Week Three: Computer-Controlled Machining

assignment

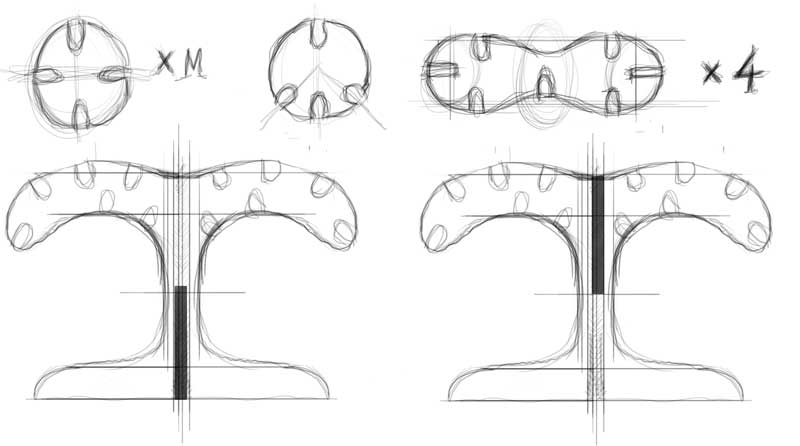

design, make, and document a press-fit construction kit. My first thoughts on what to make was to make a small version on tent. But that didn't fit in to the assignment of the week so my idea is to make a tree that can be put together in many different ways.

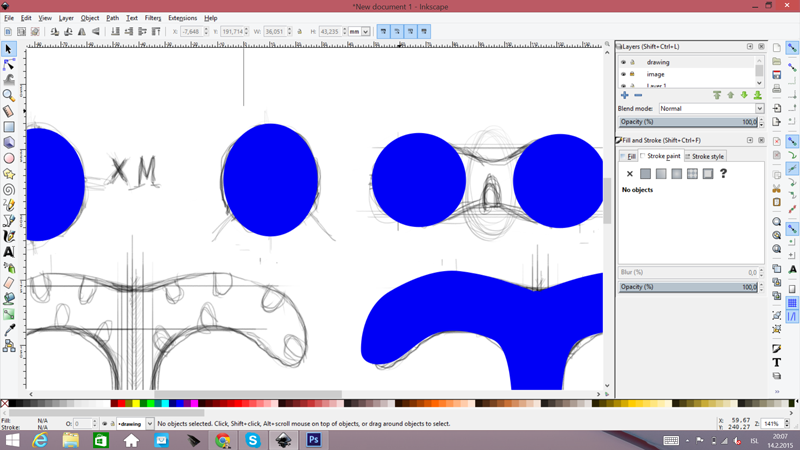

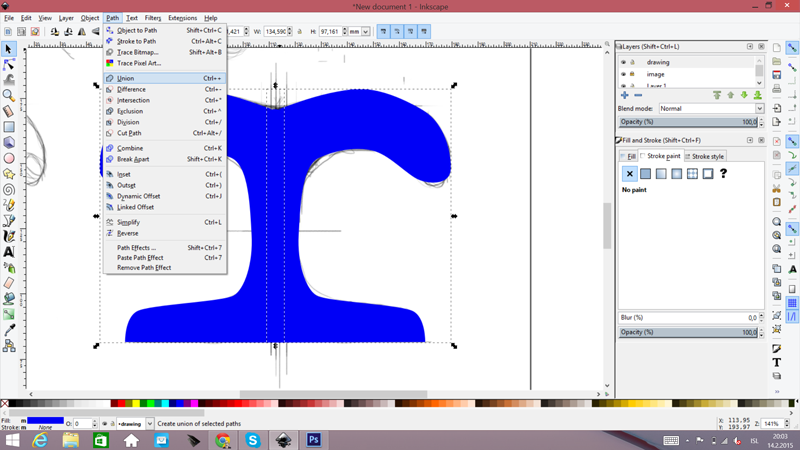

then I made rectangle where I want the cut to be, later in the fablab I measure the right thickness and chance the clone so all cuts will be right, after checking if my press fit is working by doing just 2 pieces I duplicate the layer and I unlinke clone so that I can use the Differenc command. I used this method to add the 0,2 stroke, stroke to path, break apart and the 0,01 in stroke.

Success

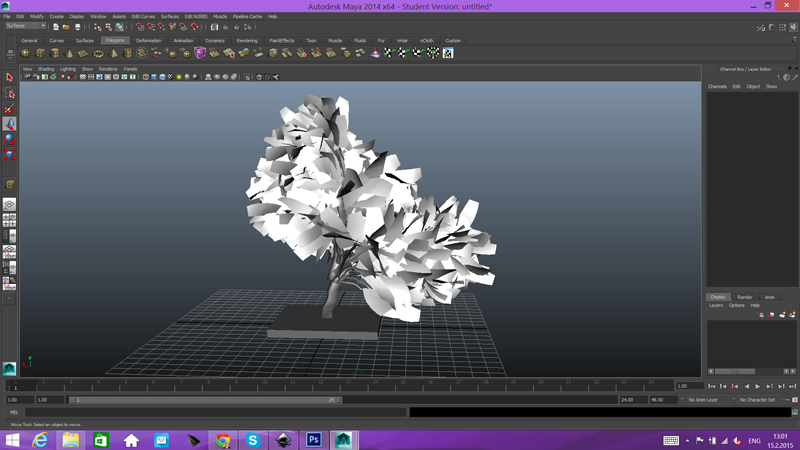

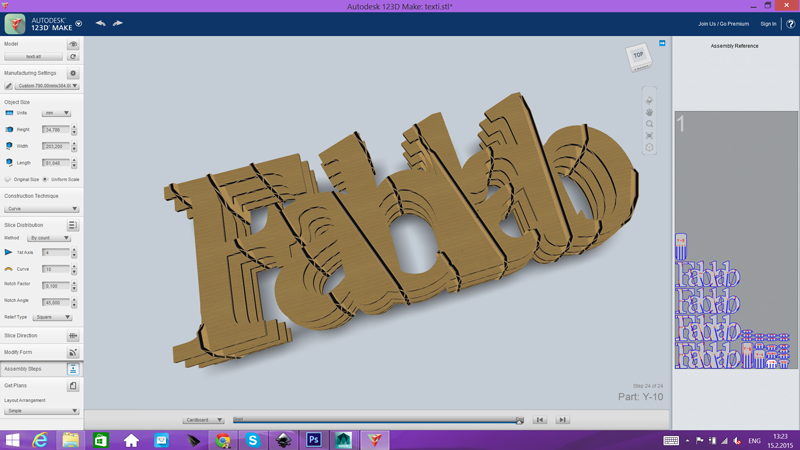

123D make is a program that I was interested to test. I did start on making a tree in Maya and testing how it will be in 123D. This tree did not upload, I think it is becouse its has plane with no volume.

I would like to explore possibilities in sketchup there is a plugin..unfolding plugin.

something that unfold 3d artwork with pdf output. I will do that later.