Aplications and Implications

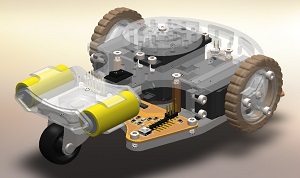

The idea of my final project is a modular mobile robot, the motion will made by a hacked servomotor. Also will has sensors and a programable control board. At first I will work with light sensor, photodiodes; on ly at first, the idea is to upgrade and create more sensors for it.

What will it do?

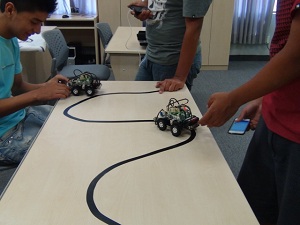

It will be educational robot. It would be a modular platform with different kinds of sensors, some actuators (servomotors). At first it will track a line, but the idea is to develop more sensors.

Who's done what beforehand?

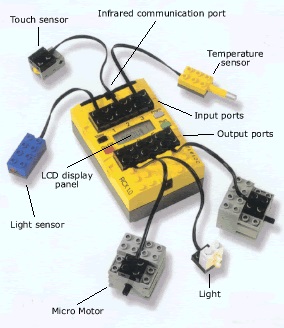

The LEGO company with the Mindstorm series, RCX and NXT modules are the most highlighted products previously developed.

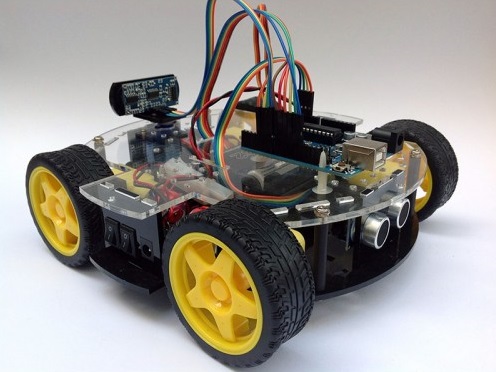

There are many other robotic systems like the Arduino Robot or the KM82 (robot made by Openhardware designed and commercialised locally in Perú).

What materials and components will be required?

The acrylic board, the machinable wax, urethane resine, baquelite board, cables and generel components. Only servo motors, some electronics devices like microcontroller (Atmel 328p) and white LEDs, a pair of Li-Ion batteries, and some bolts and nuts will need to buy.

Where will they come from?

The SMD electronics will be imported, but the THD and all the other parts could buy locally.

How much will it cost?

The expensive components are the servomotors that cost aproximately $15 and the Li-Ion battery $10/pair; the rest of components are really cheap all the electronics will cost approximately $15, other parts like bolts nuts, the caster wheel, etc, at much $10. The manufacture could be subsidized by the educational institution.

What parts and systems will be made?

All the structure, the boards, the wheels, the tires, the battery holder, and the circuits will be made with digital fabrication as explain in the Final Project page

What processes will be used?

What is the schedule?

How will it be evaluated?

The principal test to evaluate is a functional testing. If the robot follow the line with the program.

Dissemination Plan

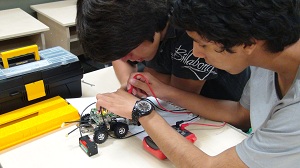

We and some friends was teaching robotics to kids and teenagers. We have some experience in and many contacts in many educational institutions to teach with this kind of modules.

The first step will be this coming summer, when this module will be tested in a real class.

Maybe we could make it a comercial product for the next years.