Week 3

Computer-controlled cutting

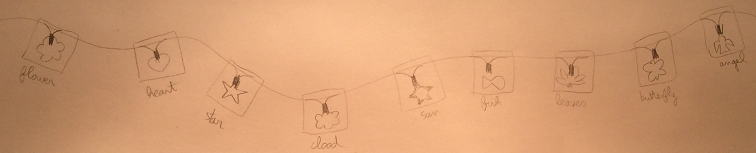

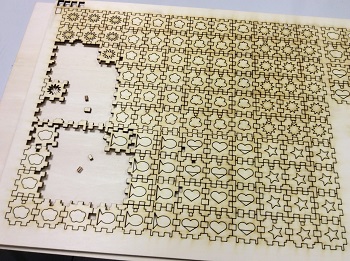

This week the aim was to use the laser cutter to make a press-fit construction. I didn't wanted to make something just to do the assignment but to create something I could use. That's why I decided to built some boxes to make a guarland of tiny lights.

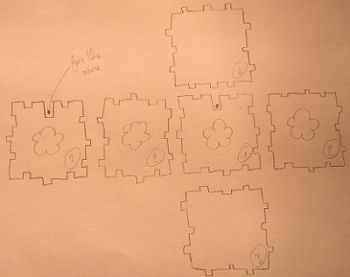

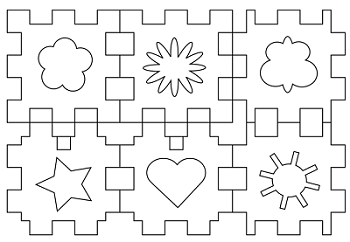

I decided to use wood for the boxes and the labmanager gave me the dimensions there was. It's really important to choose the thickness of the material before strating to draw what we want to cut because it really depends on that for a press-fit construction !!! I chose wood with 5mm thick and I started to try inkscape. At the beginning it was not simple but I found some help on few forums. I finally succeded to draw what I wanted and after 3 days using inkscape, I really like it.

Here is the DXF file.

The labmanager explained to me how to use the laser cutter and the software CorelDraw during a little formation

and I started to make a boxe with cardboard. I asked a lot of things to the labmanager because it was my first

time with a laser cutter but my principle problem was the format ! I had a .svg file and when I opened it on

CorelDraw, it was a big disaster, absolutly not what I have done. So I converted it into a .dxf file, it was

better but not exactly perfect and the dimensions was not the same than those in the initial the svg. file.

So I have made some change before cutting. I tried some different speed but it was not complicated, cardboard is

easy to cut. I was happy to see that it works, the boxe was like I wanted (not perfect because the cardboard

had less than 5mm thick).

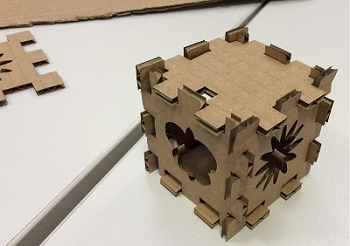

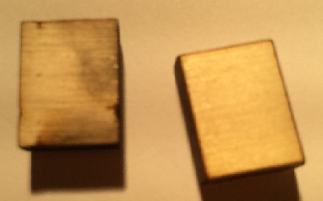

After that I wanted to try with wood. I started with some tiny pieces to see how fast I could cut. I had a lot of boxes so I increased the speed to the higher value to cut trought the wood. It was not only for the speed : with low speed the wood became black and it was not nice.

After doing all the settings, I cut.

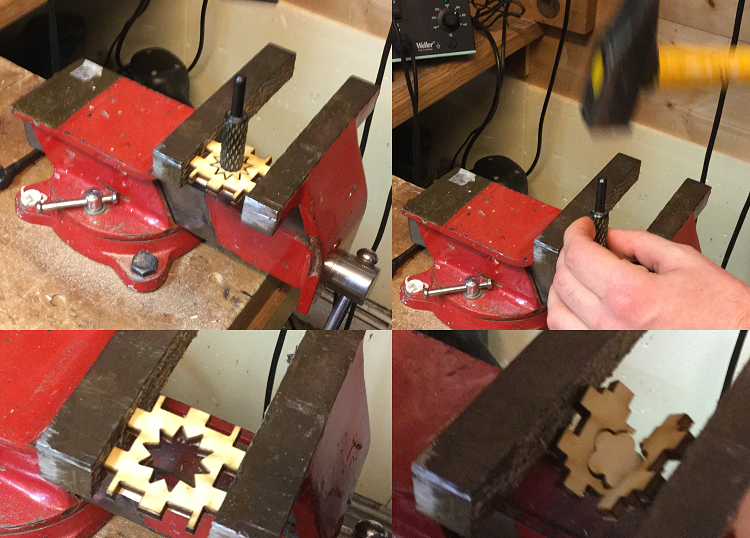

Some pieces were easy to detach but for some others it was really hard and sometimes not possible. The laser cutter didn't cut every pieces in the same way. I think it's because the wood was cambered. Next time if I use a large piece of wood I will surtenly make the focus many times and cut piece by piece. For those which were hard to detach, I used a vice and a hammer : it didn't worked for all as we can see on the pictures.

Finally I had less boxes that I wanted so I used boxes just for the half of the lights and I improvised for the others. I fixed the good boxes around the garland and the result is really nice (:

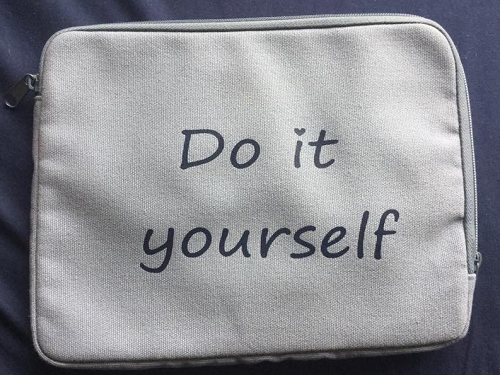

I also tried the vinyl cutter to decorate my ipad cover. Everything worked properly rather if we ignore the vectorization problem with the small heart drawn by hand. I used a special paper and then applied the pattern with heat to 170 degrees. Here is the svg file.

Software and website used