Charlotte Latin 2020 Week 15 Group Assignment

Molding and Casting

The assignment for this week was to review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of themSmooth-On Task 3

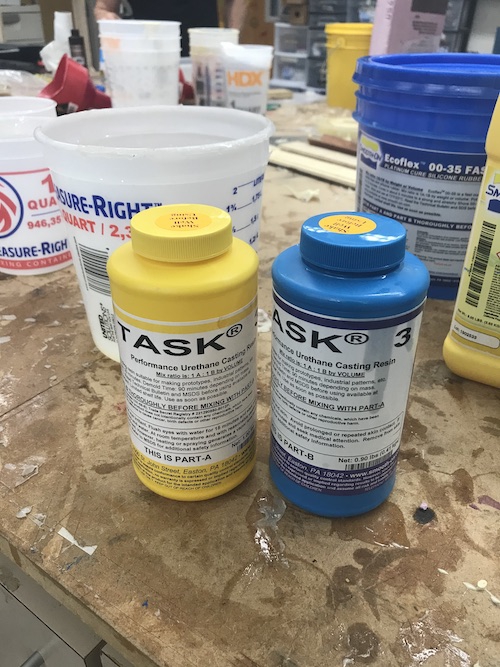

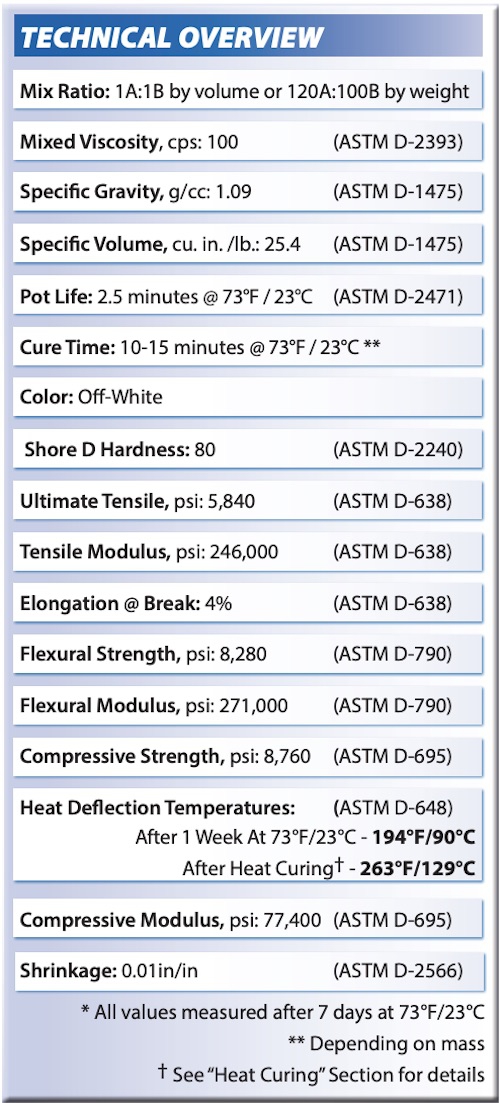

The material to create the final product from the cast is called Task 3. We read the datasheet here to learn about the safety, ratios, and other details about how it works.

Here are parts A and B of Task 3.

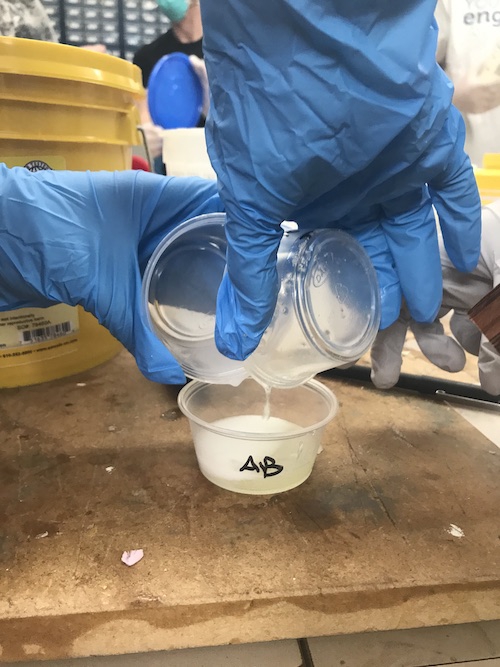

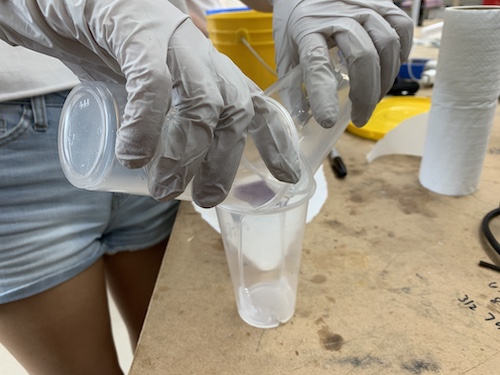

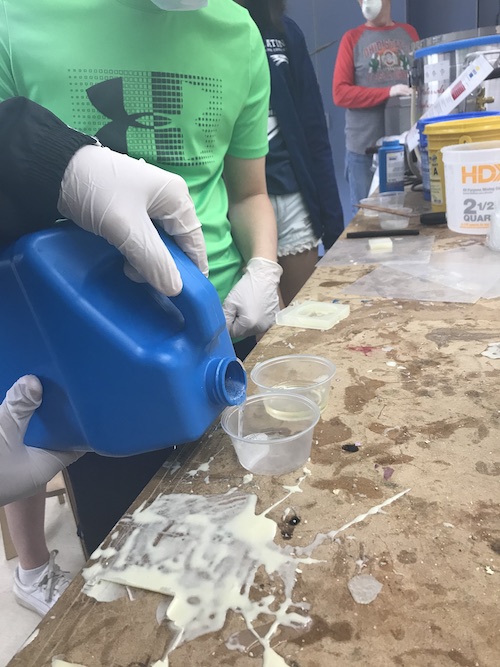

The summary, which was the most important part of the datasheet, described all the essential knowledge about Task 3. The pot life, the time it takes for the combined parts to settle and begin hardening, is 20 minutes. The cure time, the time it takes for the mixture to dry, is 90 minutes. The ratio of part A to part B that should be combined is 1:1, and when it completely hardens it turns white. Here is the process of our group creating a test cast. We first poured equal amounts of each part into separate cups.

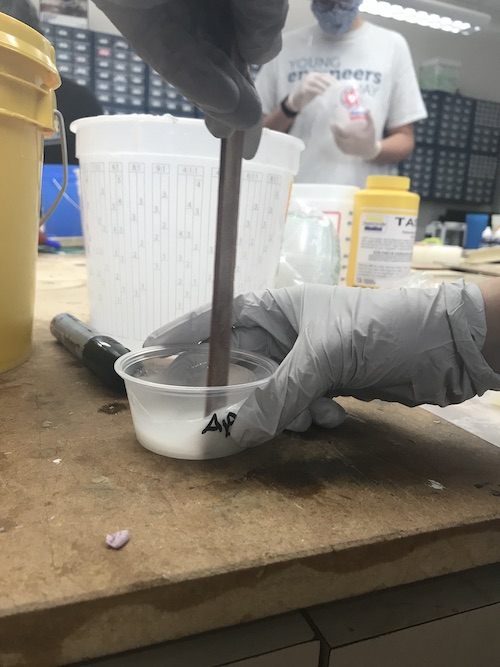

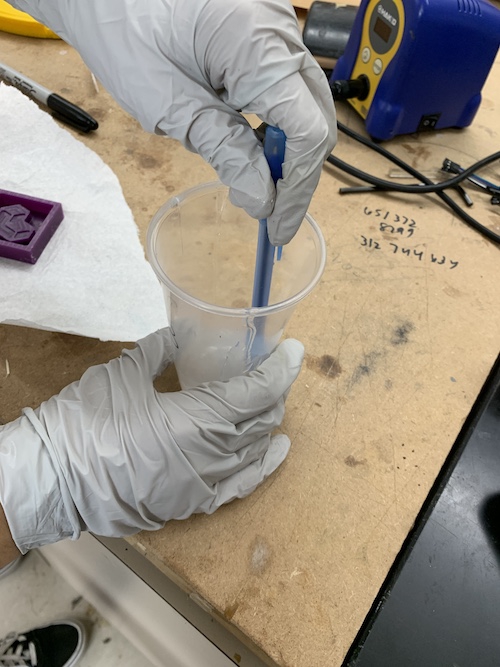

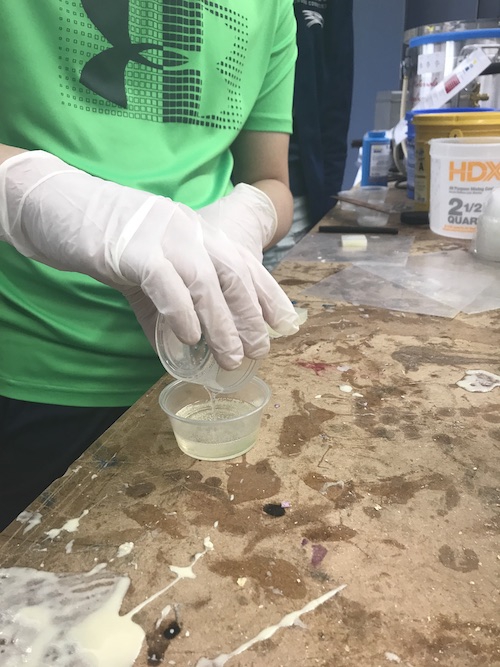

We then poured both parts at the same time into a separate cup and thoroughly stirred the mixture.

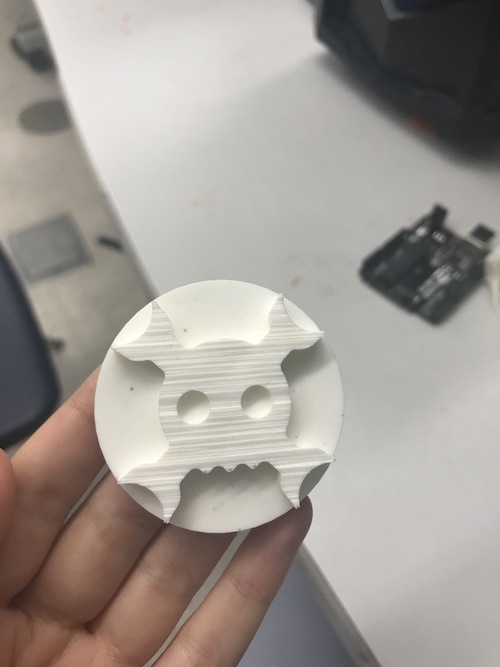

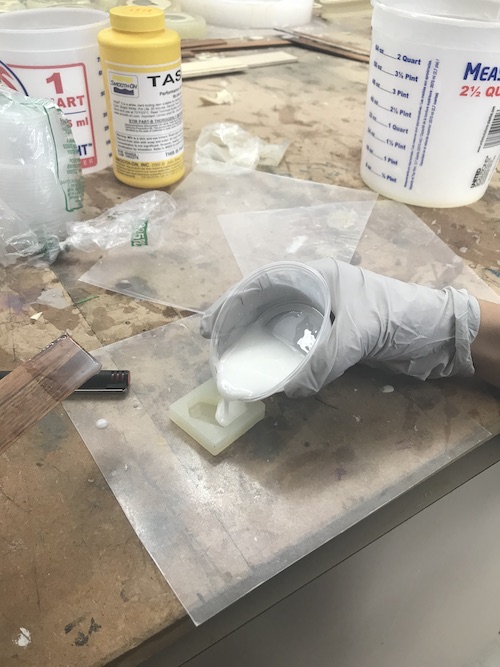

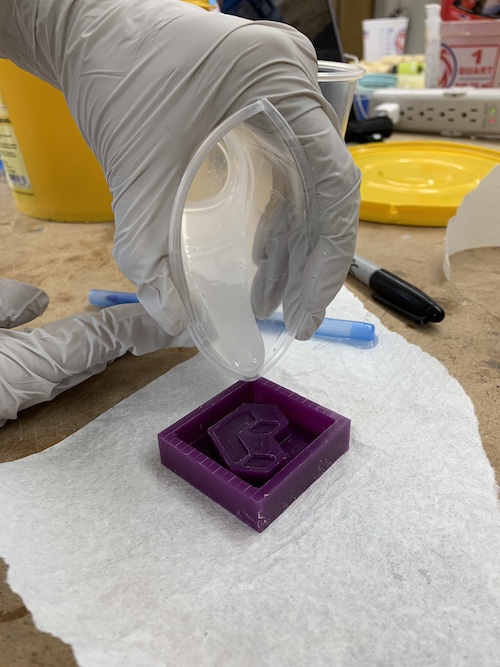

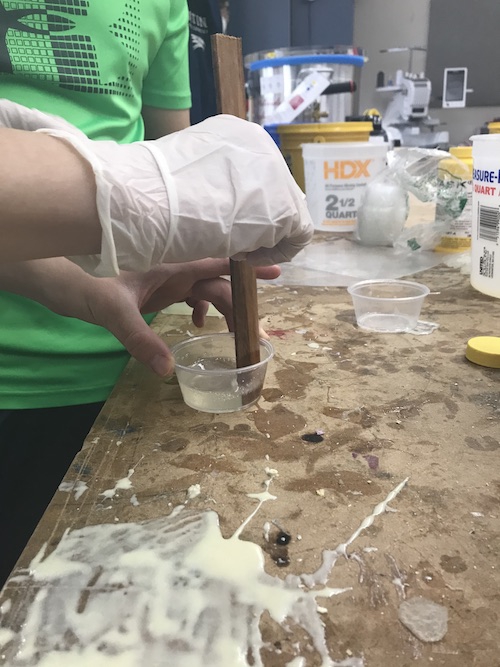

Next, we carefully pour the mixture into Elaine Liu's mold from her individual assignment.

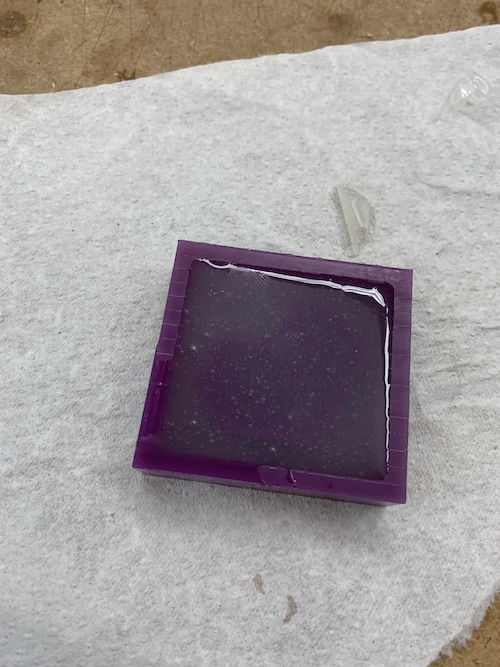

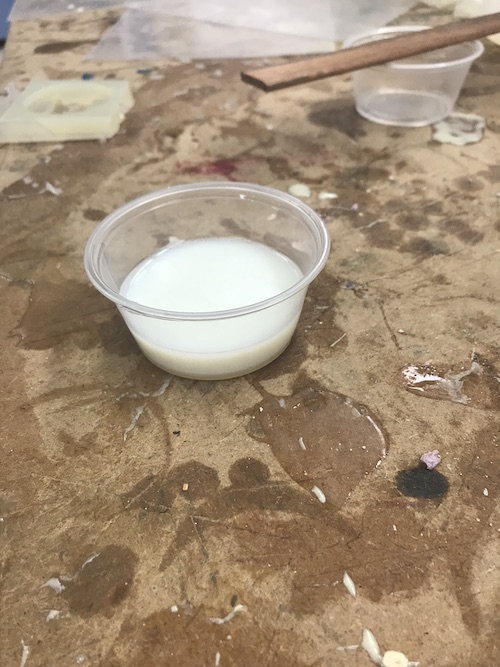

Here is a picture of the final cast:

Smooth-On Task 8

The material to create the final product from the cast is called Task 8. We read the datasheet here to learn about the safety, ratios, and other details about how it works. For our individual assignments, most of our group members used Task 8 to create our casts. Here are the two parts involved:

Here is the summary of Task 8. Just like Task 3, the two parts should be combined in a 1:1 ratio. It’s pot life is much faster than Task 3, taking only 2.5 minutes to settle. It also has a faster cure time: 10-15 minutes. It’s color is off-white, rather than Task 3’s white.

Here you can see part A being poured into a bucket, and an equal amount of part B being poured into it.

After being quickly mixed it is poured into Alexandra Coston’s mold from her individual assignment.

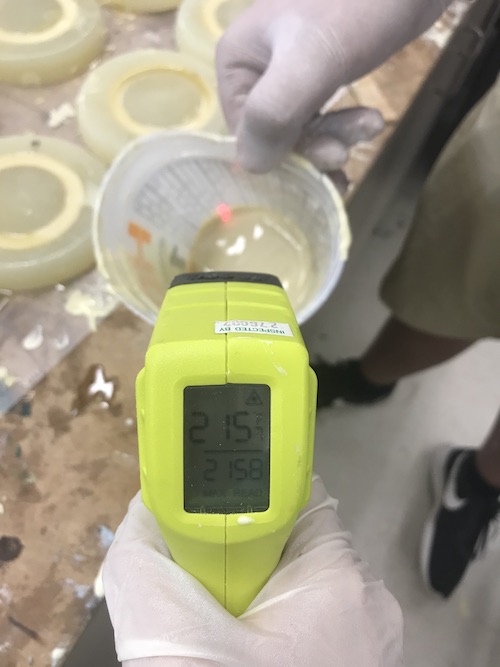

Task 8 heats up quite a bit, as can be seen upon measuring the cast and the bucket with the mixture:

Here is a picture of the final cast:

Smooth-On Ecoflex

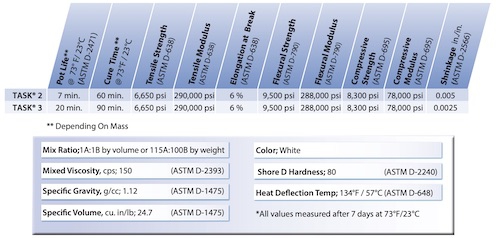

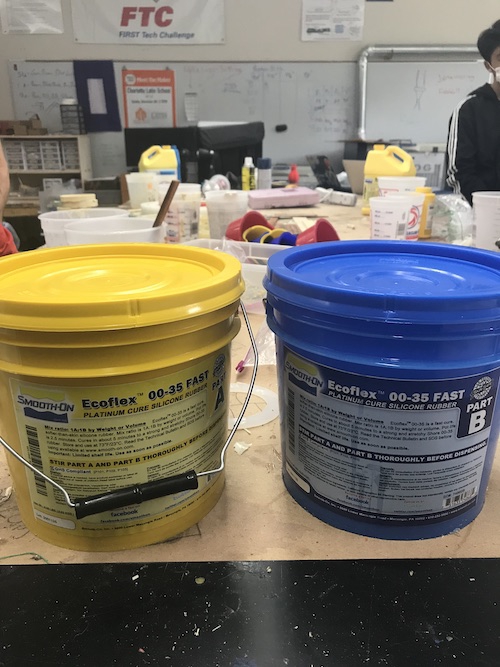

The material to create the silicone rubber mold is called Ecoflex. We read the datasheet here to learn about the safety, ratios, and other details about how it works. For our individual assignments, most of our group members used Ecoflex to create our molds. Here are the two parts involved for Ecoflex 00-35 Fast:

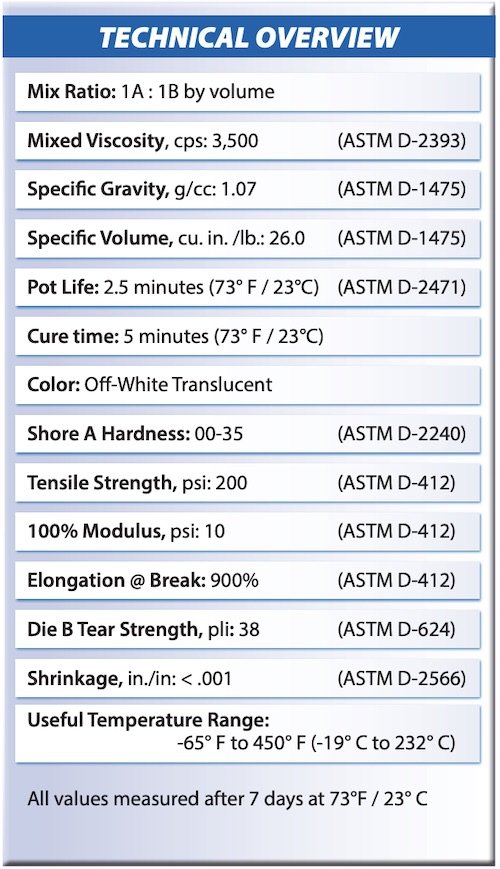

The summary describes the mix ratio, also 1:1. It has a pot life of 2.5 minutes, like Task 8, and has the fastest cure time of 5 minutes. The color is off-white translucent, so a bit similar to Task 8.

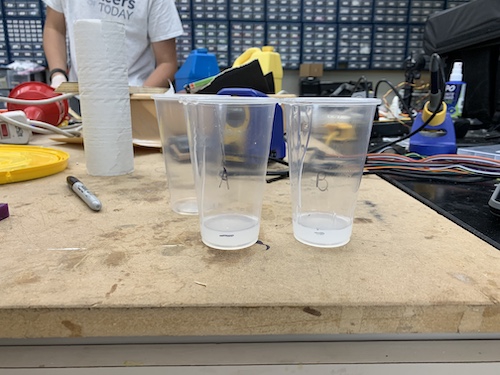

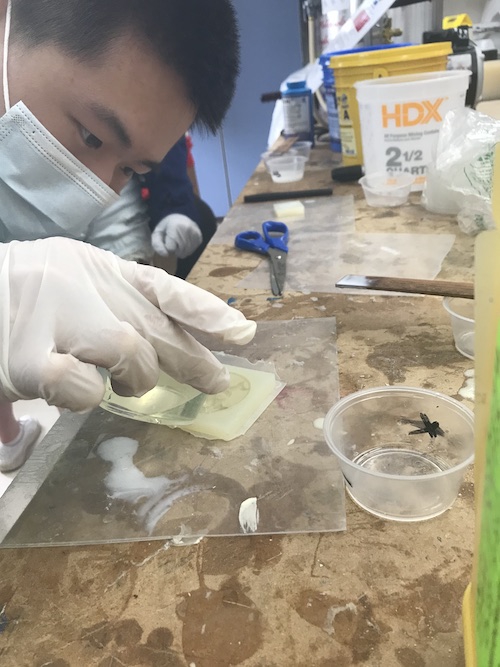

Here you can see equal parts of A and B being poured into separate cups and then combined into one.

The mixture is then stirred and poured into Elaine Liu’s milled wax from her individual assignment.

Here is the final mold:

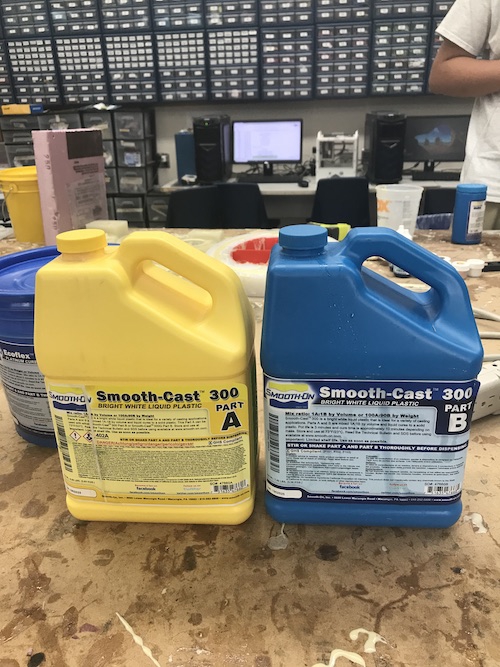

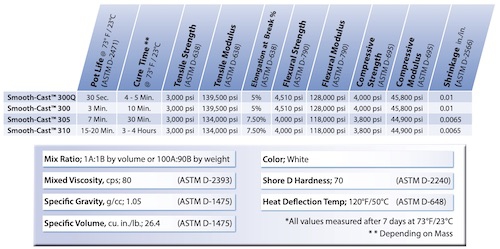

Smooth-On Smooth-Cast 300

The material to create the silicone rubber mold is called Ecoflex. We read the datasheet here to learn about the safety, ratios, and other details about how it works. Here are the two parts involved:

Smooth-Cast also has a 1:1 mix ratio and a pot life of 3 minutes, about the same as Task 8 and Ecoflex. It has a cure time of 10 minutes, about the same as Task 8. Just like Task 3, it has a white color.

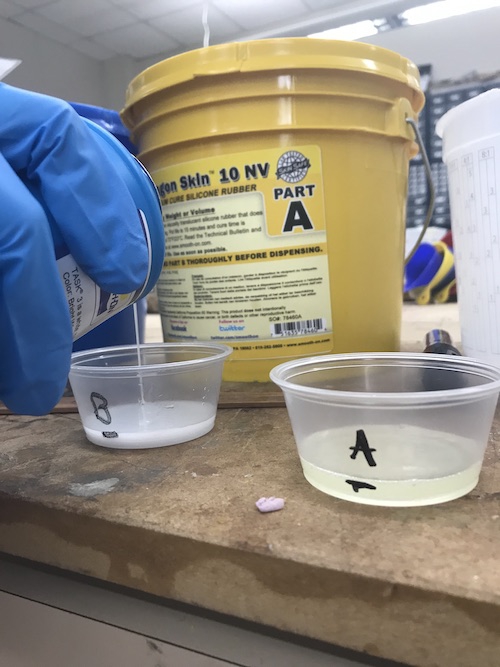

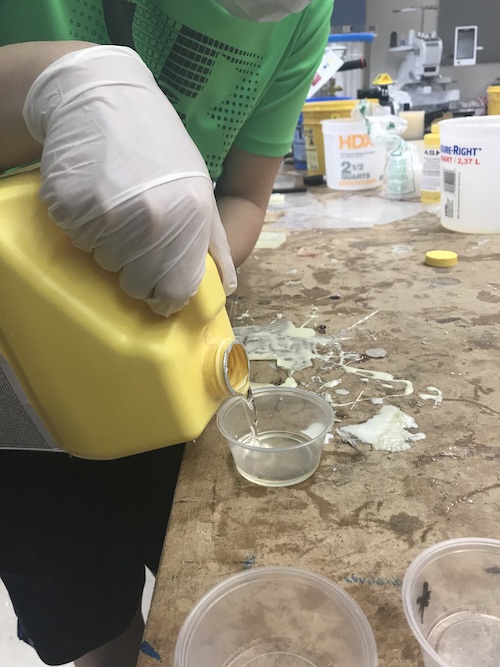

We were not sure how old the Smooth-Cast in our lab was and if it was still usable, so we did a test cast in a small cup first. Here is part A being poured into a cup and an equal amount of part B being poured into a separate cup.

Both parts were mixed together in a separate cup and stirred.

We left the two parts in this cup to see if it would heat up and harden. As you can see, the color changed to the white and we cut it out of the cup. Time to make an actual cast!

We made another mixture and poured it into Sophia Vona’s mold from her individual assignment.

After a bit, the color began to change as the mixture began hardening.

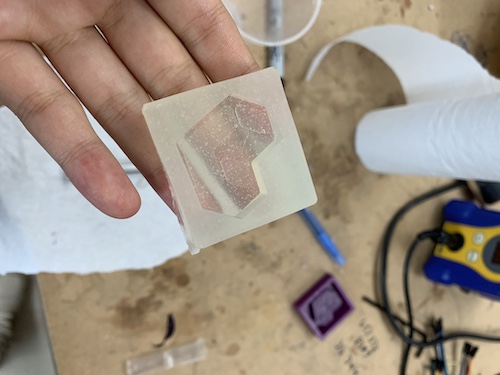

Here is the final cast: