Group Assignment – 3D Scanning and Printing - Querétaro

General objective (group assignment):

- Objective: Test the design rules for your 3D printer(s).

The Fab Lab Queretaro has one Ultimaker S5, one Ultimaker 2 Extended and one Formlabs Form 2.

For this assignment we made four test prints on the Ultimaker 2 Extended and a resume with the most important description about the quality and tolerances.

Development

We made 4 tests: angle, bridge, thickness and Surface finish.

We used Cura as slicing software for every test and exported the gcode using an SD card.

All the test were done at:

- 0.2 mm layer height

- 20% infill, with grid pattern

- Print speed 60mm/s

- No supports

- No build plate adhesión

Ultimaker 2 Extended

Technical specifications:

- Work Area: 8" x 6" x 2.38"

- Effective build area: 223 x 223 x 205 mm

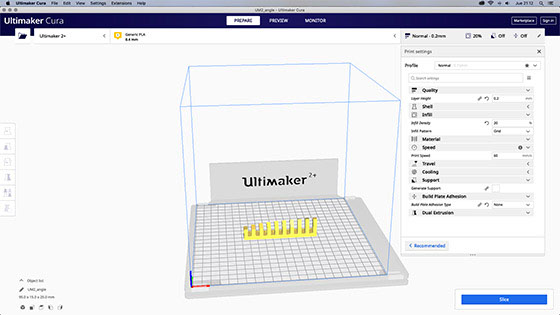

Ultimaker Cura Software

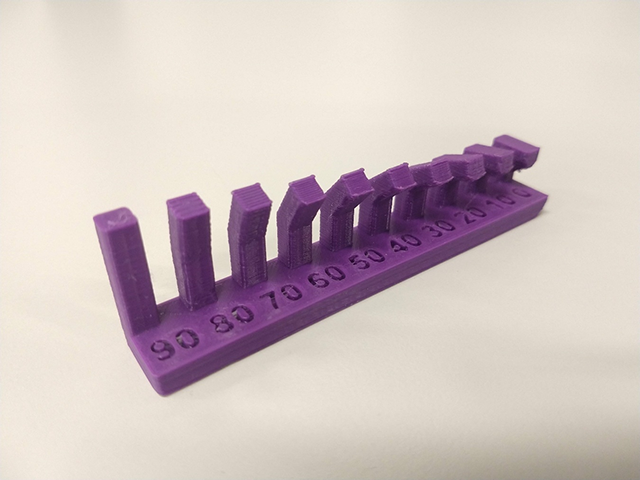

Test #1

The first test helped us determine the maximum angle of overhang that the printer is capable of printing without material falling off, and the acceptable results were between 30 and 40 degrees.

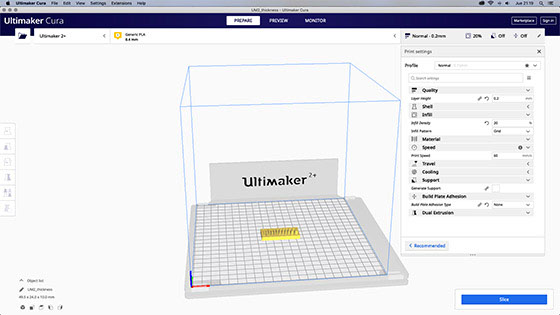

Ultimaker Cura Software

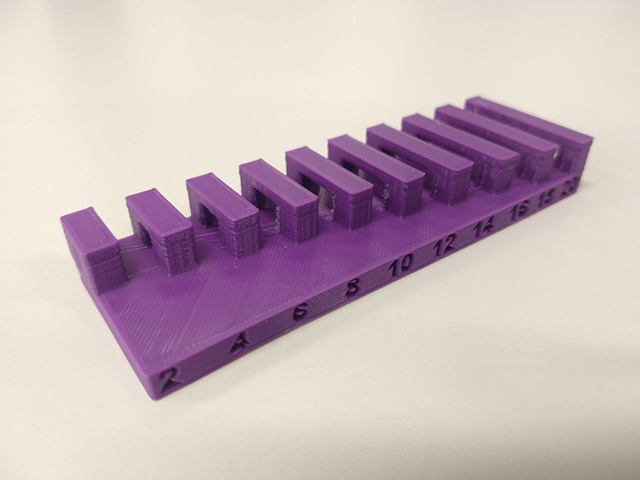

Test #2

This test helped us determine the maximum print distance without supports and without material falling off. The maximum acceptable result was found up to 8mm.

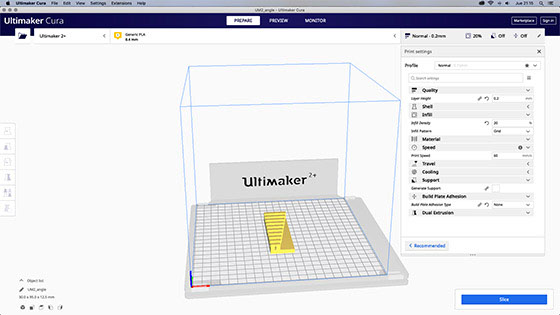

Ultimaker Cura Software

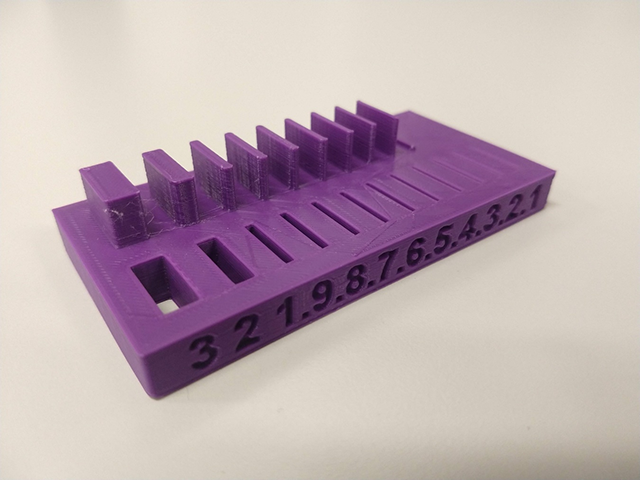

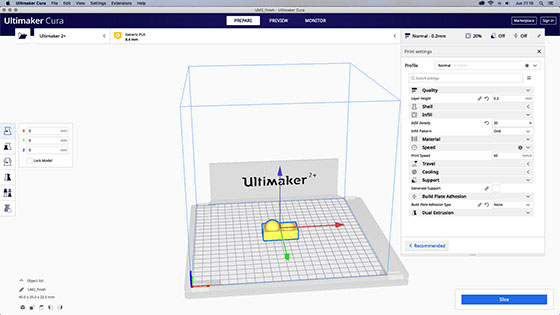

Test #3

This test helped us determine the minimum printable wall thickness as well as the thickness at which the material begins to fuse in the perforations. With this 0.4mm nozzle and printing in PLA the results are satisfactory with 0.4mm walls (thinner thicknesses do not print) and 0.2mm perforations (thinner thicknesses merge with each other and the perforation closes).

Ultimaker Cura Software

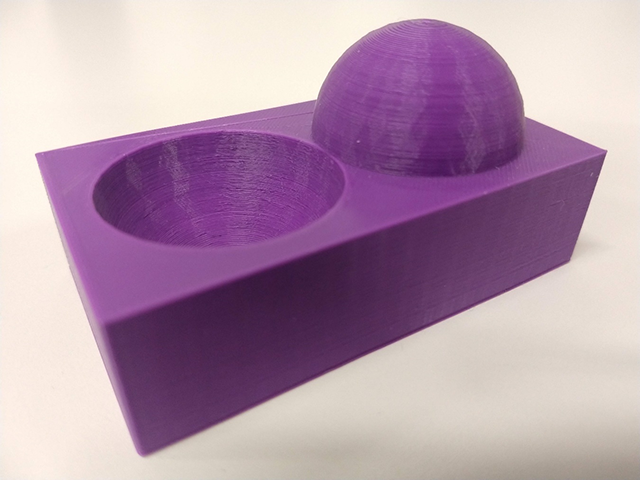

Test #4

This test showed us the quality of the curved surfaces with these spherical parts.

Overall, the Ultimaker 2 Extended 3D printer is a magnificent desktop device for everyday prototypes, as well as small models.

It can be used for architecture, industrial design and engineering, focusing in a small scale, quite rapid and nice quality finished product.