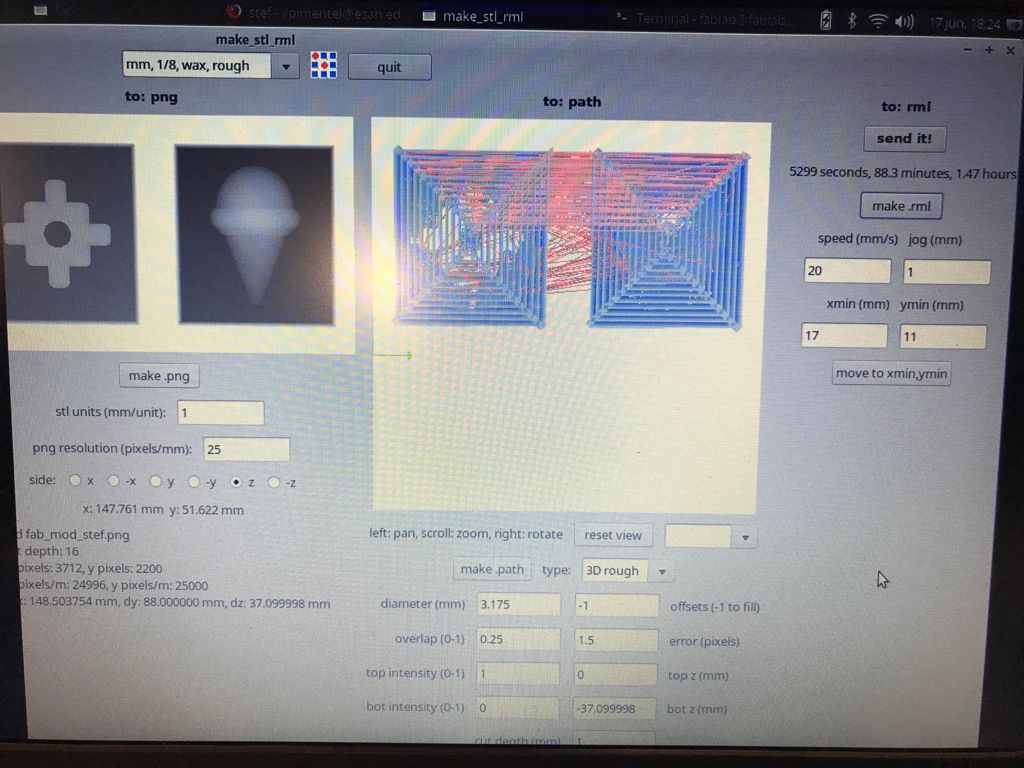

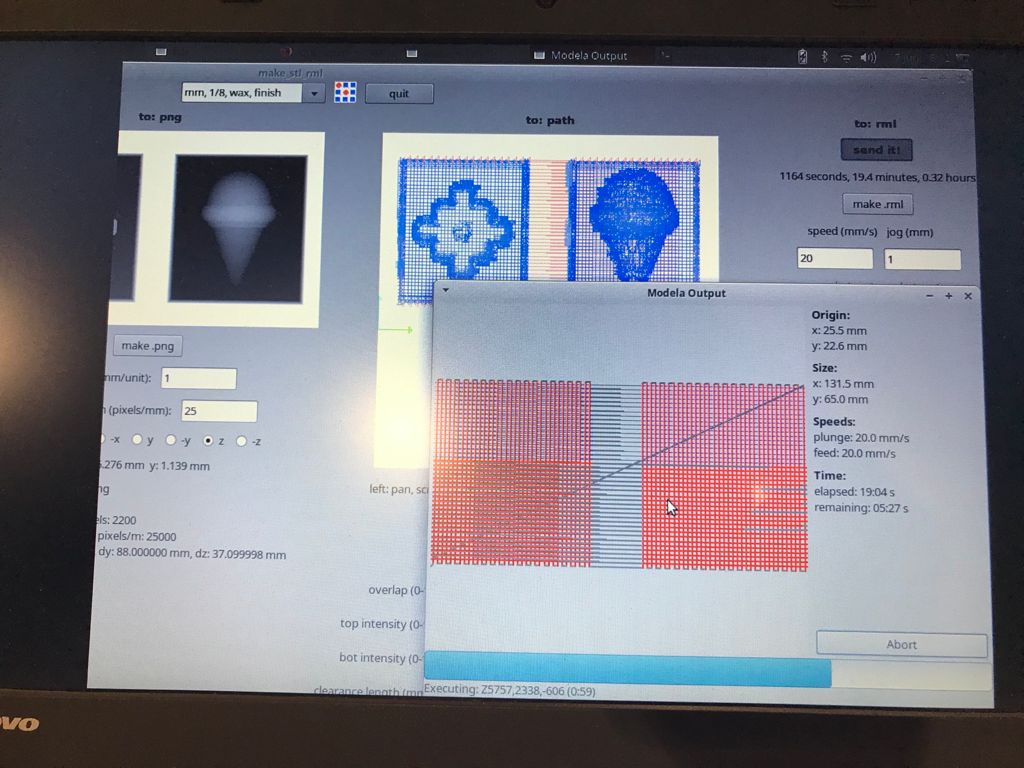

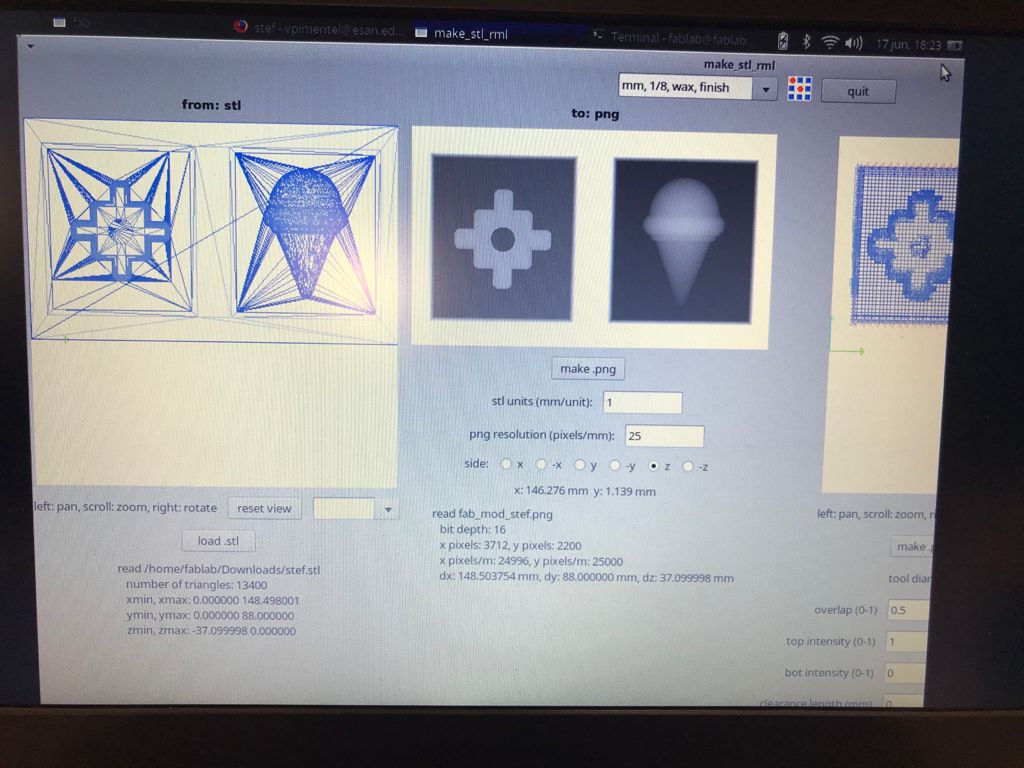

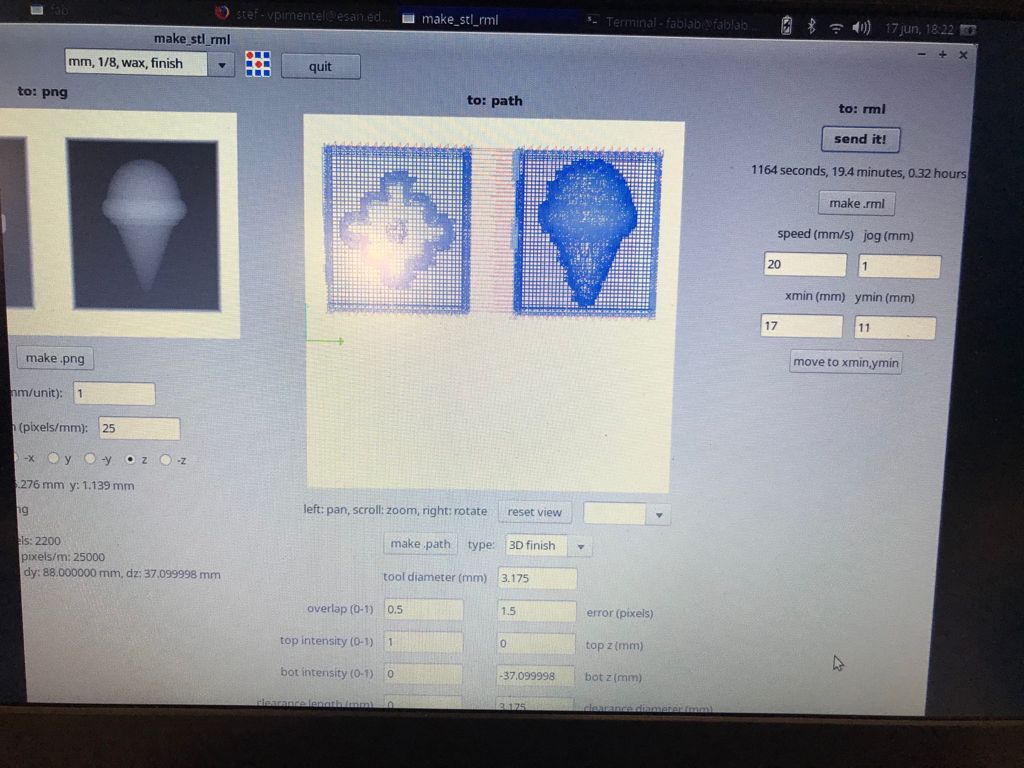

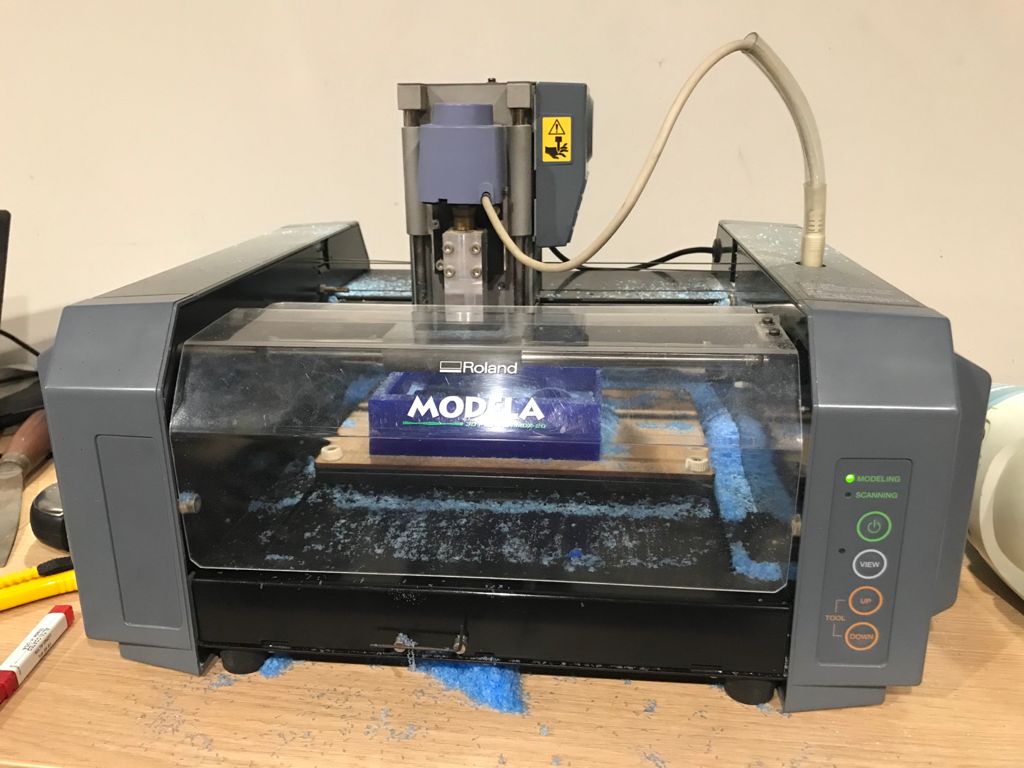

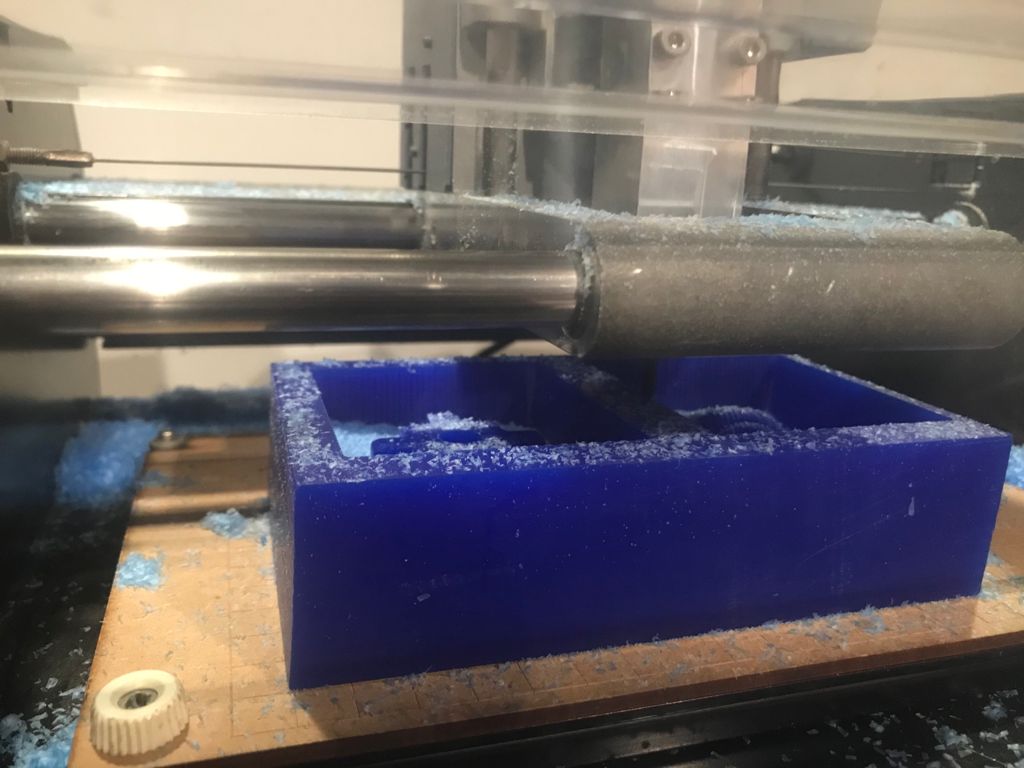

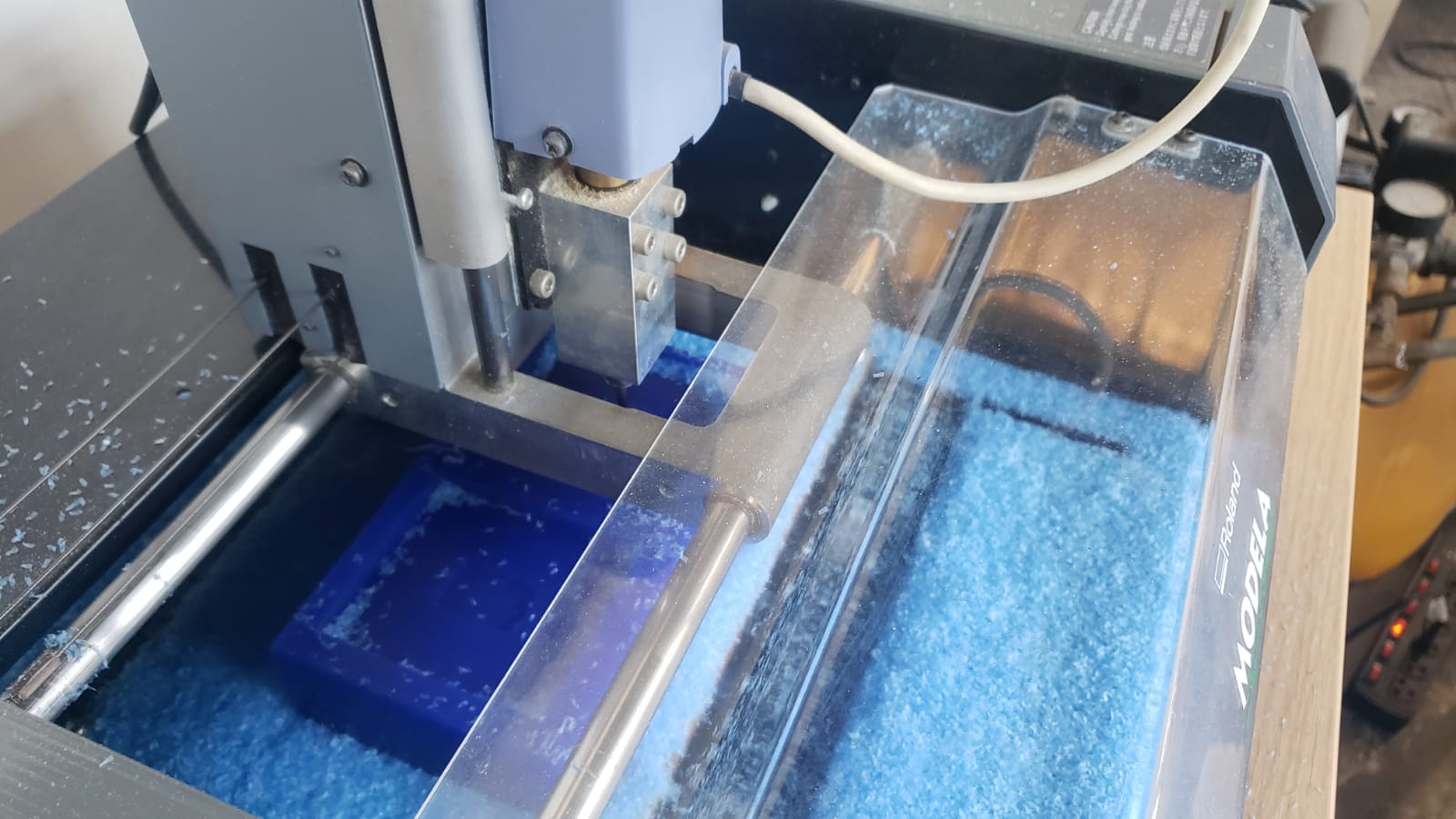

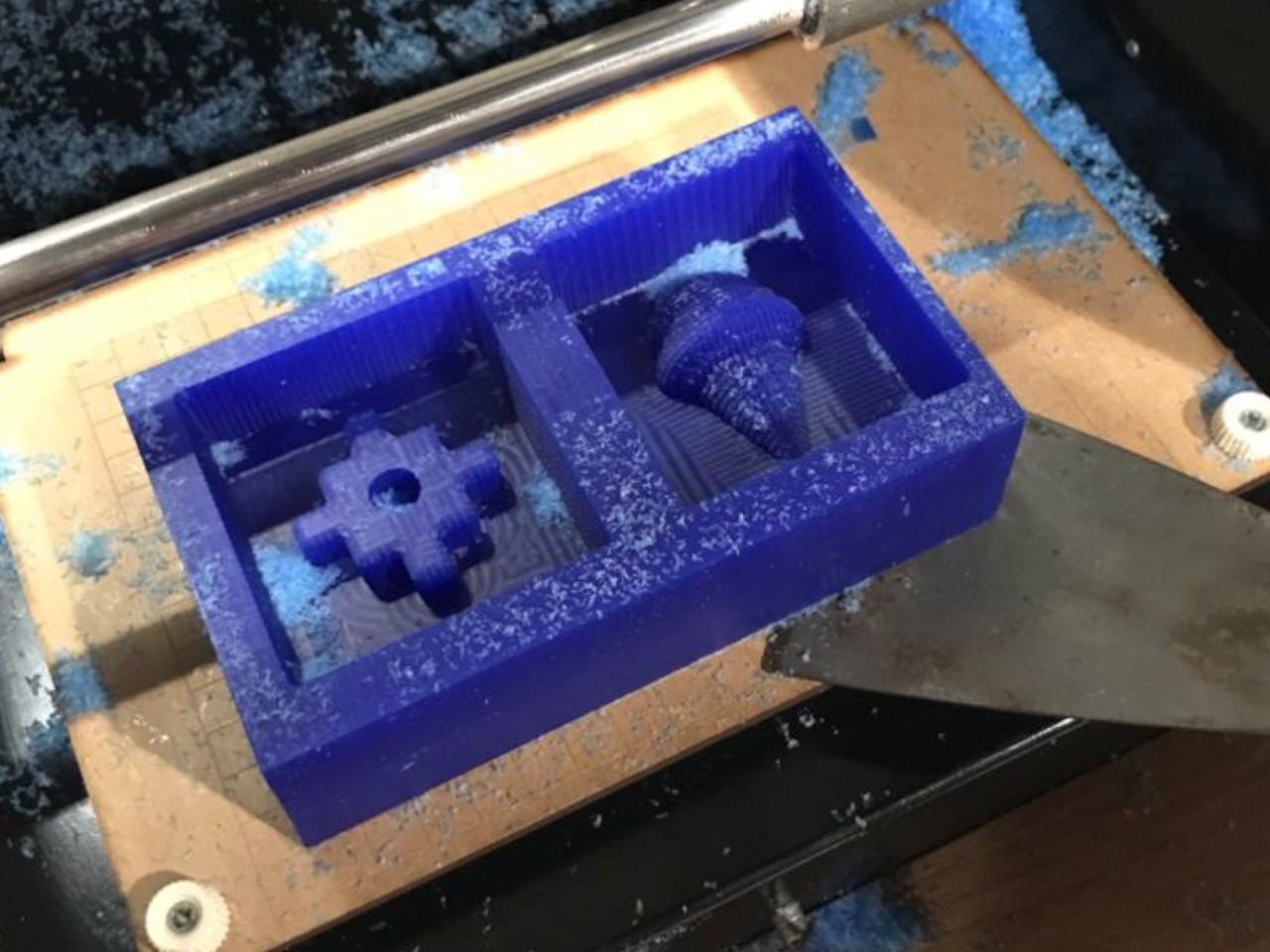

It's time to move on to the milling process. Thanks to Fab Lab Esan and its instructors for allowing us access to equipment, we were able to carry out this part of the task. We use the Modela MDX-20 together with the Fab Modules to achieve the machining of our wax block. Together with Mayra, we successfully achieved this goal and now we have a joint wax mold ready to go to the "Casting" stage.

Modela_FabModules_parameters

Modela_FabModules_parameters

Modela_FabModules_parameters

Modela_FabModules_parameters

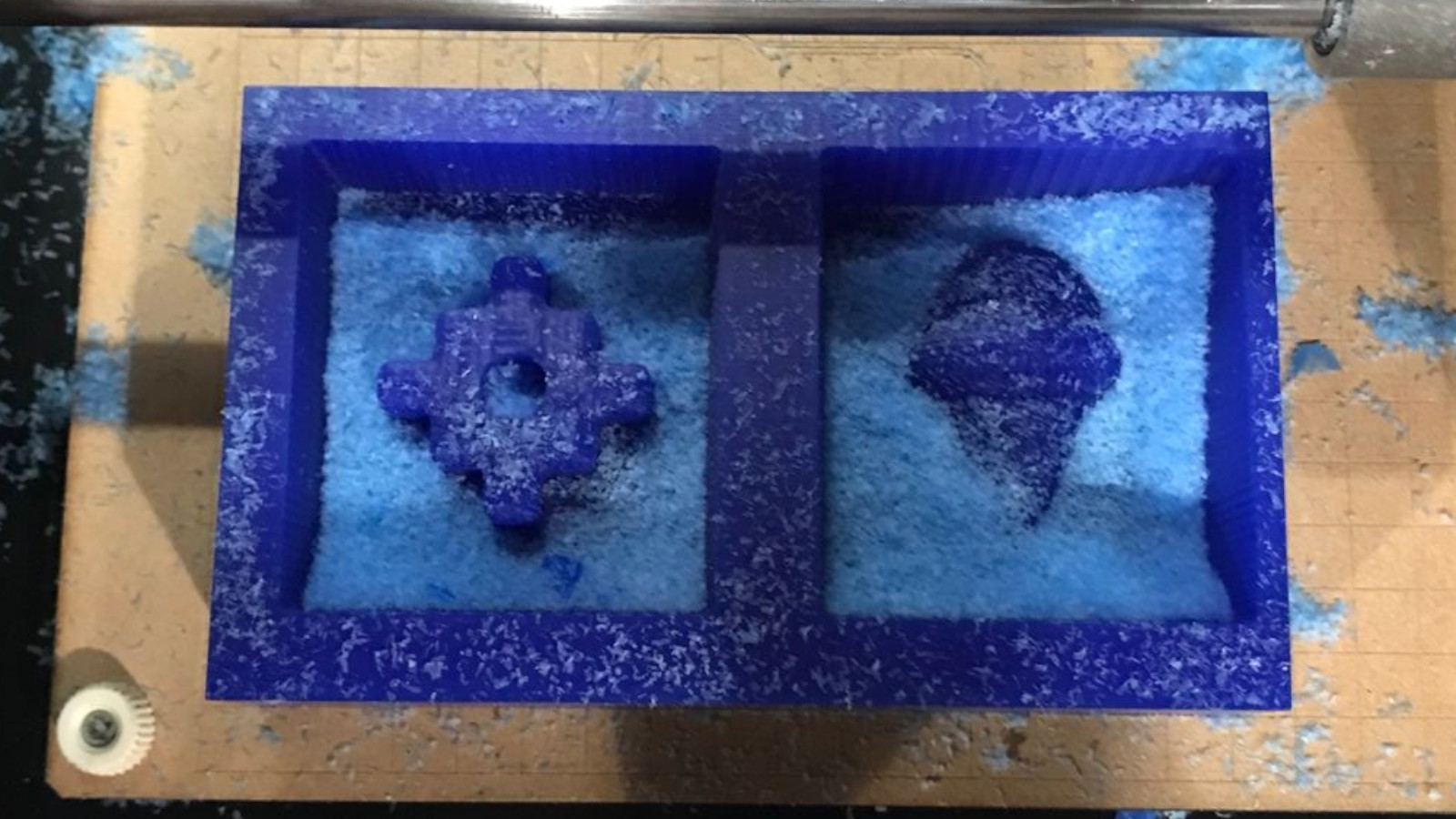

Modela Mdx-20 Milling Process

Modela Mdx-20 Milling Process

Modela Mdx-20 Milling Process

Modela Mdx-20 Milling Process

Modela Mdx-20 Milling Process

Modela Mdx-20 Milling Process_Final

Wax Mold

Wax Mold

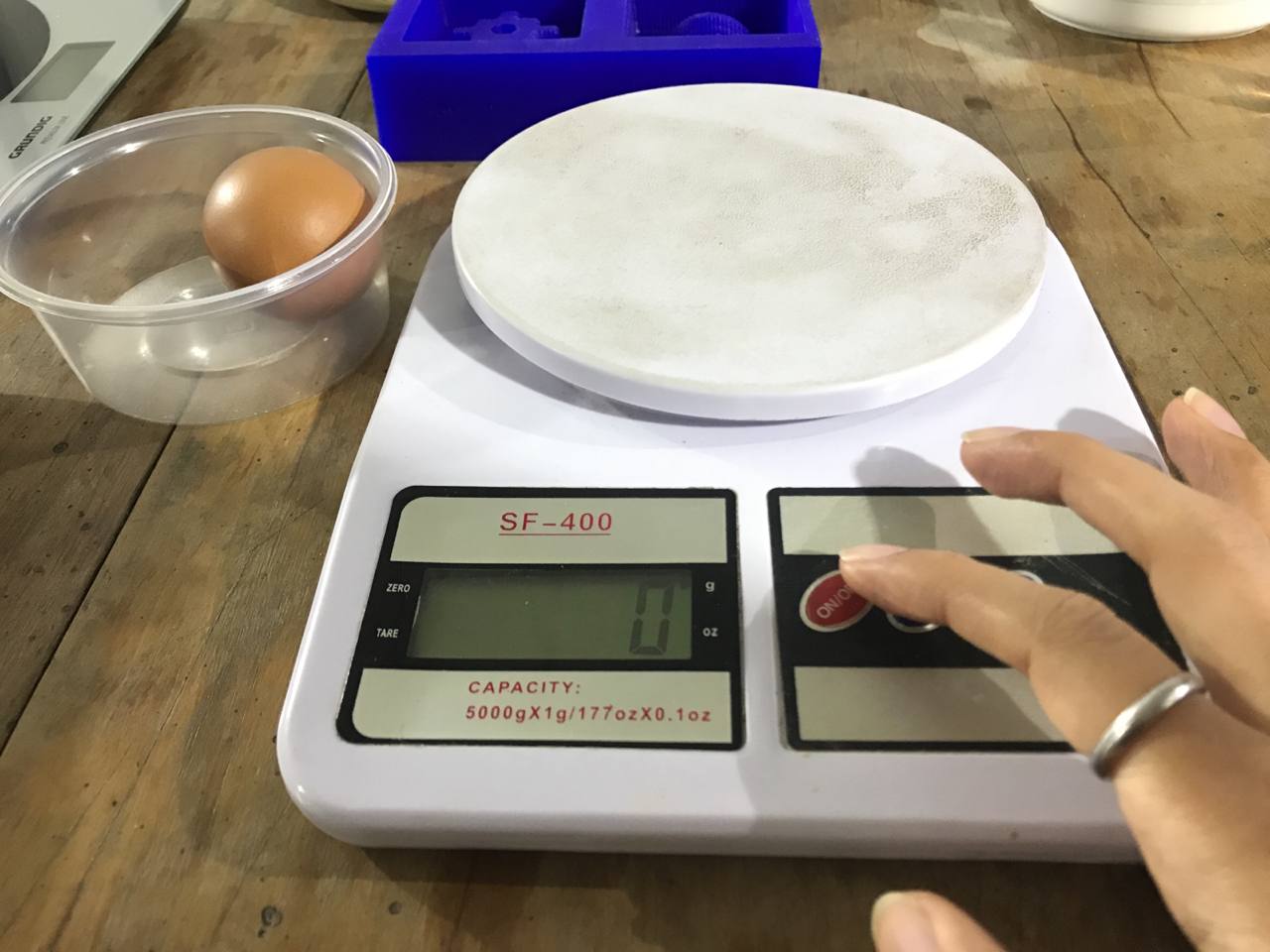

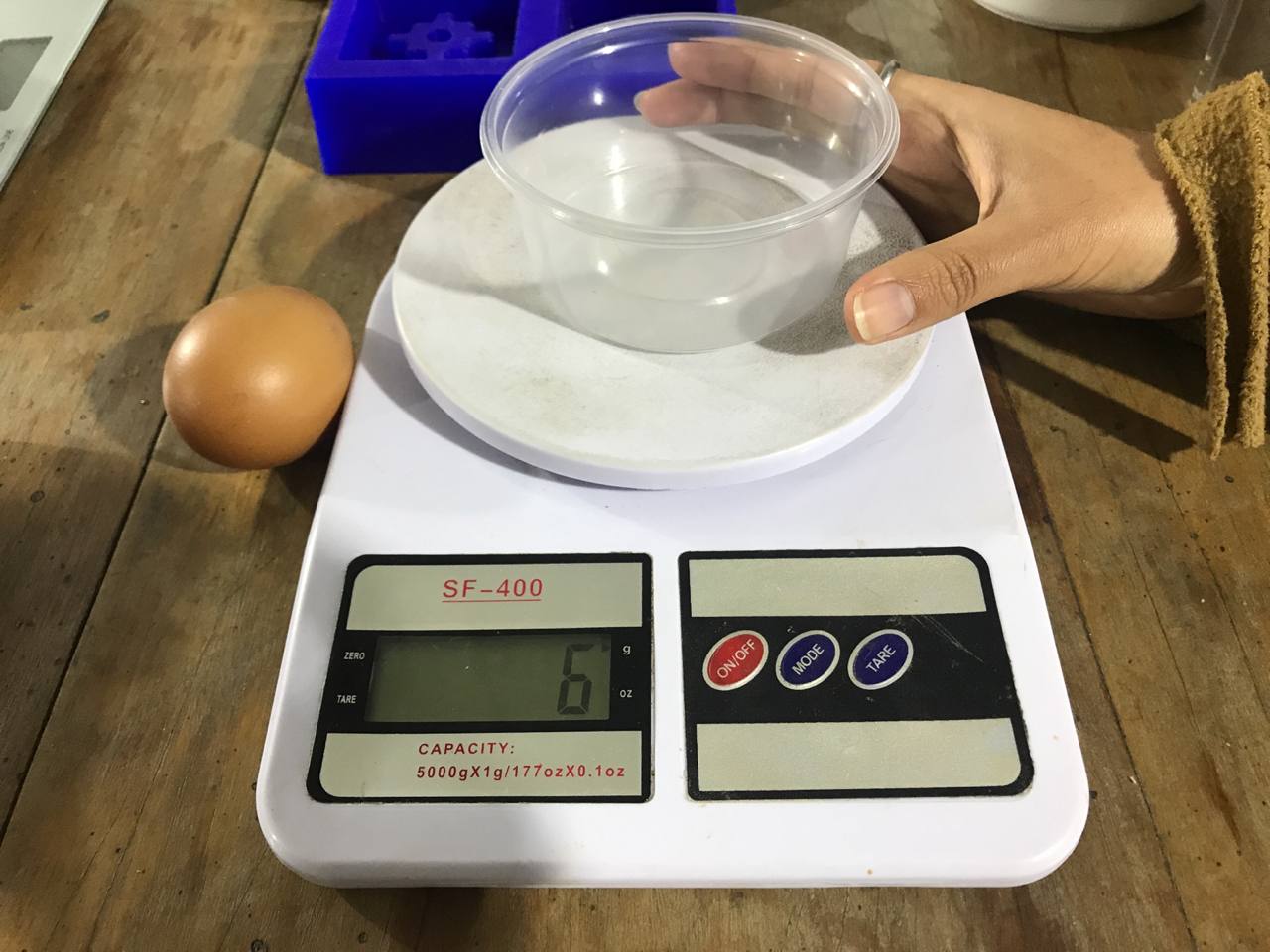

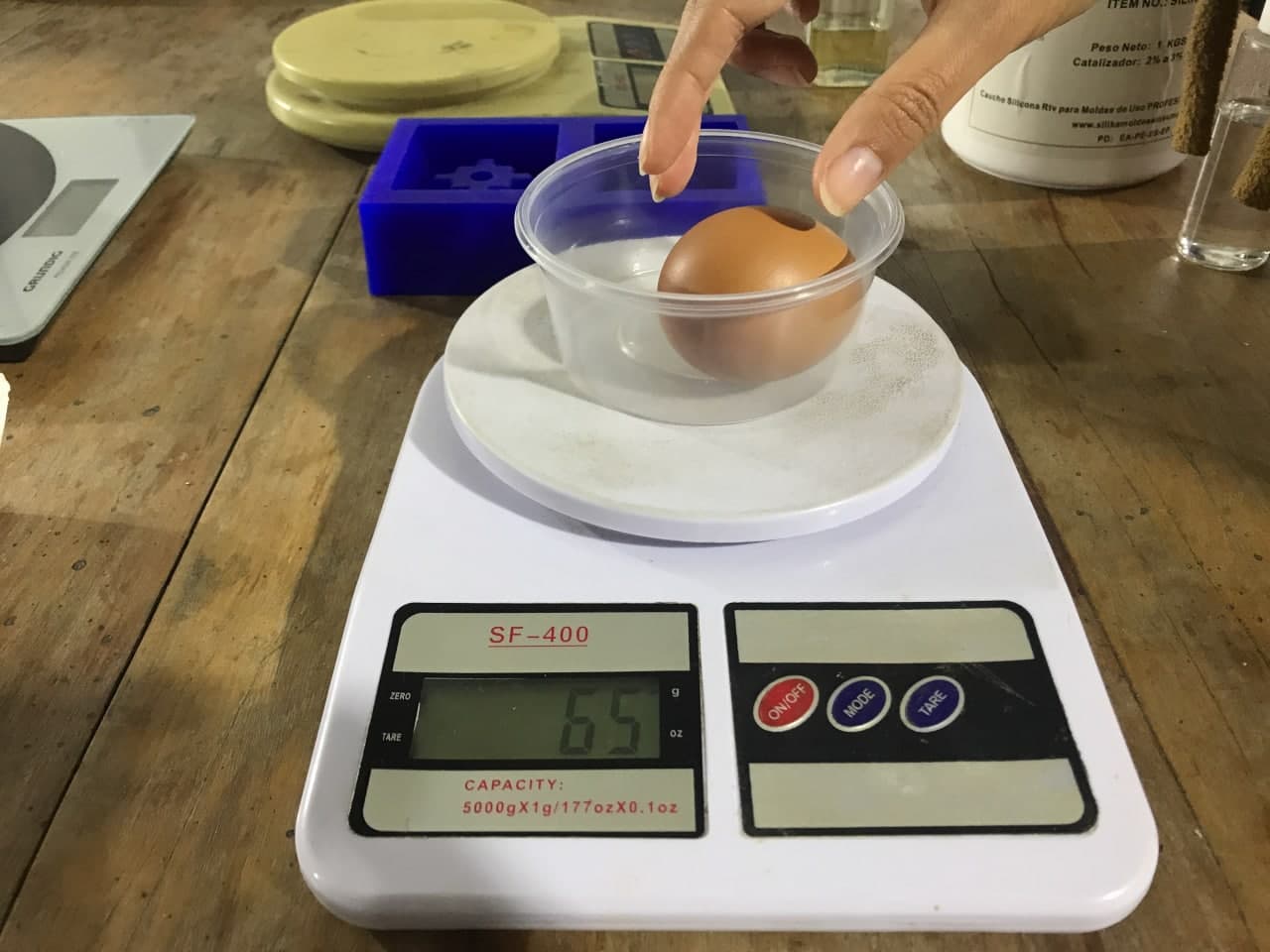

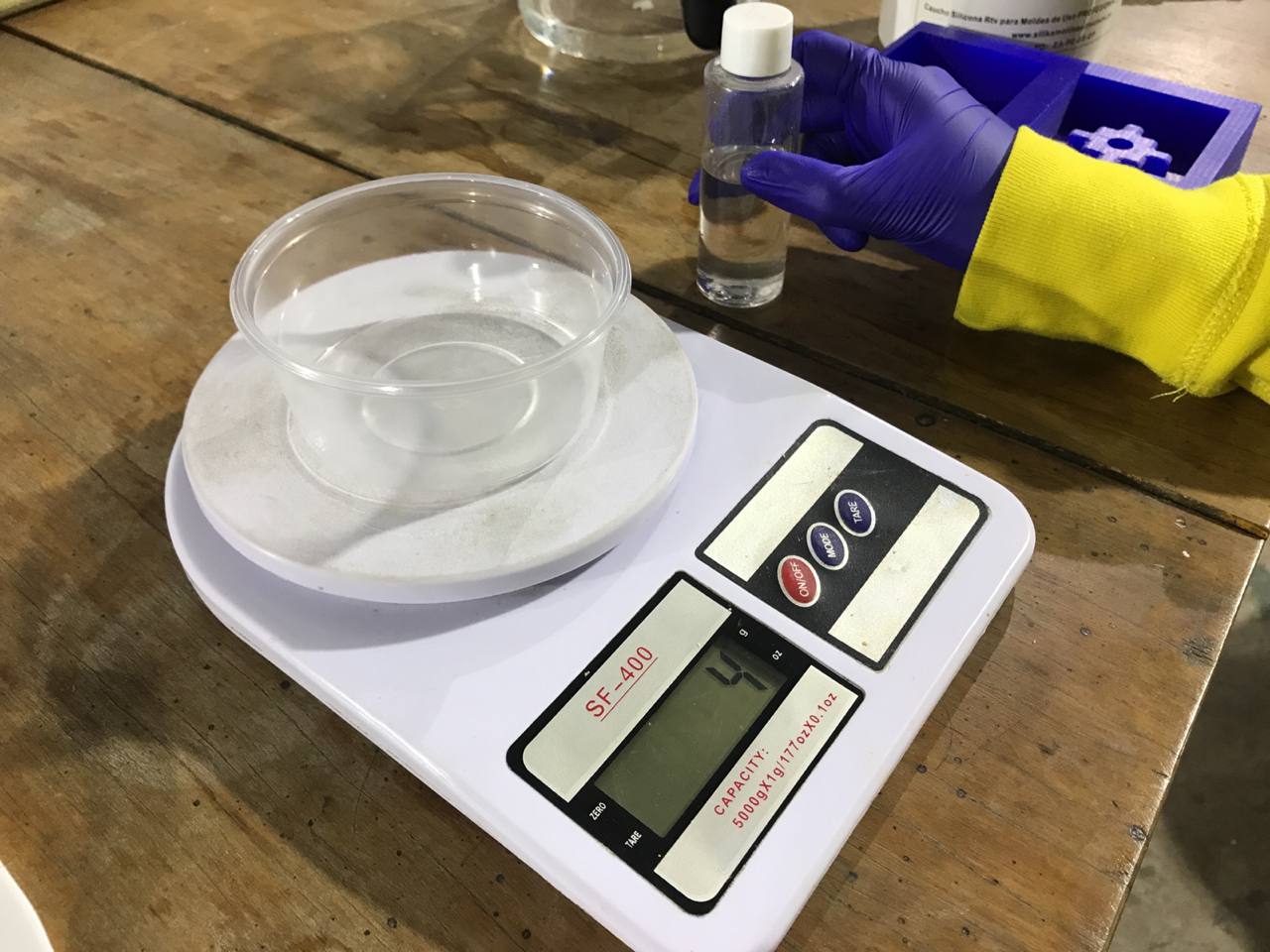

TareProcess

Before any casting in Silicone, we first had to measure the amount in grams that we needed to prepare. It’s important to take the weight of the container away from the weight of the material being weighed on the scale. For this, we first weigh an egg. Then we weigh the empty container, press the button that says "Tare" and the scale returns to 0, we put the egg into the container and the scale gives you the weight of the egg and subtracts the weight of the container. In this way, we obtained an accurate weight.

Weigh the egg

Start the scale

Weigh the empty container

Press the button: Tare

Weigh all

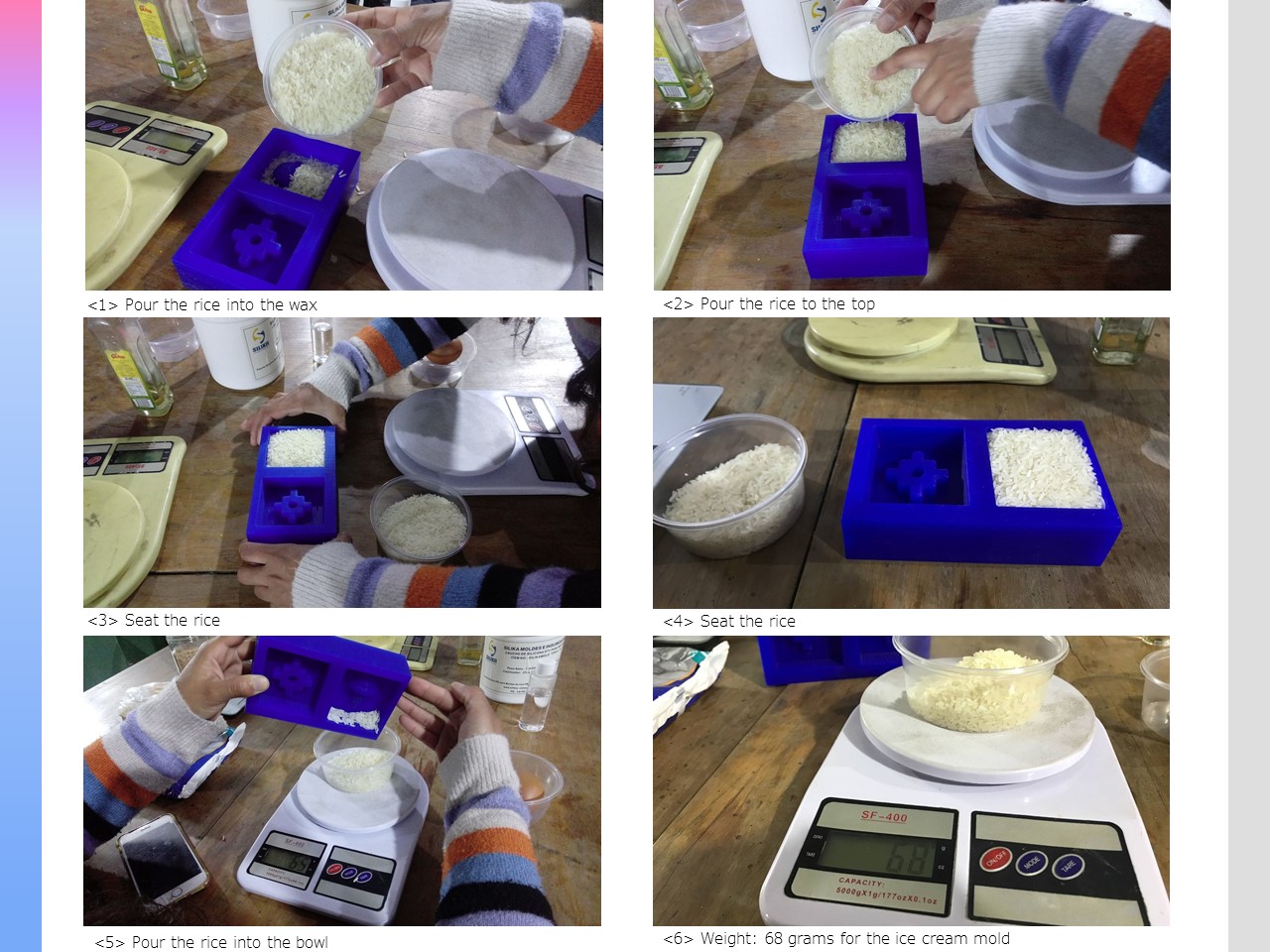

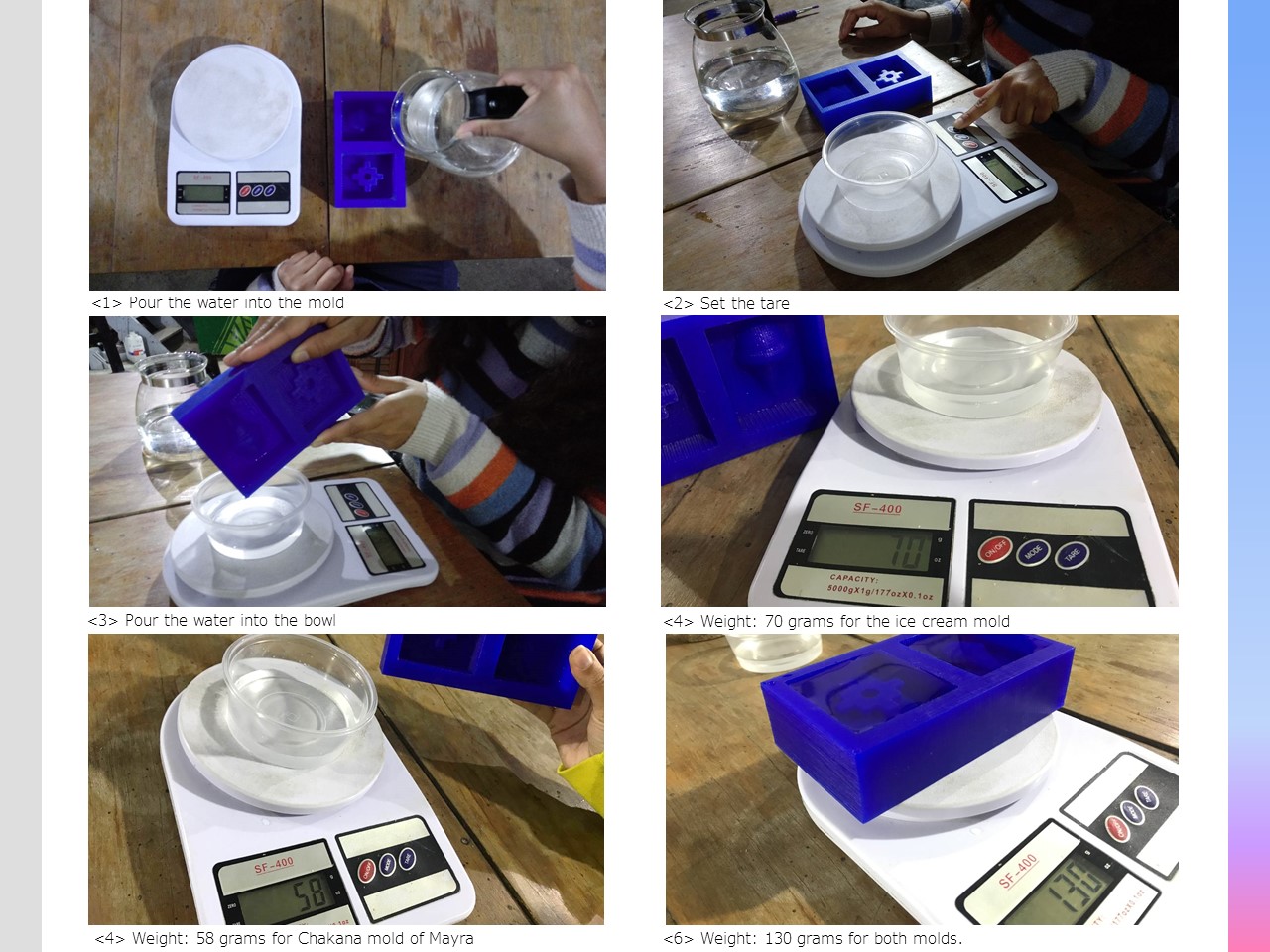

Pre-CastingProcess

After learning how to use the scale correctly, we decided to measure the amount of grams that we needed with different elements; Rice, Wheat bran and Water. So we gather all the materials we need.

Materials

Silicone Process

Measurement with Rice

In the rice test the data were similar to the water test, we obtained the following data:

- Ice Cream Mold: 68 grams

- Chakana Mold: 55 grams

- Total: 123 grams

Measurement with Rice

Measurement with Wheat Bran

In the Wheat Bran test, the data was very intriguing, apparently the wheat has more volume than its real weight, the measurements were much lower than the other two tests, we obtained the following data:

- Ice Cream Mold: 17 grams

- Chakana Mold: 12 grams

- Total: 29 grams

Measurement with Wheat Bran

Measurement with Water

In the test with Water, we did the measurement separately and also of everything together. The result is closer to the measurement with rice, but even more accurate. We obtained the following data:

- Ice Cream Mold: 70 grams

- Chakana Mold: 58 grams

- Total: 128 grams

- Complete mold: 130 grams

Measurement with Water

Castingwith Silicone

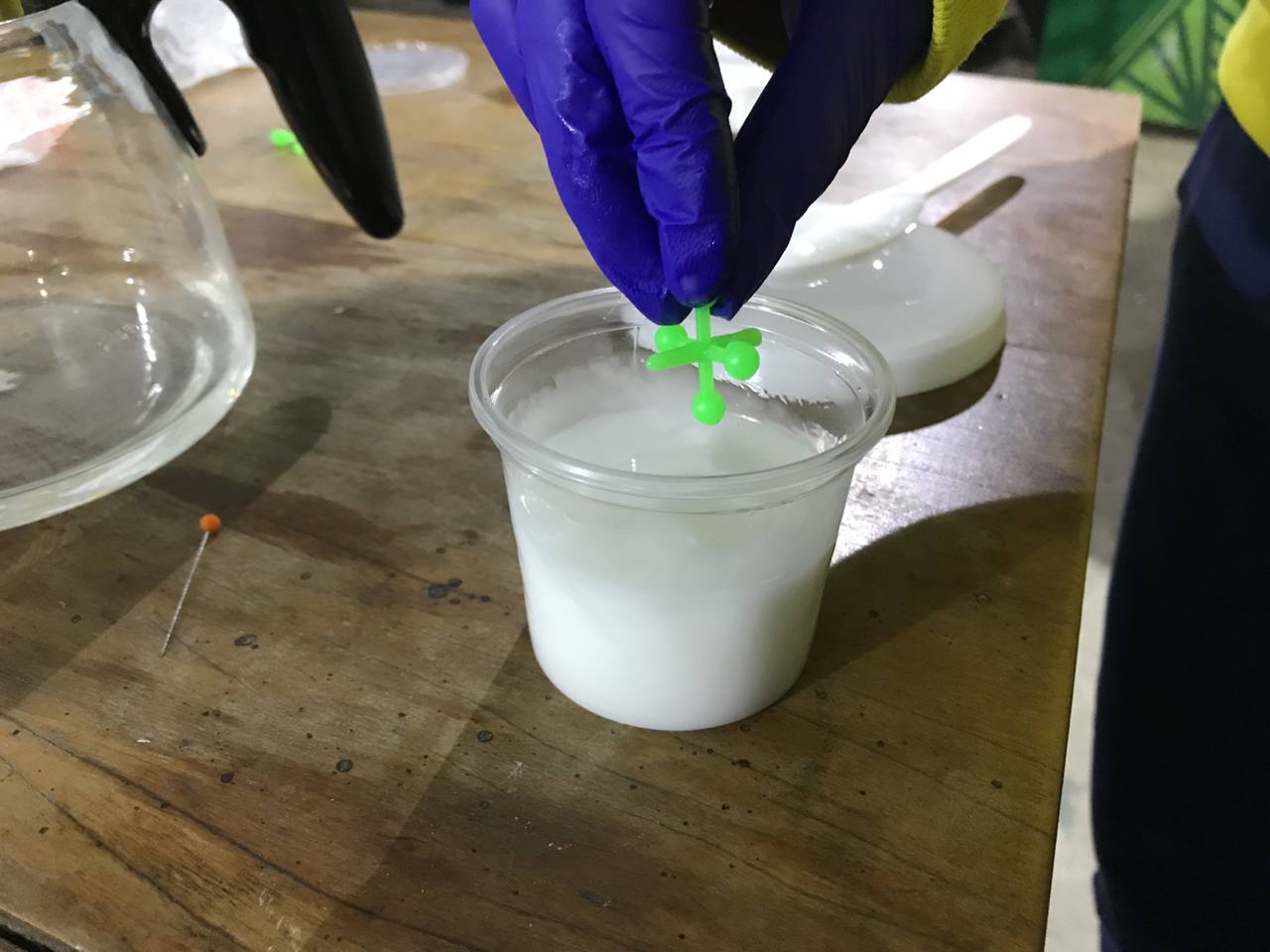

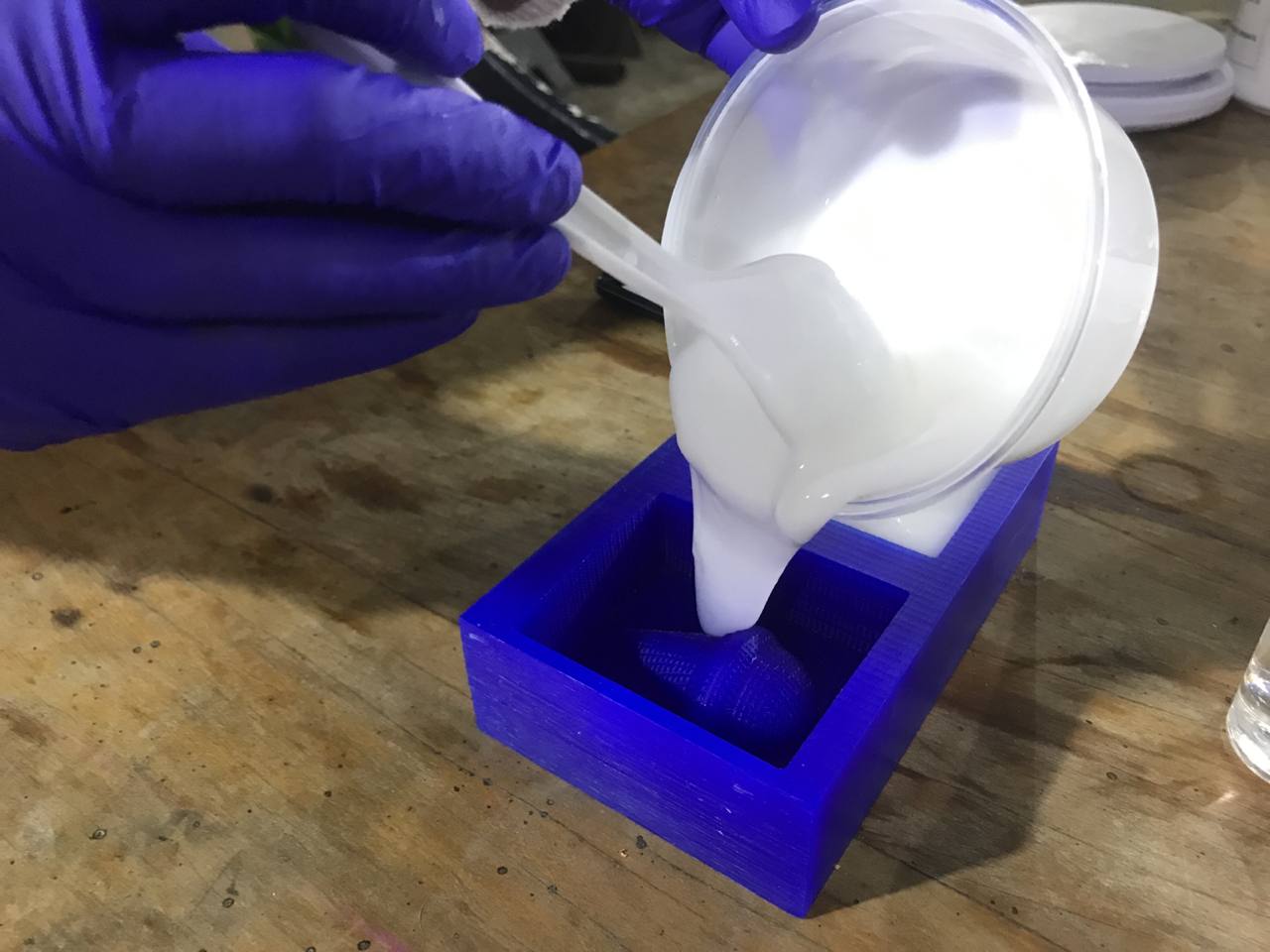

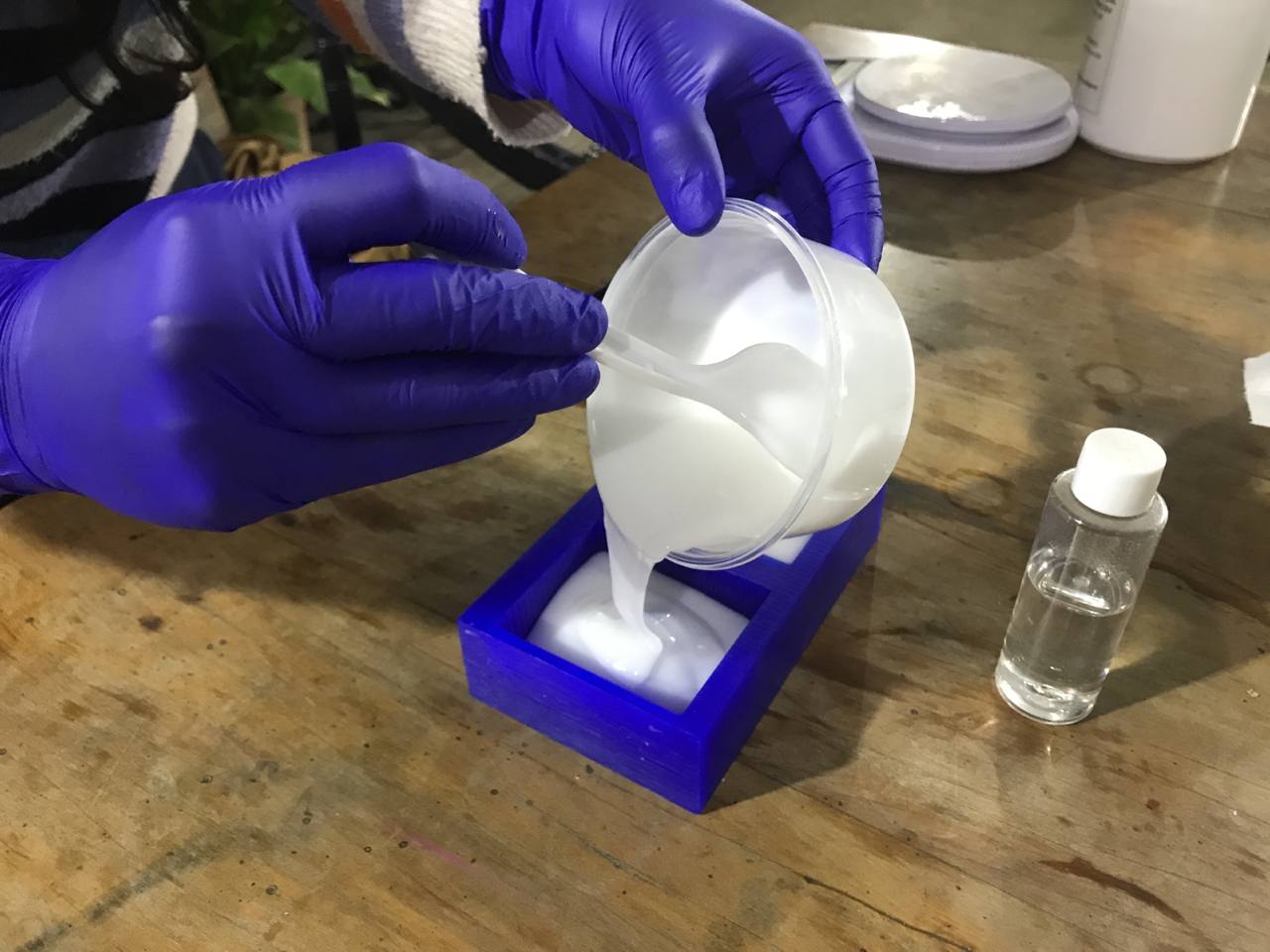

After the measurements we decided to prepare 150 grams of silicone, to ensure that the wax block was completely filled.

The mixing ratio with the catalyst is 2% to 3%; for example, if you need 100 grams of silicone, you will have to mix 2 grams of catalyst. We decided to mix our catalyst by 2.5%.

150 grams of silicone X 0.025 (2.5%) = 3.75gr.

- 2% slow curing process

- 2.5% intermediate curing process

- 3% fast curing process

Catalyst

150 grams of Silicone

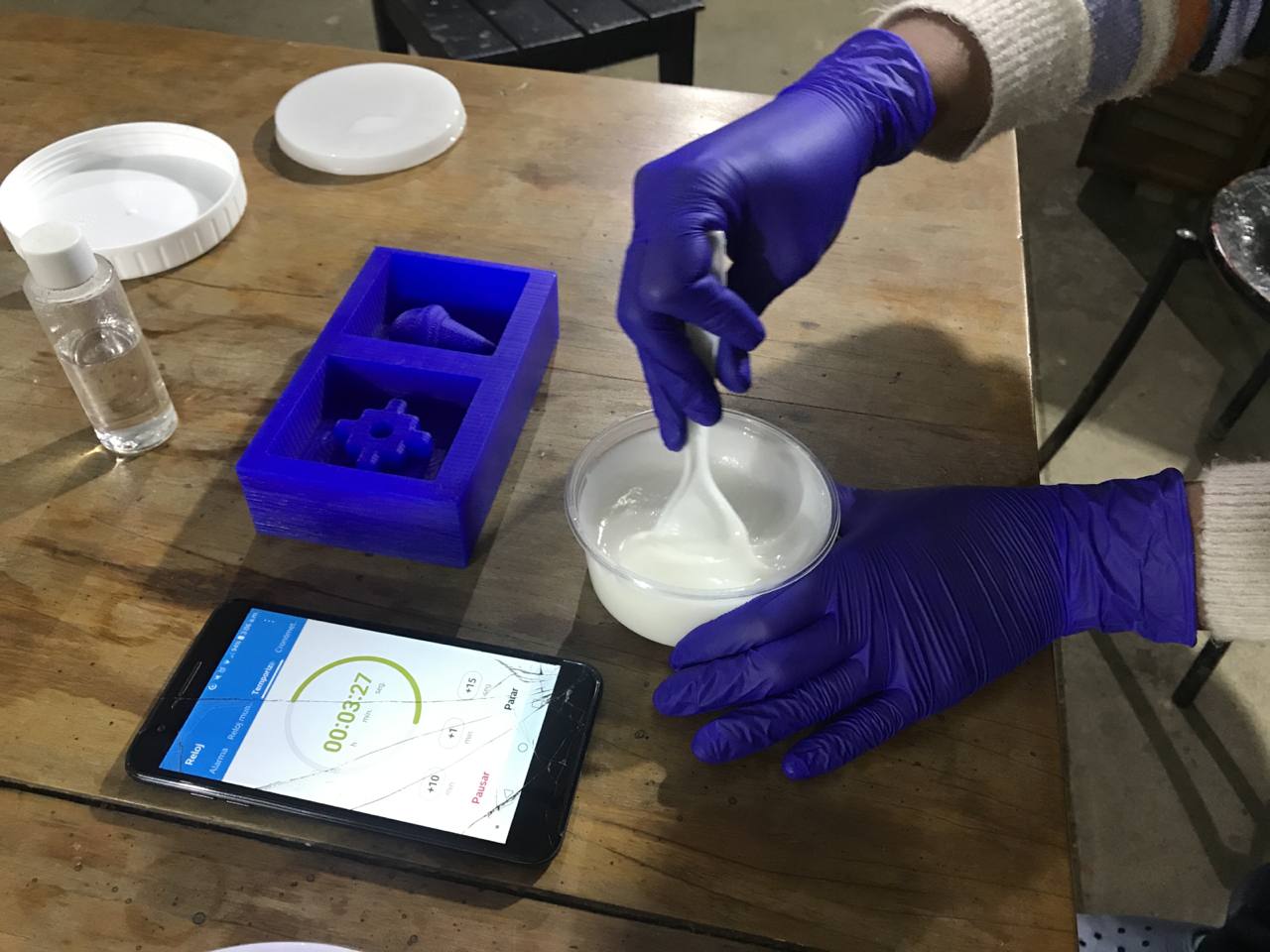

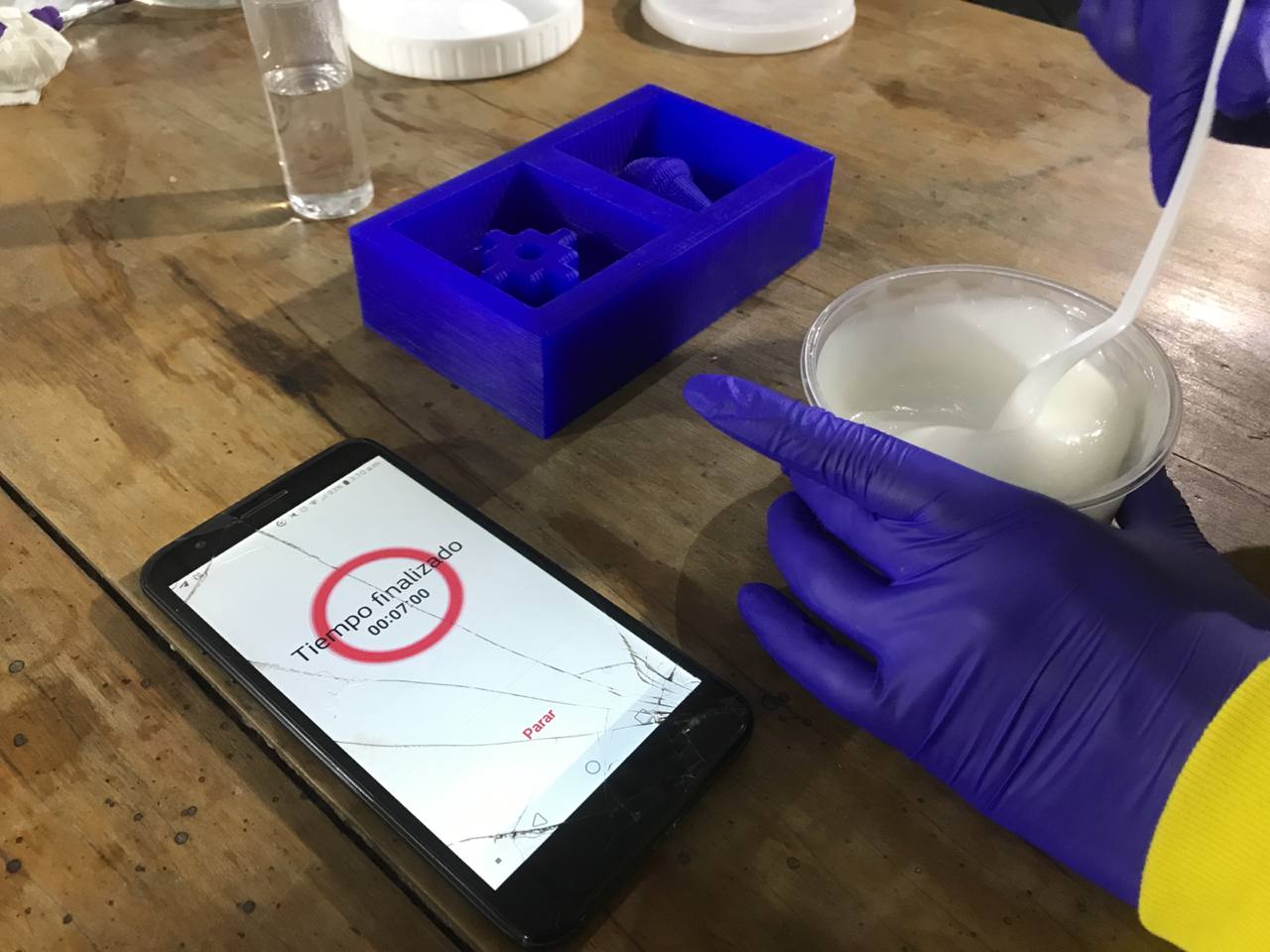

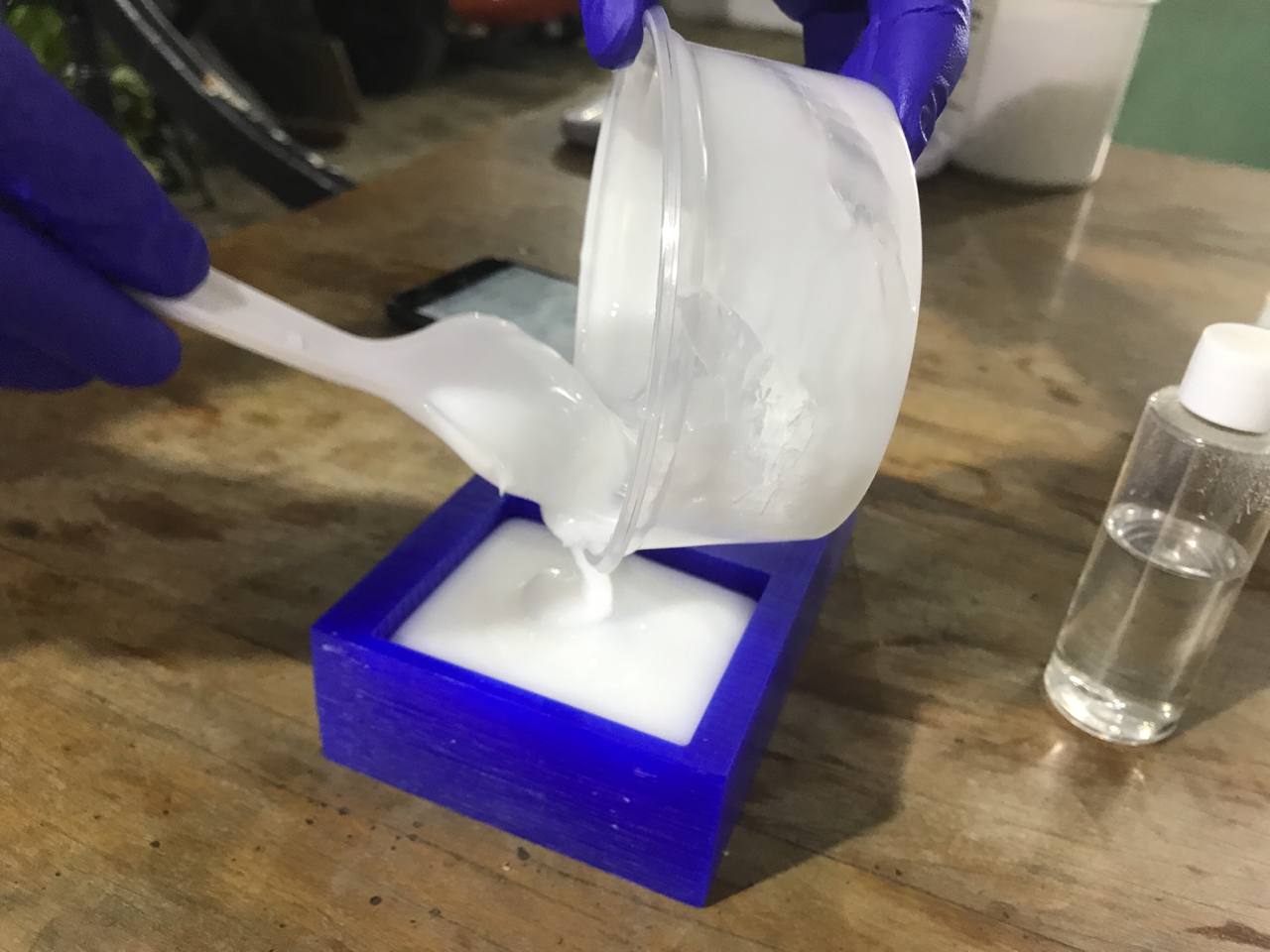

Rossmery, a sculptor friend, advised us to mix the two components in a continuous, uniform and circular way for 7 minutes, being very careful not to remove the spoon with which we mixed. This helped us a lot to reduce the amount of bubbles, which eventually came to the surface, and were not in the reproducible part of the design. Once we pour the silicone into our wax mold, we wait for the time for the silicone to cure and we can unmold.

Mixing

Mixing

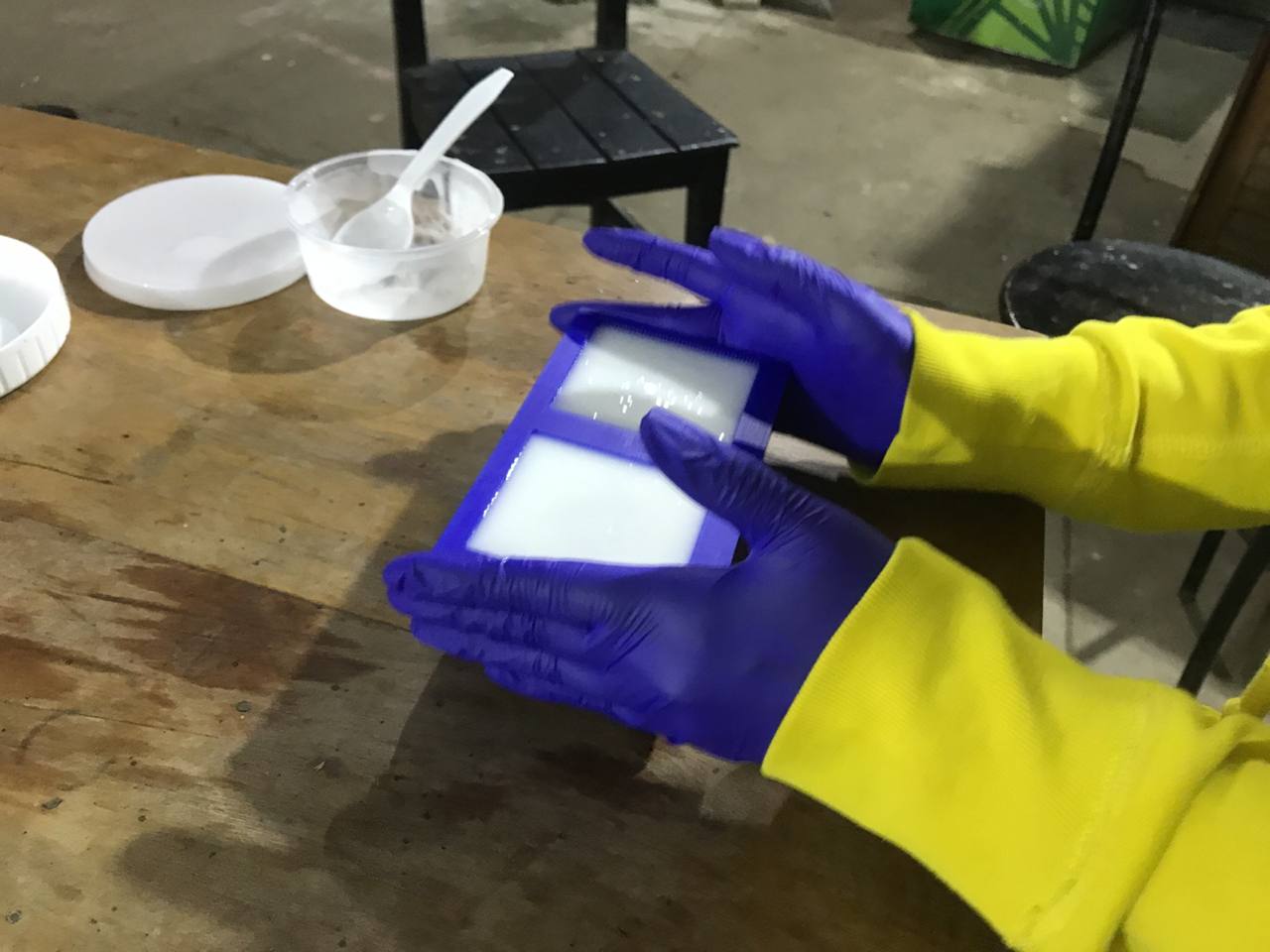

The curing system works by condensation. When you mix and pour the catalyst into the silicone; alcohols begin to form and the silicone loses moisture; for this reason, there is a slight contraction from 0.01% to 0.02%. If you let the mold rest for 24 hours, while it's in the contraction process, you ensure the faithful reproduction of all the details of your mold, otherwise, if you remove it after 4 hours, you could lose quality if you make molds of sculptures or complex miniatures.

24 hours later we proceeded to unmold. Let's see what happened!⏰

Pouring the silicone

Pouring the silicone

Pouring the silicone

Seated silicone

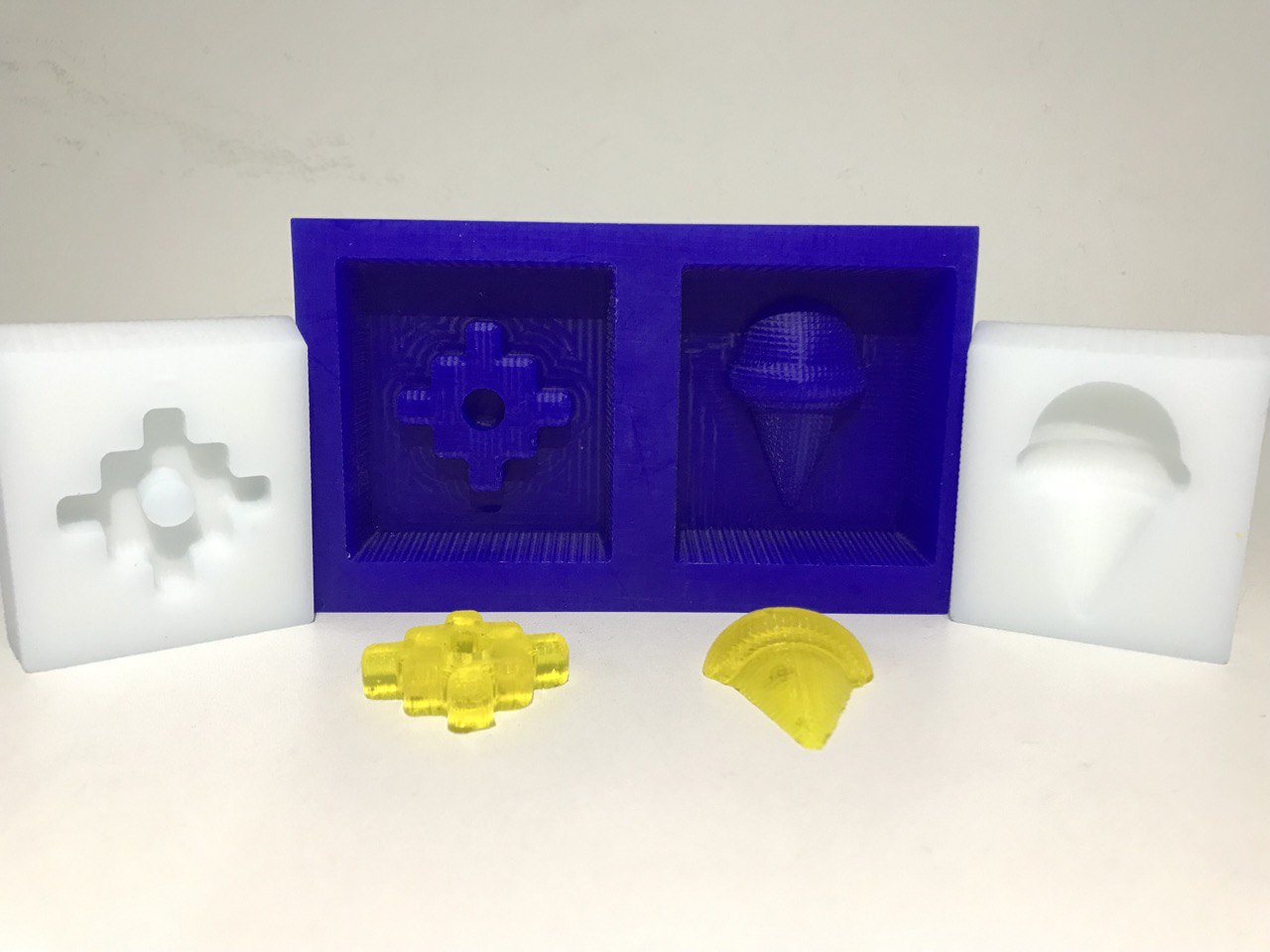

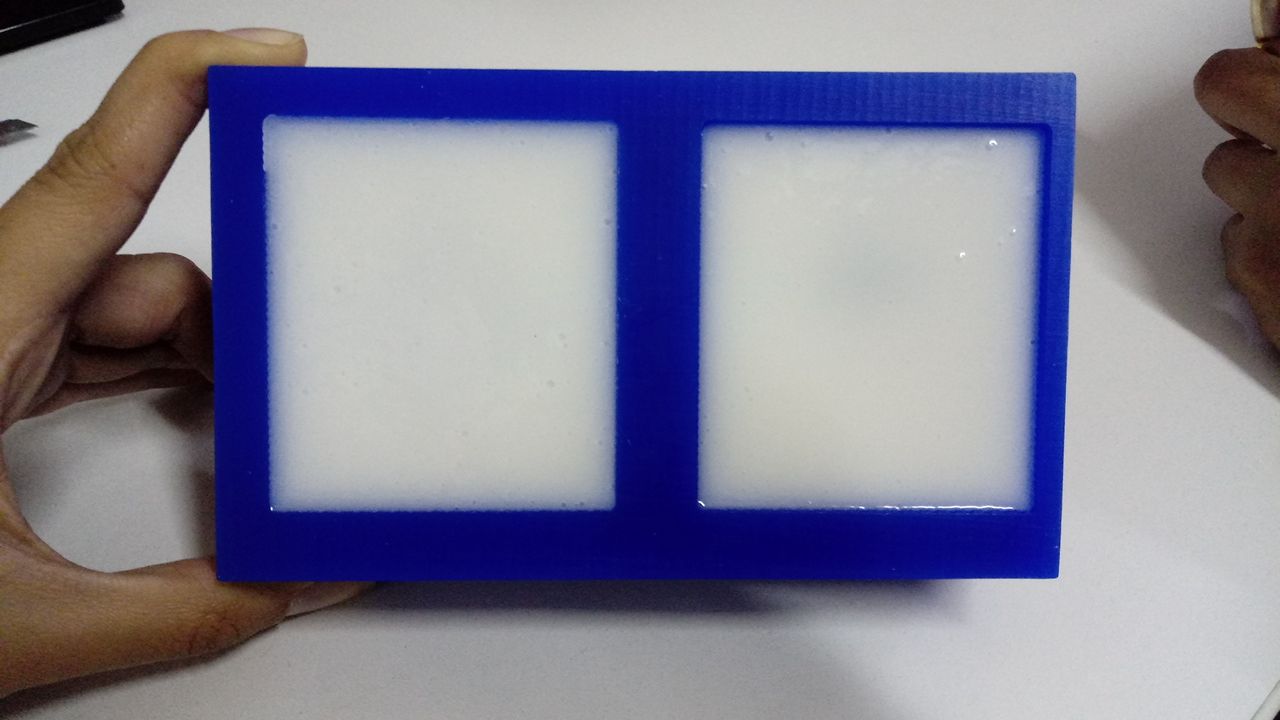

Unmoldingthe Silicone

When the time comes, we check with our hands that the silicone has hardened and we proceed to unmold. The sloping walls were very helpful, it takes a little force to unmold. The result was good, the few bubbles remained on the outside. The reproduction was faithful to detail.

Silicone ready

Unmold Silicone

Unmold Silicone

Unmold Silicone

My Ice Cream Mold

JellyIce cream

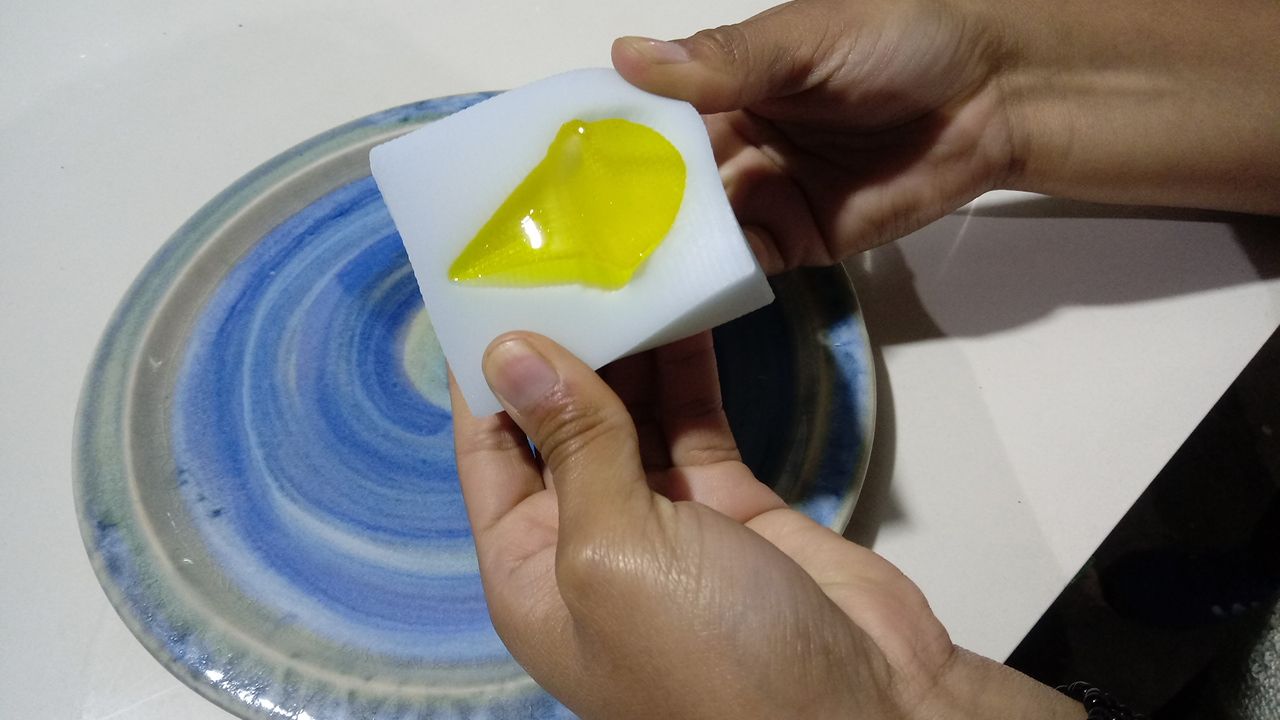

This is the most anticipated step of all: reproduce the first object. Together with "GMH 000", we tried to make ice with our molds, but it failed. As a second option, we use pineapple jelly 🍍 and pour it into our silicone molds. as you can see, the result is satisfactory.

Jelly Ready

Unmold Jelly

Unmold Jelly

Jellies

Ice Cream Jelly

AboutLearning

-You must correctly measure the work area in x, y, z of the milling machine that you own; because any 3d machining work you do will depend on it, remember that wax is manipulable and that you could build your own custom block according to the measurements you need.

-It's important to have more than one cutter for milling available, so as not to suffer in the expectation of it breaking!

-If possible, next time I would try to buy the materials in a place where the products have available and up-to-date technical data sheets. Unfortunately we did not find a provider with these characteristics this season.

My Verdictfrom what I learned

-Due to lack of materials, I could not develop more than one mold. But I had liked to experience a little more.

-I loved the level of detail that can be obtained with 3d machining. You can design thumbnails and highly accurate things.