Computer-Controlled Machining

Objective

- Make something from wood using computer controlled machine

Procedure

- Design anything in your mind for example a rocking chair using 360 fusion.

- Make a sample using Laser Cutter.

- Cut 18 mm wood using CNC machine to make the object parets and assemble it.

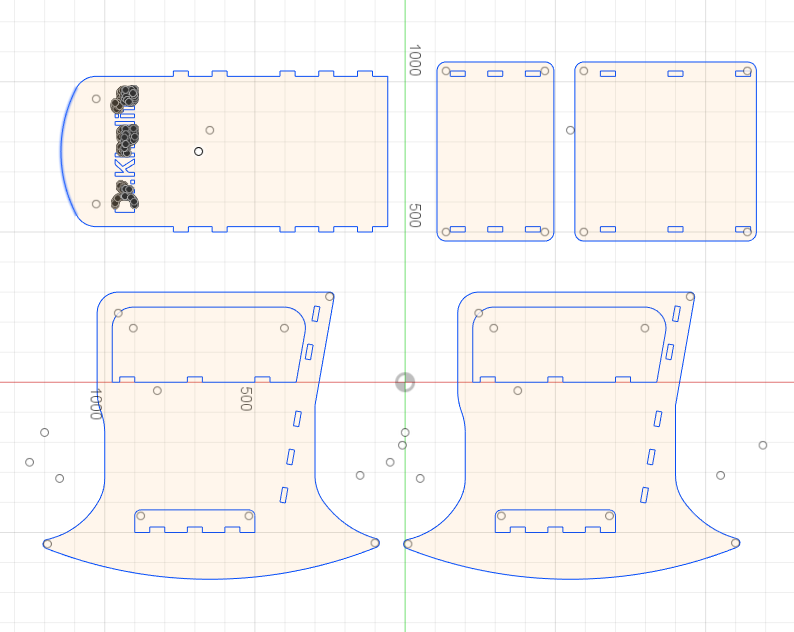

Design

To design the rocking chair I used Fusion 360 software

Test the design using 3mm MDF by laser Cutting

VCarve pro Software setup

In this assignmement I learned about Vcarve pro software. it is designed to give complex 2D patterns with profile, pocket and mill and inlay toolpaths

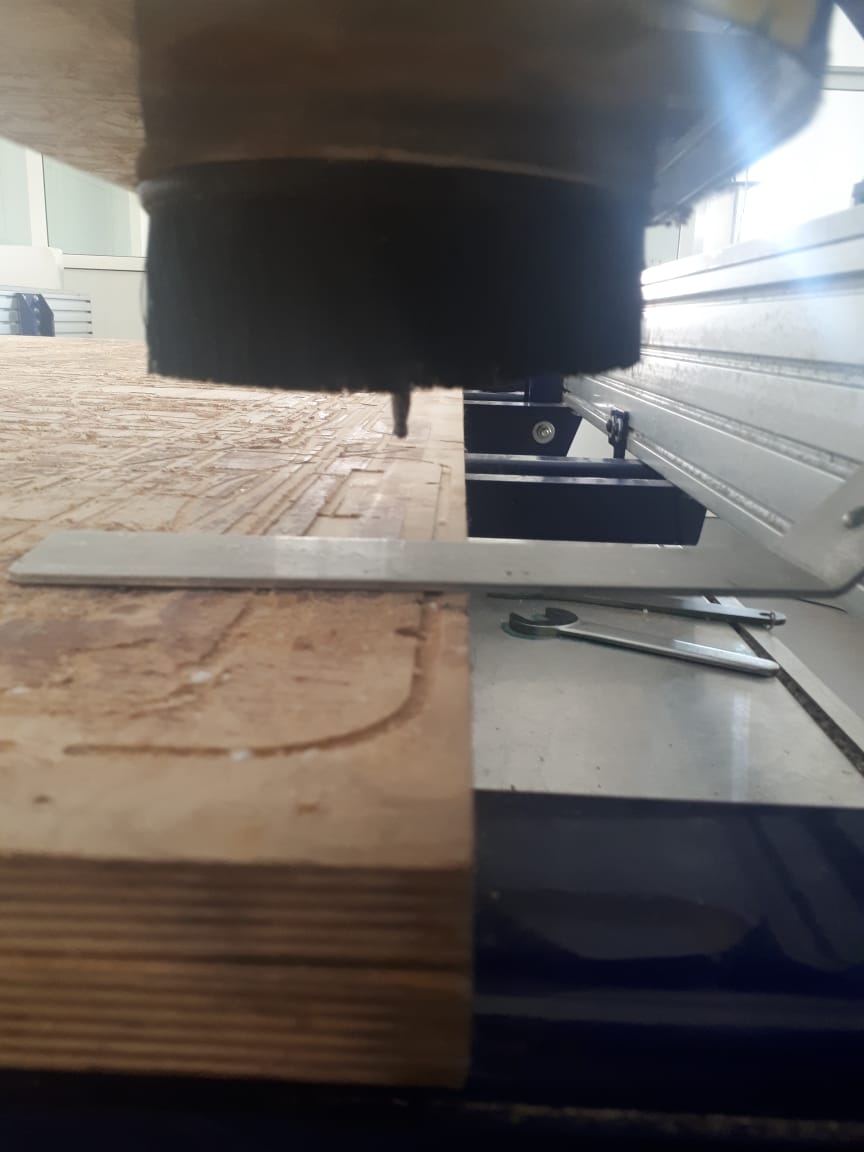

Here we use CNC machine to cut 18 mm wood

specify the work space and thickness of the wood piece as per the design specification

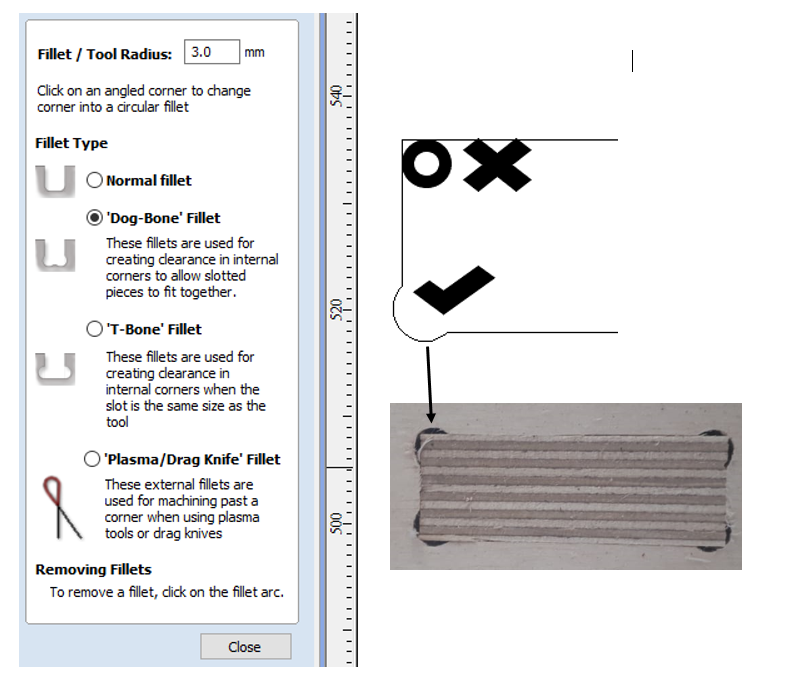

Why Dog bone fillet? the milling bit is rounded shape and will not mill the joint area corners in 90 digrees so the joint of parts will not fit correctly

Profile toolpath setup!!?

To specify what to do, engraving or cutting. you can manage start depth as per the wood piece thickness. since the thikness of the wood piece is 18mm, the cut depth sould be 19mm (1mm offset) and start depth must be 5mm. We cannot cut19mm directly so the cnc will cut 5 mm depth 3 times and the last cut will be 4 mm depth equivalent to 19mm

Toolpath list: the toolpath list is where you save the worklist after profile toolpath setup completed. all saved files will be visible in the list and ready to start milling in the cnc machine

I used to use 6mm milling bit

After that click on Calculate and save the files

Now we shift to CNC softwre to setup X, Y and Z before start cutting

We need to clibrate x and y axis. to do that we can use arrows to move the head to the corner of the bed and click select axis to zero. For z axis, there is a limit switch contact between the conductor placed on the bed and start Z axis adjustment. whe the milling bit toch the condutor, nz axis controller wil stop and you needto click on select axis to zero

Now we can start cutting

Assemble the Parts and The final Product as shown

References

Softwares

Autodesk Fusion 360

CorelDraw

VCarve pro

Files

Week 8 Fusion

\