Electronics production

For this week the assignment we had to make the FabLabISP. I thought the one made by Valentin was really nice so I opted for his approach.

This is the first week dealing with electronics and a lot of things had to be learned. First thing we had to do is stocking of some of the materials and components used for the PCB. That delayed us one week. We are still waiting for the solder station... But at least we had the milling bits for the PCB.

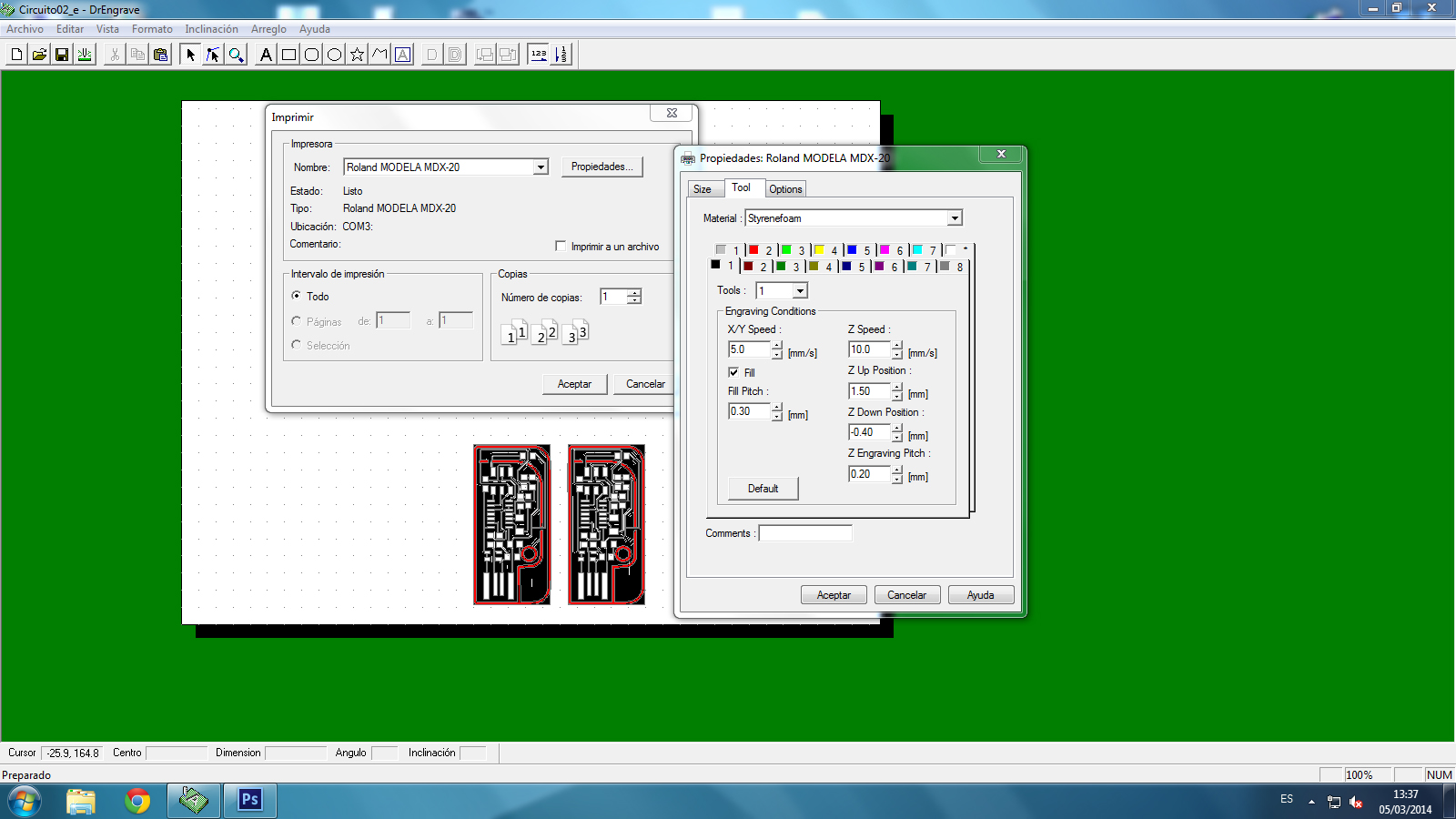

We're using the software that comes with the modela MDX-20 for doing the milling. I know that results with Fab Modules are more controlled and more open to discussion within email exchange between Labs, and we'll implement that method as soon as possible, but right now we had to test the equipment and check that everithing was fine on Roland's behalf.

The problems are mostly with width of the tracks. First, it were too thick... so much that they made contact with eachother, so they were not usuful. When filling the form you want to engrave, you can specify offset between passes, this was done with 0.3 mm. Not good.

This was made with 0.20 and the tracks are getting too thin... So much in fact, that I doubt it will work well. I have to check continuity to see if it's right (will have to be next week, we're waiting for the multimeter to arrive).

This is still a work in progress and I hope we can get all the components and electronic equipment as soon as possible. It'll be marked as updated in my index page, with the date revised next to it.