Applications and implications.

What will it do?

The project that I am going to carry out is a steam generator for an iron, the project is oriented for an industrial sector or a clothing repair company, which requires a more powerful iron than a conventional one.Who's done what beforehand?

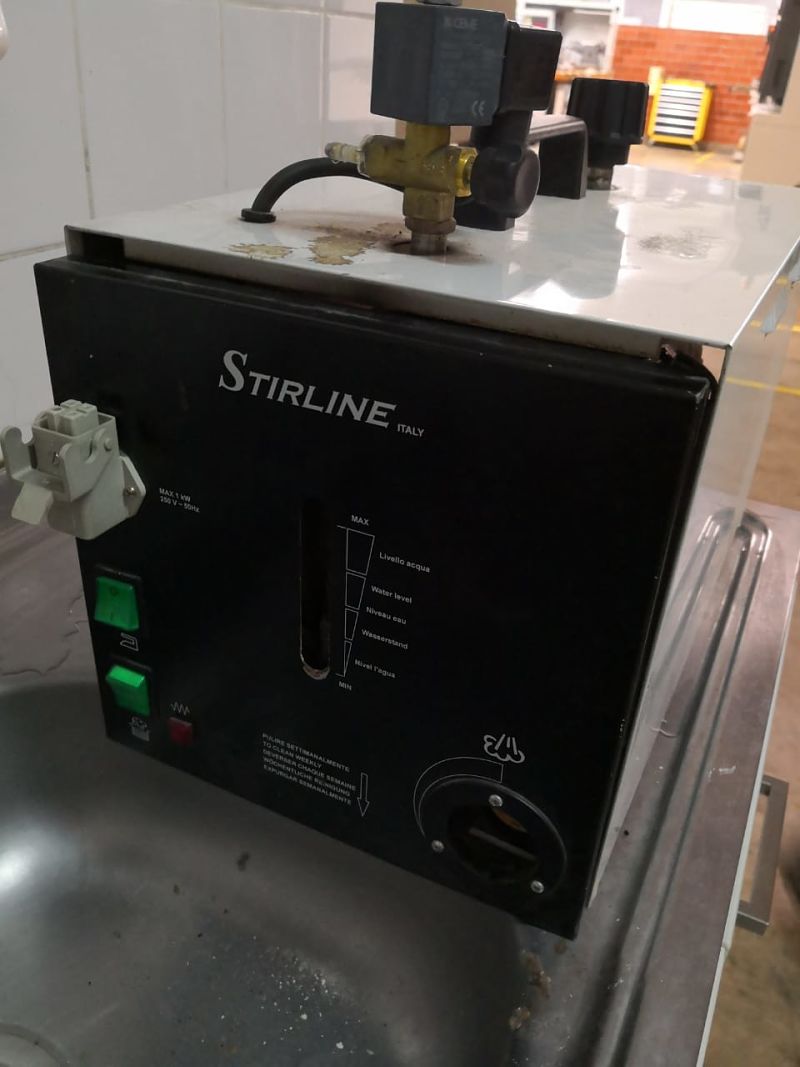

Looking in the files of the Fabacademy, I have not found anyone who has made a project like mine, but nevertheless there are many trademarks that are dedicated to manufacture the machine.In this case I will build on the model of the brand Stirline from Italy.

As much as I searched the internet, I did not get the website or the technical specifications of the machine, so I will have to personally experience the operation.

As much as I searched the internet, I did not get the website or the technical specifications of the machine, so I will have to personally experience the operation.What will you design?

In principle I have an iron that works but in an analogical way and it is in bad conditions. I will design the electronic boards to perform the control and measurement with various sensors such as temperature, level and pressure.

The board must be ready to send information to a screen where vital information will be displayed.

I will design the electronic boards to perform the control and measurement with various sensors such as temperature, level and pressure.

The board must be ready to send information to a screen where vital information will be displayed.A new water tank will also be designed where it will incorporate the level and pressure sensors, in addition to the resistance that will heat the water. This resistance will be reused from the old machine.

Finally, a new enclosure will be designed where everything explained above is located.

The reused parts will be: The iron, the electrovalve, the switches, the electrical connectors and the resistance that heats the water.

What materials and components will be used?

The materials needed to carry out my project are the following:- Electronic control board.

- Switches to turn on the machine and steam.

- LED lights that give us a function indicator.

- Thermal resistance, used to heat the water.

- Sensors: temperature, pressure and level.

- 20x4 LCD screen to visualize the values of the measurement

- Internal tank drainage valve.

- Solenoid valve to activate steam passage.

- An iron.

Where will come from?

The materials used will come from the CIT laboratory, apart from the machine that I have, and other components will be purchased in local stores.How much will they cost?

When reusing some of the components of the machine, it will be invested in the rest of the materials, having an approximate cost of no more than $70.What parts and systems will be made?

The operation of the machine is basic, it has a switch that directly connects the iron and another switch that activates the internal resistance to start heating the water tank.The external structure will be made with Medium Density Fibreboard, the internal deposit will be made with stainless steel and will be lined with fiberglass to keep the heat. Some fasteners will be manufactured in 3D printers.

In the following image you can see all the internal components of the machine, which will reuse a majority of them such as switches and resistance.

What processes will be used?

For the design the inventor software is used, you can see the prototype thought in week 3: Computer-Aided design.The printed pieces will be used Makerbot printers, which were used in week 6: 3D Scanning and printing.

The external and internal structure is made a first prototype with the laser cutter (week 4: Computer controlled cutting) and the final design with the Multicam 3000 (week 8: Computer controlled machining).

The manufacture of the control board will be used the Roland MDX540 (week 5: Electronic design).

For the programming of the board will be used the IDE Arduino 1.6.11.

What questions need to be answered?

The main questions to ask are the following:- How does the machine work?

- How do we go from a conventional ignition system to a control with a microcontroller?

- What variables are necessary to measure?

- What is the maximum temperature and pressure values that the tank should have to avoid accidents?

- How much amperage consumes the resistance?

- What power supply will we need?

How will it be evaluated?

The way to evaluate the project is the correct operation of the iron without the use of steam. The temperature and pressure of the tank must be controlled to overcome critical levels.The manufactured parts must be in a correct manner and, finally, the consumption, the capacity of the power supply that is provided.