Principles of proyect management

In this first assignment, we had to catch up with version control

software. Although it may seem easy, it ended being a little bit more

troublesome than expected.

Mercurial console commands were easy, and workflow of the software was understood, but the hard part, at least for me, came with the keys needed. I find nearly impossible to believe that the only way to get the certificates working on windows was installing Cygwin or using Tortoise... There must be some way, but there is not much time to stop on this matter, so...

moving on!

Mercurial console commands were easy, and workflow of the software was understood, but the hard part, at least for me, came with the keys needed. I find nearly impossible to believe that the only way to get the certificates working on windows was installing Cygwin or using Tortoise... There must be some way, but there is not much time to stop on this matter, so...

moving on!

Next, we had to start thinking about what we want to do

as the Final Project

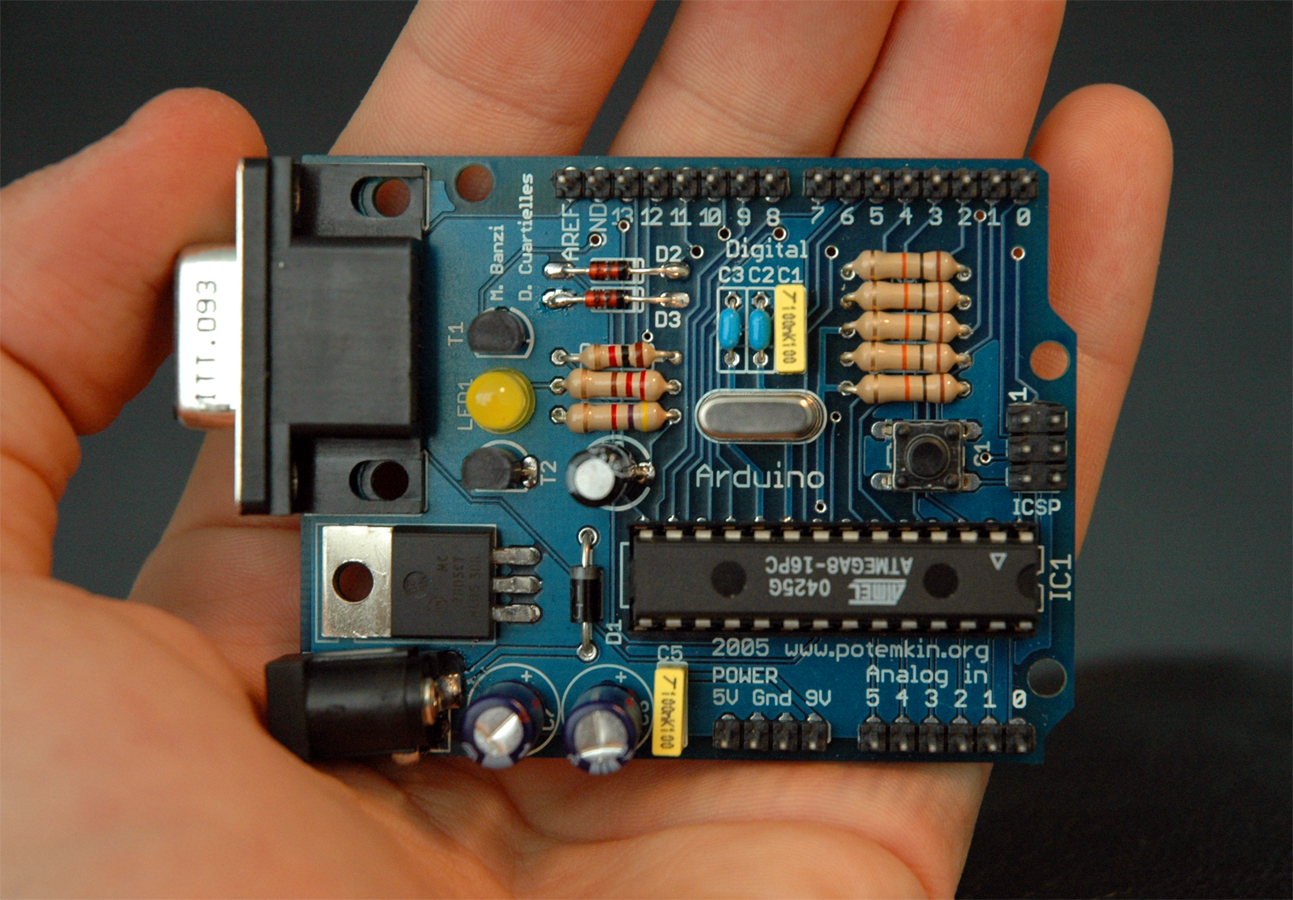

That little board, right above us, makes me sudder. I've never done serious programming neither fabricate electronics, so... Let's get on with it!

Our FabLab hasn't got many resources at the moment and one of the most convinient ways for solving this is doing workshops. People seem really interested in 3d printing, but I've found that plastic extruded priters have some deep learning curve. Once you get out of the comfort zone (use this material, use this settings, etc.) given by the manufacturer and start experimenting with different plastics things (PVE, Nylon...) things start to get downhill fast. And you've got to have "fun" with, for example, Skeinforge settings.

Explaining settings to students is not an easy task. Mostly because they have to see the printer malfunctioning and then understand why you are doing what you are doing. Also, those tests take quite a bit of time, and case study during the workshop doesn´t seem to be an option.

But maybe, designing and building some kind of tool, could be a good thing for all these testings.

That little board, right above us, makes me sudder. I've never done serious programming neither fabricate electronics, so... Let's get on with it!

Our FabLab hasn't got many resources at the moment and one of the most convinient ways for solving this is doing workshops. People seem really interested in 3d printing, but I've found that plastic extruded priters have some deep learning curve. Once you get out of the comfort zone (use this material, use this settings, etc.) given by the manufacturer and start experimenting with different plastics things (PVE, Nylon...) things start to get downhill fast. And you've got to have "fun" with, for example, Skeinforge settings.

Explaining settings to students is not an easy task. Mostly because they have to see the printer malfunctioning and then understand why you are doing what you are doing. Also, those tests take quite a bit of time, and case study during the workshop doesn´t seem to be an option.

But maybe, designing and building some kind of tool, could be a good thing for all these testings.

I was thinking about trying to make something similar to the 3Doodler, but with a setup and parameters

as close as possible to the way skeinforge works. Doing so, you may be able to explain to students and

users configurations and posible problems in a much faster way.

In plain terms, a 3Doodler with more settings and that "speaks" in skeinforge terms and with an assembly near the hot end that alows moving it along a surface keeping always the same offset (and sub-milimeter) distance to it.

In plain terms, a 3Doodler with more settings and that "speaks" in skeinforge terms and with an assembly near the hot end that alows moving it along a surface keeping always the same offset (and sub-milimeter) distance to it.