3D scanning and printing

- 1.- 3d print somethin that's additivly that's couldnt be done sustractivly

- 2.- use the 3D scanner to scan something

group assignment

the groupal assignment was to define the design rules on our printers in order to be able to avoid common issues when modeling a 3D part that will require a lot of support in order to reduce bridging,wrapping,stringing wrapping

from here you can see what we did on the group assignmentindividual assignments

for the individual asssignment the objective was to model a 3D ptintable object that wasnt able to create sustractivly io choose a tweezer 'cause it is really dificult to hold on the SMD components and i wanted to test the mechanical propierties of PLA plastic i based my idea on a youtube on complaint mechanisms

here you can watch the video i was talking about the model he build

1.- 3d print somethin that's additivly that's couldnt be done sustractivly

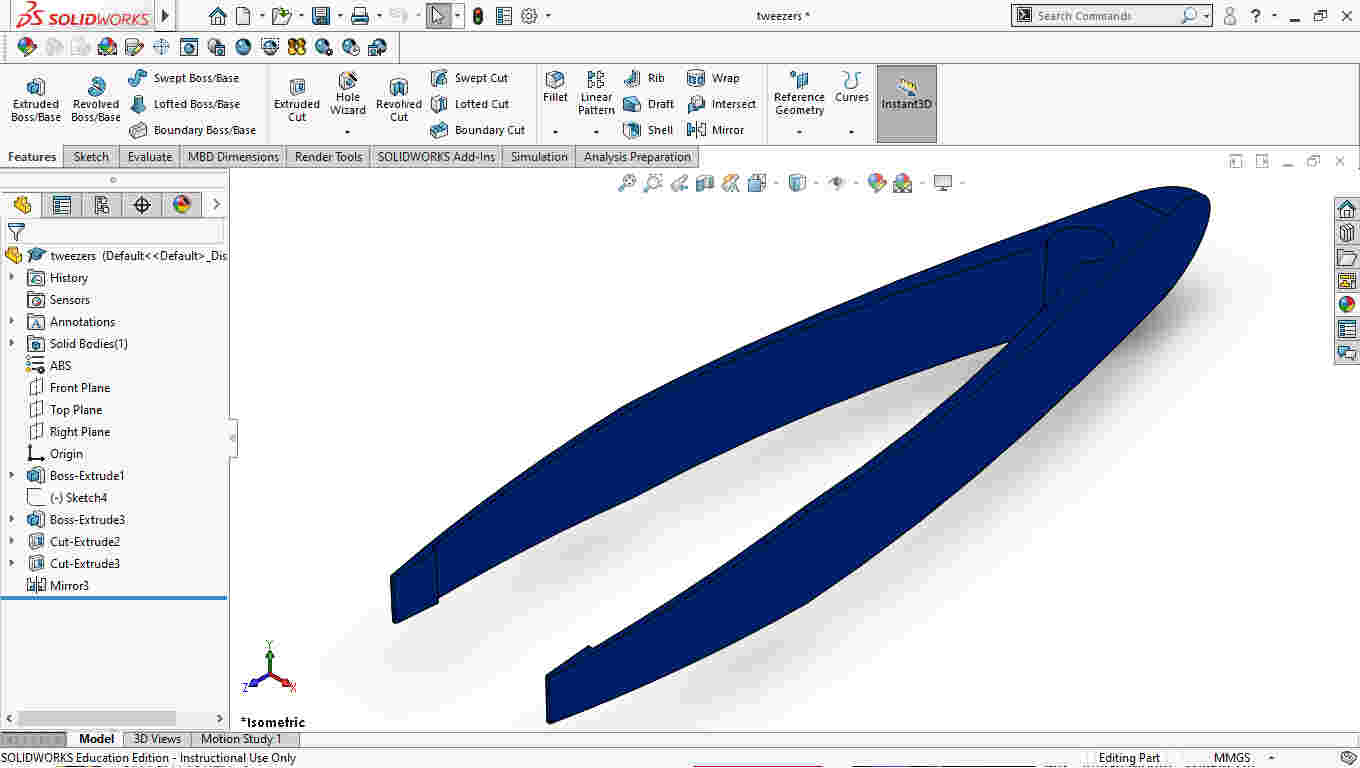

So i modeled a pair of tweezers for smd components using solidworks

picture directly taken from solidworks

i used some basic geometrical constraints and dimensions considering the diameter of the extrusor wich is about 0.4 mm using expresions on solidworks

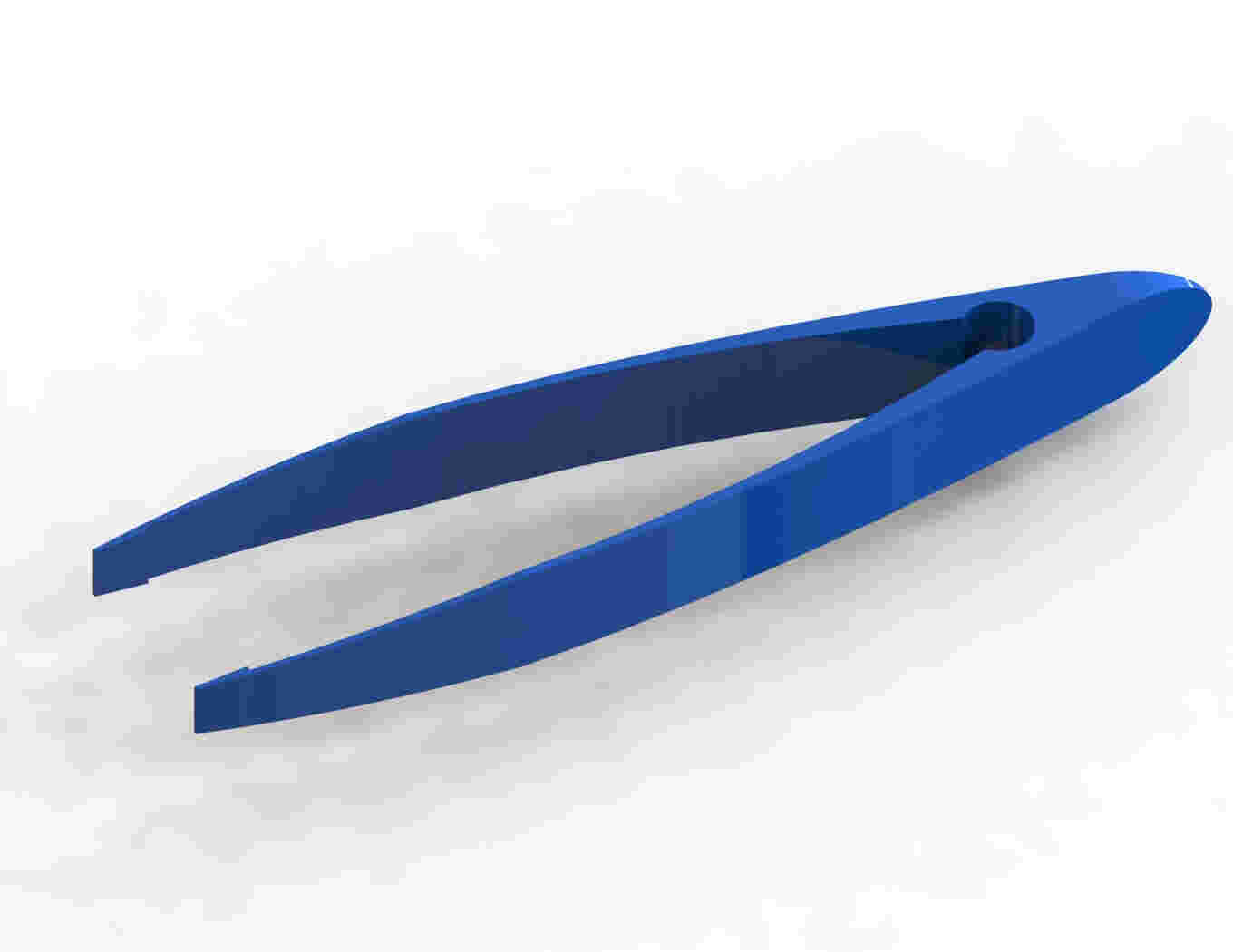

i also did a renderized picture using solidworks

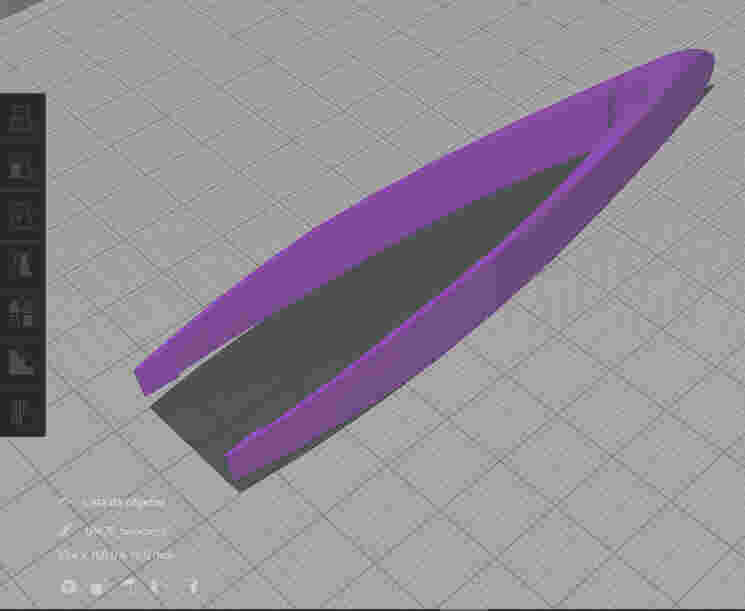

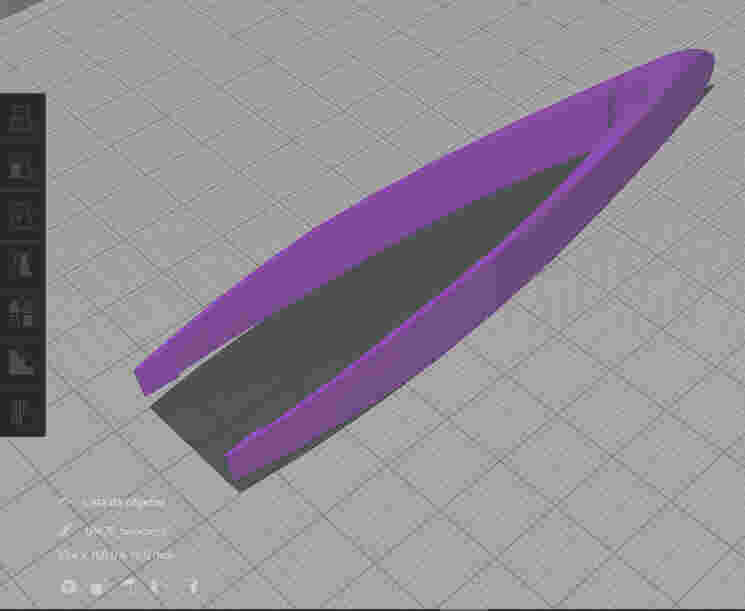

then i imported into ultimaker's slicer software named cura

where i twitched a little the default presettings to rush it a little, i set the layer height to 0.2 mm the speed to 60 mm/s and 10% infill.In the future i'd like to experiment with the formalbs flexible resin to make a 3 fingered gripper using the same principle of compliant mecanisms

after setting the parameters i clicked on the slicer button and saved it as G-code

here you can download my G-codeHERE you can download all of the files (solidowks native,stl,g-code for ultimaker)from the tweezer

then set the printer making the tweezer

so, i tried to print one and this was the result

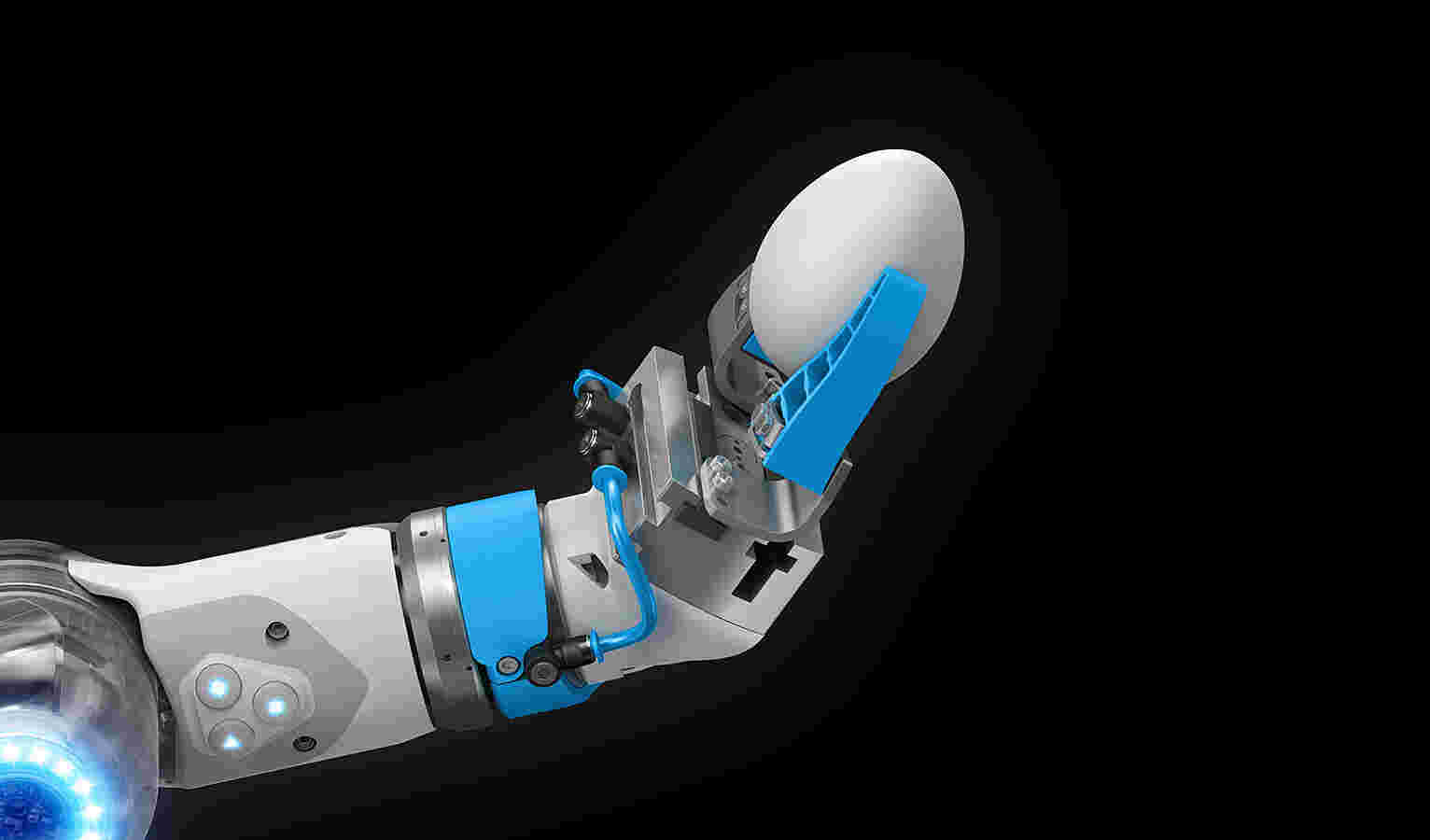

since college i was mezmerized by festo's gripper design

HERE you can download all of the files (solidowks native,stl,g-code for ultimaker)from the Festos's bootleg

and here i will post a link in case you're interested in reding about itfesto's adaptative gripper design

it seems that i derailed from the objective for this assignment a little

2.- use the 3D scanner to scan something. but soon i hope i'll be testing this prototype on flexible resin on the formlabs resin based printer

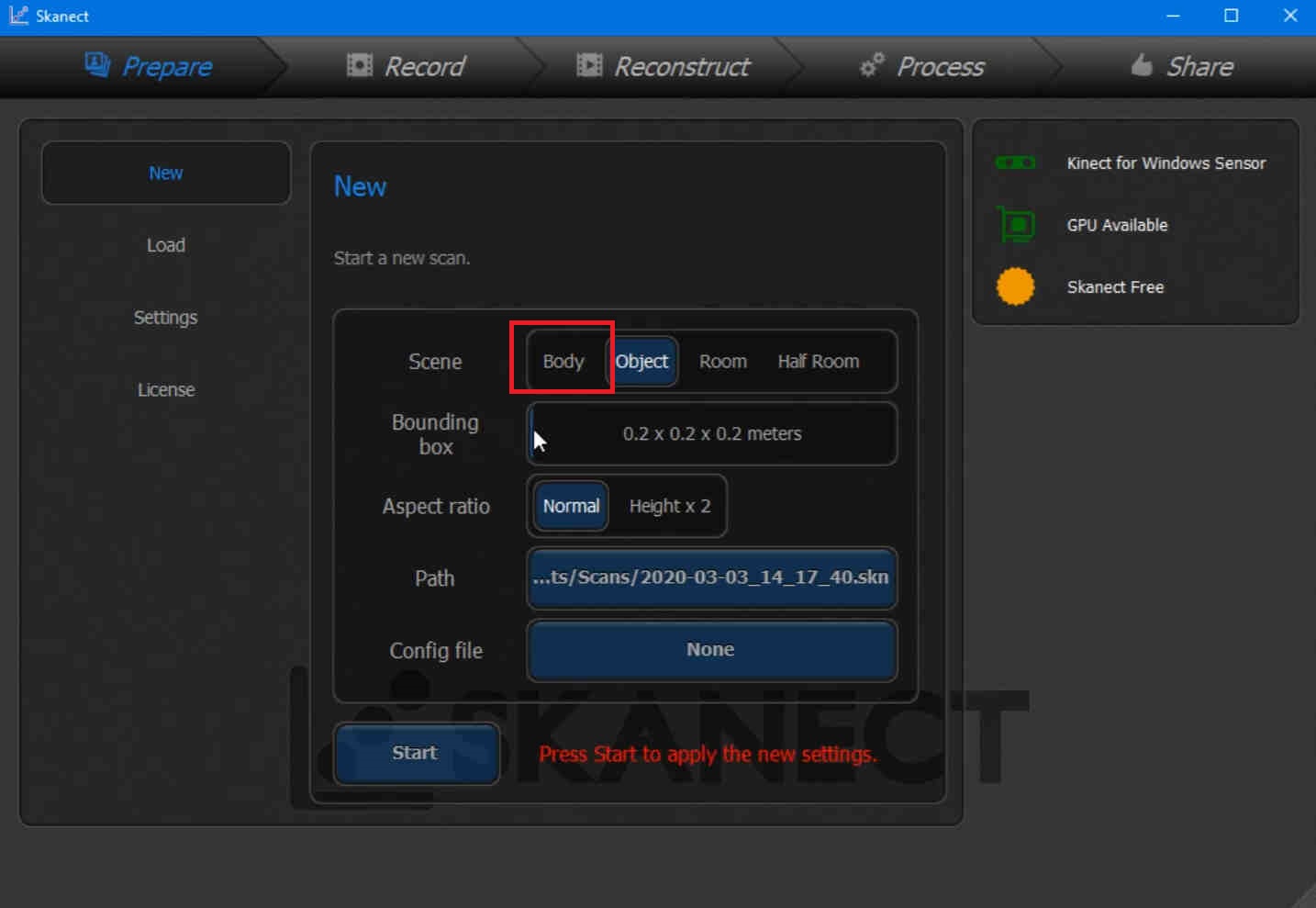

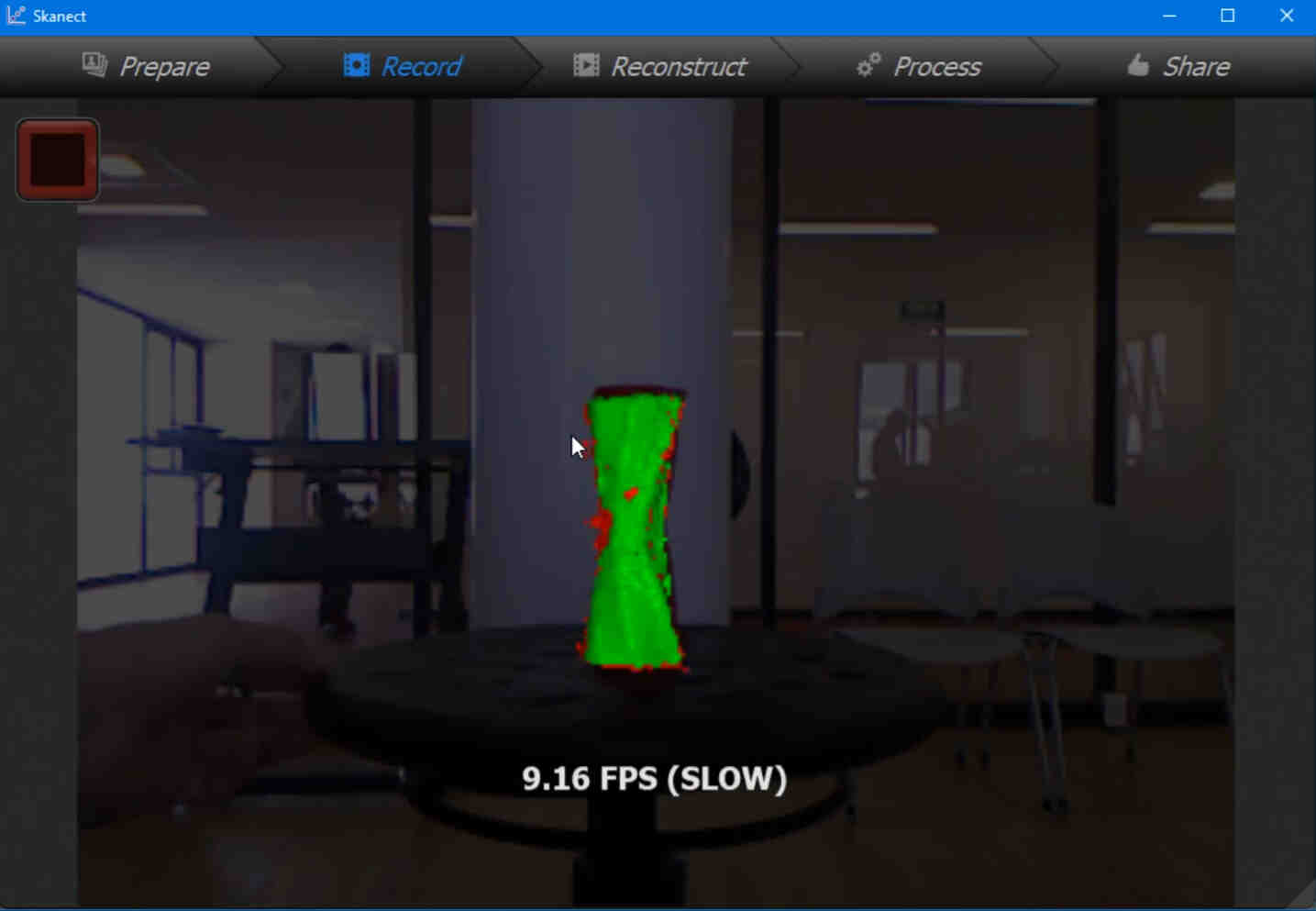

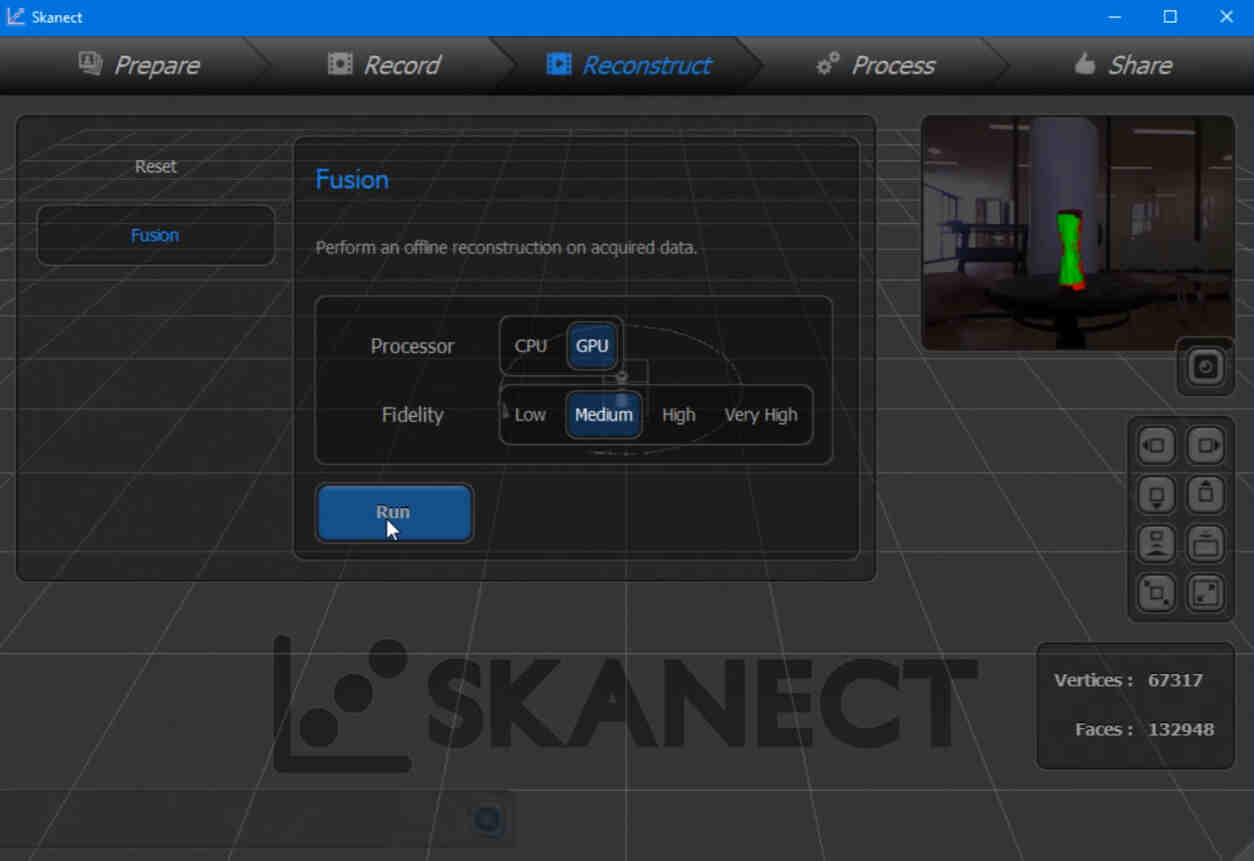

for this part of the assignment i used the microsoft kinect and usb adapter to 3D a printed part that i had near and made a video tutorial out it however i previously installed the kinect driver and a software called skanect that has a really nice freemium version. here you can go to download the driver i used on windows 10

here you can download skanect software

HERE you can download all of the scaning project files

a litle step by step tutorial

since we´re running the free version of the software we are just using objecto for this tutorial

after that you should start recoding the scan while you rotate the object in front of the scanner.

since i was using an alienware laptop i choosed GPU.

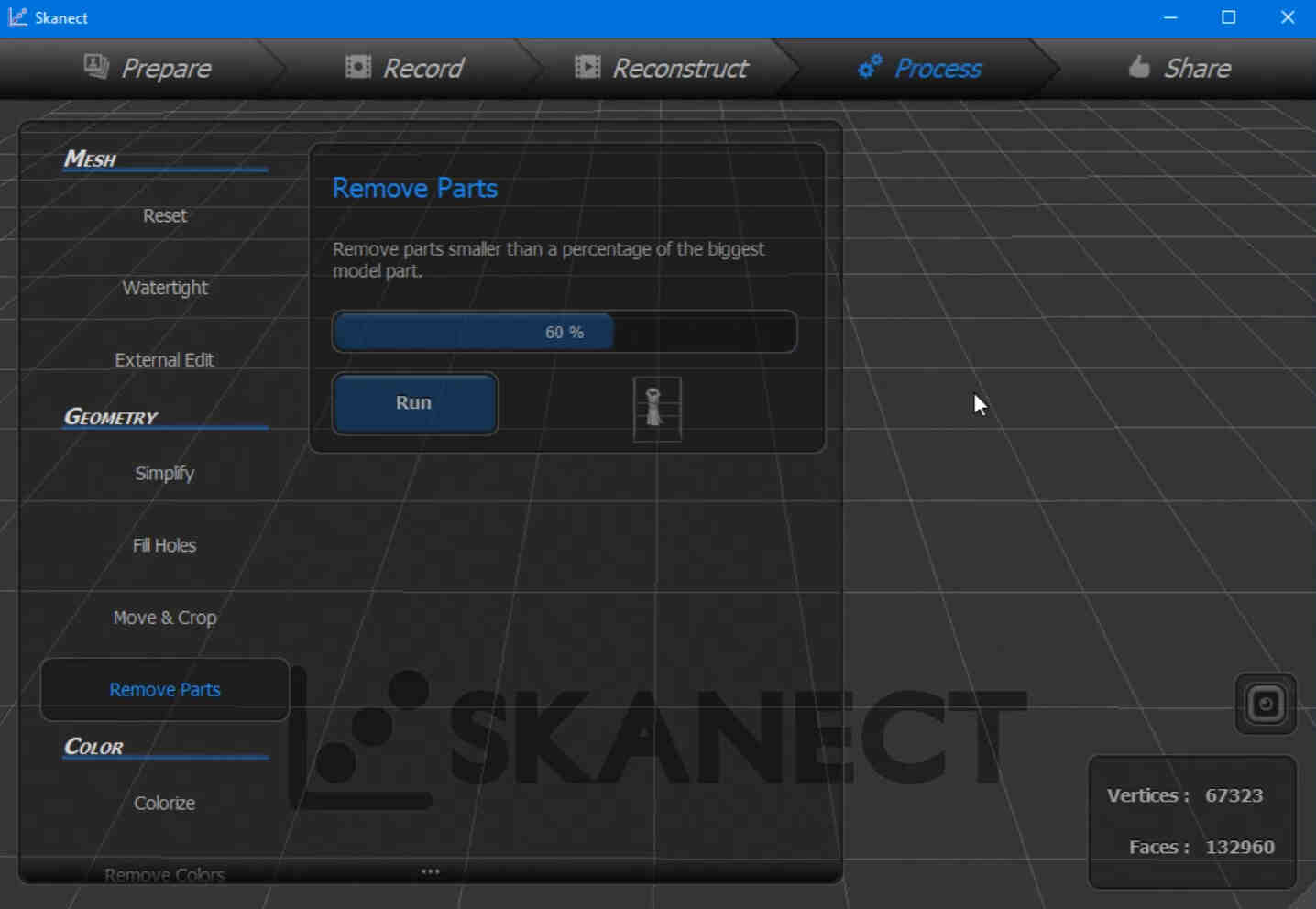

and here you'll tell the software. that you want a watertigh obj, stl,ply or anotherfile type

since this is just a tutorial i selected a stl in millimeters.

this video is hosted from my youtube account

links and references

HERE you can download all of the files (solidowks native,stl,g-code for ultimaker)from the tweezer

HERE you can download all of the files (solidowks native,stl,g-code for ultimaker)from the Festos's bootleg