W9 - MOLDING AND CASTING

w9 - REFERENCES

link: led calculator

link: shopbot

w9 - DOWNLOADS

design files

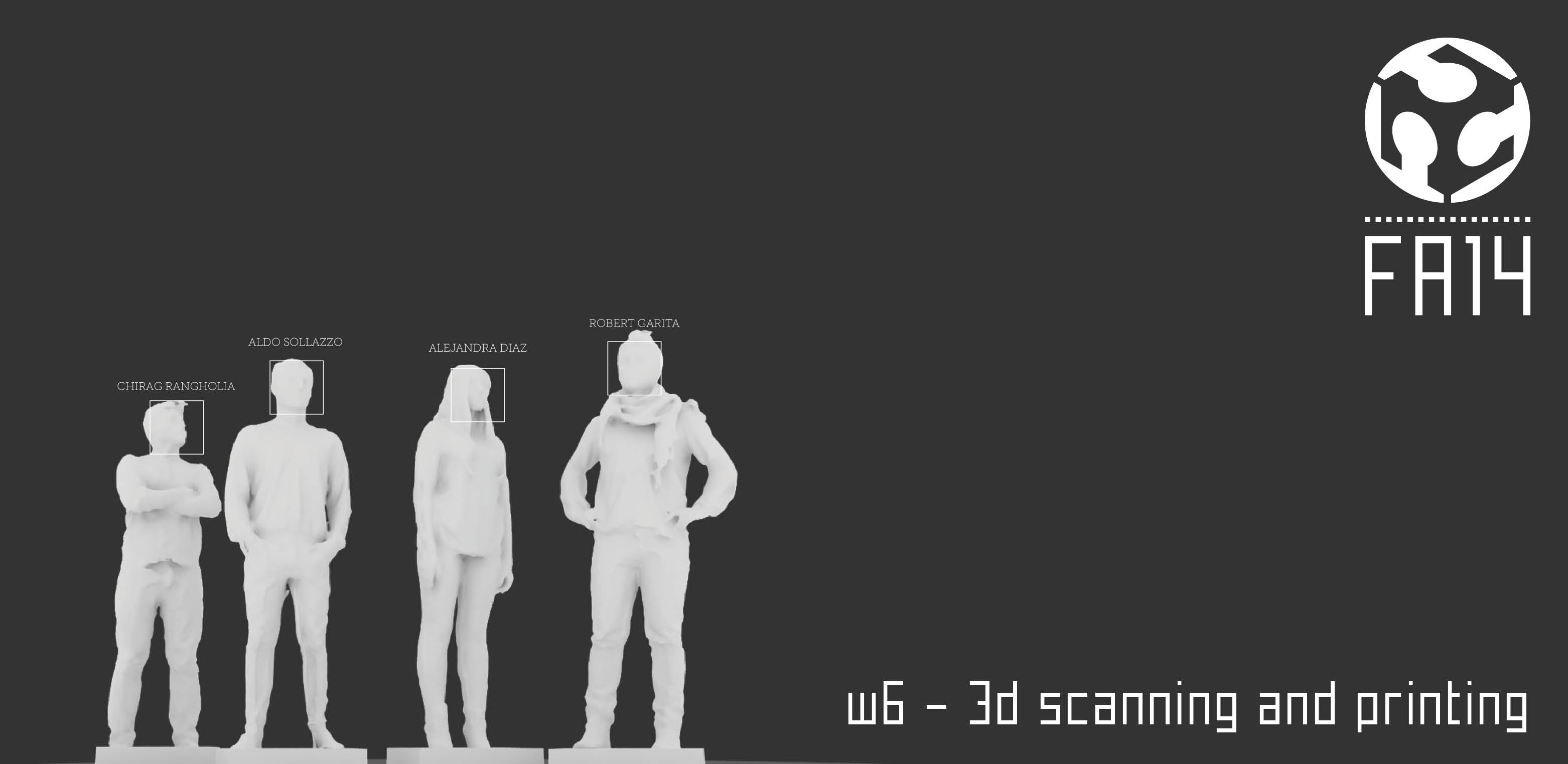

In this week assignment I focused on casting a medal to reward the three first winner entries of RESHAPE | digital craft competition.

Reshape is a community for designer and makers created by Noumena and Advok Communication in collaboration with Iaac, Fab Lab Barcelona, Solido 3d, Mediterranean Fab Lab and with the media partnership of Archello, Cityvision, 3ddreaming.

The winner proposal are all visible in our blog.

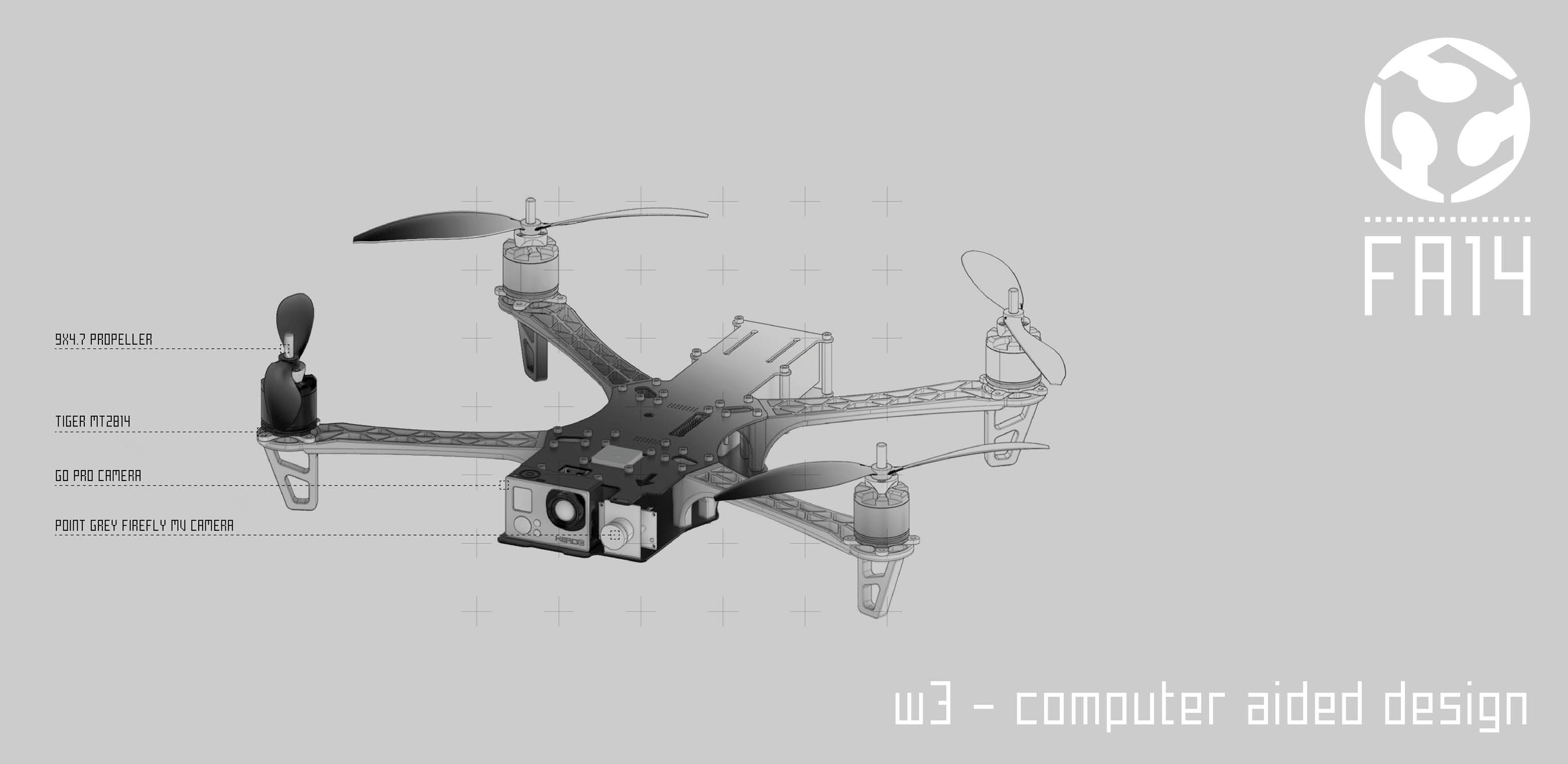

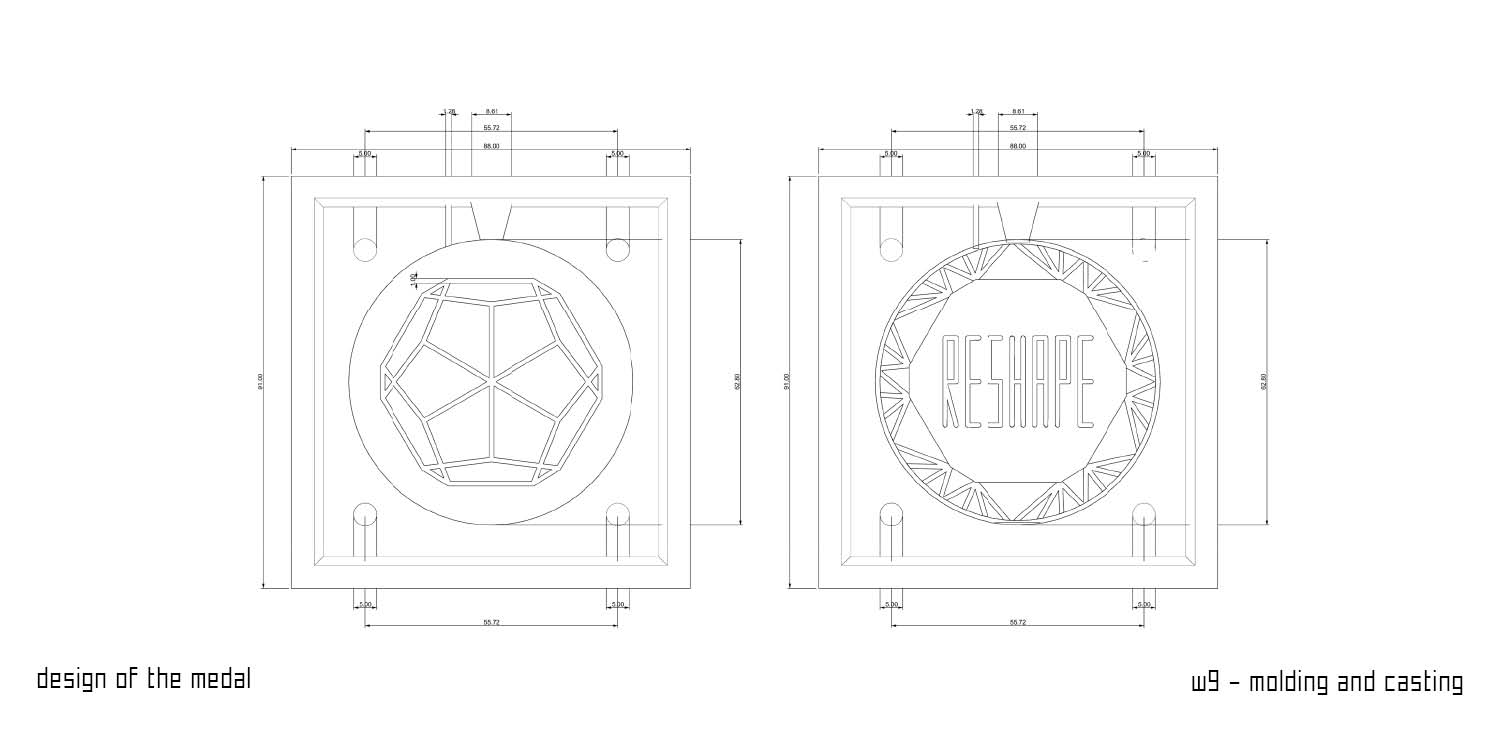

img 2 - 3d visualization

So I start by designing the medal and adjusting the details using 3d visualization to test those criterias (img 1). Those models are generated in Rhinoceros and rendered in Vray for Rhino.

The idea is to have two faces for our medals. On one side there will be the logo of RESHAPE and on the other side the text and some lines.

Again I fixed sevearl times the dimension of those ones deciding by the end to stay at 1 mm thickness for the letters and lines. Also I extruded those lines on one face with the height of 1mm and engraved

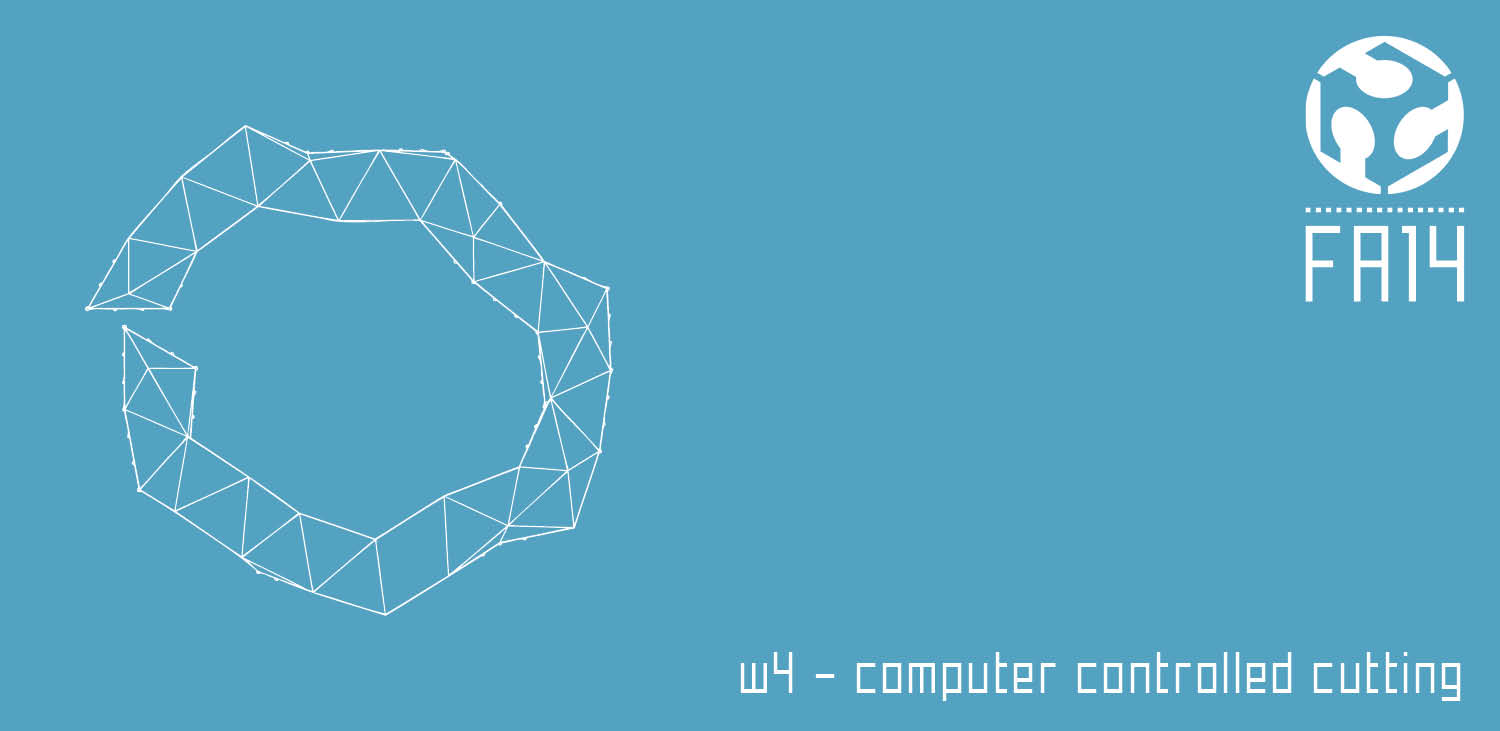

img 3 - mold design

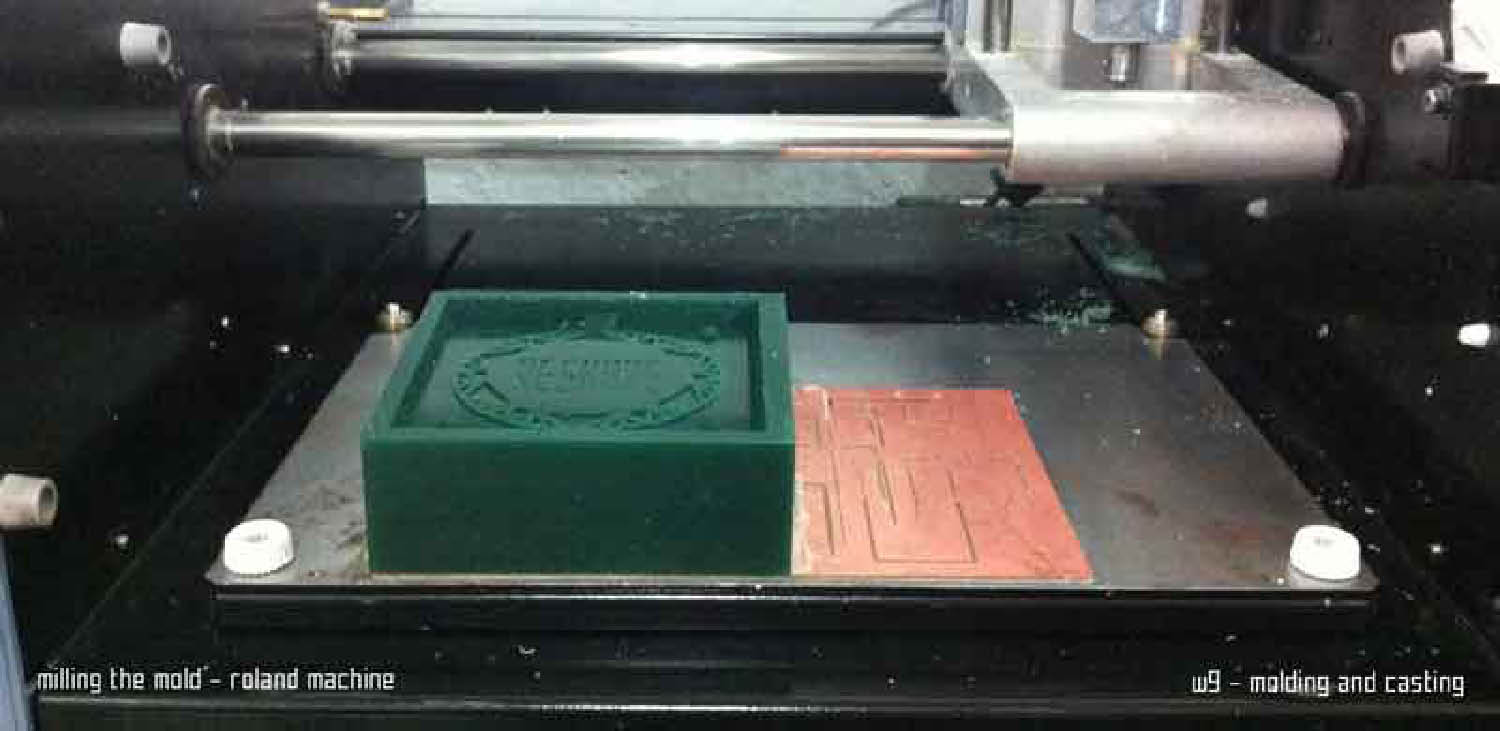

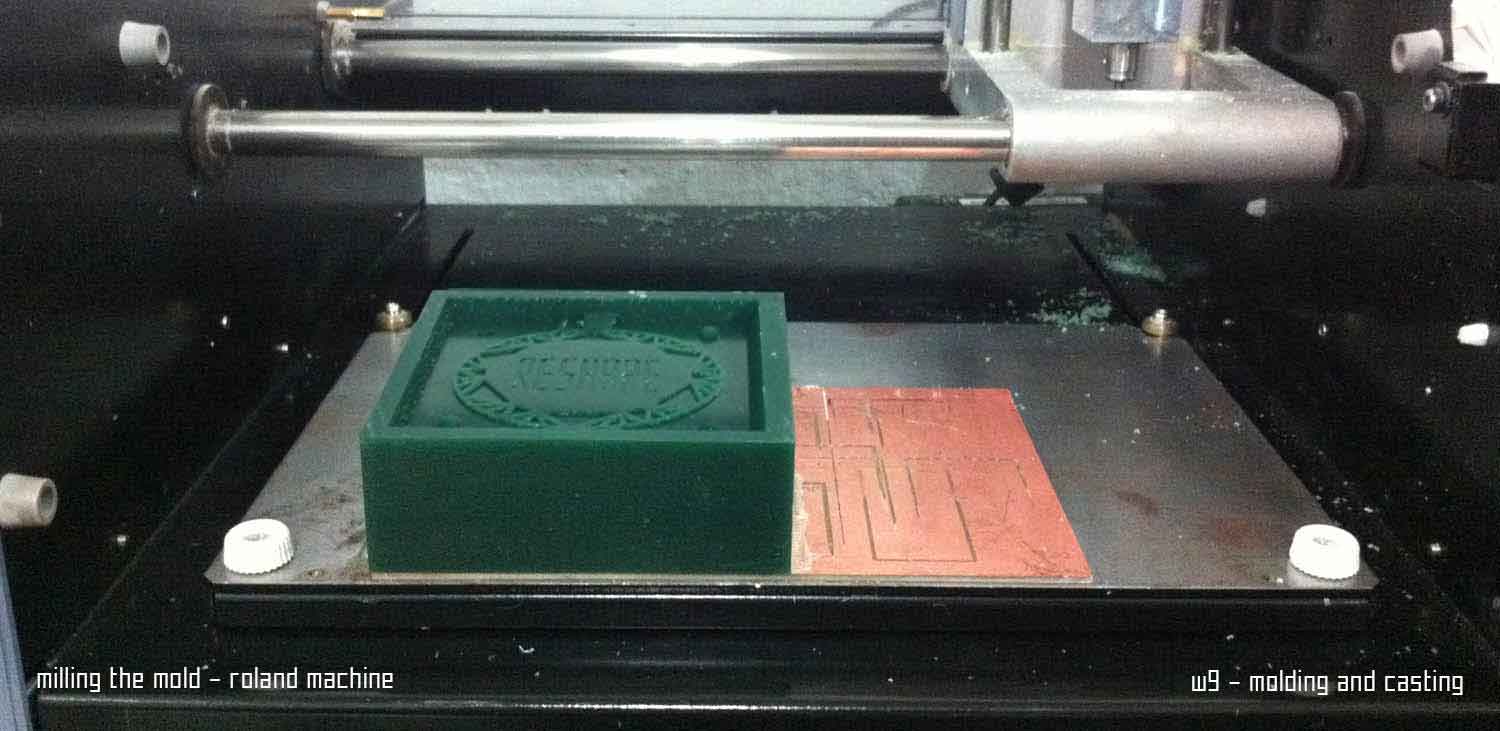

Once the design was decided I focused on creating the mold, fixing the proper dimension that the milling machine was requiring. I focused and change several times the thickness of the lines of the medals, according to the dimension of the tools provided by our milling machine Roland Modela.

The dimensions of the mold of course are relative to the wax Fab Lab Barcelona provided us. The one we used is the Ferrris File-A-Wax Square Block 3-9/16" X 2-3/8".

To use it properly for the soft mold I left 5mm all around the block and the medal was 1 cm in the inside of the mold.

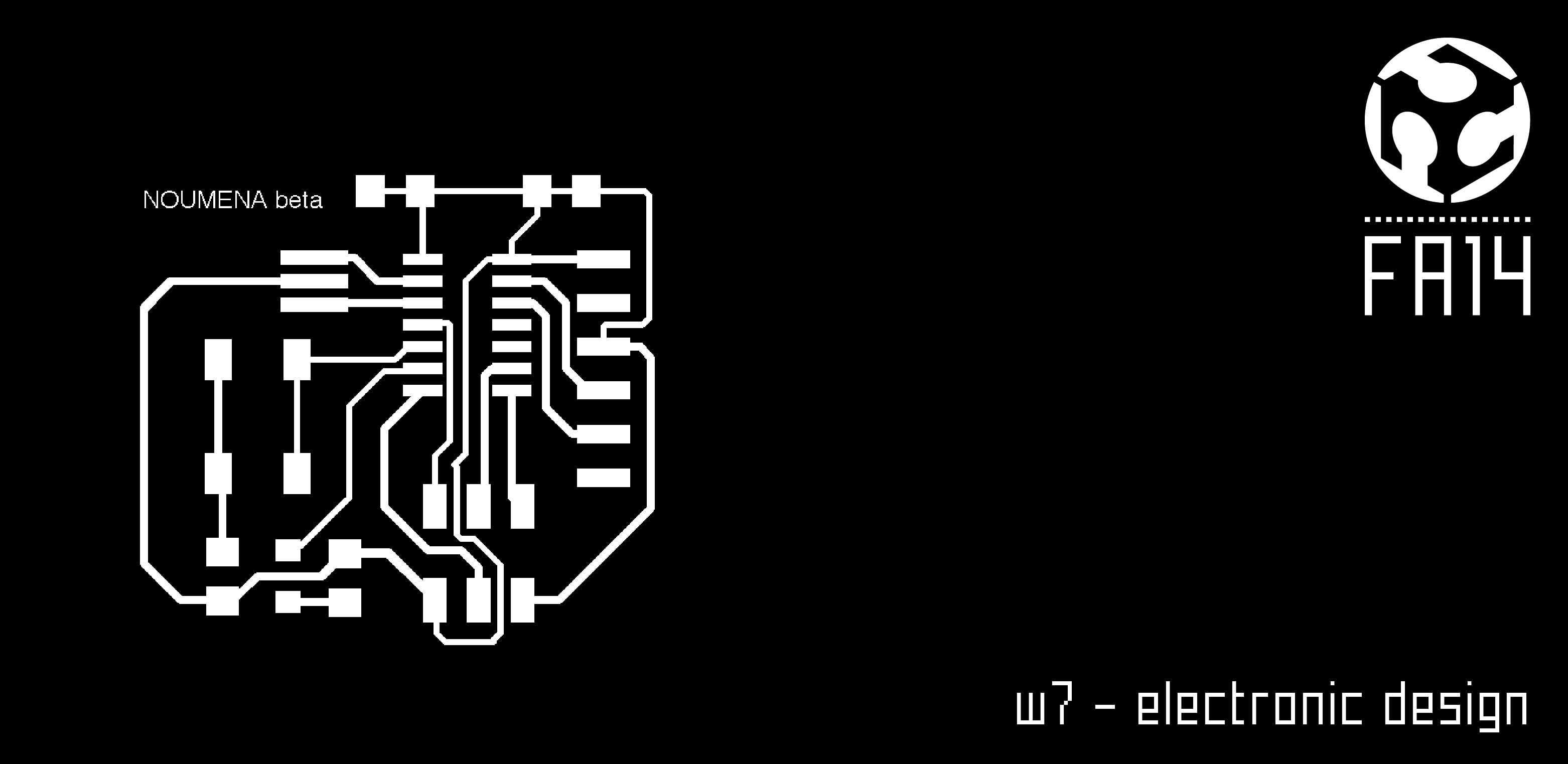

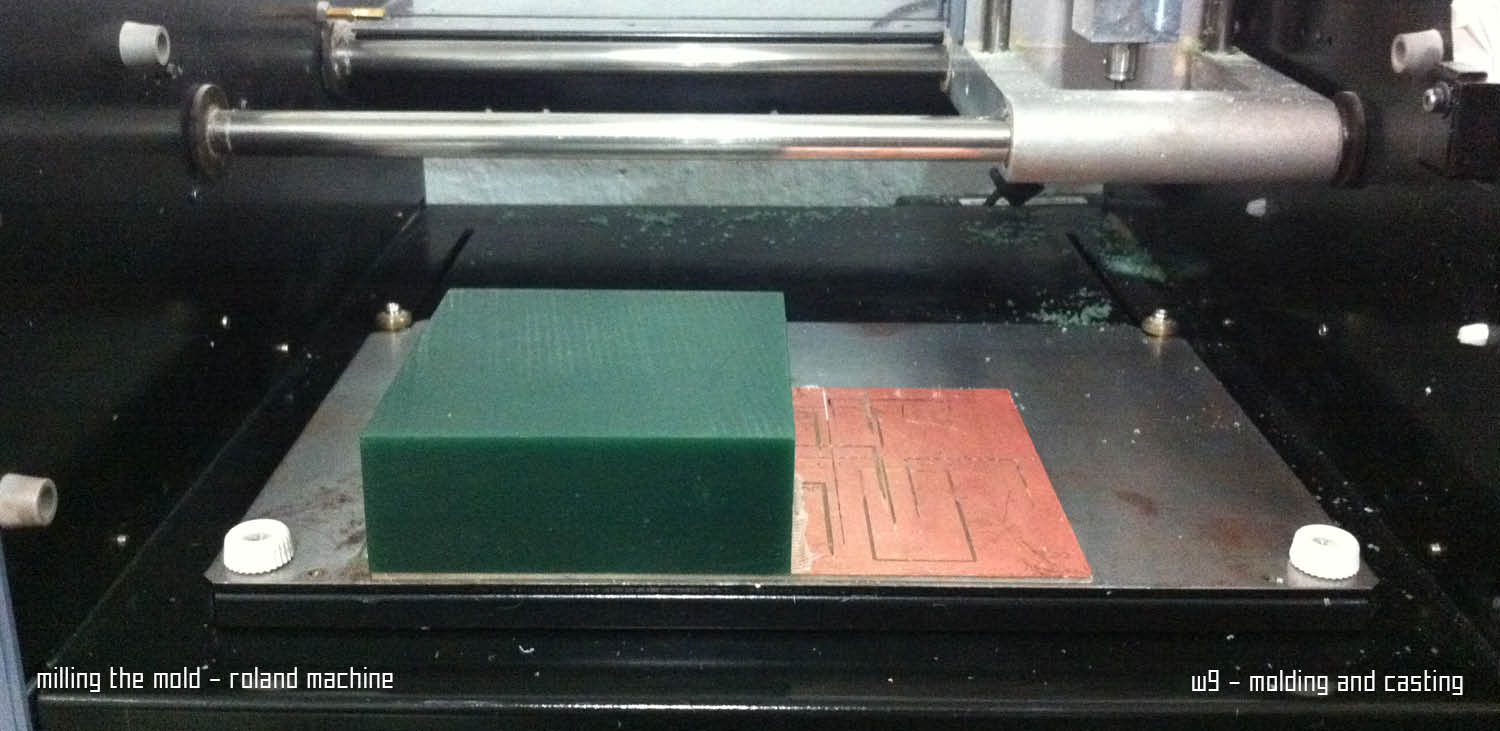

step 05 - board

Once the stl file is ready we can upload it into the sudo fab in ubuntu.

The first process is to use a mold bet with the thickness of 1/8 for the rough pass.

step 05 - board

The result after the rough finish.

The process took 33 minutes. While the drill is milling is very usefull to extract the pouder of the wax in order to melt it again for doing another brick. It's a good way to maximize the material.

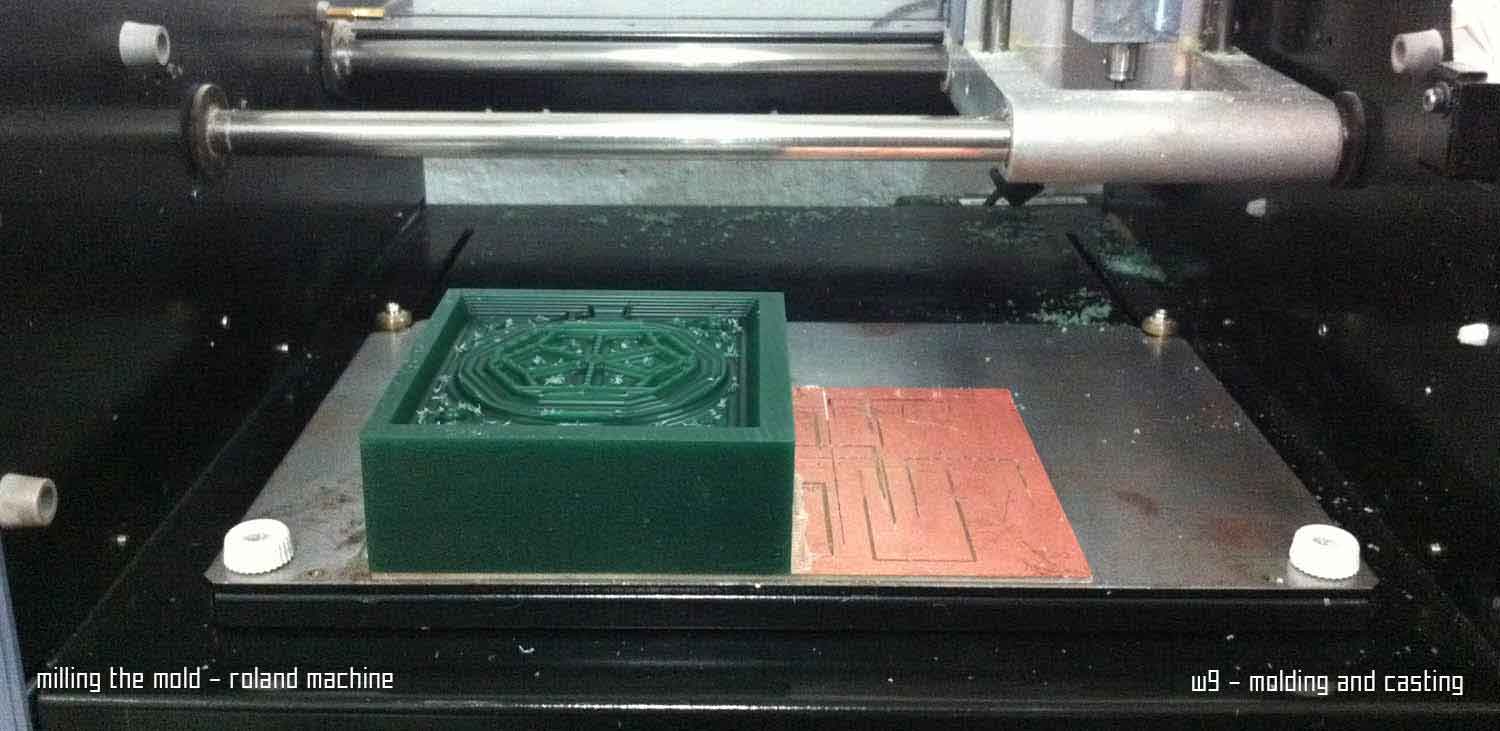

step 05 - board

The result after the final finish.

To reach this level I use the drill with 1/32 dimension. The Roland is set only for the 1/8 so in order to use a smaller dimension you have to calculate the mm dimension and insert it diretly in the program.

Also the possible direction the machine is milling are xz and yz. In this case I used both creating a grid pattern on the finished mold. That increase even more the smoothness but is very good to use only for detailed molds like this one because it also increase the time for the machine to mill.

The all finishing process took anyway very few time: 15 mins. That because the drill doesn't need to extract too much material like the rough finishing.

step 05 - board

The all process is repeated for the other side of the mold.

Since my goal is to do a medal with two faces and I have only one box of wax to work with I used the other side of it to mold the second face.

The process take more or less the same time.

The total amount of time of the all process is 1 hours 30 min.

step 05 - board

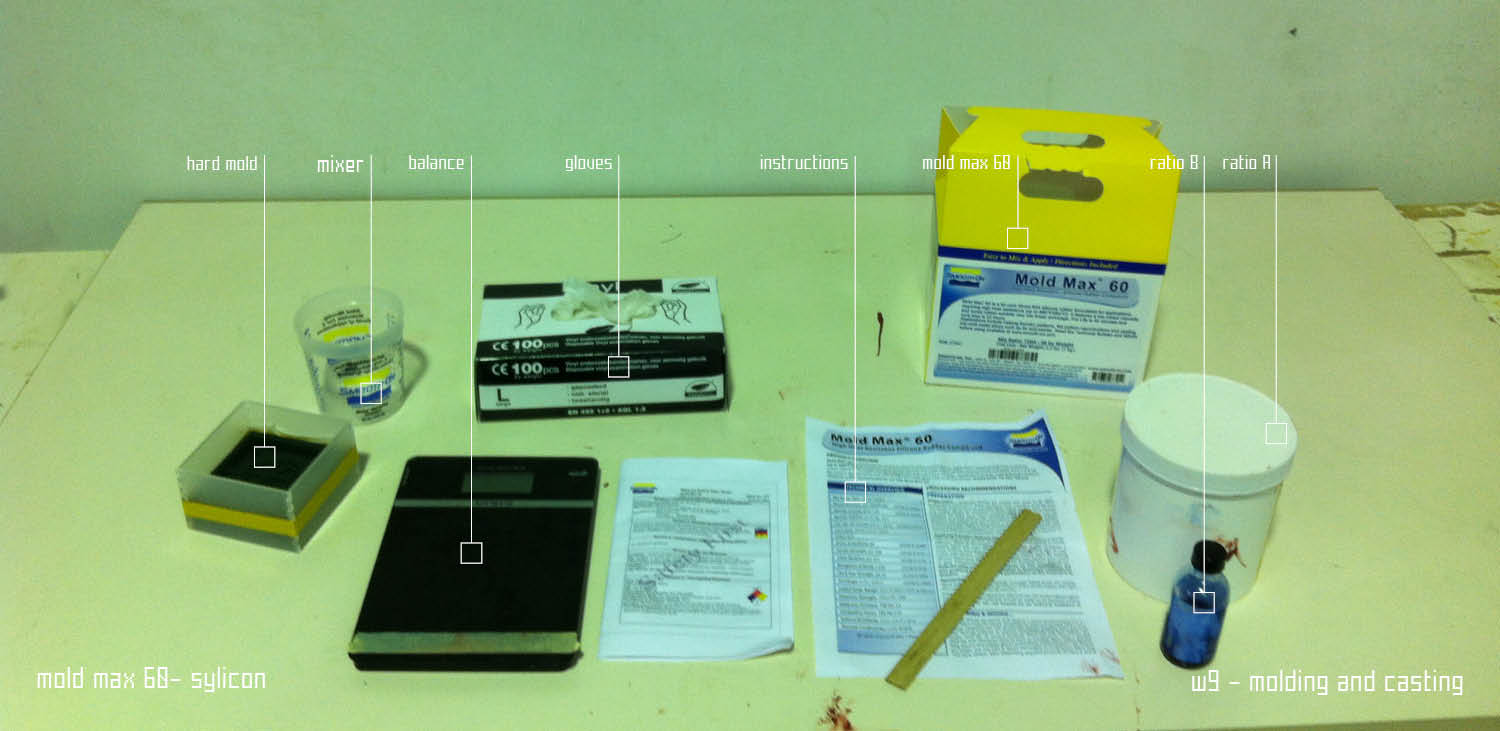

Once the mold is ready we can start working on the soft mold in silicon.

Since I want to do the medal in metal I'm using a silicon for the soft mold that is able to resist very high temperature.

The one provided by Fab Lab Barcelona isMold Max® 60 .

The process is here is very important. First of all wear gloves. The material is toxic. Second use a balance becasue to get your silicone you need to mix in the right Ratio two differnets parts.

Parts A and B are mixed 100A:3B by weight.

Pot life is 40 minutes and rubber cures in 24 hours to a relatively hard Shore 60A.

step 05 - board

final board

After 48 hours I have finally both my soft molds. Unfortunatly having two faces in on mold means you have to wait the double of time for your silicone.

Once ready is finally possible to pass to the hard mold again.

Of course the two molds have to fit inside each other. Is very important to leave two channels in both of them. One is for the air to go out and the second is for the material to go in.

step 05 - board

final board

The process of molding this time requires another material.

The material we are usign here is the Smooth-Cast 305

The Smooth Cast® 300 Series of liquid plastics are ultra-low viscosity casting resins that yield castings that are bright white and virtually bubble free. Vacuum degassing is not necessary. They offer the convenience of a one to one mix ratio (one part A to one part B by volume). Fully cured castings are tough, durable, machinable and paintable. They resist moisture and mild solvents. Applications for Smooth-Cast® Liquid Plastics include reproducing small to medium size sculptures,making prototype models, roto cast pieces, and special effect props.

step 05 - board

final board

The final result here in plastic. The three medals are now ready for the winners of the competition.