8/4/2015 // Molding & Casting //

Planning

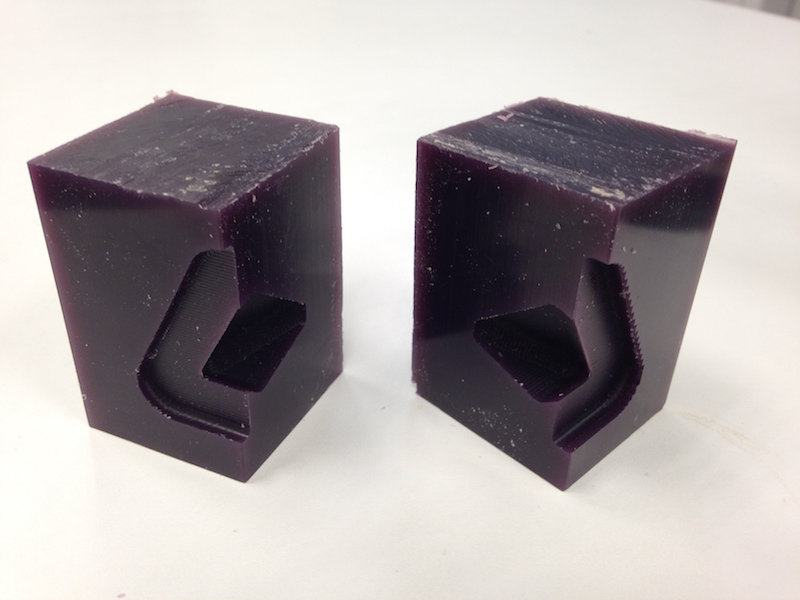

For this week I wanted to challenge myself a little. Since I have previous knowledge with molding and casting I wanted to try to make a mold from more than two parts.

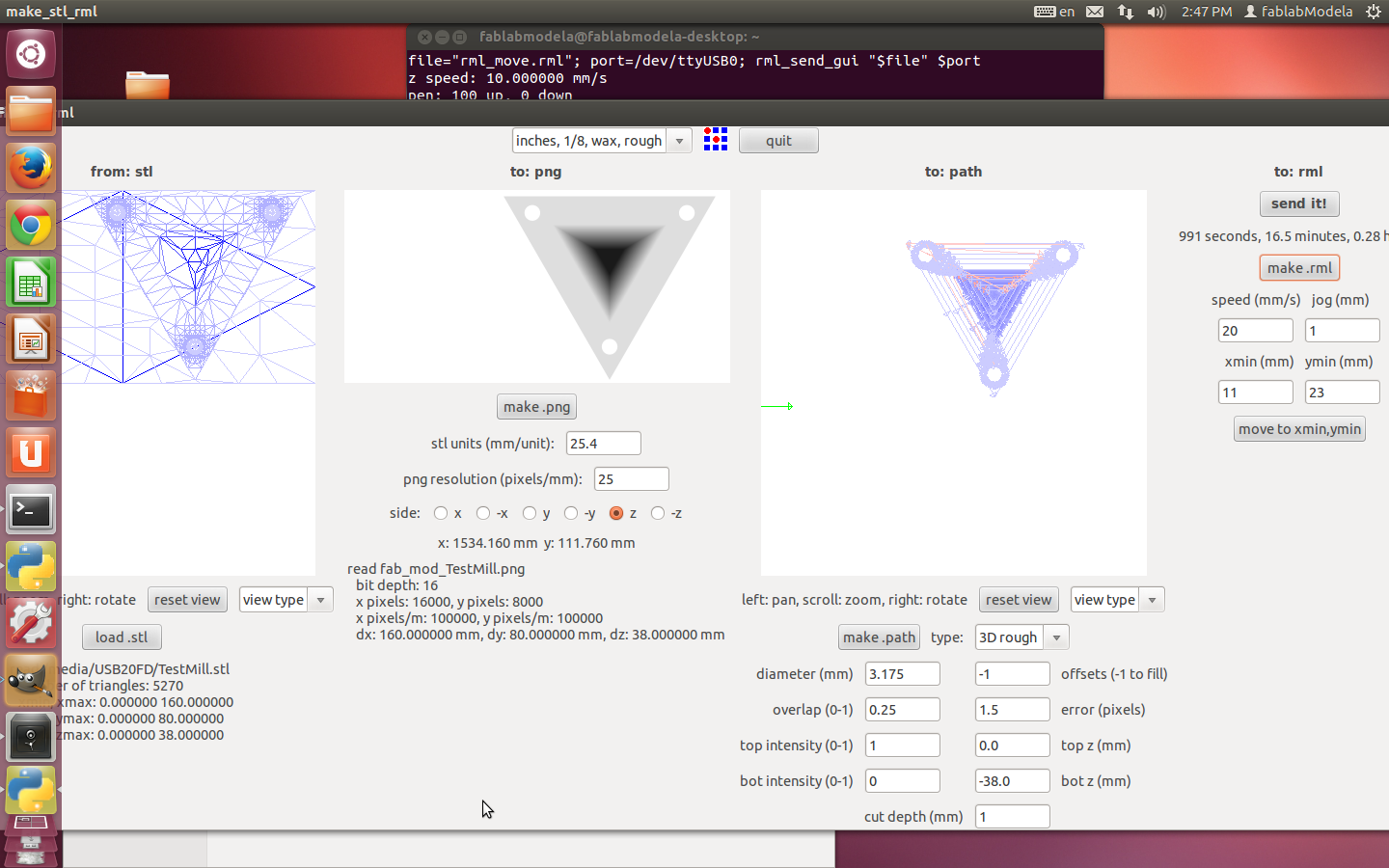

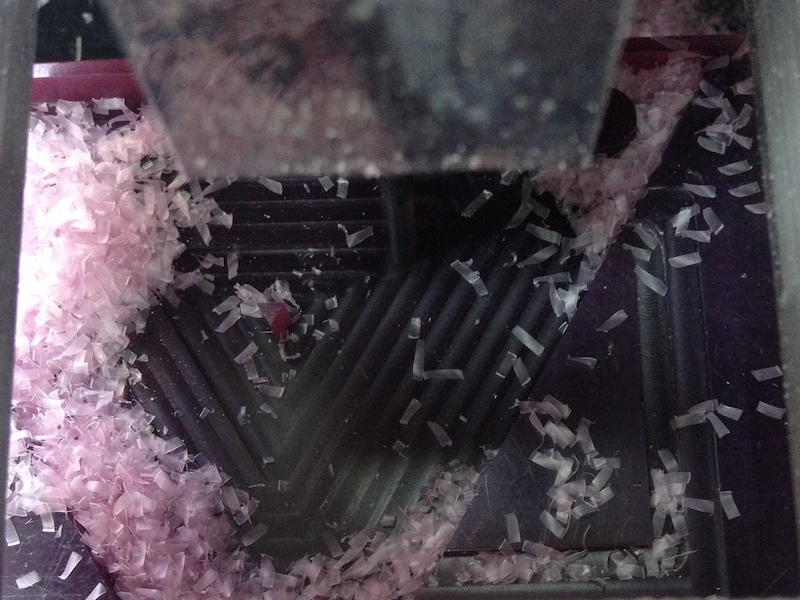

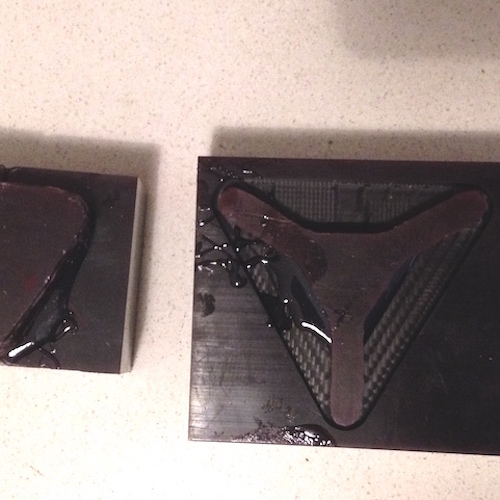

My plan was to start out with what I was sure was a simple form and later evolve into something more complex. And I decided that I was going to cast Chocolate.

My regular tool of choice for CAD is SolidWorks but since I got a new mac I haven't had the chance [or the courage] to install the program so here's what I did using Rhino.

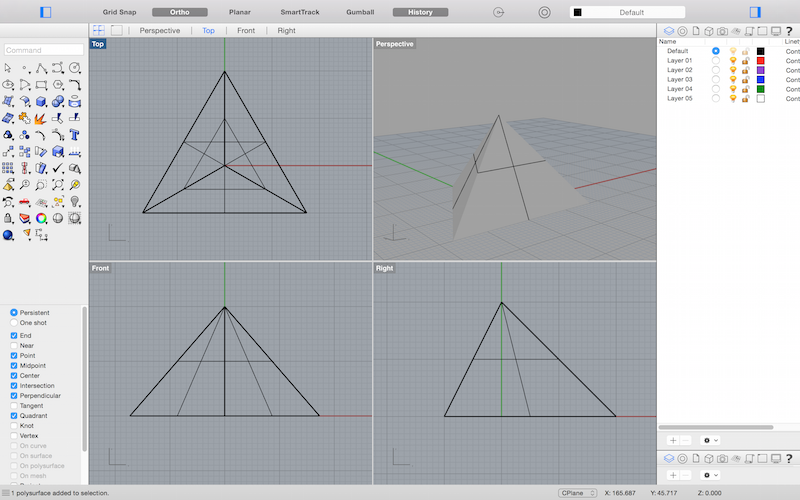

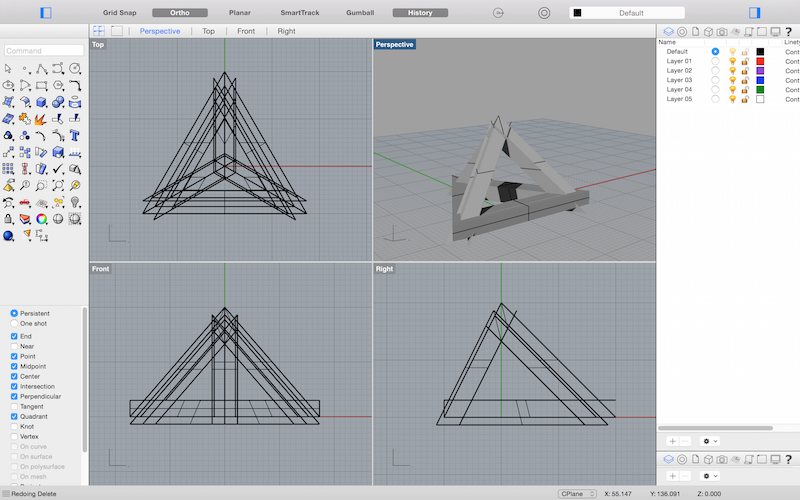

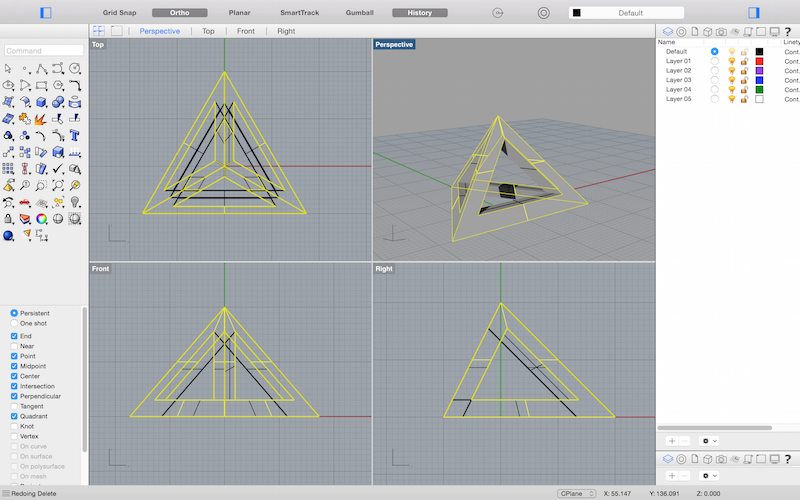

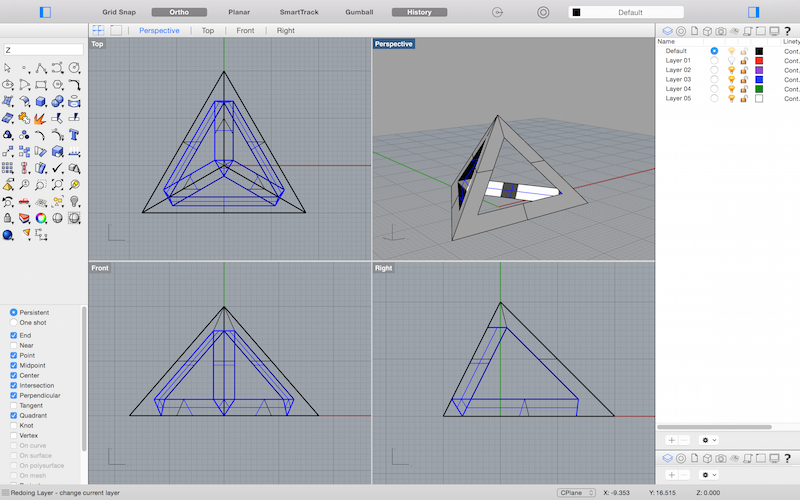

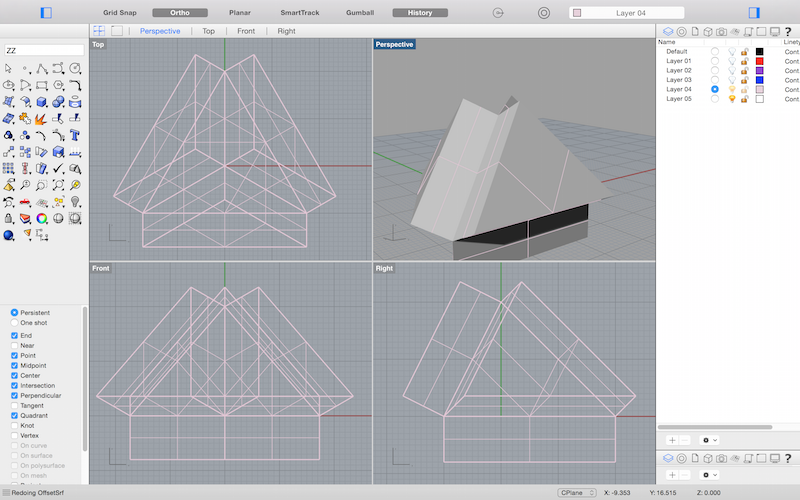

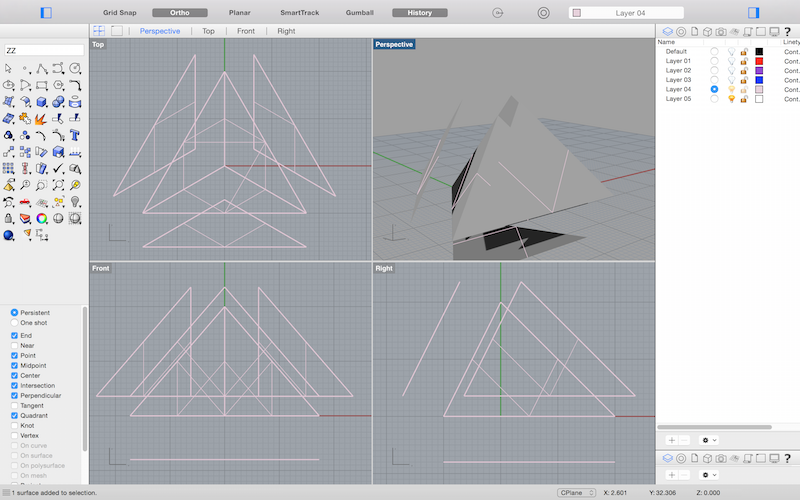

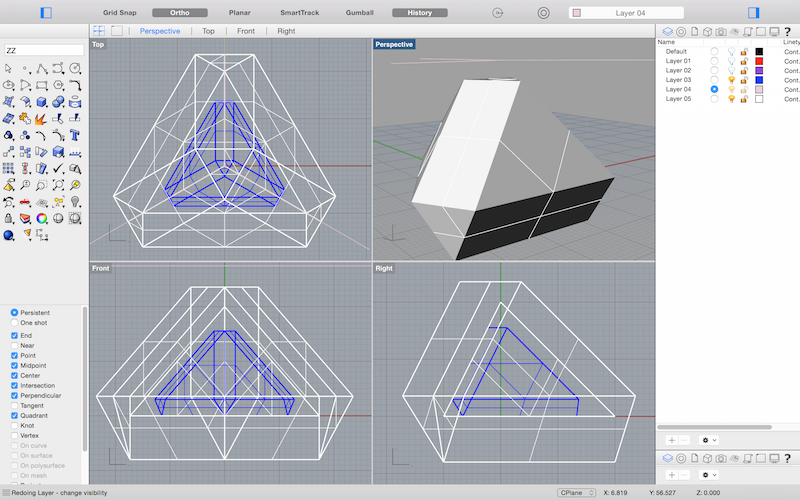

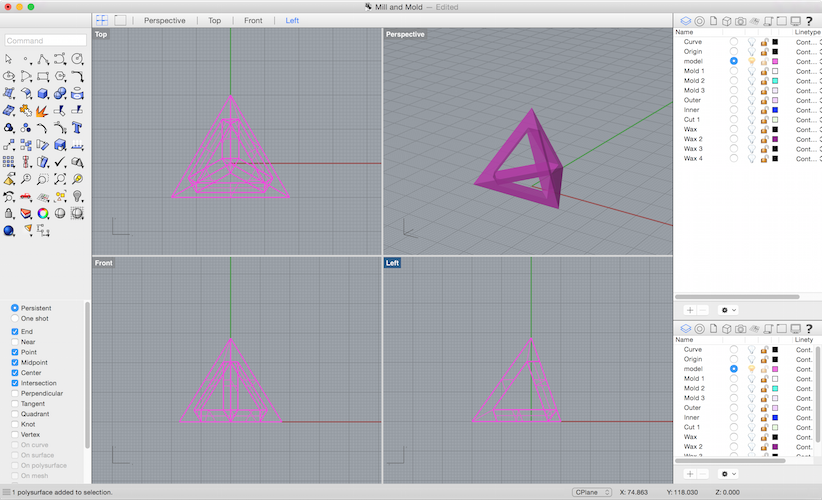

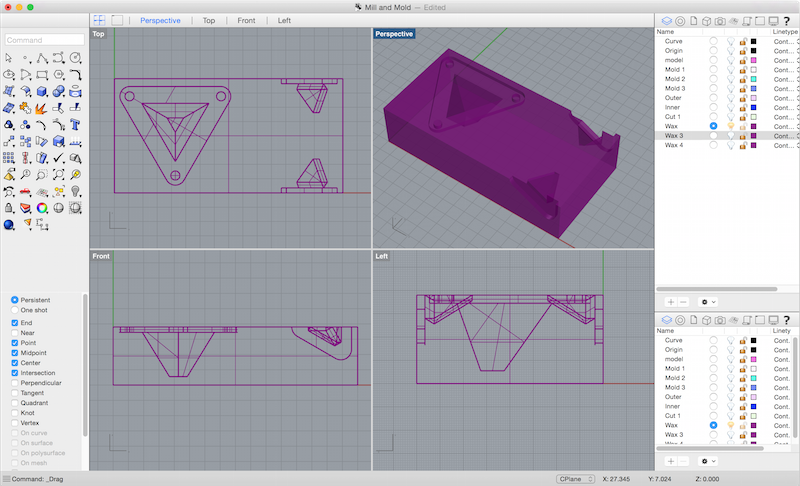

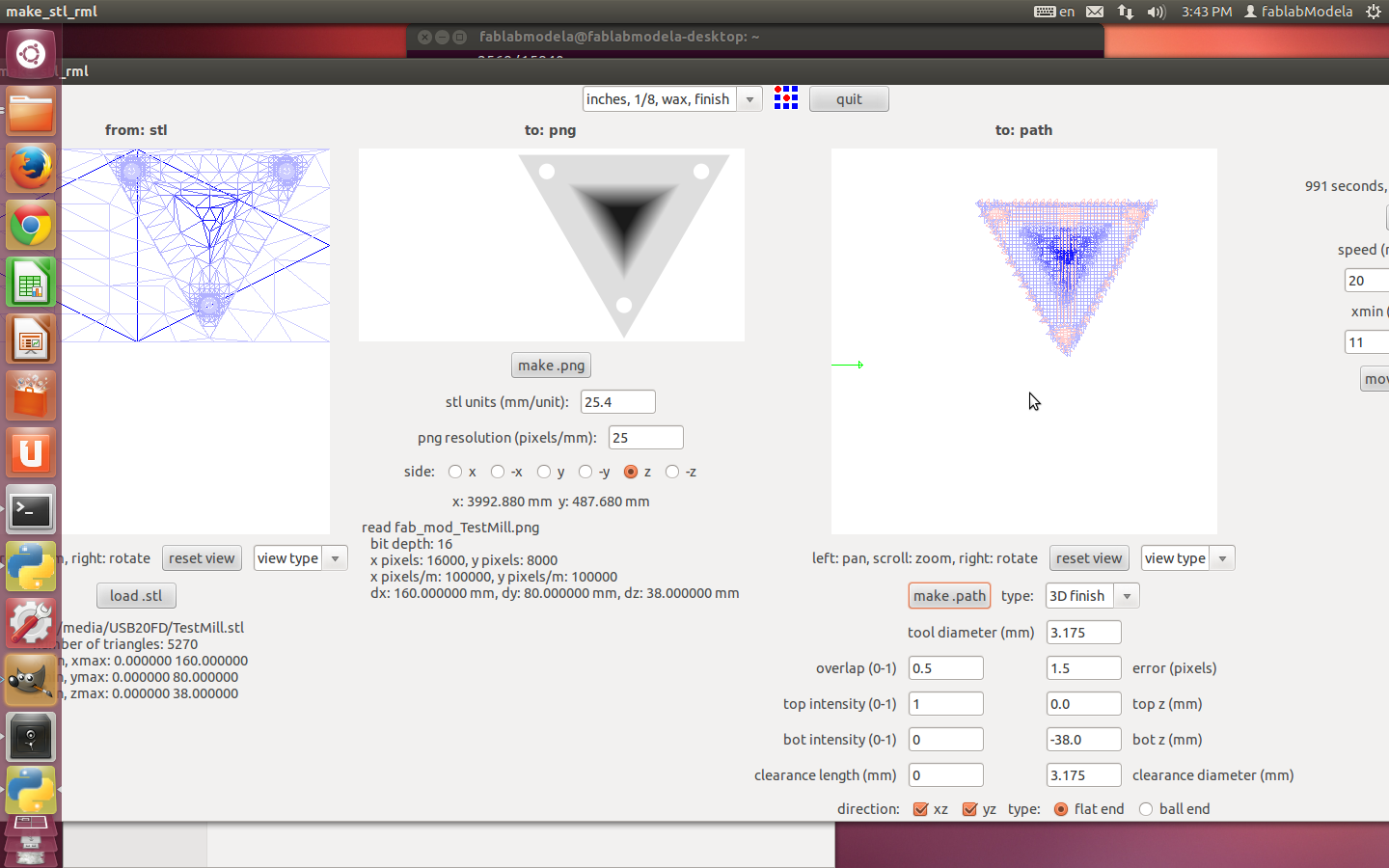

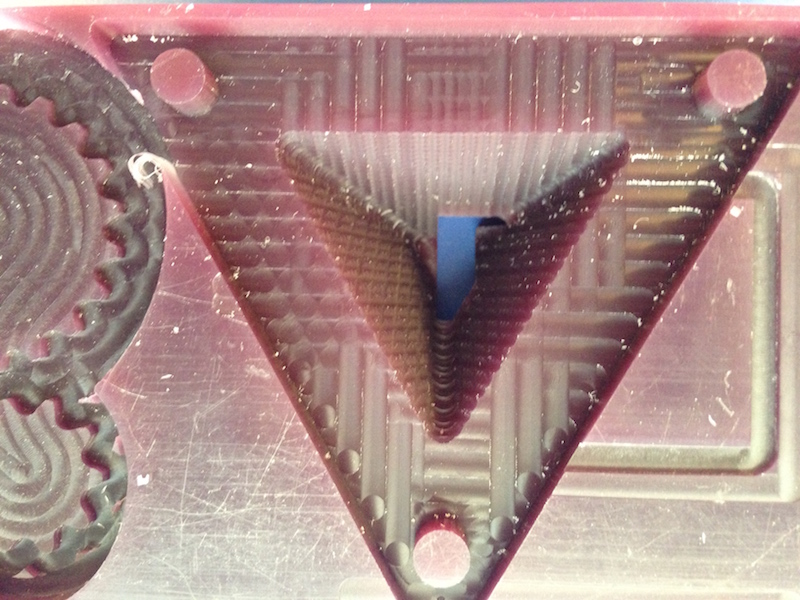

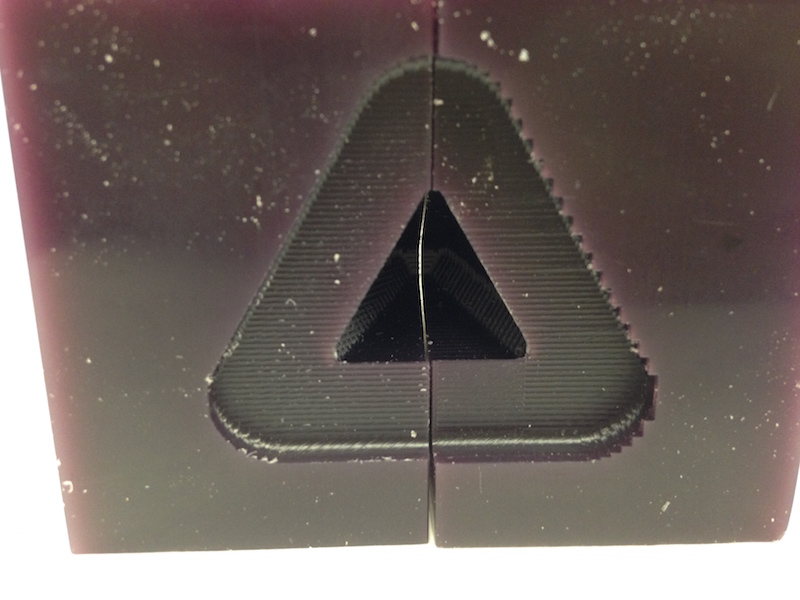

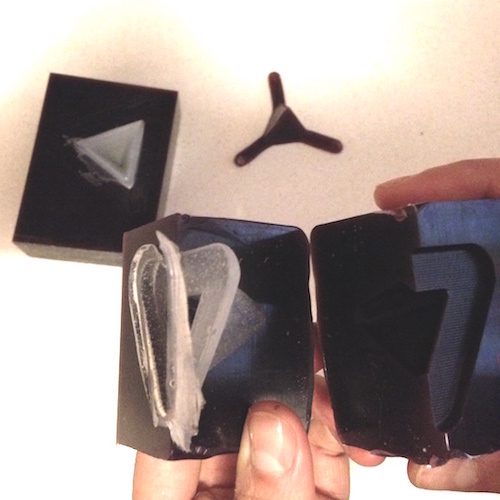

At first I tried to make a tetrahedron

freehand using the tools I know in Rhino.

Here are my steps for this shape:

1. I made a Pyramid using Rhinos Solid tools.

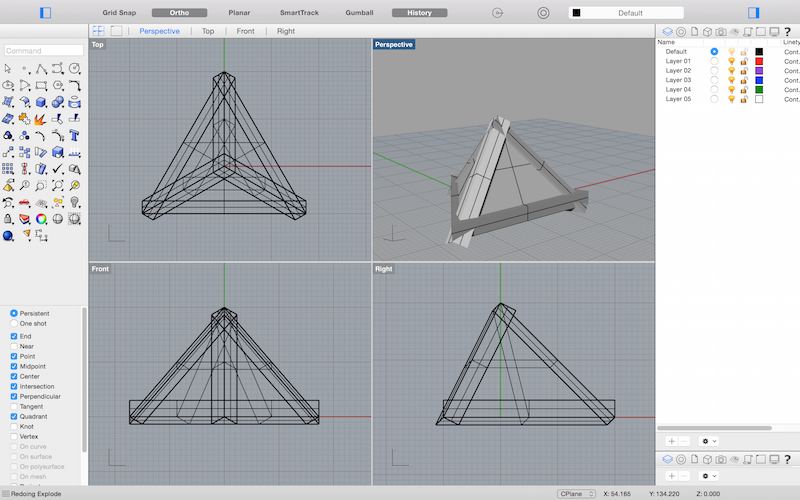

2. To hollow the shape I made an Offset srf to each of the shapes surfaces.

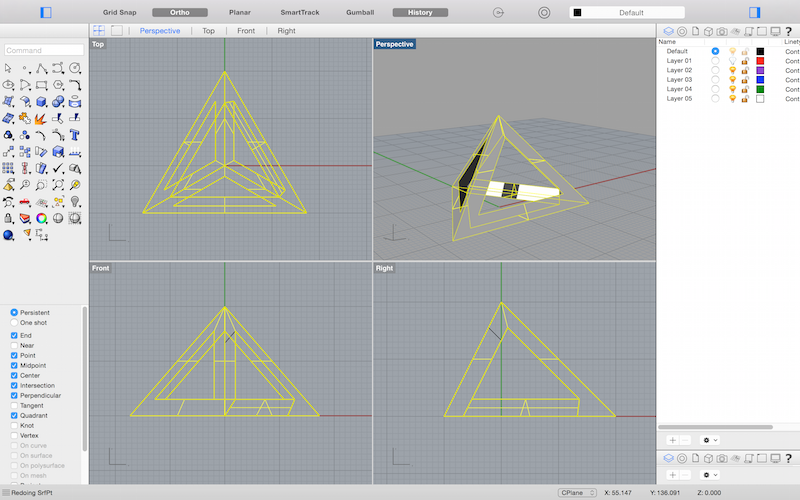

3. Then I used Trim until I had the shape hollow.

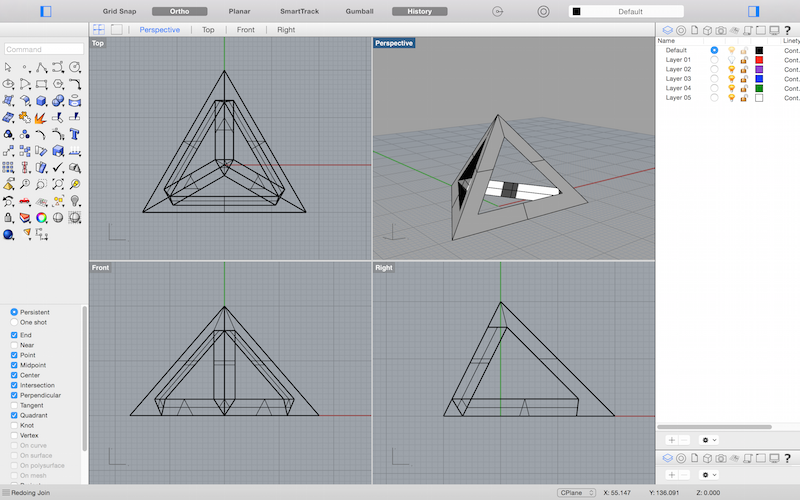

4. To make the surfaces into a solid i Joined them.

5. I then copied the shape inside and closed it to have the solid of the inner space.

6. For the outer part of the mold I again used offset srf.

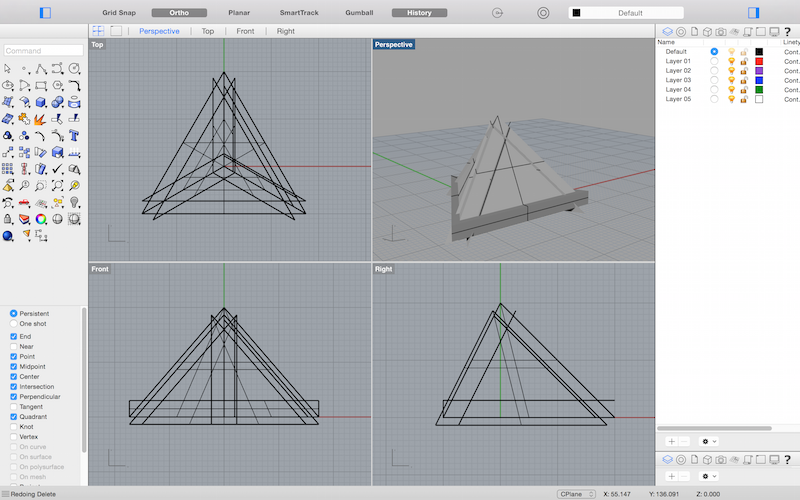

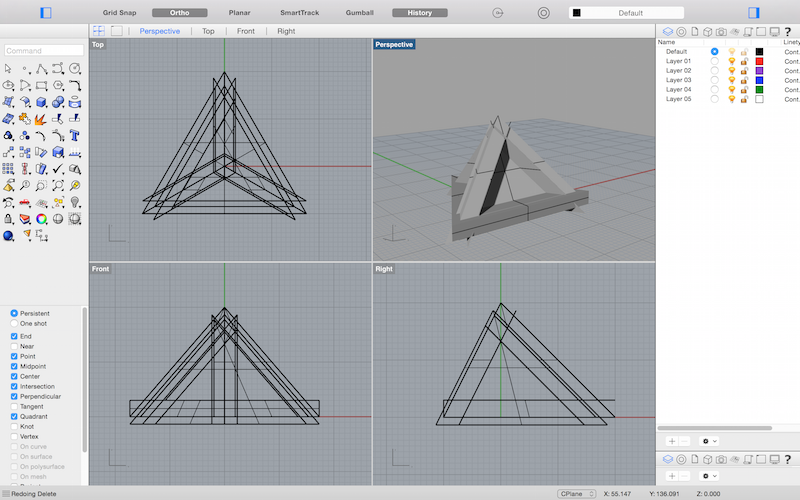

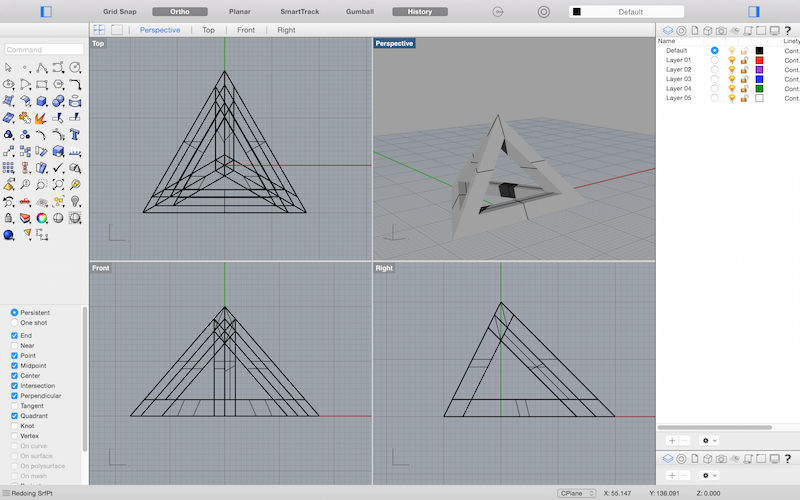

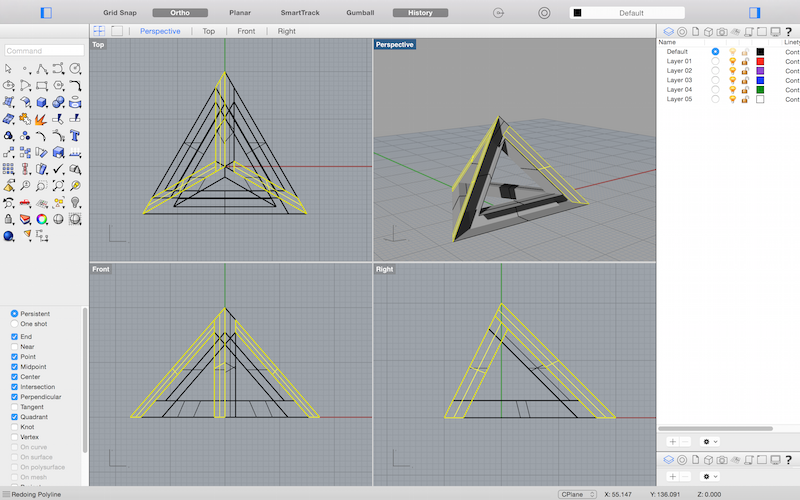

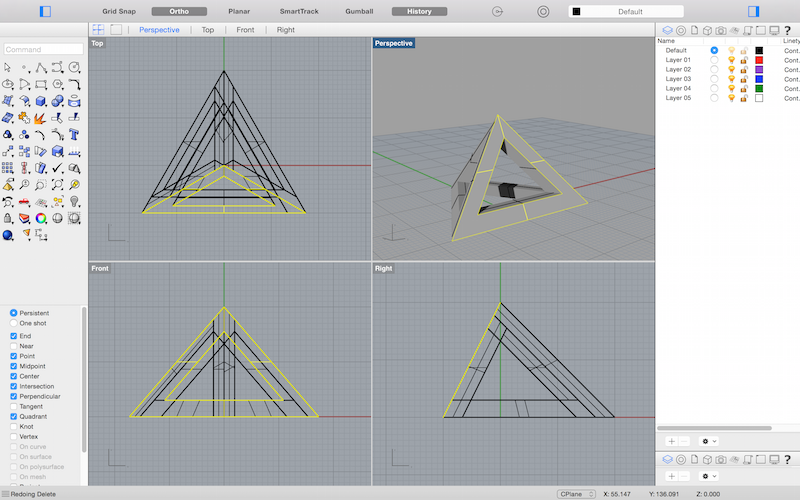

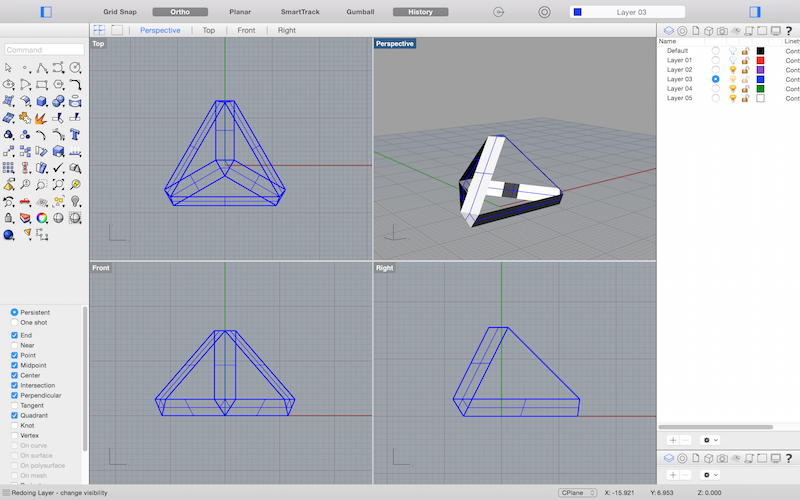

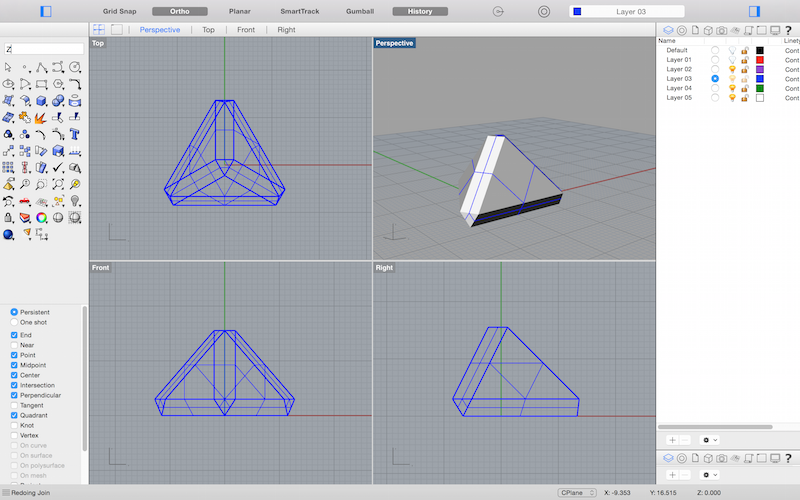

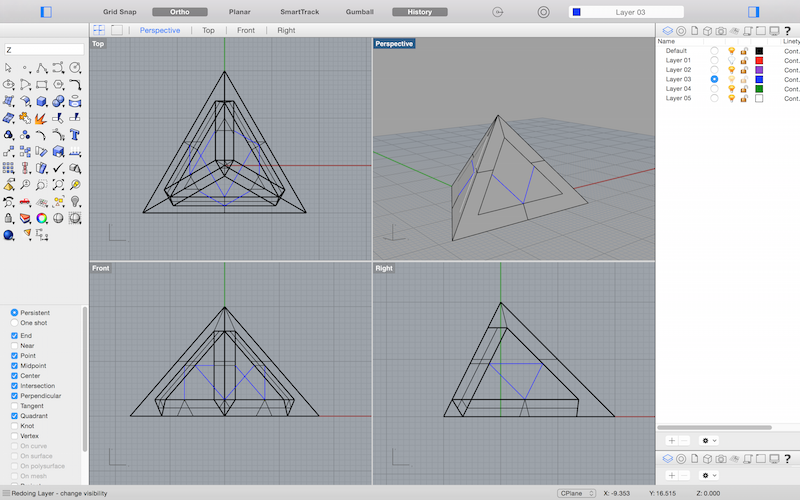

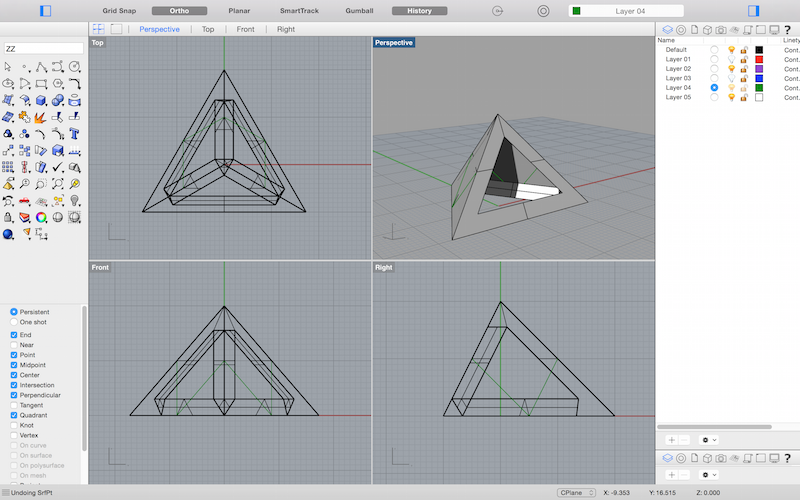

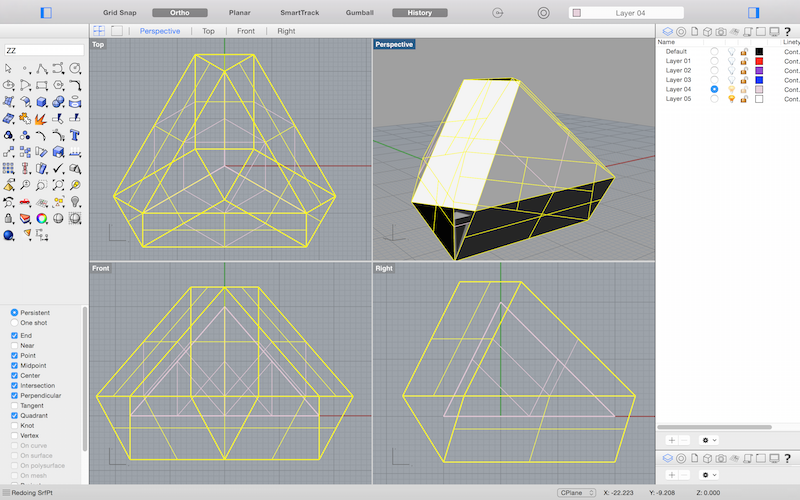

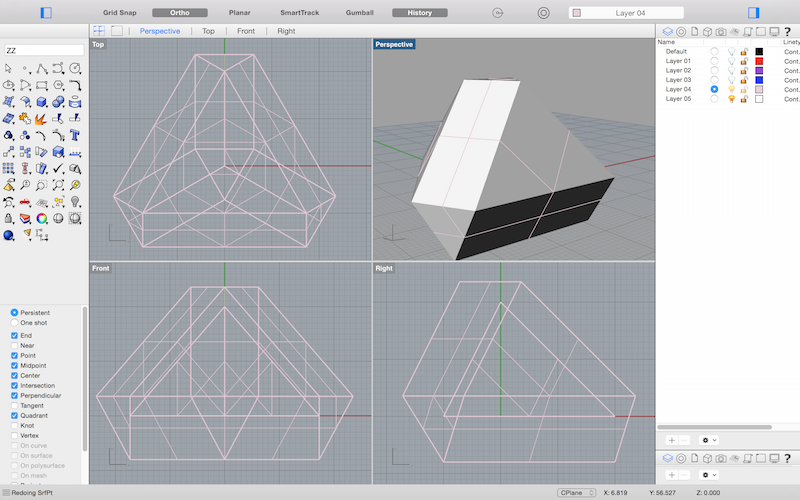

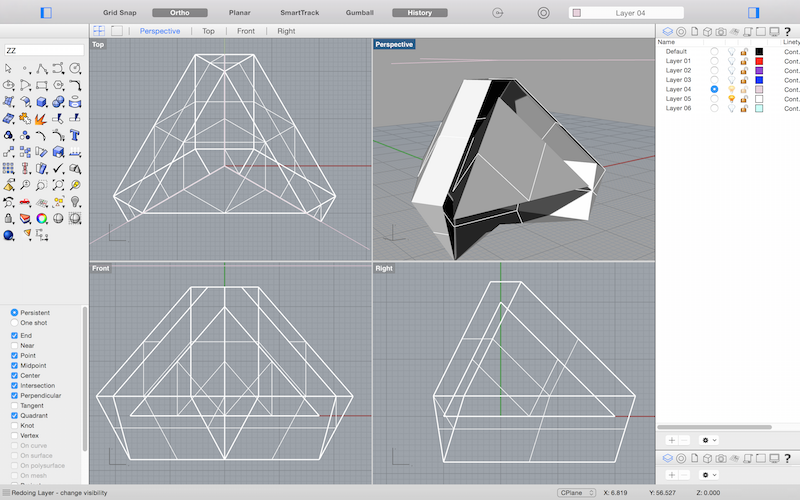

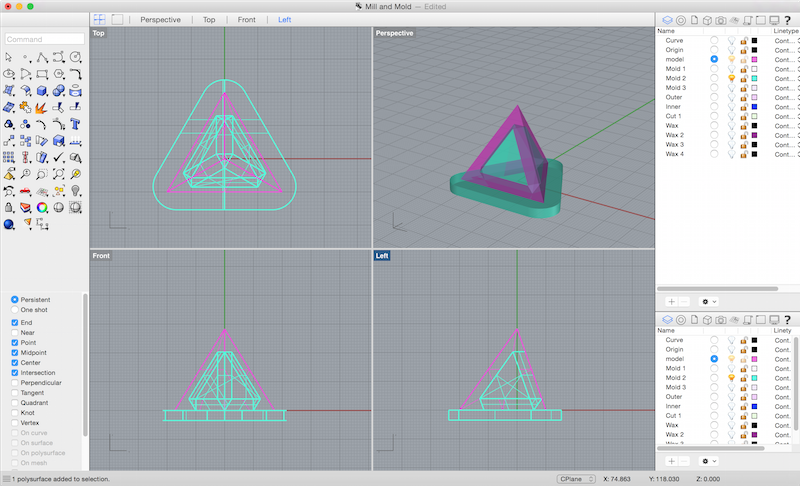

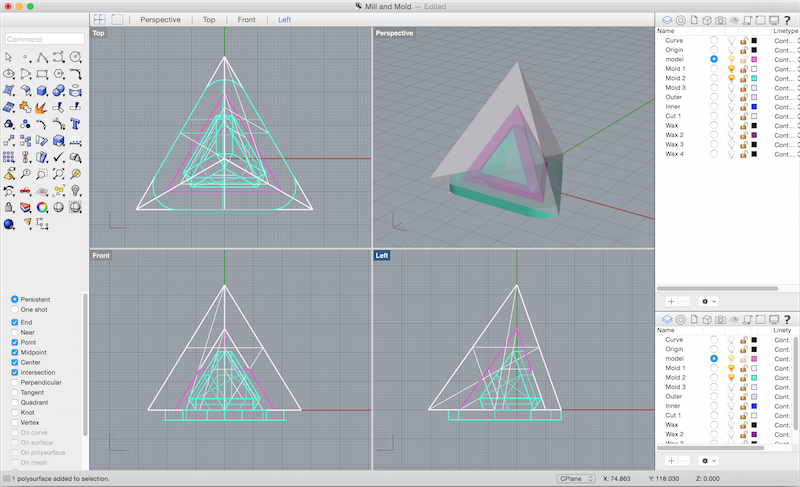

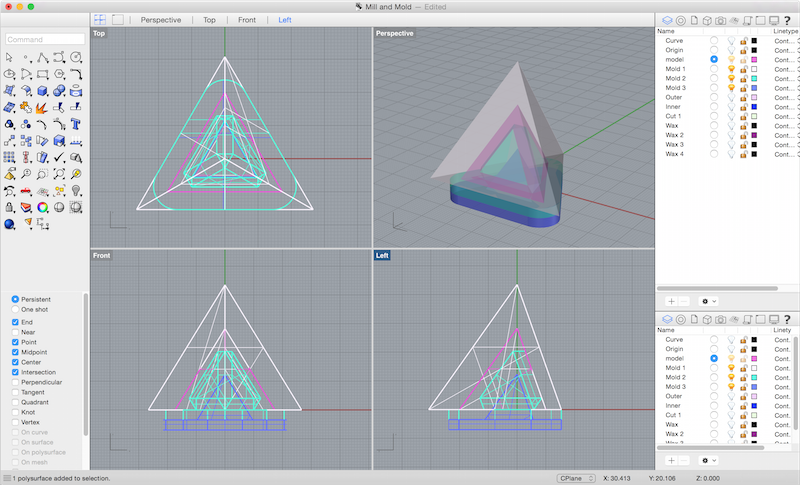

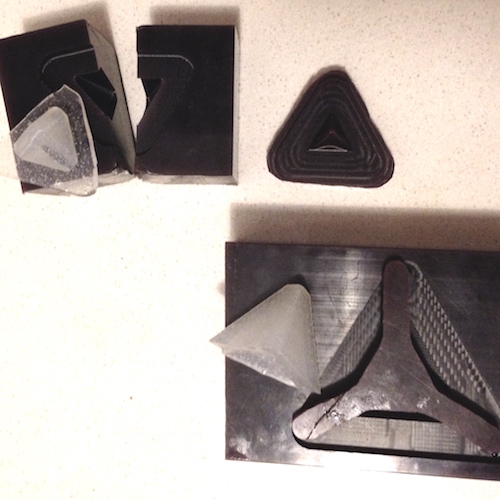

After I thought I was done molding the shape I wanted I checked to see if it's symmetric and to my (not so happy) surprise it wasn't. While I did try through methods I thought right to make a perfectly symmetric tetrahedron it didn't work and the result was something close but not quit what I was aiming for. So I went and redid everything only better this time. I found a the shape online and downloaded it free here.

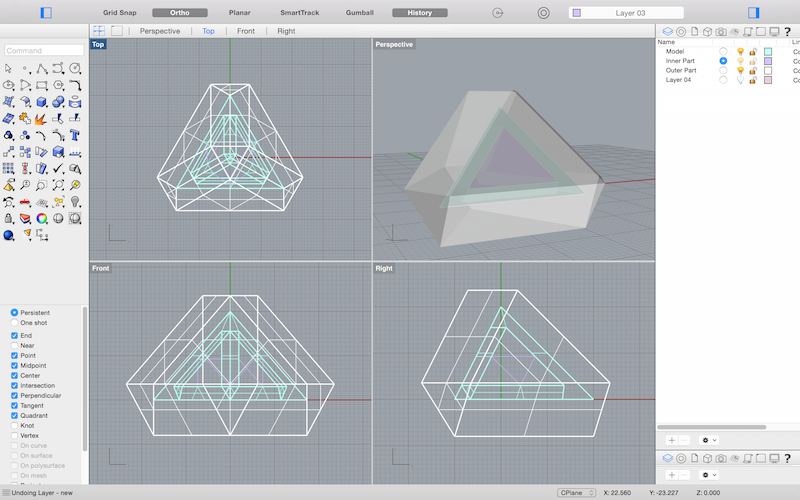

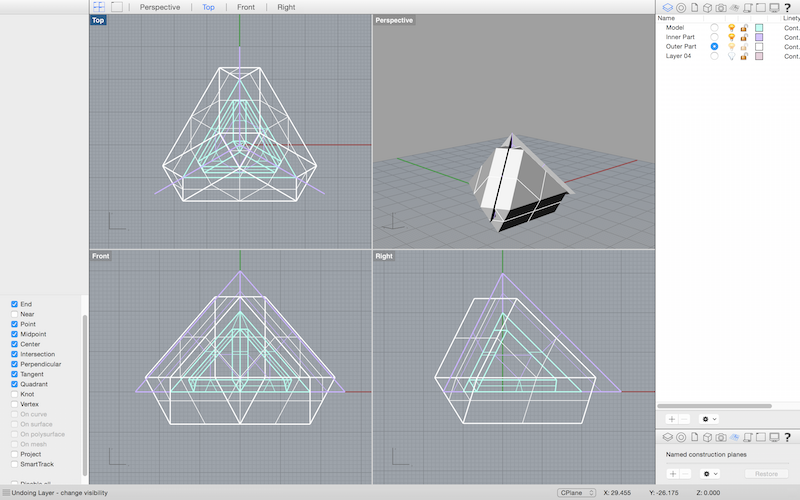

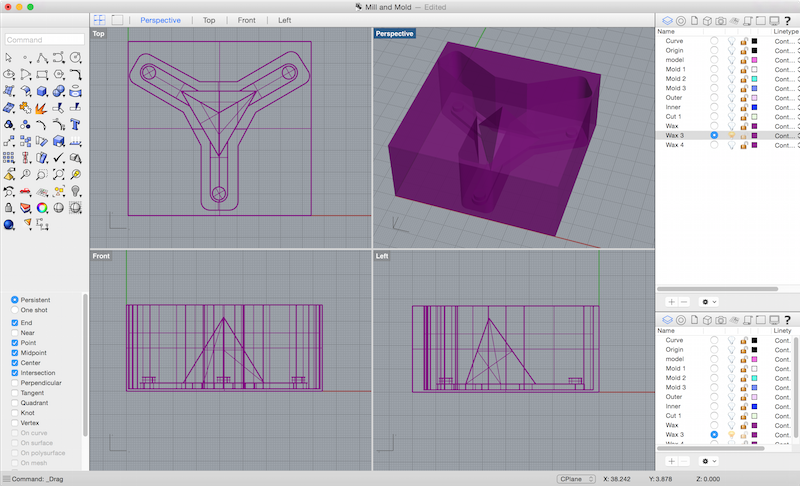

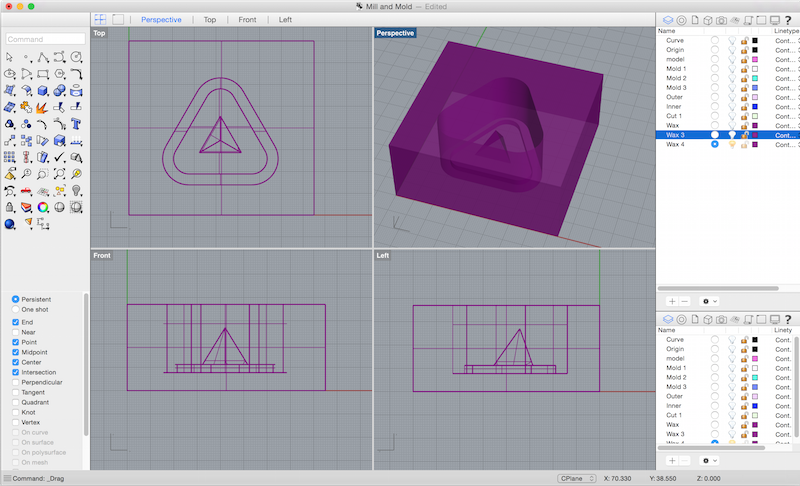

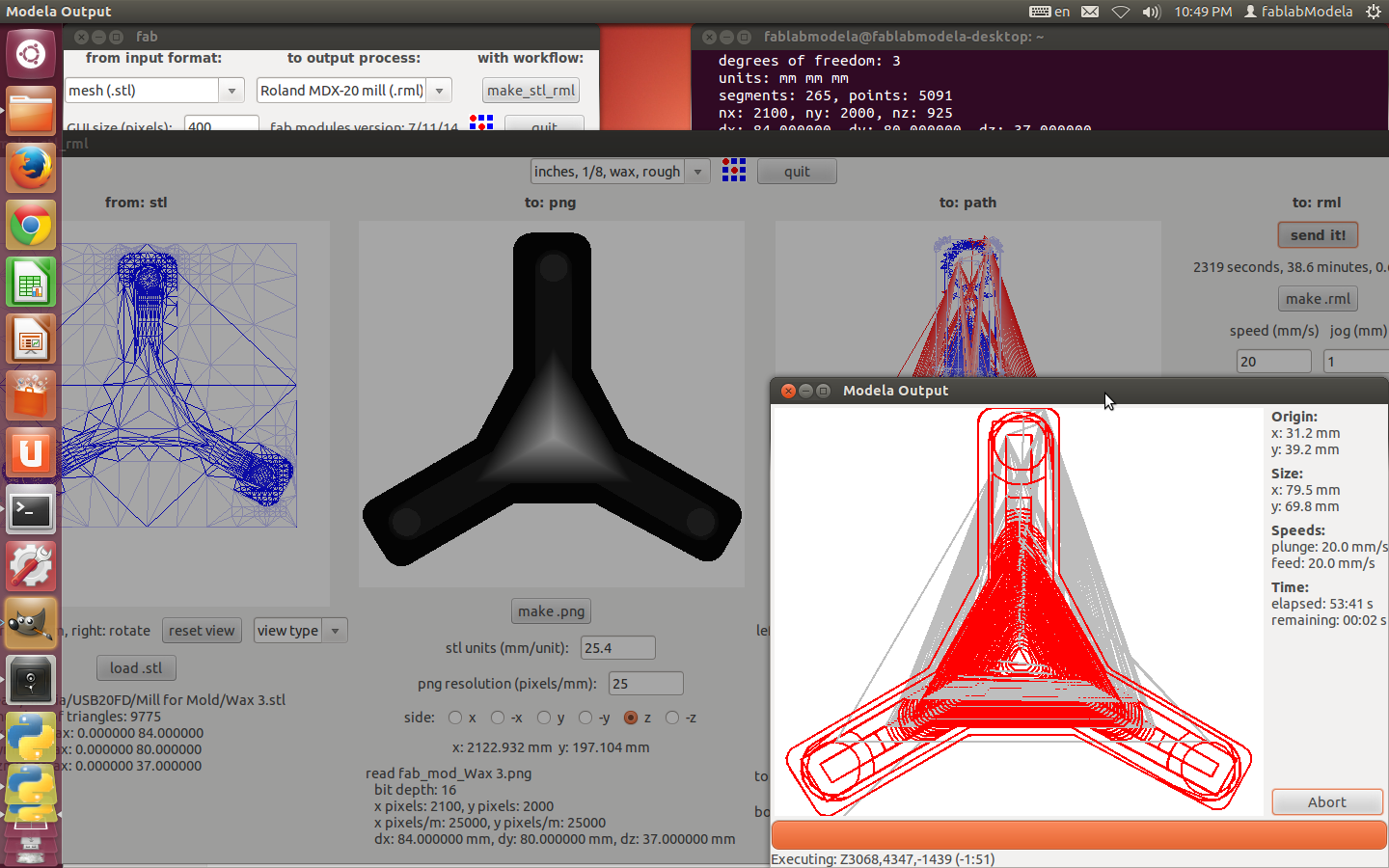

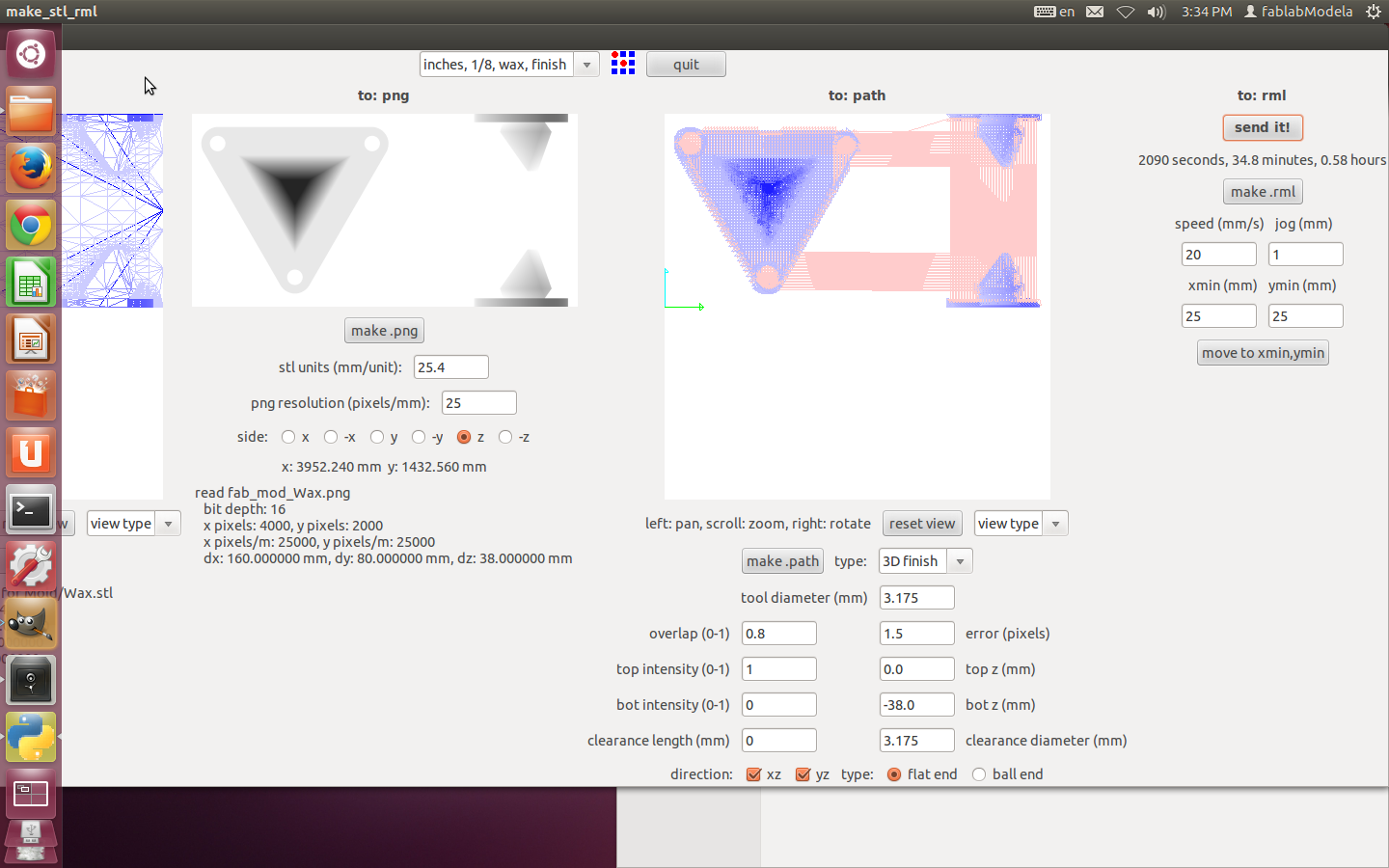

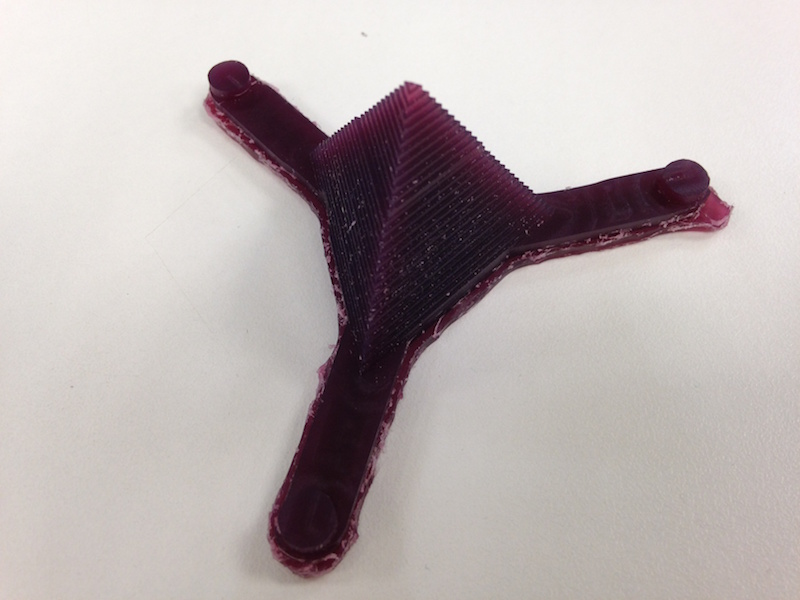

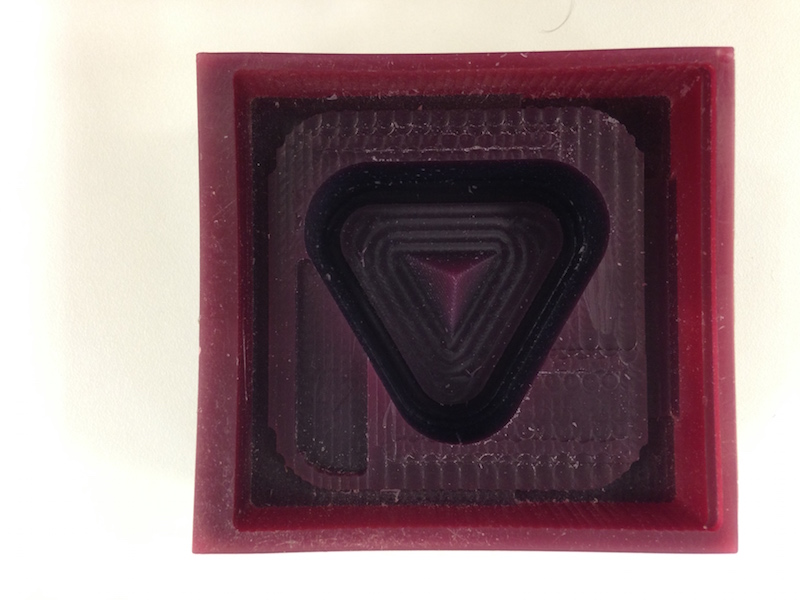

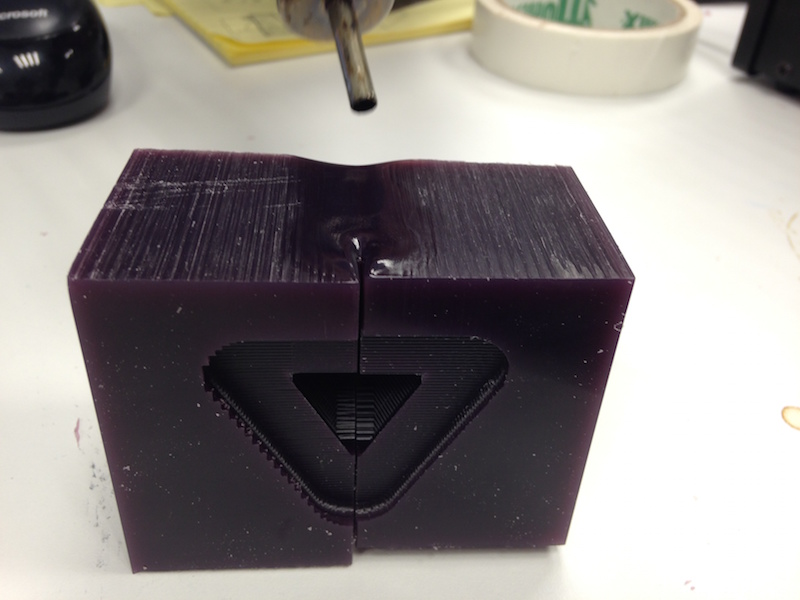

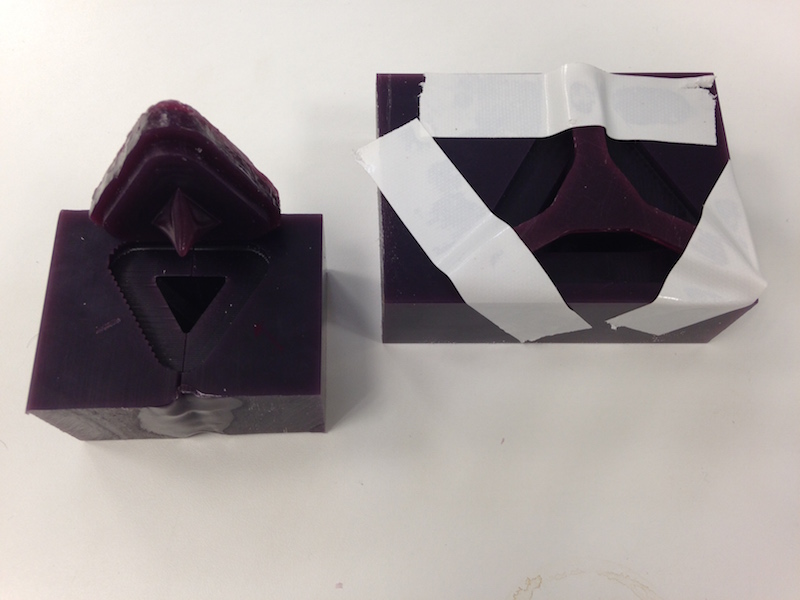

For the second model I used the same steps and added some more to make the molds.