29/4/2015 // Composites //

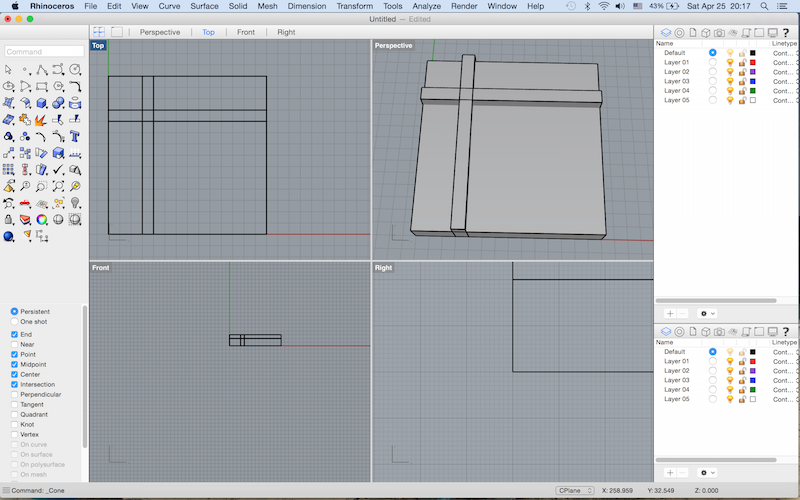

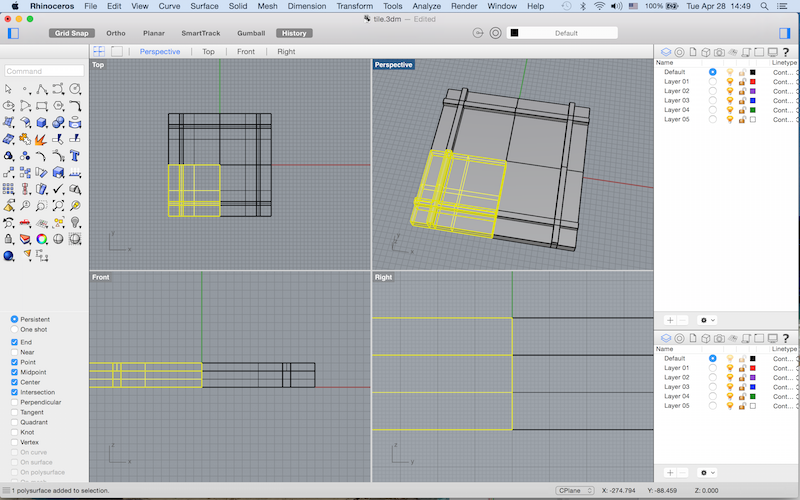

The mold

For this week we in FabLabIl decided to do some matching tiles. The object was to make 14/14cm tiles with any kind of pattern on it so we can multiply them and maybe mix them together. I've made a simple pattern because I wanted to check how the details would come out. I thought that the tiles would be 3D milled but eventually they were 2D milled, something that has changed my pattern in an interesting way.

Preparation

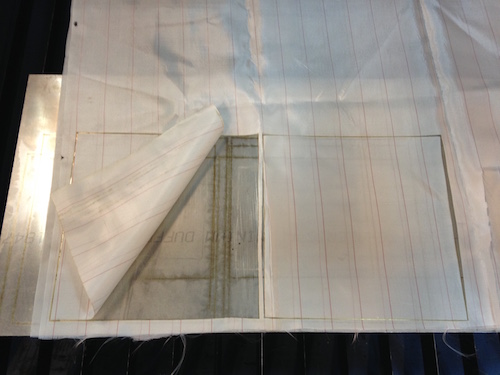

After the mold was done I've proceeded with the preparation of materials needed for the process:

1. Fabric- We used old t-shirts and cut them using the laser cutter into squares of 23/23cm.

2. Cloth- This is a fabric composed of fiberglass and a composite. Its propose is to separate the material and the resin from the mold and to give a smooth exterior surface to the final product.

3. Resin- we used XXXXX. We mixed it 1:0.3 ratio then soaked it into the fabric using a simple brush.

4. Felt- In the top lair we put some thick felt to create grater pressure on the mold once the vacuuming started.

5. A standard vacuum bag- Witch unfortunately got pierced somehow in the process, a problem we fixed with lots of tape.

6. Tape- To fix the vacuum bag in place and to fix its hole.

Extraction

After about 24H the tile was ready to be removed from the other materials. First I removed the plywood mold from the separating cloth. That was easy. You can see there are some holes in the plywood. I made them because I thought they might help with the vacuuming process, something I often used when doing vacuum forming with plastic, they didn't.The rest of the removal wasn't as easy and took great force. It might have something to do with the fact that I had used chop-sticks to push the fabric down into the mold and left them there as part of the mold, once they were soaked with resin they were really hardened and made the hole removal process even harder.

The result is, to my humble opinion, the most useless piece of material I have made during this course and no doubt the ugliest. Since I had some prior knowledge but lacked experience I thought that this might be a great lesson for me. I can now safely say that it was a lesson but one that I could have skipped. I think that this is a very wasteful process and all thought important for some areas of manufacturing I hope that designers and engineers would try to use it less in the future until a completely eco friendly material is available for all.