FAB ISP

The assignment for this week was to create an in system programmer. This device is the important first step in building curcuit boards that need programing, which we will be doing in the coming weeks. There are a few steps to the process.

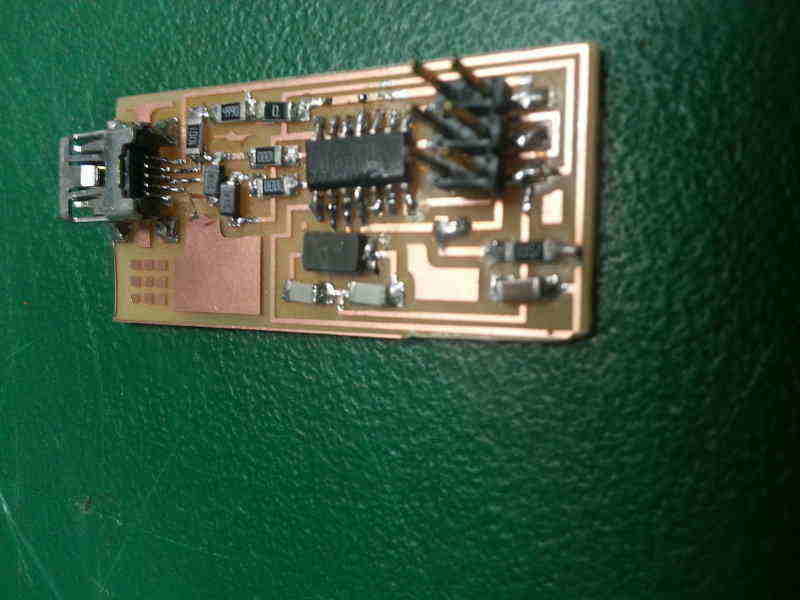

First, we cut out the design on the roland modela. We use the PNG design available online, and set up the machine to cut the traces out of copper coated board. Then we run the PNG that cuts the design out. Next it is time to stuff the board with components. The components are surface mounted, and are very small. At first I tried to use solder paste, but after a few minutes of pieces slipping off and having to start from square one, I decided just to solder them by hand. I have done a fair bit of soldering in the past, so it didn't take me long to get it all put together.

Next it was time to program the board. I downloaded the required drivers to my mac, and then with help from Lorenzo, we were able to program my board. It was very painless compared to some of my classmates, who experienced problems getting their boards to work. The finished product is just a small board, but it will be a very important tool in the next few weeks.