Group project

Fab Lab Raykjavík,

Arnar Daði,

Jón Þór,

Svanur og Karítas

We meet again on Thursday to continue our project, Handy McHandface

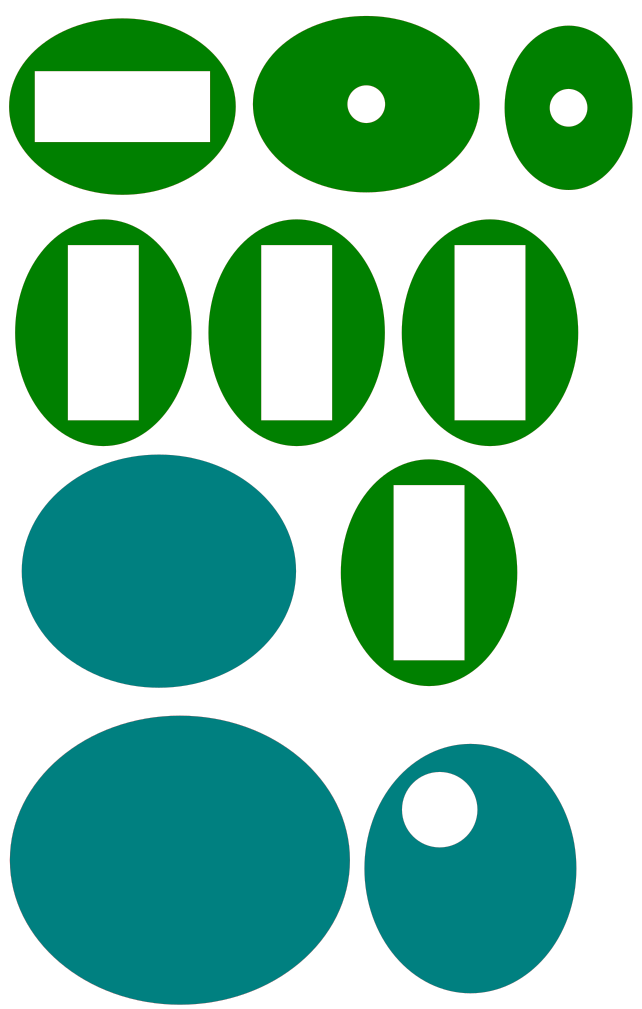

Incision in flexible joint lessens load on stepper motor.

So the 3D printing of the fingers is done, so my job to day was to start the assembling fingers and to get the hand together with all its fingers.

We used a fishing wire tied to the fingertipp, the design of the fingers and hand was with a hole through out so we could have the wire all the way from fingertipp to the motor.

So the wires came all together in one and then to the motor which was down the forearm.

I also had to fasten the motor down on the akryl plate and in the forearm.

Wrist to hand interface.

Here you can see the file for the wrist to hand interface, we made it out of plaiwood and cut it in the laser, it was then clued ald together.

We also saw that we needed to fasten the motor so it would not been pulled up when its on.