Week 8

Computer-controlled machining

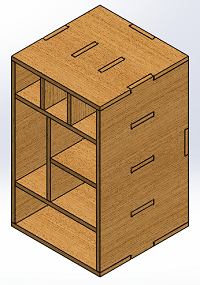

This week we had to make something BIG with the cnc mill. I decided to make a nightstand to have a

little link with my final project (the alarm clock). Furthermore a nightstand is not so big and I

have to come back in France with at the end of June x)

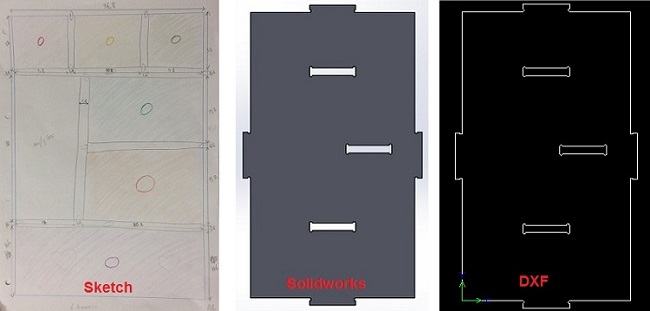

As always, before drawing on Solidworks I spent a long time deciding what I wanted to do on paper.

And it was supposed to look like that (:

Here is the ZIP file with all the parts in DXF format. And

here are the original file from Solidworks.

This time I used Cut2D to generate the G-code. This is a really simple tool to use. We have to enter

the material dimensions and the origine on the piece and select the tool. Then we have to connect vectors

to create only lines. And finally we have to create the way of the tool for each lines. We can eventually

choose to put some tabs to prevent the wood from moving during the last pass.

Machining was not so hard because I already use the CNC mill for the pcb during the last weeks.

For this nightstand I used a tool 6mm diameter and wood 16*400*7500 (mm).

I saw the too long boards that did not fit in the milling machine.

Problem with the last piece : at the end of the last pass, as the part was not really holding, it moved...

Once all machined parts, I file down edges of which had a not very nice condition.

The final nightstand (:

Software and website used