May 2013

Networking and Communications / Machine Design /

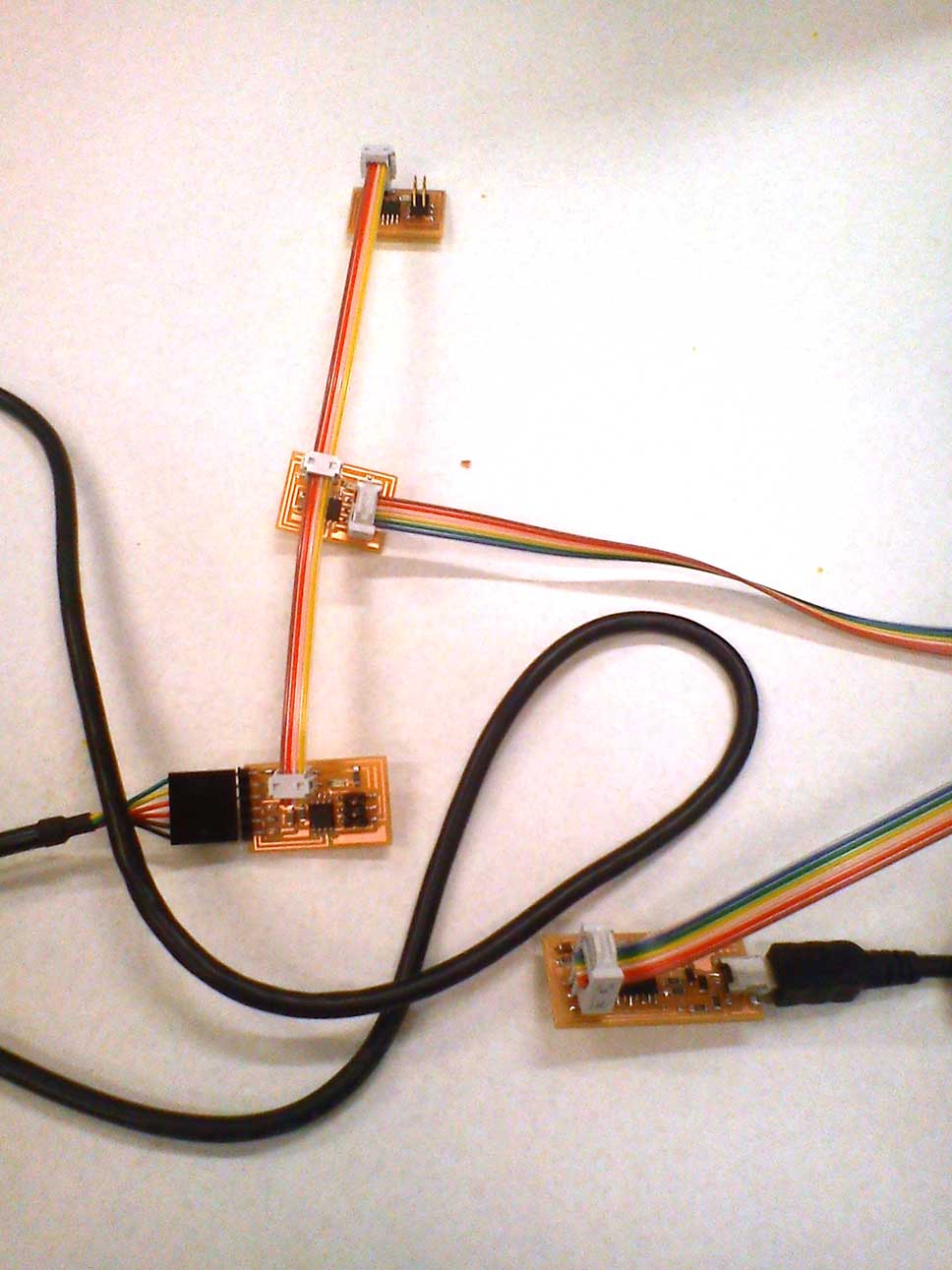

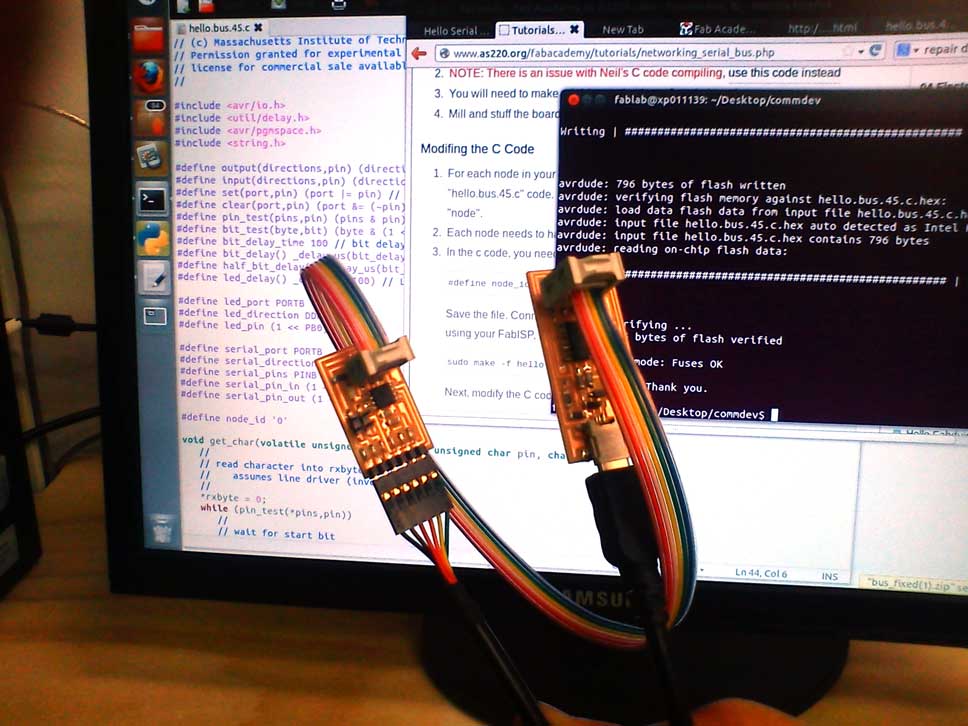

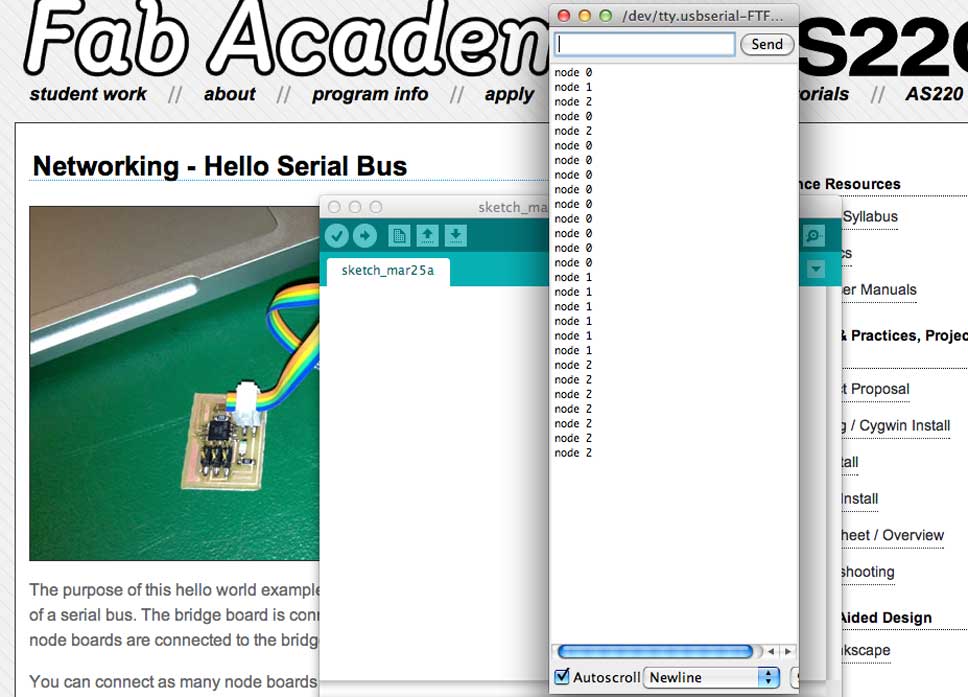

So I chose to make the hello bus with two nodes. Milling and stuffing is getting so much easier. It was the programming where I got stuck on this project. I often have issues with my laptop USB ports, and when the programming wasn't working I assumed it was that, so moved to another computer. Still no luck....it turned out that the mini USB was broken on my Fab ISP, so I replaced it (and at the same time fixed another of my Fab ISPs with the heat gun and plier pressure) and then the programming went well.

The files for this project are here.

Machine Design

We have a lot of waste PLA from our up!+ Printers so I'd like to start working on a machine that will recycle that waste. We have looked at the machine on thingiverse that does that. First we'll make one that munches the plastic into useful small pieces, not pellets, but that sort of size. Probably using a hand operated meat grinder, and then mechanising that. Otherwise Bas has suggested that we work with a couple of the Fab Academicians from Japan, so we've started conversations about that too.

In the meantime, here is a link to our photo album of the New Zealand Wikihouse prototype that we made the other week. Which is unfinished but developing nicely.

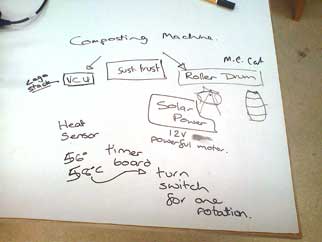

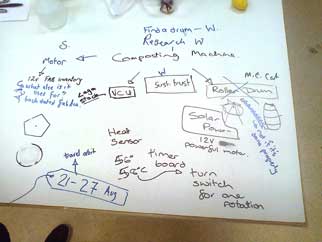

So we've been researching our ideas about the PLA, and talked to the gardener at our University and she is very supportive of us setting up an industrial composting system, where we can deal with that waste, the green waste and end up with compost she can use. At the moment we send away our green waste and buy compost. We also have a lot of paper towels from the bathrooms, our clean wood dust, and any number of other recyclables that end up in the rubbish when they could go into a composting system. We'll do a small test composter in the first instance and then work with the Sustainability Trust and the Council to develop it further.

We've done some planning, put out the word that we're looking for a 44 gallon drum (yes, we are metric, but back in the day we used to be imperial which is why they're still called that) and are trialling a stepper motor and some cogs to see how that works and what torque the motor will handle.

what questions need to be resolved?

Lots really - I went to see the Sustainability Trust and they're quite excited about the possibilities of units of industrial composting and of people making their own by either making their circuits at Fab Lab and getting the drum and other bits from the Tip Shop (the shop at the municipal rubbish dump that gleans useful things from there and sells it to the public, who aren't allowed to take things from the Tip/rubbish dump), or by getting a cheap kit from us. They will help us to research the requirements for an industrial composter as compared to a domestic composter. The City Council waste management officer is also interested in assisting us with this project after we make our test version.

what tasks need to be completed?

Stuart has spent a bit of time getting the stepper motor programmed and playing with the output of the driver to see what we can do with it.

We need to get all the components for the composter - drum, frame, paddles for the inside. Ideally, we'll make it so that we can retrofit a temperature gauge at some point which will trip the stepper motor when the compost gets too hot.

what has not/worked?

As per usual, it's a magical mystery when the programming works - usb ports, laptops and desktops, trying and trying again... Mostly we find that if we work on our electronics all week, they only work just before our phonecall with Bas on Monday evening or they work when we try to show him that they don't work.

When semester finishes next week, the students go on holiday, I've fixed all the machines, Stuart has done all his assessments, we will both focus on Fab Academy again so that we can finish everything by July 29th. Looking forward to having the focus back again - and to seeing our final projects and the composter in action. Booked our flights to Japan today. Yay.

I went to see the industrial composter at the Transfer Station in Petone - really interesting. Obviously huge - they process 18 tonnes a day. Also went to see a smaller one at the Wellington Zoo (which is the first carbon neutral Zoo in the world) - the compost guru there is keen to see whether our ideas work, and will try out our waste PLA in his to see how it goes. We've got a couple more people on the team for this - some of our undergrads are really interested, and I've had emails from people in other areas of the Campus who are very keen to have one when we've worked it all out.

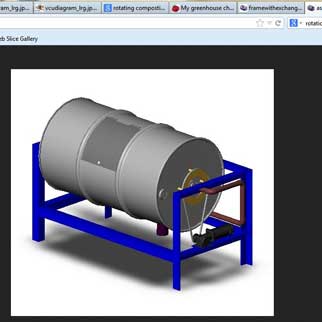

We (Nina and I) went to the Tip shop and bought two broken skooters for their wheels and Stu turned them up so all four are the same size to support the barrel and we've got a windscreen wiper motor, below left, to use to turn the barrel with the cogs that we've made.

We also quickly made a mock-up of the composter using stuff we found around the Lab and Shona from the High School next door lent us a barrel to play with until we get the barrels from Dulux paints. On the way back from the Tip Shop we stopped off at a fish processing business where I'd seen a big box similar to the Zoo composter and I spoke to the manager about it. He is happy to give us the box, and to deliver it for free, if we decide that we need it later. It is insulated, which will help with the heat, but is huge and would require a bit of work to make it functional, so it's something we'll have to think about. It's already decorated though! The other thing the business owner is happy to give us is fish waste for our compost. Hmmm... this is getting really big...

Buster and Nina found the barrels, after a bit of googling and a few phonecalls, acheiving our objective of using free or cheap stuff - I went to pick up three barrels from Dulux Paints yesterday, two with lids and one without. The two with lids are pretty similar in size to the one above, so now we can move on to working out the dimensions of the frame to support the barrel.

We attached the larger cog to the barrel and the smaller one to the wiper moter - and you will see that the door has already been cut out of it. We've attached some castor wheels to the table frame we've been using for a temporary stand. The motor is plenty powerful enough to turn the bin, but we'll need to secure it better. Stuart wanted to butcher my roller skates to do this, but I prevailed... we used them intact. We're going to change the cogs tomorrow and hopefully get a better frame set up for more testing.