INPUT

In this assignment I had to design a 3D mold, machine it, and cast parts from it.

LESSON >> video recording - web

In this assignment I had to design a 3D mold, machine it, and cast parts from it.

LESSON >> video recording - web

>>> DESIGNING

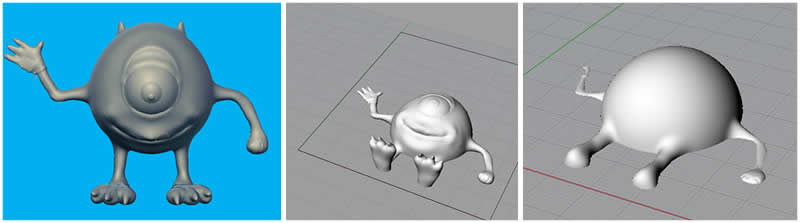

I made the 3D model in Sculptris and divided in 2 parts (positive and negative) in Rhinoceros.

>>> MOLDING

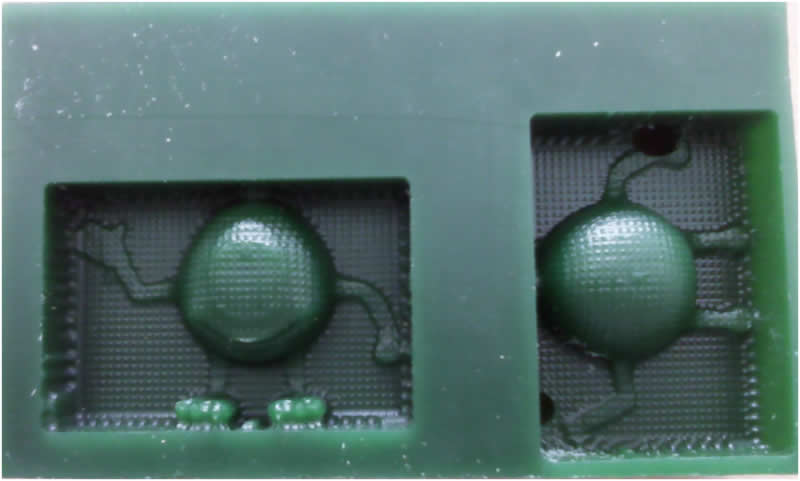

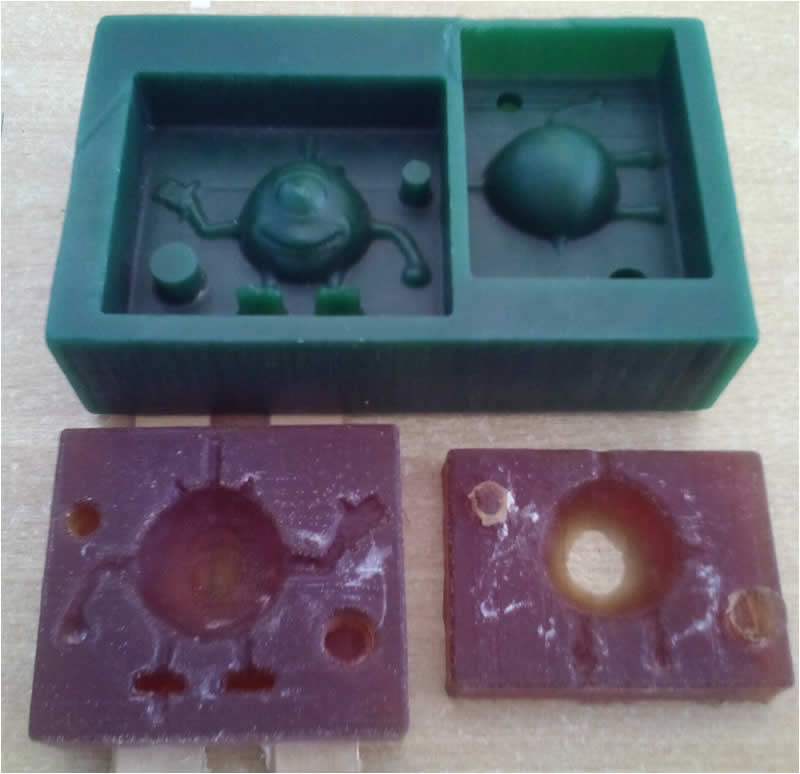

I used industrial wax and the MODELA machine to make my positive and negative mold.

In this case I used the knowledge acquired in ELECTRONIC PRODUCTION about Modela machine.

Paremeters:

Paremeters:

I needed to repeat the process twice.

* Mill: first: mm, 1/8, wax, rough. | second: mm, 1/8, wax, finish

* Tool diameter: 1.875

* Error: 0.9

* Top z: 0.0

* Bot z: -4.2

After made the firts molds I had this result.

So I did a new and better version.

>>> NEGATIVE MOLD

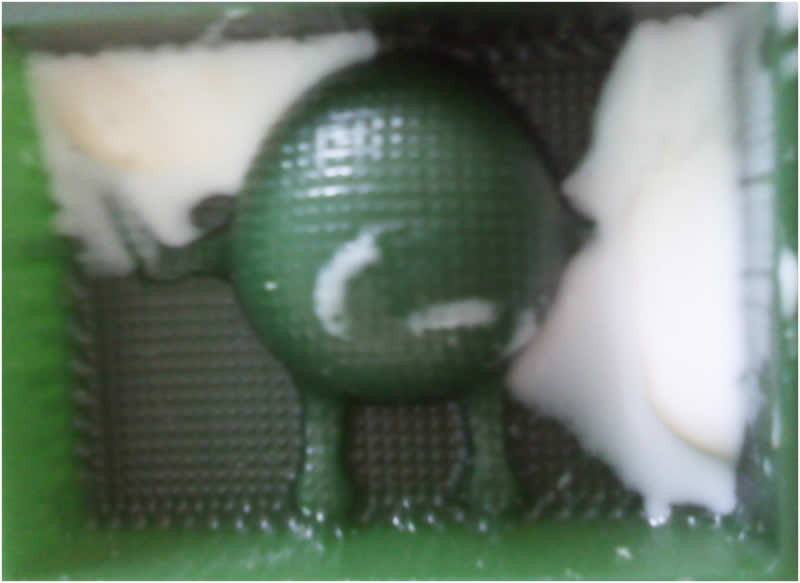

Before to do the casting I needed to cover the imperfection of my mold with glue.

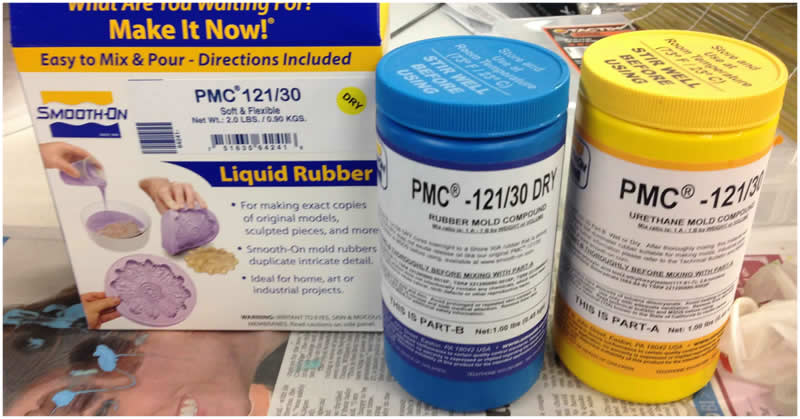

After using dry Urethane rubber (PMC-121/30).

The PMC®-121 Series urethane rubbers feature convenient one-to-one by volume mix ratios. PMC®-121/30 Dry and PMC®-121/30 Wet are exceptionally strong and abrasion resistant for soft urethane mold rubbers. These rubbers will meet the stringent demands of production casting of wax, plasters, concrete, resins and epoxies

STEPS: Combine equal amounts of liquid parts A and B >>> mix liquid rubber content thoroughly >>> pour over prepared model and let it cure to a solid, flexible rubber mold >>> demold to reveal mold cavity.

This was my negative flexible mold.

I had some problems with parts I divided in rhinoceros, so I could not use both parts.

>>> FINAL WORK

To do my final work I used Smooth-Cast 326 and Dry Stone casting media

Using Smooth-Cast 326

I combined equal parts A and B.

Using Dry Stone casting media

I combined 100-18.

FILES >>

Here are the files that I created if you wish to study or replicate this assignment:

3D model Scupltris -

3D model OBJ-

Front part in Rhino -

Back part in Rhino