My Final Project 2D & 3D Design

My Final Project Phases :

Project

Conception

Project

Planning

2D & 3D Design,

3D Print & Laser Cut

Electronics Design

and Fabrication

Programming &

Testing of

Electronics

Project

Presentation

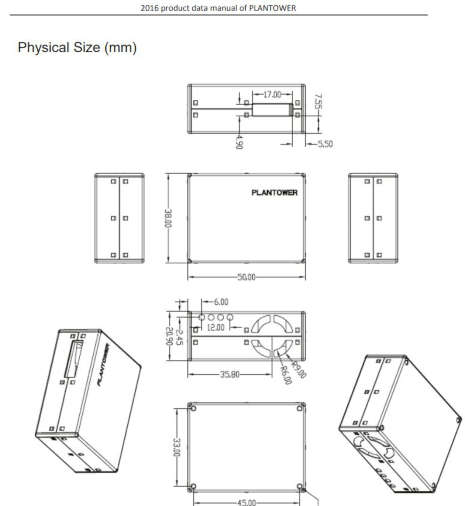

I had a rough idea and visualisation of my final project in week 1, but I only started to draw my design on 18 Apr 2019 (which is after week 13 - Applications and Implications week). It took some time for the components which I ordered online to arrive, like the dust sensor module, power switch, power jack, etc.

What will I design?

| Parts | Fabrication Process | Remarks |

|---|---|---|

| Enclosure Box (or case) | laser cutting | The enclosure box will provide protection against water, dust, insect, etc. I intend to use 3mm acrylic plastic as it will be rigid and strong. |

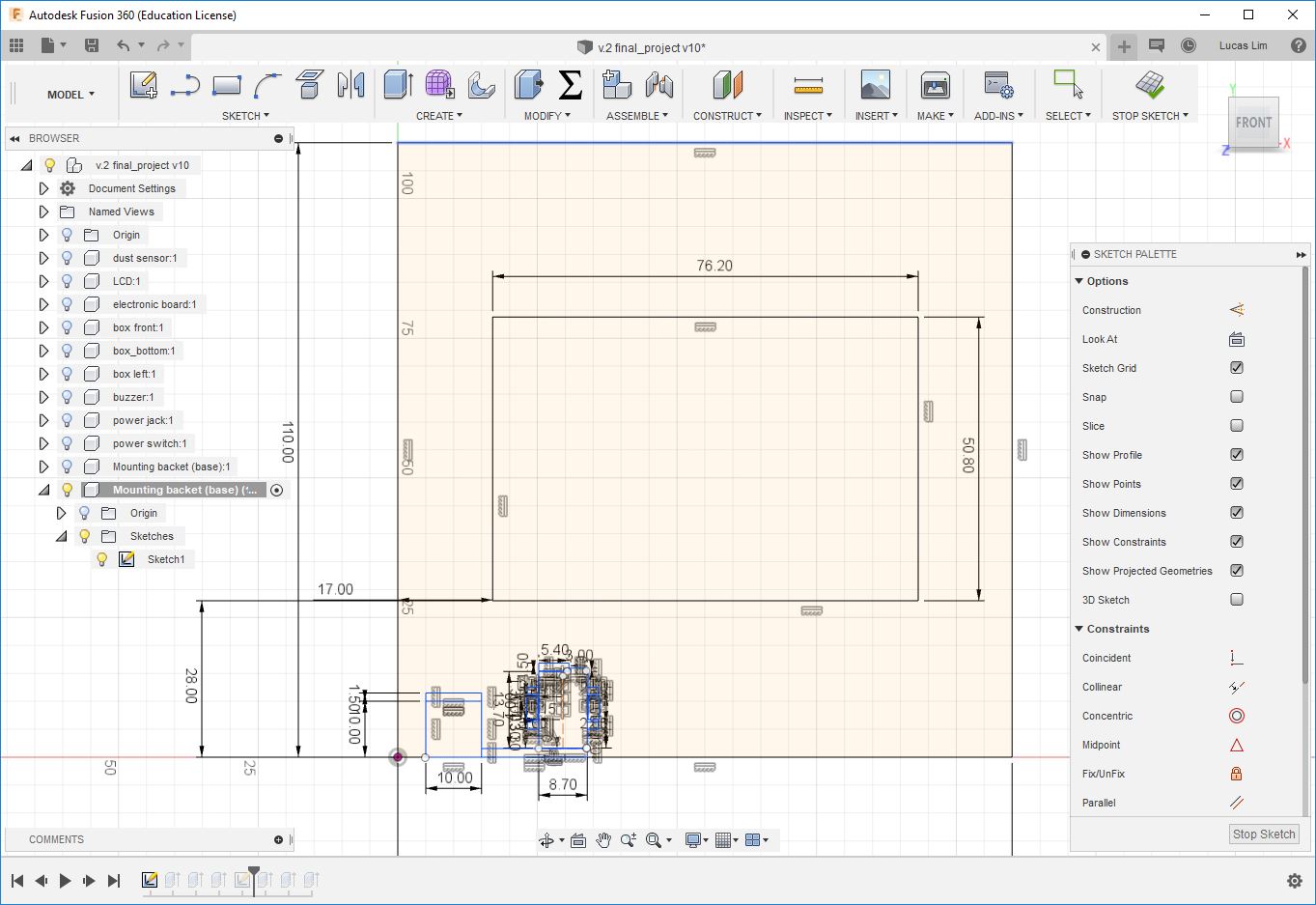

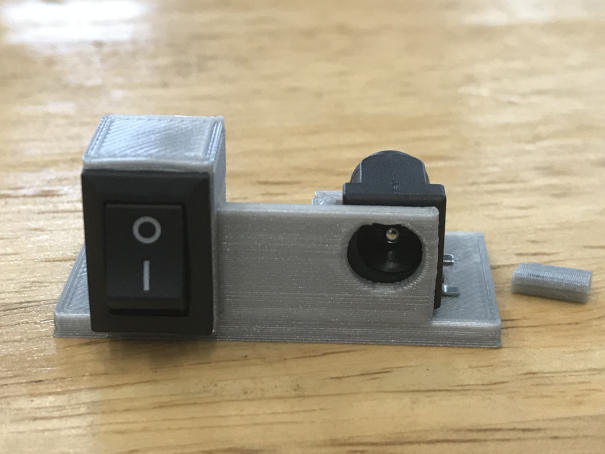

| Support frame | 3D Print | To hold the internal components like LCD display module, dust sensor module, power switch, power jack and buzzer in place. This will be 3D printed. Since it is 3D printed, I try to use less material as possible in my design but ensuring it will be rigid and strong. |

| Electronics board | PCB etching, soldering | The electronics board will integrate the various components (mainly dust sensor, LCD, Buzzer) together. |

The first few 3D prints failed due to curved-up of the base surface, malfunction of 3D printer, filament not flowing properly, etc. It resulted in a bit of delay.

In term of design, an after-thought arises after I printed my parts, I think I can further compact everything and reducing up to 20% or 30% space as well as material. Maybe by having the electronic board slotted in vertically instead of flat.

For laser cutting, the 3mm thick recycled acrylic sheet is easier to handle and join up together as compare to the 3mm plywood. The surface of the plywood near the joints tend to have some peeling off after you assemble and dismantle a few times.

- My Fusion 3D drawing (final_project frame and enclosure only.f3d)

- Enclosure front panel for laser cutting (Enclosure front.dxf)

- Enclosure back panel for laser cutting (Enclosure back.dxf)

- Enclosure side panels for laser cutting (Enclosure side.dxf)

- Enclosure top and bottom panels for laser cutting (Enclosure top.dxf)