5. Electronics production¶

This week I worked on defining my final project idea and started to getting used to the documentation process.

Group Assignment: Characterizing the machine¶

In this week, we are given a circuit called the Fab ISP that we must produce. This circuit can be used as an Arduino to program other boards to make different tasks. So we use a CNC for Pcbs to fabricate our Fab ISP.

what is a CNC for Pcbs ?¶

Printed circuit board milling is the process of removing areas of copper from a sheet of printed circuit board material to recreate the pads, signal traces and structures according to patterns from a digital circuit board plan known as a layout file. The mechanics behind a PCB milling machine are fairly straightforward and have their roots in CNC milling technology.

description owr machine CNC for pcbs¶

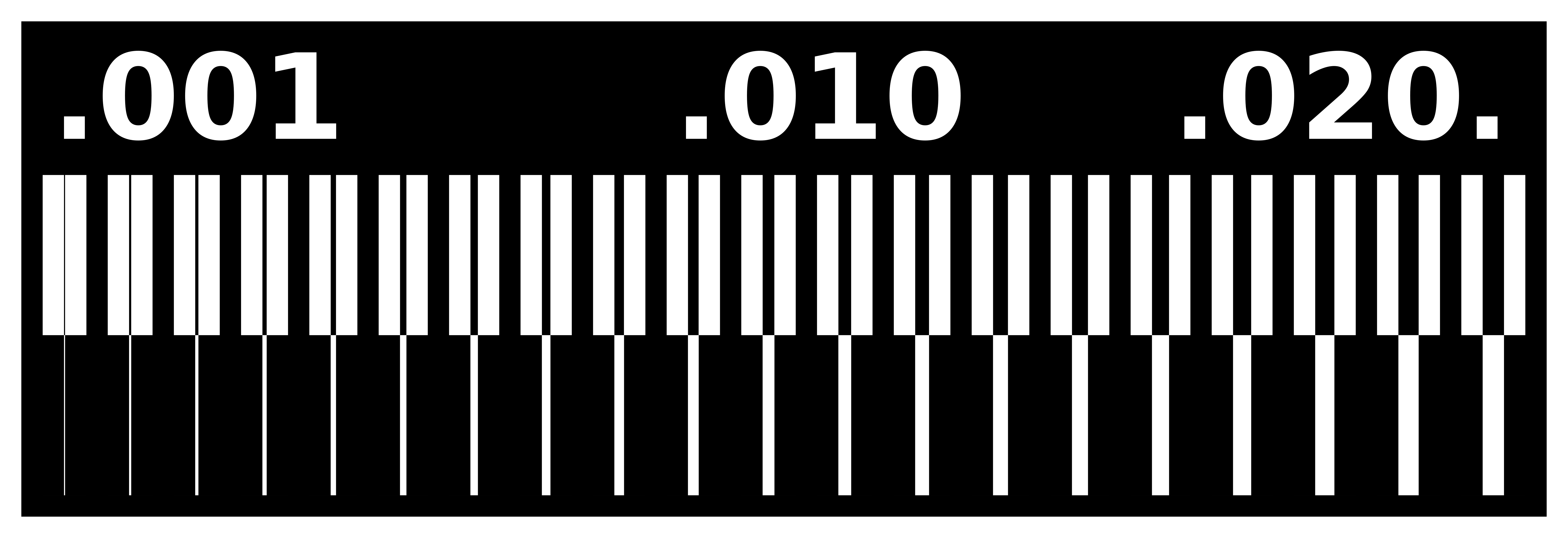

we had to characterize the specifications of our PCB production process on our CNC 3040.

data sheet for machine¶

After using the machine we start to read her data sheet

software¶

The software that we used for milling was Fab Modules, online at FabModulesormods and send nc files trough Mach3 software sender.

Fab Modules is a browser-based CAM system, which allows to generate toolpaths for and control lasercutters, CNC-mills and waterjets commonly found in fablabs. we test the machine

)

)

First we generate the gcode

what is a g code ?¶

G-code is a language in which people tell computerized machine tools how to make something.

how to generate a g code?¶

To generate ower g code we use a software whitch is mods

- open the software click on the mouse’s right button.choose programes , click to open an server programe and choose shobot mill 2D png

- we import ouwrs files png for test click to select file

- we configurate the setting of cut we choose tool diameter ,cut depth and offset number

-

we configurate also shopbot like cut speed ,jog speed and spindle speed

-

click to calculate

-

we save the fils of ower g code

how to mill the pcb ?¶

we exporte the gcode to the machine controller .we calibirate the Z we fixe the plate and we choose ower origin and click start

it s owr pcb test

individual Assignment¶

I work in this assignment to make a pcb circuit

i work to product my FabTiny ISP

FabTiny*ISP¶

The FabTinyStar is yet another version of an AVR ISP programmer/board that can be produced in a fab lab using a milled PCB and readily available components.

component

1x ATtiny45 or ATtiny85 2x 1kΩ resistors 2x 499Ω resistors 2x 49Ω resistors 2x 3.3v zener diodes 1x red LED 1x green LED 1x 100nF capacitor 1x 2x3 pin header

I creat a board with eagle

To generate the gcode i use FlatCAM so i exporte the eagle file to gerbre

I open the Gerbre in the FlatCAM